Impact Crusher Selection Guide: Precision Choices Based on Material Characteristics

This comprehensive guide provides essential knowledge for selecting the optimal Impact Crusher based on specific material properties and operational requirements. Impact Crushers are versatile crushing machines that utilize the principle of impact crushing to reduce materials through high-speed rotation of rotors and impact against plates. Unlike compression-based crushers like jaw or cone crushers, impact crushers are particularly effective for medium-hard materials and produce a well-shaped cubic end product. We will explore how material hardness, moisture content, and size distribution fundamentally influence crusher selection, how production scale dictates equipment configuration, and how to evaluate both initial investment and long-term operational costs to make the most economically sound decision for your crushing operation.

Understanding Basic Material Characteristics

The foundation of proper Impact Crusher selection begins with a thorough analysis of the material to be processed. Different materials behave uniquely under impact forces, and their physical properties directly determine the crusher's design requirements, wear part specifications, and operational parameters. A comprehensive material analysis should include hardness testing, moisture content measurement, abrasiveness assessment, and size distribution analysis. This scientific approach to material characterization prevents costly mismatches between equipment capabilities and processing requirements.

Material characteristics influence virtually every aspect of crusher performance. Hard, abrasive materials demand robust construction and specialized wear materials, while moist, clay-rich materials require design features that prevent clogging and facilitate material flow. The size and shape of feed material determine the necessary feed opening dimensions and crushing chamber geometry. Understanding these relationships allows operators to select impact crushers that will deliver optimal performance, minimal downtime, and the lowest cost per ton of processed material.

The Influence of Material Hardness on Impact Crusher Selection

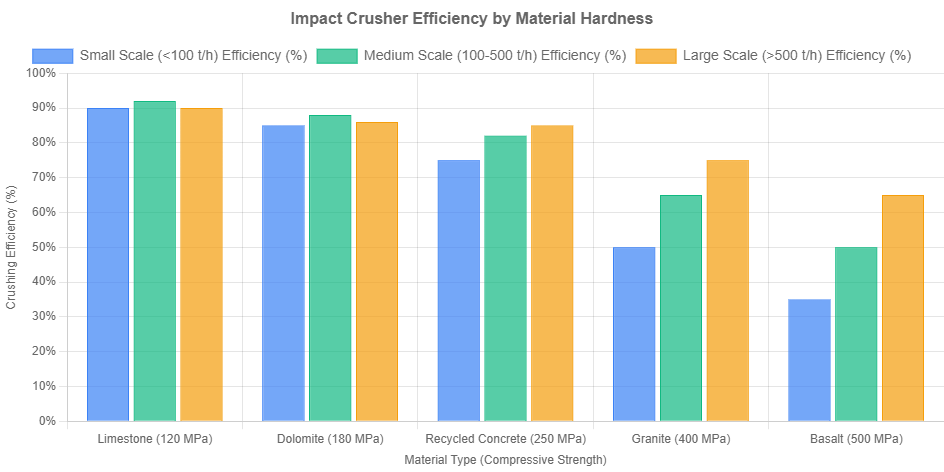

Material hardness, typically measured on the Mohs scale or by compressive strength testing, is perhaps the most critical factor in crusher selection. Impact crushers excel with materials of low to medium hardness (below 350 MPa compressive strength) such as limestone, dolomite, and recycled concrete. For harder materials like granite or basalt (exceeding 350 MPa), impact crushers may experience accelerated wear unless specifically designed with enhanced features. The hardness directly affects the wear rate of critical components like blow bars and impact plates.

When processing hard materials, the impact crusher must be designed with sufficient rotor mass and rotational speed to transfer adequate energy to fracture the particles. The kinetic energy required for effective size reduction increases exponentially with material hardness. Additionally, harder materials typically exhibit higher abrasiveness, which compounds the wear challenges. Manufacturers often provide hardness ratings for their equipment, guiding users toward appropriate models for their specific material characteristics and preventing premature component failure.

The Effect of Material Moisture on Crushing Efficiency and Equipment Wear

Moisture content significantly impacts material flow characteristics and crushing efficiency. Materials with high moisture content (typically above 5-8%) tend to be more cohesive and can cause packing, clogging, and reduced throughput in impact crushers. The presence of moisture can also create a cushioning effect during impact, reducing crushing efficiency and increasing energy consumption. In extreme cases, moist materials can build up on interior surfaces, potentially leading to blockages that require operational shutdowns for cleaning.

Beyond operational challenges, moisture accelerates wear through corrosive mechanisms and by facilitating the adherence of abrasive particles to metal surfaces. For wet or sticky materials, impact crushers require specific design features such as larger crushing chambers, specialized liner designs that prevent material buildup, and sometimes even internal cleaning systems. Some models incorporate additional openings or access points for maintenance and cleaning. In applications with consistently high moisture, considering alternative crushing technologies or pre-drying processes might be necessary to maintain efficient operation.

Matching Material Size Distribution with Feed Opening Dimensions

The size distribution of feed material must be properly matched to the crusher's feed opening dimensions and crushing chamber geometry. Impact crushers typically have a maximum feed size that should not exceed 80-90% of the feed opening dimension to ensure proper entry into the crushing chamber. An improperly sized feed can cause bridging, reduced capacity, and uneven wear patterns. Modern impact crushers often feature hydraulic or mechanical adjustment systems that allow operators to optimize the feed size acceptance based on current material characteristics.

The natural size distribution of the feed material also affects crusher performance. Well-graded material with a variety of particle sizes typically processes more efficiently than uniformly sized material, as smaller particles help cushion the crushing action and improve overall throughput. For materials with extreme size variations, pre-screening might be necessary to remove oversize particles that could cause blockages or fines that could pack the crushing chamber. Understanding the relationship between feed characteristics and crusher geometry is essential for achieving optimal performance and product quality.

Evaluating Production Scale and Capacity Requirements

Production requirements fundamentally influence impact crusher selection, with different operational scales demanding specific machine configurations and features. The required throughput, measured in tons per hour, determines the necessary crusher size, power requirements, and overall system design. Small operations might prioritize flexibility and lower capital investment, while large-scale operations typically focus on efficiency, reliability, and the lowest possible operating cost per ton. Understanding your current and projected production needs is essential for selecting equipment that won't become obsolete as your operation grows.

Beyond mere throughput numbers, production planning should consider operational hours, maintenance windows, and potential expansion plans. Impact crushers selected for high-volume operations must demonstrate proven reliability and ease of maintenance to maximize availability. The crushing system should be designed with adequate capacity buffers to handle unexpected production surges or variations in material characteristics. A well-planned crushing circuit matches the impact crusher's capabilities with upstream feeding equipment and downstream processing stages to create a balanced, efficient system.

Flexible Equipment Selection for Small-Scale Production

Small-scale operations, typically processing less than 100 tons per hour, benefit from compact impact crushers that offer versatility and ease of operation. These applications often value equipment that can handle multiple material types and product specifications without major reconfiguration. Smaller impact crushers generally require less infrastructure investment and can be more easily integrated into existing operations. Their lower power consumption and smaller footprint make them suitable for operations with space or power constraints.

For small operations with multiple sites or changing material sources, mobile impact crushers offer significant advantages. These self-contained units can be quickly relocated between sites, reducing material transportation costs and enabling on-site processing. Modern compact impact crushers incorporate many of the technological advancements of larger units, including hydraulic adjustment systems, advanced control systems, and efficient drive designs. Despite their smaller size, they can produce high-quality cubical products suitable for various applications.

Stability Considerations for Medium-Scale Production

Medium-scale production operations, typically processing between 100-500 tons per hour, require impact crushers that balance capacity with reliability. At this scale, equipment downtime translates directly into significant production losses, making reliability a primary consideration. Medium-sized impact crushers should feature robust construction, quality components, and designs that facilitate routine maintenance without extended shutdowns. The selection process should prioritize manufacturers with proven track records in similar applications and readily available service support.

Equipment for medium-scale operations often incorporates more advanced features than smaller units, including automatic control systems that optimize performance based on material conditions and wear state monitoring systems that predict maintenance needs. These crushers typically feature more durable wear components with longer service lives, reducing changeout frequency and associated downtime. The electrical systems often include sophisticated protection and monitoring capabilities to prevent damage from operational abnormalities and to provide operators with detailed performance data.

High-Efficiency Configuration for Large-Scale Continuous Production

Large-scale operations exceeding 500 tons per hour demand impact crushers engineered for maximum availability and efficiency. These high-capacity machines represent significant capital investments and must deliver the lowest possible operating cost per ton over their service life. Large impact crushers feature heavy-duty construction, oversized bearings, and robust rotors designed to withstand continuous operation under full load conditions. They often incorporate multiple impact zones and sophisticated material flow optimization to maximize reduction efficiency.

In the largest operations, multiple impact crushers may be configured in parallel to achieve required capacities or to provide operational redundancy. These systems typically incorporate advanced automation that balances feed between units and optimizes individual crusher settings based on real-time performance data. Large impact crushers often feature integrated condition monitoring systems that track vibration, temperature, and performance parameters to enable predictive maintenance and prevent unexpected failures. The design focus for these machines is maximizing availability while minimizing operating costs through energy efficiency and extended component life.

Considering Equipment Costs and Maintenance Accessibility

The economic evaluation of an impact crusher extends far beyond the initial purchase price to encompass the total cost of ownership throughout the equipment's operational life. This comprehensive financial analysis includes energy consumption, wear part replacement costs, maintenance labor requirements, and potential production losses during downtime. Equipment with a lower initial price might ultimately prove more expensive if it consumes more power, requires frequent wear part replacements, or experiences extended downtime for maintenance. A thorough cost-benefit analysis should project these expenses over the expected service life.

Maintenance accessibility significantly influences operating costs and equipment availability. Impact crushers designed with maintenance in mind feature easy access to wear parts, lubrication points, and inspection areas. Quick-change systems for blow bars and impact plates can reduce replacement time from hours to minutes, dramatically increasing equipment availability. The availability and cost of replacement parts should be considered during the selection process, as proprietary components from some manufacturers may be expensive or have long lead times. These factors collectively determine the crusher's operational economics and should be carefully evaluated before making a purchase decision.

Purchase Cost and Value Assessment

The initial purchase price of impact crushers varies significantly based on size, features, and manufacturer. While price is an important consideration, it should be evaluated in context with the equipment's capabilities, durability, and expected operating costs. Established manufacturers typically command premium prices but often deliver better long-term value through higher reliability, better performance, and comprehensive support services. The purchase decision should consider the total package offered, including warranty terms, technical support availability, and the manufacturer's reputation for standing behind their products.

Value assessment should extend beyond the crusher itself to include the entire crushing system. Compatibility with existing equipment, installation requirements, and necessary infrastructure modifications all contribute to the total project cost. Some impact crushers offer features that reduce secondary costs, such as integrated dust suppression systems that eliminate the need for separate equipment or hydraulic adjustment systems that simplify integration with plant control systems. These integrated solutions often provide better overall value than selecting individual components separately.

Energy Consumption Optimization Solutions

Energy costs typically represent a significant portion of an impact crusher's operating expenses, making energy efficiency an important selection criterion. Modern impact crushers incorporate several energy-saving features, including high-efficiency motors, optimized rotor designs that maximize energy transfer to the material, and control systems that adjust operation based on load conditions. The specific energy consumption, measured in kilowatt-hours per ton of processed material, provides a standardized metric for comparing efficiency between different models and manufacturers.

Operational practices significantly influence energy consumption. Properly balancing the feed rate to match the crusher's capacity prevents energy waste from operating below optimal load. Regular maintenance, including timely replacement of worn components, ensures the crusher operates at peak efficiency. Some advanced impact crushers feature energy recovery systems that capture energy during non-crushing portions of the rotor cycle or use hydraulic systems that consume power only when adjustment is needed. These technologies can reduce energy consumption by 15-20% compared to conventional designs.

Design Features for Maintenance Accessibility

Maintenance-friendly design significantly reduces downtime and labor costs associated with impact crusher upkeep. The best designs provide safe, easy access to all regularly serviced components without requiring special tools or equipment. Hydraulic-assisted opening systems for the upper frame allow quick access to the crushing chamber for inspection and component changes. Rotors designed with removable end disks facilitate blow bar replacement without completely disassembling the rotor assembly. These features transform maintenance from a major production disruption to a quick, routine procedure.

Modular component design represents another maintenance advantage in modern impact crushers. Quick-change systems for wear parts allow replacement in minutes rather than hours. Standardized component sizes reduce inventory requirements for operations with multiple crushers. Comprehensive monitoring systems track component wear and provide advance warning of necessary maintenance, allowing scheduling during planned downtime rather than emergency shutdowns. These design considerations collectively maximize equipment availability and minimize the lifetime maintenance costs of the impact crusher.