Configuring an Impact Crusher for High-Silica Abrasive Material: Wear Solutions & Cost Models

Processing highly abrasive materials like quartzite and basalt presents a significant challenge in industrial crushing operations. The high silica content in these rocks accelerates wear on crusher components, leading to frequent downtime and substantial operational costs. This comprehensive guide explores a multi-faceted approach to conquer these demanding conditions through advanced material science, equipment optimization, operational adjustments, and detailed cost analysis. The strategies outlined here will provide operators with the knowledge to extend component life, reduce maintenance frequency, and ultimately improve profitability when working with nature's most abrasive materials.

Understanding High-Silica Abrasive Materials and Their Challenges

Materials with elevated silica content possess distinct characteristics that make them particularly damaging to crushing equipment. Quartz, a common mineral with a hardness of 7 on the Mohs scale, acts as a natural abrasive that progressively wears down metal surfaces through mechanical action. The angular nature of crushed particles further exacerbates this wear process, creating a challenging environment for conventional crusher components.

The Bond Work Index serves as a valuable indicator of material abrasiveness, with high-silica rocks typically registering elevated values that correlate directly with increased wear rates. This abrasiveness manifests through two primary wear mechanisms in impact crushers: forceful impact events that create surface deformations and microscopic cutting actions that gradually remove material. These processes collectively contribute to premature failure of critical components, resulting in operational inefficiencies and escalated production costs that can undermine profitability in aggregate operations.

Quartz Content and Abrasiveness Correlation

The relationship between quartz concentration and material abrasiveness follows a predictable pattern that directly influences equipment longevity. Rocks containing over forty percent silica quartz demonstrate exponentially increasing wear rates on crusher components. This correlation exists because quartz crystals maintain sharp fracture edges even after initial breakage, continuously presenting fresh abrasive surfaces throughout the crushing process.

Laboratory testing has confirmed that materials with silicon dioxide concentrations exceeding sixty percent can reduce crusher component life by as much as seventy percent compared to less abrasive limestone formations. This dramatic reduction in operational lifespan necessitates specialized approaches to material selection and equipment operation. The microscopic structure of quartz particles enables them to act as natural cutting tools when subjected to the tremendous forces within a crushing chamber.

Material Hardness and Crushing Resistance

Beyond silica content, the overall hardness of feed material significantly influences the wear processes within impact crushing systems. The Mohs scale provides a useful reference for comparing mineral hardness, with quartz registering at approximately 7.0 while typical crusher liner materials range between 5.5 and 8.0 on the same scale. This narrow margin between material and tool hardness creates ideal conditions for rapid abrasive wear.

The Bond Work Index quantifies the energy required to reduce material size, with high-silica rocks often requiring thirty to fifty percent more energy than sedimentary formations. This additional energy input translates directly into increased mechanical stress on crusher components. The angular fracture patterns of igneous rocks like basalt create particles with sharp edges that accelerate wear through microscopic cutting and plowing mechanisms against metal surfaces.

Impact and Micro-Cutting Wear Mechanisms

Impact crushers subject components to a combination of wear processes that operate simultaneously at different scales. Macroscopic impact events occur when large particles strike wear parts at velocity, creating surface deformations and initiating crack formations that propagate with repeated loading. These impact events typically occur at the moment of particle acceleration by the rotor assembly and subsequent collision with impact plates or other particles.

Simultaneously, microscopic cutting wear progresses as smaller abrasive particles slide across metal surfaces under extreme pressure. This process effectively machines away material from critical components through a mechanism similar to precision grinding. The combination of these wear modes creates a particularly damaging environment that demands specialized material solutions beyond conventional steel alloys to maintain operational efficiency.

Consequences of Unchecked Abrasive Wear

Without appropriate countermeasures, the processing of high-silica materials leads to operational challenges that significantly impact profitability. Component replacement intervals may decrease from several months to just weeks, creating substantial downtime for maintenance activities. This unpredictable operational schedule disrupts production planning and increases labor costs associated with frequent component changes.

The financial implications extend beyond direct component costs to include secondary effects from reduced throughput and increased energy consumption. As wear parts deteriorate, product quality often suffers through inconsistent particle size distribution and increased fines generation. These operational deficiencies collectively increase the cost per ton of processed material, potentially rendering otherwise viable deposits economically marginal.

Advanced Material Technologies for Critical Wear Parts

Material selection represents the most fundamental defense against abrasive wear in impact crushing applications. Modern metallurgy has developed specialized alloys and composite materials specifically engineered to withstand the extreme conditions encountered when processing high-silica rocks. These advanced materials typically command premium prices but deliver superior performance that justifies their increased initial cost through extended service life.

The evolution of wear-resistant materials has progressed from basic carbon steels through complex alloy systems incorporating ceramic reinforcements. Each material generation offers distinct advantages in hardness, toughness, and wear resistance characteristics. Proper selection requires careful consideration of the specific application conditions, including impact energy, abrasiveness, and operational parameters that influence component performance.

Evolution of Blow Bar Materials

Blow bars have undergone significant material evolution to meet the challenges of abrasive crushing applications. Traditional high-manganese steels provided excellent impact resistance through work-hardening characteristics but offered limited protection against pure abrasion. The development of high-chromium iron alloys represented a substantial advancement with hardness values exceeding 60 HRC, providing significantly improved resistance to abrasive wear.

Contemporary solutions incorporate ceramic inserts within metallic matrices, creating composite structures that combine the toughness of metal with extreme hardness of ceramic materials. These advanced composites can extend service life by factors of three to five compared to conventional materials when processing highly abrasive feeds. The strategic placement of ceramic reinforcements in high-wear areas maximizes protection while maintaining structural integrity under impact loading.

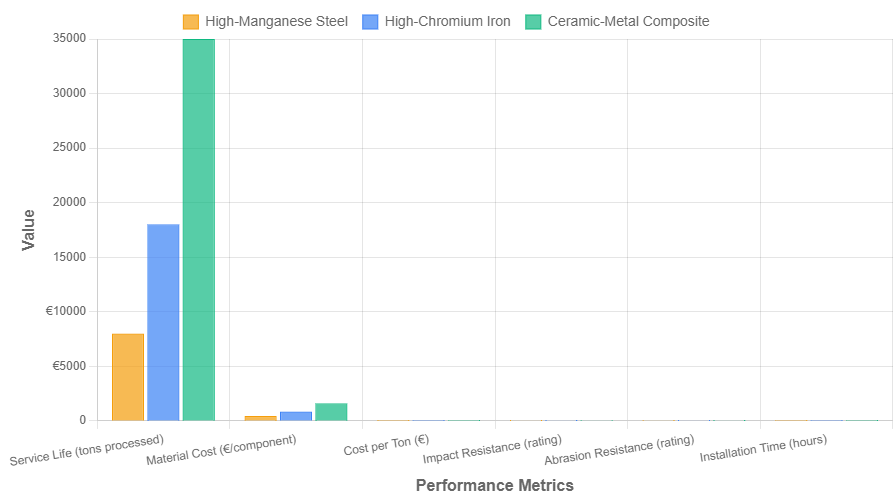

Comparative Analysis of Material Properties

Each class of wear material offers distinct advantages and limitations that must be carefully balanced against application requirements. High-manganese steels provide exceptional toughness and impact resistance but demonstrate relatively low initial hardness around 20 HRC that increases through work-hardening during operation. These materials perform well in applications involving high-impact energy with moderate abrasion.

High-chromium cast irons deliver superior hardness values between 58-65 HRC with good compression strength but reduced impact toughness compared to manganese steels. Ceramic-metal composites achieve surface hardness exceeding 70 HRC while maintaining adequate fracture resistance through metallic support structures. The selection process must consider both mechanical properties and economic factors to identify the optimal solution for specific operating conditions.

Selection of Impact Plates and Liners

Impact plates and side liners require material properties that differ slightly from those optimal for blow bars due to variations in impact angle and energy. These components experience more sliding abrasion than direct impact, favoring materials with maximum hardness rather than extreme toughness. Modern impact crushers often utilize modular designs that allow different materials to be installed in specific zones based on wear patterns.

Composite solutions incorporating replaceable wear inserts have gained popularity for their ability to maximize material utilization and simplify maintenance procedures. These systems allow critical wear areas to be protected with premium materials while supporting structures utilize more economical alternatives. This approach optimizes both performance and cost-effectiveness for operations processing highly abrasive materials.

Professional Hardfacing and Repair Techniques

Specialized hardfacing technologies extend component life through the application of wear-resistant alloys to critical surfaces. Automated welding systems deposit complex alloy compositions that provide customized protection against specific wear mechanisms. These techniques allow worn components to be restored to serviceable condition at a fraction of replacement cost while incorporating improved material properties based on operational experience.

Advanced repair protocols include pre-heat and post-heat treatment processes that ensure proper metallurgical bonding and stress relief. The economic value of professional repair services becomes particularly evident when processing high-silica materials, where component replacement costs constitute a significant portion of operational expenses. Properly executed repairs can restore components to original performance specifications while incorporating design improvements based on field experience.

Equipment Configuration and Operational Parameter Optimization

Beyond material selection, equipment configuration and operational parameters significantly influence wear rates in impact crushers processing abrasive materials. Optimizing these factors reduces the severity of wear mechanisms without compromising processing capacity or product quality. Modern crusher designs incorporate adjustable features that allow operators to fine-tune machine operation based on feed material characteristics.

The relationship between rotor velocity, material flow, and wear progression follows predictable patterns that can be leveraged to extend component life. Crusher manufacturers have developed specific configurations for abrasive applications that modify impact angles, material trajectories, and chamber geometries to reduce wear rates. These design modifications often involve trade-offs between reduction ratio, capacity, and component longevity.

Rotor Speed Optimization

Rotor velocity directly influences both impact energy and wear rate, creating a complex optimization challenge for operators. Higher rotational speeds increase impact forces, improving reduction ratios and capacity but accelerating component wear through increased abrasion and impact events. Finding the optimal balance requires careful consideration of material characteristics and product requirements.

For highly abrasive silica-rich materials, operators often reduce rotor velocity by fifteen to twenty percent compared to standard operation with less abrasive feeds. This reduction decreases the kinetic energy of particles striking wear parts while maintaining adequate fragmentation energy. The resulting increase in component life typically outweighs the modest reduction in processing capacity, particularly when considering avoided downtime for component replacement.

Rock-on-Rock versus Rock-on-Iron Configuration

Impact crushers can operate in two distinct crushing modes that significantly influence wear patterns and component life. Rock-on-iron configuration directs material against metal wear parts, maximizing reduction efficiency but accelerating component wear. Rock-on-rock configuration encourages particle-to-particle impact, reducing direct wear on components but potentially limiting reduction capabilities.

For extremely abrasive materials, a hybrid approach often delivers optimal results by combining both crushing mechanisms in sequence. Initial fragmentation occurs through particle-to-particle impact in a rock-on-rock chamber, followed by final sizing against metal components. This configuration reduces the abrasive load on wear parts while maintaining product quality specifications, extending component life by thirty to forty percent in high-silica applications.

Crushing Chamber Geometry Optimization

Modern impact crusher designs incorporate advanced chamber geometries that create material-on-material crushing zones to protect wear components. These designs utilize cascading material flows to form a protective layer of processed particles between the feed material and metal surfaces. The geometry ensures that fresh feed primarily contacts previously processed material rather than directly impacting wear parts.

Optimized chamber designs incorporate adjustable elements that allow operators to modify material flow patterns based on feed characteristics. These adjustments maintain optimal protection across varying feed conditions and wear states. The effectiveness of material-layer protection depends on maintaining consistent feed rates and characteristics, highlighting the importance of integrated system design beyond the crusher itself.

Feed System Optimization for Consistent Operation

Consistent feed distribution represents a critical factor in maximizing component life when processing abrasive materials. Irregular feed patterns create uneven wear across crushing components, prematurely necessitating replacement due to localized deterioration. Modern feed systems incorporate level sensors and variable-speed feeders that maintain optimal material depth within the crushing chamber.

Pre-screening systems remove fine material that would otherwise absorb impact energy without contributing to fragmentation, reducing effective capacity and increasing specific wear rates. These systems improve overall efficiency while reducing the abrasive load on crusher components. The integration of feed control systems typically increases component life by twenty-five to thirty-five percent when processing high-silica materials through more uniform wear distribution.

Preventive Maintenance and Intelligent Monitoring Systems

Transitioning from reactive replacement to proactive maintenance management significantly improves operational efficiency when processing abrasive materials. Preventive maintenance programs schedule component inspection and replacement based on operational hours or throughput volume rather than waiting for failure. This approach minimizes unplanned downtime and allows maintenance activities to be scheduled during natural production pauses.

Advanced monitoring technologies provide early warning of component deterioration before failure occurs, allowing planned intervention at optimal times. These systems track operational parameters that correlate with wear progression, enabling operators to predict remaining component life with increasing accuracy. The integration of monitoring technologies with maintenance management systems creates a comprehensive approach to equipment reliability.

Component Lifecycle Tracking Systems

Comprehensive record-keeping forms the foundation of effective maintenance planning for crushers processing abrasive materials. Digital tracking systems record installation dates, operational hours, and throughput tonnage for each wear component, creating a historical database for life prediction. This information allows operators to forecast replacement needs and schedule maintenance activities during planned downtime periods.

Historical data analysis identifies relationships between operational parameters and component life, enabling continuous improvement of maintenance strategies. These systems typically reduce emergency downtime by sixty to seventy percent through improved planning and component availability. The data collected also provides valuable information for component selection and operational parameter optimization based on actual performance metrics.

Strategic Component Rotation Practices

Blow bars and other wear components often exhibit uneven wear patterns that limit their usable life if not addressed through strategic rotation. Regular rotation practices distribute wear more evenly across multiple components, extending their collective service life before replacement becomes necessary. This approach typically increases total material processed per component set by twenty to thirty percent.

Rotation schedules vary based on material abrasiveness and operational parameters, typically occurring after processing twenty-five to forty thousand tons of high-silica material. Modern crusher designs facilitate this process through quick-change attachment systems that reduce downtime during rotation procedures. The economic benefit of rotation strategies significantly outweighs the modest labor requirements involved in the process.

Vibration and Thermal Monitoring Technologies

Advanced monitoring systems track vibration signatures and temperature patterns that indicate developing mechanical issues before they cause catastrophic failure. Wireless sensors mounted on bearings, rotors, and other critical components continuously monitor operational parameters, alerting operators to abnormal conditions that require investigation. These systems typically provide twenty-four to forty-eight hours warning of impending bearing failures.

Thermal imaging cameras detect abnormal heat patterns that indicate misalignment, inadequate lubrication, or component deterioration. Regular thermal inspections identify developing issues during routine operation without requiring equipment shutdown. The integration of these monitoring technologies with automated alert systems prevents secondary damage that often follows primary component failures.

Critical Component Inspection Protocols

Regular inspection of structural components including the main shaft, bearing housings, and frame assemblies prevents catastrophic failures that result in extended downtime. These inspections follow detailed protocols that specify measurement points, acceptable tolerances, and documentation requirements. Advanced inspection techniques including magnetic particle testing and ultrasonic thickness measurement detect developing issues not visible through visual examination alone.

Inspection frequency depends on operational intensity and material abrasiveness, typically occurring at five hundred to one thousand hour intervals for crushers processing high-silica materials. Detailed inspection records track component condition over time, identifying trends that indicate developing issues before they reach critical severity. These preventive measures typically reduce unplanned downtime by forty to fifty percent in demanding applications.

Developing a Scientific Cost-Per-Ton Calculation Model

Accurate cost calculation provides the foundation for informed decision-making regarding equipment configuration, component selection, and operational parameters. The cost-per-ton model aggregates all operational expenses associated with material processing, providing a comprehensive metric for performance evaluation. This model enables objective comparison between different operational approaches and equipment configurations.

Modern tracking systems automate data collection for cost calculation, integrating information from multiple sources including production monitors, maintenance records, and energy consumption meters. This automation reduces administrative burden while improving data accuracy and timeliness. The resulting information enables operators to identify improvement opportunities that might otherwise remain hidden within general operational expenses.

Components of Comprehensive Cost Calculation

The cost-per-ton model incorporates all expenses directly attributable to the crushing process, creating a complete picture of operational efficiency. Wear component consumption typically represents thirty to fifty percent of total costs when processing high-silica materials, followed by energy consumption at twenty to thirty percent. Labor, maintenance supplies, and equipment depreciation constitute the remaining operational expenses.

Indirect costs including lost production during downtime and associated overhead expenses must also be incorporated for accurate analysis. These often-overlooked factors can represent twenty to twenty-five percent of total operational costs in abrasive applications. Comprehensive accounting ensures that operational decisions consider all financial implications rather than focusing exclusively on direct component costs.

Tracking Wear Component Consumption Rates

Accurate measurement of wear component consumption requires precise tracking of both material processed and component weight loss. Modern crushers incorporate automated production monitoring systems that record throughput tonnage with accuracy exceeding ninety-eight percent. Component weight documentation before installation and after removal provides data for consumption calculation.

The metal consumption rate expressed as grams per ton processed provides a standardized metric for comparing performance across different operational conditions and component materials. This metric typically ranges from fifteen to forty grams per ton for impact crushers processing high-silica materials, depending on specific conditions and component materials. Tracking this metric over time identifies trends and measures improvement initiative effectiveness.

Comparative Analysis of Material Options

Cost-per-ton calculations enable objective comparison between different wear material options based on actual performance rather than initial purchase price. Premium materials typically demonstrate twenty to forty percent lower cost-per-ton despite higher initial costs due to extended service life and reduced replacement downtime. This analysis must consider total operational impact rather than simply dividing component cost by tons processed.

Advanced accounting methods incorporate the time value of money through net present value calculations for long-term component strategies. These analyses often justify capital investments in premium components or equipment modifications that reduce operational expenses over time. The comprehensive financial perspective ensures that decisions maximize long-term profitability rather than minimizing short-term expenses.

Return on Investment Calculation for Improvements

Capital investments in equipment upgrades or premium components require rigorous financial analysis to ensure economic justification. Return on investment calculations compare projected operational savings against implementation costs, typically requiring payback periods of twelve to twenty-four months for approval. These analyses incorporate all financial benefits including increased production capacity, reduced downtime, and lower component consumption.

Advanced financial models incorporate risk assessment through sensitivity analysis that evaluates performance under varying operational conditions. This approach ensures that investment decisions remain sound even if actual savings fall twenty to thirty percent below projections. The disciplined financial evaluation of improvement opportunities prioritizes initiatives that deliver maximum economic benefit within resource constraints.

Comprehensive Solution Development and Future Perspectives

Addressing the challenges of high-silica material processing requires an integrated approach that combines equipment selection, operational practices, and maintenance strategies. Modern crusher designs incorporate features specifically engineered for abrasive applications, including enhanced protection systems and improved accessibility for maintenance. These specialized configurations typically command a fifteen to twenty-five percent premium over standard models but deliver substantially improved operating economics in demanding applications.

The future development of crushing technology continues to focus on wear reduction through improved materials, innovative designs, and advanced control systems. Emerging technologies including real-time wear monitoring and automated adjustment systems promise further improvements in operational efficiency and cost control. These advancements will gradually transform how operators approach the most challenging crushing applications.

Equipment Selection for Abrasive Applications

Impact crusher selection for high-silica applications requires careful consideration of design features beyond basic capacity specifications. Machines designed for abrasive conditions typically incorporate heavier construction, enhanced protection systems, and improved maintenance accessibility. These features increase initial investment but deliver superior operating economics through extended component life and reduced maintenance requirements.

Modern impact crushers offer specialized configurations including hybrid crushing chambers that combine impact and grinding actions for improved efficiency in abrasive applications. These designs typically reduce wear rates by twenty-five to thirty-five percent compared to conventional impact crushers when processing high-silica materials. The selection process must balance initial investment against long-term operating costs to identify the optimal solution for specific operational conditions.

Strategic Supplier Partnership Development

Long-term relationships with component suppliers and service providers deliver significant advantages when processing abrasive materials. Strategic partners develop deep understanding of specific operational challenges and can provide customized solutions rather than standard products. These relationships typically reduce total operating costs by ten to fifteen percent through improved component performance and enhanced technical support.

Advanced supplier partnerships include joint development initiatives that create innovative solutions to specific wear challenges. These collaborations leverage supplier expertise in material science and application knowledge from operators to develop superior solutions. The resulting improvements typically exceed what either party could achieve independently, creating mutual benefit through enhanced performance.

Automation and Operational Parameter Stability

Advanced automation systems maintain optimal operational parameters despite variations in feed material characteristics, improving consistency and reducing wear rates. These systems continuously adjust crusher operation based on real-time performance monitoring, maintaining peak efficiency across changing conditions. Automated systems typically reduce wear component consumption by fifteen to twenty-five percent while improving product consistency.

Modern control systems incorporate adaptive algorithms that learn from operational experience, continuously refining control parameters for improved performance. These systems reduce reliance on operator skill and attention, maintaining optimal operation across shift changes and personnel variations. The resulting consistency extends component life and improves overall operational efficiency.

Emerging Materials and Manufacturing Technologies

New material development continues to advance wear component performance through innovative alloys and composite structures. Functionally graded materials with varying properties across their volume offer potential for improved performance by providing hardness where needed and toughness in supporting structures. These advanced materials typically increase service life by thirty to fifty percent compared to conventional alternatives.

Additive manufacturing technologies enable production of complex component geometries that optimize material distribution based on wear patterns. This approach reduces weight while improving performance, potentially revolutionizing how wear components are designed and manufactured. These emerging technologies promise continued improvement in wear resistance and operational economics for crushing applications.