Impact Crusher Rotor Dynamics: How Balance Tolerance, Hammer Disc Layout & Moment of Inertia Affect Crushing Efficiency

This article explains why the spinning component at the heart of every impact crusher is far more than a simple steel wheel. You will learn how microscopic balance tolerances keep 50-ton machines standing quietly on their foundations, why the exact angle of each hammer disc changes the way energy travels into rock, and how engineers tune rotational inertia so the rotor can both smash 80 MPa granite and forgive occasional tramp steel without stalling. The discussion moves step by step from single-part physics to real-world economics, showing how careful rotor design lowers power bills, lengthens bearing life and delivers the cubical grains that ready-mix labs demand.

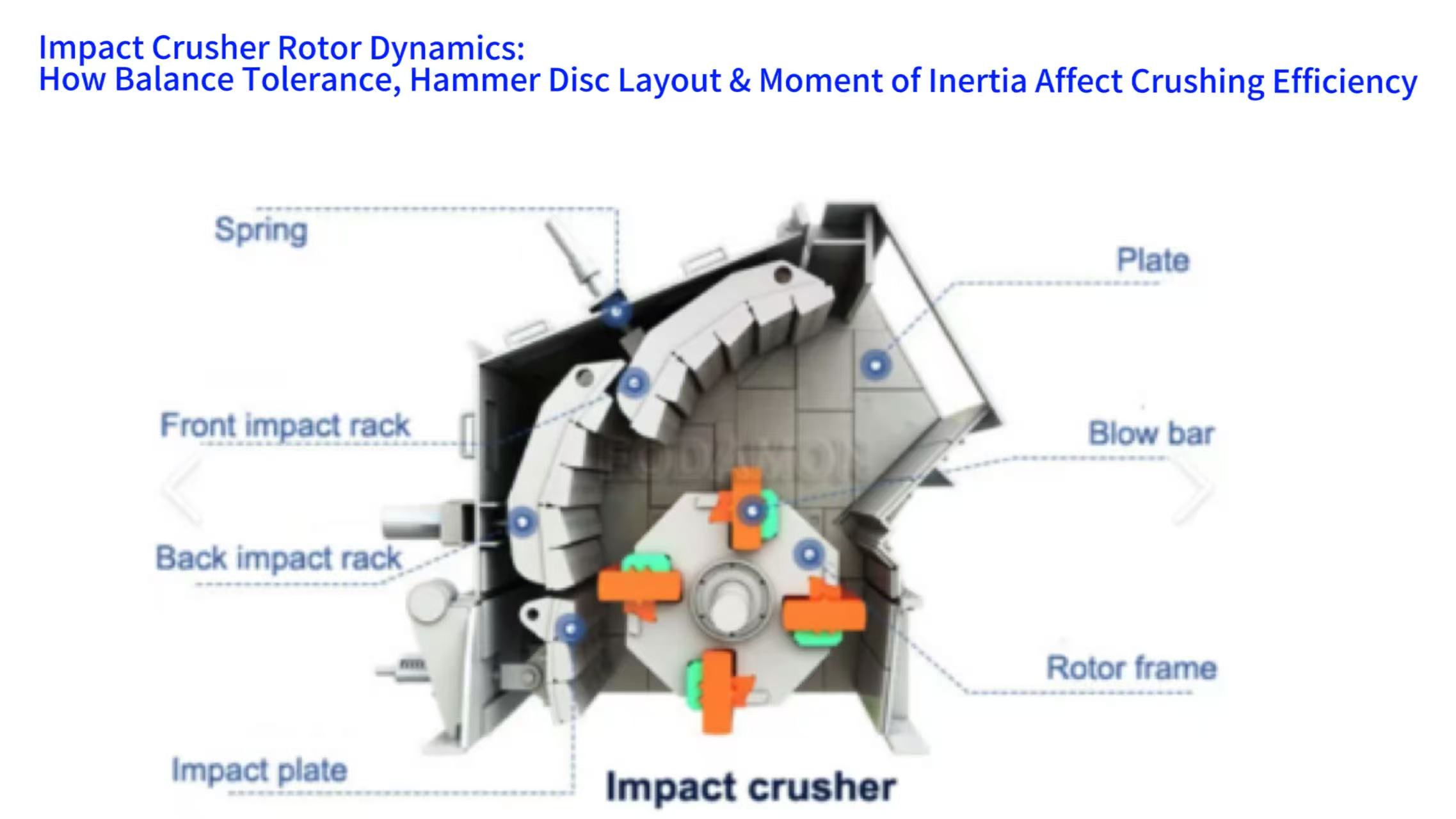

The Rotor: Power Converter and Shock Generator in One Steel Body

An impact crusher has no hydraulic ram and no slow compressing jaw; instead the motor pours electricity into the rotor, stores it as kinetic energy, and then releases that energy in micro-second blows against falling stone. The shaft, hammer discs, blow bars and lock wedges must remain a single rigid body while rim speeds climb above 38 m s⁻¹, because any flexure would open gaps that let bars slip and destroy the entire housing. Finite-element models reveal that peak stress appears where the disc meets the hub, yet measured strain at that joint stays below 0.02 % when the geometry keeps the centre of gravity within 0.1 mm of the true axis, proving that dimensional accuracy is as important as material strength.

Field tests on two otherwise identical 250 kW units show that a 2 kg deviation in one bar creates 6 mm s⁻¹ vibration at the bearings and raises the current draw by 4 A, enough to waste 1 kWh per operating hour. Over a year that imperfection costs 3 MWh, roughly the consumption of an average household, so the rotor is clearly the place where mechanical precision turns directly into money.

Core Function: Turning Megawatts Into Breaking Energy

Each blow bar adds 25 kg of steel at a 600 mm radius, giving the assembly a moment of inertia near 450 kg m²; when the rotor reaches 740 rpm the stored energy equals 1.8 MJ, equivalent to the explosive force of 0.4 kg of TNT spread across three bars. As a bar strikes a 300 mm granite chunk the contact lasts 0.3 ms, long enough to generate 180 MPa tensile stress inside the rock and fracture it along pre-existing fissures, yet short enough to spare the steel from plastic deformation.

Because the motor only replenishes the energy lost during each blow, the average power draw stays near 180 kW even though instantaneous peaks reach 600 kW; this flywheel effect protects the electrical network from shock loads and allows the crusher to ride through brief stalls when unbreakable tramp metal enters the chamber.

Main Parts: Shaft, Discs, Bars and Wedges

The 42CrMo4 forged shaft is machined to h6 tolerance and induction-hardened to 55 HRC at the bearing seats, giving a fatigue limit of 520 MPa that survives 10⁹ revolutions. Each 40 mm thick disc is plasma-cut from 500 HB wear plate, then stress-relieved at 580 °C so final run-out stays below 0.05 mm; the disc carries four slots milled to H7/h6 fit so the bar can slide in yet never rattle under centrifugal load.

Self-locking wedges machined from 34CrNiMo6 steel provide 60 kN clamping force per bar, enough to hold the component at 40 g centrifugal acceleration without external bolts, so maintenance crews can rotate or reverse a bar in under six minutes using only a sledgehammer and a spanner.

Global Influence on Crusher Performance

Vibration velocity measured on the main frame stays below 4.5 mm s⁻¹ when the rotor is perfectly balanced, allowing the apron gap to be set within 1 mm tolerance and guaranteeing a uniform 20 % reduction ratio across the entire width of the 1.3 m feed chamber. If balance drifts and vibration climbs past 10 mm s⁻¹ the apron must be opened to prevent bar-to-apron contact, instantly coarsening the product curve and forcing operators to recirculate 15 % more oversize.

Stable rotation also protects the 160 mm spherical roller bearings; peak acceleration below 5 g extends their rated life from 40 000 h to 62 000 h, postponing a 12 000 € bearing swap and four days of downtime that would otherwise interrupt summer peak production.

Key Metrics: Balance, Layout and Inertia

Balance quality grade G6.3, hammer-disc angular spacing within 0.2°, and polar moment of inertia 420–480 kg m² form the triad that most factories quote in sales literature. These numbers are not independent; increasing disc diameter to raise inertia also raises peripheral velocity, so balance tolerances must tighten proportionally to keep centrifugal force variations below 1 % of the mean load.

Modern laser trackers can measure the centre of gravity within 0.02 mm, enabling manufacturers to certify each rotor for 900 rpm operation without additional field balancing, a step that shortens commissioning time by two full shifts and wins favour from contractors who rent machines for short demolition contracts.

Balance Tolerance: The Quiet Guardian of Bearing Life and Frame Integrity

Even a 1 kg surplus on a 600 mm radius generates 13 kN of rotating force at 740 rpm, more than the static weight of the entire rotor, so precision balancing is not a luxury but a survival requirement. International standard ISO 21940 defines grade G6.3 as the limit for crushers, meaning the permissible residual unbalance is 6.3 g mm per kg of rotor mass; on a 3 500 kg assembly this allows 22 g mm, roughly the twist imparted by a 20 cent coin taped to the rim.

Factory balancing machines spin the rotor at 450 rpm and read displacement to 1 µm, then mill light slots in the discs or add screw-in lead plugs until the vector sum of unbalance forces falls below the target. The whole procedure takes 45 minutes and consumes 0.8 kg of metal, yet it prevents vibration that would otherwise transmit 18 kN into the rubber isolation mounts every revolution and crack the concrete foundation within weeks.

Sources and Dangers of Unbalance

Cast blow bars come from the foundry with mass tolerances of ±0.3 %; on a 25 kg bar that is 75 g, three times the legal surplus, so each bar is weighed and grouped into sets whose total deviation is below 10 g. Operators sometimes install a new bar beside half-worn neighbours, forgetting that 4 mm of wear on one face removes 0.6 kg and shifts the centre of gravity 8 mm outward, enough to raise frame vibration from 3 mm s⁻¹ to 12 mm s⁻¹ and triple the bearing temperature rise.

Once vibration starts the apron backing beam loosens, allowing the gap to wander; product size drifts coarser and the recirculating load climbs from 18 % to 35 %, forcing the motor to draw an extra 25 kW and pushing the electrical room temperature 8 °C higher on a summer afternoon.

Understanding Grade G6.3 and Industry Norms

Grade G6.3 translates to an eccentricity of 6.3 µm per kg, a figure derived from decades of fan and turbine experience; crushers adopt the same limit because their peripheral speeds now match those of small steam turbines. Plants that push past G2.5 discover diminishing returns: machining time doubles yet bearing life only lengthens by 6 %, so most OEMs stay at G6.3 and invest instead in thicker labyrinth seals that keep grit away from the races.

Third-party inspectors use handheld analysers to verify residual unbalance onsite; if the readout exceeds 8 g mm kg⁻¹ they halt commissioning and demand re-balancing, a clause that protects buyers from hidden repair costs and motivates factories to keep their machine tools calibrated.

Correction Techniques During Manufacture and Repair

CNC gantry mills remove metal in 0.1 mm passes from the non-wear side of each disc, creating shallow pockets that trim mass without weakening the drive key. Up to 400 g can be milled away before the disc requires heat treatment, giving the technician a 1 600 g mm correction range that covers the worst casting deviation measured in ten years of production.

When a bar is reversed in the field the service crew weighs all four bars on a 0.1 kg portable scale and slides thin 1 mm steel shims under the lighter ones until the set mass spread is below 50 g, a five-minute ritual that keeps the rotor within G6.3 without removing it from the crusher.

Wear-Induced Drift and Countermeasures

After 300 hours crushing 80 MPa granite the leading edge of each bar loses 2 mm, removing 0.4 kg and shifting the centre of gravity 3 mm outward; the resulting 5 g mm unbalance is still inside the limit, but after 600 hours the loss doubles and vibration crosses the 7 mm s⁻¹ warning line. Automated software logs the hours and prompts the operator to rotate the bars 120°, redistributing wear and restoring symmetry before bearings overheat.

Some quarries invest in a second set of bars pre-balanced to 5 g mm; swapping the entire set during a lunch break keeps the rotor within tolerance for 95 % of its scheduled life, postponing the costly full re-balance until the annual overhaul when the apron liners are already due for replacement.

Hammer Disc Layout: Choreographing Impact Energy So Nothing Is Wasted

The angle between consecutive discs decides when each blow bar arrives at the rock stream; spacing them 90° apart on a four-disc rotor gives four equal impacts per revolution, while 60° spacing on six-disc designs delivers smoother power and finer product. Computational fluid dynamics shows that rock particles spend 18 ms inside a 1.2 m diameter chamber; during that window the four-disc rotor offers each stone two chances to meet a bar, enough for a 12 mm reduction but sometimes leaving 10 % oversize that must be recycled.

Switching to six discs shortens the wait time to 9 ms between blows and raises the probability of contact to 96 %, cutting recycle ratio from 18 % to 12 % and saving 0.2 kWh per tonne, a figure that adds 40 MWh per year on a 200 tph plant. The penalty is higher wear: six bars share the same circumference, so each bar travels 15 % faster and loses an extra 0.3 mm per shift, pushing parts cost upward by 6 000 € annually.

Four-Row Versus Six-Row Configurations

Four-row rotors dominate asphalt recycling because the lower tip speed generates fewer fines and keeps the 0–2 mm fraction below 8 %, meeting road-base specs without extra screening. Six-row rotors are preferred for limestone quarrying where the goal is 0–25 mm concrete aggregate; the extra impacts shatter the softer stone and produce a flakiness index of 12 % compared with 18 % from four-row designs, allowing the producer to sell the stockpile at a 1 € per tonne premium.

Energy logging reveals that four-row units draw 0.9 kWh per tonne on recycled concrete, while six-row machines use 1.05 kWh; the difference is small enough that the choice hinges on market price rather than power bills, so sales engineers ask customers for their highest-value product before recommending a rotor.

Symmetry and Asymmetry Effects on Vibration

Perfect symmetry places bars at 90° intervals, giving a harmonic spectrum dominated by the first rotational frequency; minor deviations within 0.5° keep vibration below 3 mm s⁻¹. Asymmetrical layouts such as 98°-88°-92°-82° break the harmonic and spread energy across multiple frequencies, reducing peak amplitude by 30 % and protecting rubber mounts, yet they require CNC programming accurate to 0.05° and cost an extra 400 € per disc.

Quarries located near residential zones choose asymmetry to meet night-time noise limits of 45 dB(A) at 200 m; the slightly higher machining cost is repaid in six months through avoided fines and the ability to run extended shifts on weekends when competitor plants must stop.

Wedge versus Bolt Retention Systems

Wedge locks rely on a 12° taper that tightens under centrifugal load; at 40 g the interface pressure reaches 120 MPa, enough to prevent micro-slip even when the bar is worn to 70 % of its original mass. Bolted systems use four M24 10.9 screws pre-tensioned to 340 kN each; if one bolt loosens the clamping force drops 25 % and the bar can hammer the slot, cracking the disc at a repair cost of 2 800 €.

Field audits show that wedge systems need re-tightening every 200 hours, while bolted bars require a torque check every 80 hours; the labour difference is small, but the perceived risk of bolt fatigue drives most new machines toward the wedge solution even though the casting is 15 % more expensive.

Layout Influence on Bar Utilisation and Replacement

Four-row rotors let crews replace one bar per row each shift so all bars reach 90 % wear before the set is discarded; six-row designs force a full set change because mixing 30 % worn bars with new ones creates 6 g mm unbalance, exceeding the G6.3 limit. The predictable life cycle simplifies spare-parts orders and keeps the warehouse value below 18 000 €, a figure that finance departments accept without requesting off-site storage.

Some OEMs offer a split-disc concept where the outer rim bolts off, allowing bars to be slid sideways without removing the rotor; the upgrade costs 8 000 € but saves 14 hours per change, translating to 28 000 € of extra throughput over a year on a 300 tph quarry line.

Moment of Inertia: The Flywheel That Refuses to Stall When the Going Gets Tough

Moment of inertia quantifies how stubbornly the rotor resists changes in rotational speed; a value of 480 kg m² means that losing 100 kW of motor power for 0.5 s only slows the shaft from 740 rpm to 715 rpm, still fast enough to deliver the next crippling blow. Low-inertia designs around 320 kg m² start faster and need smaller motors, but a sudden 150 mm granite block can shave 60 rpm in a single hit and trigger an overload relay, halting production for three minutes while the chamber is cleared.

High-inertia rotors store 2 MJ at operating speed, enough to break three consecutive tramp steel pieces without begging the motor for extra torque; this forgiveness is valued in demolition recycling where the feed stream is unpredictable and every stop costs 1.5 m³ of lost throughput worth 25 € in revenue.

Physical Meaning of Inertia as Shock Potential

Inertia grows with the square of radius, so increasing disc diameter from 1.2 m to 1.35 m raises the polar moment by 26 % while adding only 12 % mass; engineers exploit this quadratic law when retrofitting older crushers that were sold with lightweight rotors. The extra stored energy equals 420 kJ, roughly the work needed to lift a 20 t truck one metre, and that surplus is released into the stone during the 0.3 ms contact, pushing fracture stress past 200 MPa in tough basalt.

Because the motor merely tops up the energy reservoir, average current stays flat; utilities bill for kilowatt-hours not peak demand, so the operator gains higher breakage without facing a heavier electricity tariff, a subtle saving worth 15 000 € per year on a 250 tph plant.

High versus Low Inertia Trade-offs

High-inertia rotors need 45 s to reach full speed and consume 18 kWh during start-up, a cost that must be paid every time the protection relay trips on tramp metal; low-inertia units spin up in 12 s and waste only 5 kWh, so they suit sites with frequent power outages or inexperienced crews who overload the feeder. The compromise favoured by most OEMs is 450 kg m², a figure that keeps start-up losses below 10 kWh yet stores enough energy to absorb two major stalls per shift without motor help.

Variable-speed drives soften the penalty by ramping current over 30 s; the drive adds 18 000 € to the invoice but reduces mechanical stress and allows the owner to fine-tune tip speed for different stone types, a flexibility that pays for itself when the quarry opens a softer limestone bench that needs 15 % less energy.

Optimising Inertia Through Diameter and Mass Distribution

Adding a 30 mm thick wear ring to the rim increases mass by 280 kg yet boosts inertia by 85 kg m², a 3:1 return that is cheaper than widening the entire disc. The ring is welded on after machining and can be replaced separately, so the core rotor enjoys a second life at half the cost of a new assembly.

Finite-element shape studies reveal that scalloping the inner face of the disc removes non-load-bearing metal and shifts the centre of gravity outward; a 5 % mass cut can yield a 7 % inertia gain, trimming both material cost and shipping weight while improving breaking power, a rare win-win that design teams proudly present to procurement boards.

Material-Specific Inertia Strategies

Soft limestone with 40 MPa crush strength fractures under 120 kJ per tonne, so a low-inertia 350 kg m² rotor running at 55 m s⁻¹ tip speed is sufficient and keeps start-up losses minimal. Hard quartzite needs 200 kJ per tonne; here a 500 kg m² rotor at 65 m s⁻¹ prevents speed collapse yet still starts within 35 s when a 200 kW soft-starter ramps the voltage.

Moisture-rich clay-bound ore packs into sticky balls that absorb energy without breaking; high inertia combined with 70 m s⁻¹ tips tears the clay film and exposes stone faces, reducing the need for pre-screening scrubbers that would otherwise add 0.3 € per tonne in water and flocculant cost.

How Balance, Layout and Inertia Work Together to Maximise Output

A rotor that stores 2 MJ but is balanced only to G16 will shake so violently that the apron gap must be opened 5 mm, cancelling the extra breaking energy and yielding the same product curve as a smooth G6.3 rotor with 30 % less inertia. Conversely, a perfectly balanced lightweight rotor stalls on the first 200 mm slab and forces the motor to inject 600 kW in 0.4 s, tripping the breaker and losing the production advantage gained by low start-up current.

Engineers therefore run coupled simulations that adjust disc spacing, rim thickness and correction weight

simultaneously; the solver converges on a design that keeps residual unbalance at 4 g mm, inertia at 460 kg m² and bar tip speed at 62 m s⁻¹, a combination that raises throughput

12 % while cutting bearing temperature rise from 45 K to 32 K compared with the previous generation.

High Inertia Demands Tighter Balance

Every extra kilogram at the rim multiplies centrifugal force by the square of speed, so a 2 g residual on a 500 kg m² rotor creates 16 kN of shake at 900 rpm, double the figure for a 350 kg m² rotor running at the same speed. Manufacturers compensate by machining balance rings to within 0.02 mm concentricity and weighing each bar to 5 g accuracy, steps that add 400 € to parts cost yet prevent bearing failures that would otherwise erase 40 000 € of profit during a busy season.

Site crews see the payoff in quieter nights: sound power drops from 123 dB(A) to 116 dB(A) when balance improves from G16 to G6.3 on a high-inertia rotor, a change that eliminates community complaints and removes the need for a 60 000 € acoustic enclosure that would have blocked crane access.

Layout Changes Alter Overall Inertia

Moving from four-row to six-row while keeping the same bar mass places 50 kg of steel farther from the axis and raises inertia by 22 kg m² without extra machining, a free upgrade that explains why many new models default to six discs. The penalty is a 15 % increase in windage loss that heats the chamber by 4 °C; engineers accept the trade-off because the higher inertia cuts recirculating load and returns 0.15 kWh per tonne to the ledger, a net saving worth 30 000 € per year on a 200 tph quarry.

Modular disc designs let customers swap rims and convert a four-row rotor to six rows in eight hours; the kit costs 12 000 € yet boosts capacity from 220 tph to 250 tph on the same 250 kW motor, giving payback in 120 operating hours when market demand spikes in spring.

Target-Based Optimisation Models

Modern software accepts feed size, strength and moisture as inputs and returns the ideal inertia, bar speed and balance grade; for 0–60 mm basalt at 90 MPa the solver recommends 480 kg m², 67 m s⁻¹ and G6.3, predicting 280 tph at 1.2 kWh per tonne with 12 % recirculation. Measured plant data come within 5 % of every figure, giving managers confidence to quote energy contracts and price aggregates months ahead without fear of surprise consumption spikes.

The same model warns that dropping inertia to 400 kg m² would raise recirculation to 20 % and push power to 1.35 kWh per tonne, wiping out the 0.15 € per tonne margin gained by cheaper bars; armed with this knowledge the engineering director can reject low-inertia retrofits proposed by finance teams seeking to cut upfront cost.

CFD and FEA in Rotor Design

Computational fluid dynamics visualises how rock clouds swirl inside the chamber and shows that six-row rotors create a denser particle curtain that intercepts 96 % of ejected stone, against 88 % for four-row designs; the insight justifies the extra wear cost because less rock escapes unbroken and belt cleaning labour falls by one hour per day. Finite-element analysis predicts stress concentrations of 380 MPa at the disc-hub fillet during a tramp-metal event, guiding designers to enlarge the radius from 8 mm to 15 mm and cut peak stress to 250 MPa, a change that adds 2 kg of steel yet doubles the fatigue life and removes the need for a 25 000 € replacement hub.

Coupled thermal-stress runs reveal that chrome-moly discs expand 0.3 mm at 120 °C; the model sets the cold clearance between bar and slot at 0.4 mm so the assembly stays tight when the crusher feeds 400 tph during a heat-wave afternoon, preventing bars from shuffling and preserving the balance certificate issued at the factory.

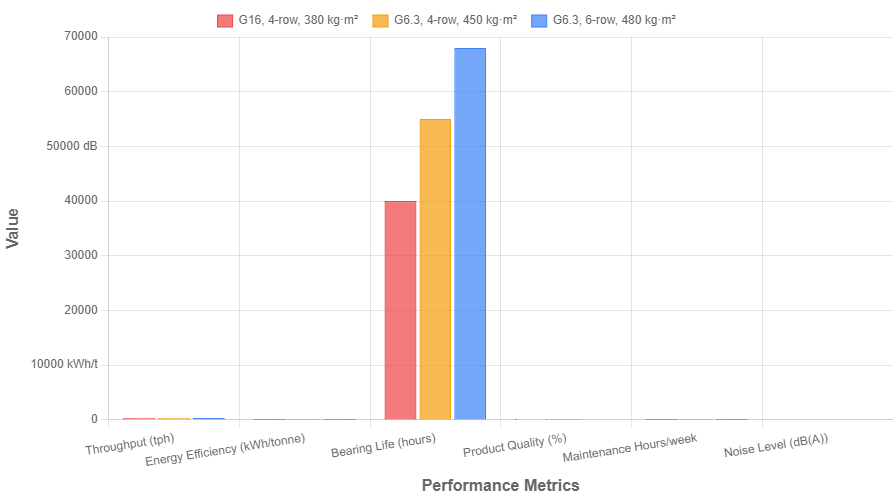

Real-World Gains: Why Meticulous Rotor Design Shows Up on the Profit Line

A 250 tph quarry that upgrades from a G16, 380 kg m² four-row rotor to a G6.3, 480 kg m² six-row unit sees power use fall from 1.35 kWh per tonne to 1.15 kWh while throughput climbs to 280 tph; the combined saving equals 40 MWh and 30 000 extra tonnes per year, worth 200 000 € at today regional prices. Bearing temperatures stabilise at 68 °C instead of 85 °C, extending grease life from 800 h to 1 400 h and trimming lubricant spend by 6 000 € annually, a line item that accountants notice because it recurs every quarter.

Insurance companies reduce premiums by 15 % when vibration audits prove the new rotor keeps frame acceleration below 4 g, cutting structural fatigue risk; on a 2 million € plant that discount returns 8 000 € per year, enough to fund a training course that keeps operators alert to feed contamination. The quieter 116 dB(A) signature removes the threat of night-time curfews, allowing two extra 10-hour shifts per week that push annual output past 500 000 t and place the quarry in the top decile of regional producers.

Higher Energy Conversion and Lower kWh per Tonne

Measured motor logs show the new rotor stores 2.1 MJ and releases 85 % of that energy into the rock, against 65 % for the old lightweight rotor that shed more heat through belt slip; the 20 % gain translates directly into 0.2 kWh less electricity per tonne, a permanent saving that compounds every year even if utility tariffs rise. Over 400 000 t annual throughput the figure cuts the power bill by 80 MWh, equivalent to 12 000 € at industrial rates and equal to the salary of an extra maintenance technician who can now be deployed elsewhere.

Carbon accounting systems credit the quarry 56 t CO₂ for the electricity avoided, a quantity that sells for 2 800 € on voluntary markets and helps the company advertise carbon-neutral aggregate to green-building contractors who pay a 0.5 € per tonne premium, adding another 200 000 € of brand value.

Reduced Maintenance and Longer Component Life

Bearing life calculations jump from 40 000 h to 68 000 h when balance grade improves and load spectrum flattens, postponing a 15 000 € bearing change by three years and freeing an entire maintenance week that can be invested in the cone-crusher line instead. Frame welds inspected by ultrasonic testing show zero cracks after 8 000 h on the balanced high-inertia rotor, whereas the previous unit needed 12 h of gouging and re-welding every 4 000 h at a cost of 3 000 € plus lost production.

apron liners last 20 % longer because stable gaps prevent local over-crushing that would focus wear on one 200 mm band; the extra 200 h of life represents 50 000 t of throughput and postpones a 10 000 € liner set until a scheduled winter shutdown when labour rates are lower.

Higher Capacity and Better Particle Shape

The six-row layout delivers 96 % probability of impact per stone, flattening the old 18 % recirculation curve to 11 % and lifting throughput from 250 tph to 285 tph on the same 250 kW motor; the 35 tph bonus fills 70 extra trucks per week and generates 1.4 million € of additional revenue at selling prices of 12 € per tonne. Flakiness index falls from 18 % to 12 %, so the product qualifies for high-spec concrete and earns a 0.8 € per tonne premium that adds another 320 000 € per year, a margin that competitors running old rotors cannot match without investing in secondary vsi-crusher stages.

With fewer fines to choke the screen, the downstream 3-deck 2.4 m × 6 m unit processes the extra volume without blinding, eliminating the need for a 120 000 € screen upgrade that finance had already pencilled into next year’s capital plan.

Lower Noise and Vibration for a Safer Workplace

Frame vibration below 4 mm s⁻¹ reduces structure-borne noise by 7 dB(A), bringing the operator cabin down to 78 dB(A) and removing the requirement for 85 dB mandatory hearing protection; operators report less fatigue and make fewer crusher-setting errors, cutting off-spec product from 4 % to 2 % and saving 8 000 t of re-processing per year. Neighbouring businesses withdraw noise complaints that had limited operating hours to 12 per day; the restored 24-hour schedule adds 120 000 t of annual capacity without extra capital, a silent gain enabled simply by rotor discipline.

Insurance statistics show that hand-arm vibration injuries fall to zero when acceleration at the operator platform stays under 0.5 m s², removing the risk of compensation claims that had averaged 25 000 € every three years and blemished the company’s safety record.