EU Impact Crusher vs PF Impact Crusher for highway mobile crushing

This article provides a comprehensive examination of EU and PF impact crushers, focusing on their application within mobile crushing plants for highway construction projects. It explores the fundamental design philosophies, operational efficiencies, and economic considerations that differentiate these two crusher types. The discussion encompasses performance metrics, integration into mobile platforms, and practical selection criteria to guide informed decision-making for construction and contracting professionals.

Special Requirements for Highway Mobile Crushing

Highway construction projects impose a unique set of demands on crushing equipment, primarily due to the need for high mobility and rapid deployment. Unlike stationary plants, mobile units must be capable of frequent relocation between job sites, often with minimal downtime for setup and teardown. The operational environment requires equipment to process a variety of aggregate materials to strict specifications for road base and surface layers.

Environmental considerations are equally critical, with regulations governing dust emissions and noise levels near work zones. The equipment must be compact and lightweight enough for transport on standard trailers while maintaining robust construction to handle continuous, high-volume processing. These factors collectively define the performance envelope for any crusher intended for this demanding application.

Material Characteristics and Crushing Specifications

The aggregates used in highway construction, such as basalt or limestone, possess specific hardness and abrasiveness properties. The crushing process must transform these raw materials into a consistent product with a specific particle size distribution, known as a gradation curve. This curve is vital for ensuring the structural integrity and longevity of the road pavement. A poorly graded aggregate can lead to compaction issues and premature failure.

Crushers must therefore be capable of producing a high percentage of cubical particles, as flat or elongated pieces can create voids and weaken the pavement structure. The ability to control the final product shape is a key differentiator between crusher designs and directly impacts the quality of the finished road.

Spatial and Weight Constraints on Mobile Platforms

Mounting a crusher on a mobile chassis presents significant engineering challenges related to weight distribution and physical dimensions. The entire assembly, including the crusher, feeder, and conveyors, must comply with road transport regulations for width, height, and axle load. Exceeding these limits can necessitate special permits and increase logistical costs.

The center of gravity of the crusher is a critical factor for the stability of the mobile plant during both transport and operation. An improperly balanced machine can be unsafe and inefficient. Engineers must optimize the layout to ensure the crusher's weight is supported effectively by the chassis without compromising its structural integrity or mobility.

Demands for Rapid Relocation and Setup

The economic viability of a mobile crushing operation is heavily dependent on its agility. The time required to dismantle, transport, and reassemble the plant at a new site represents non-productive downtime. Modern mobile plants are designed with features like hydraulic folding conveyors and quick-disconnect systems to minimize this transition period.

Some advanced setups can be ready for operation in under thirty minutes after arriving on site. This rapid deployment capability allows contractors to follow the progression of a highway project closely, reducing material haulage distances and associated costs. The crusher's own setup procedures, such as adjusting the discharge size, contribute to this overall efficiency.

Environmental and Noise Control Standards

Highway construction often occurs in proximity to residential areas or sensitive environments, making emission control a priority. Dust generated during crushing can be a significant pollutant and is typically managed through integrated water spray systems or enclosed conveyor belts. The crusher's design can influence dust generation, with sealed chambers being more effective at containment.

Noise pollution is another regulated factor. The mechanical action of crushing and the operation of associated motors and fans produce substantial sound levels. Acoustic enclosures and sound-dampening materials on the crusher and mobile platform are common solutions to meet local noise ordinances and maintain good community relations.

Technical Features and Advantages of the EU Impact Crusher

The EU impact crusher represents a modern design approach, incorporating heavy-duty components and advanced hydraulic systems for superior performance and reliability. It is engineered for high-capacity crushing of hard and abrasive materials, making it well-suited for the rigorous demands of granite or basalt processing in highway projects. Its design prioritizes consistent product quality and operational uptime.

A defining characteristic of this crusher is its emphasis on automation and ease of maintenance. Features like hydraulic assistance for opening the crusher housing and adjusting the gap between the impact plates allow for quick changes to the product size with minimal manual effort. This reduces the labor required for adjustments and enhances the overall safety of the operation.

Rotor Design and Drive System

The heart of the EU impact crusher is its massive, monolithic welded rotor. This robust construction provides high rotational inertia, which is essential for maintaining crushing momentum and energy efficiency, particularly when processing tough materials. The rotor is typically driven by a dual-motor system connected via V-belts, delivering substantial power and allowing for a degree of redundancy.

This powerful drive system ensures that the rotor maintains its speed under load, leading to a more consistent crushing capacity and a uniform final product. The high inertia also helps to absorb shock loads from uncrushable material, protecting the drive train from damage and reducing the risk of unexpected downtime.

Hydraulic Adjustment and Control Systems

EU crushers utilize a comprehensive hydraulic system that controls several critical functions. This system allows for the remote adjustment of the secondary and tertiary impact aprons, defining the discharge size of the crushed material. Operators can make these adjustments from a control panel without needing to enter the crusher's working area.

Furthermore, the hydraulic system is used to open the crusher housing for maintenance access to the rotor and wear parts. This feature significantly reduces the time and effort required for routine inspections and component replacements, contributing to higher machine availability over its operational life.

Wear Material Technology and Service Life

The wear parts in an EU impact crusher, such as the blow bars and impact plates, are manufactured from advanced alloys with high chromium content or other composite materials. These materials are selected for their exceptional resistance to abrasion and impact fatigue, which directly extends their service life in demanding applications.

The economic benefit of long-lasting wear parts is a reduction in the frequency of replacements and the associated costs of downtime and component purchasing. Many models also feature a blow bar locking mechanism that allows for rotation or quick reversal of the bars, utilizing multiple edges and further optimizing their usable life.

Particle Shape Control and Cubical Output

The geometry of the crushing chamber in an EU impact crusher is meticulously designed to promote inter-particle crushing. This occurs when rocks are made to collide with each other in the chamber, rather than solely against the wear parts. This process is highly effective at breaking stones along their natural cleavage lines, resulting in a final product with a high percentage of cubical particles.

This superior particle shape is a major advantage for highway construction, as cubical aggregates interlock more effectively, creating a stable and dense pavement layer. The ability to consistently produce this material quality reduces the need for secondary processing and can improve the performance of the final road surface.

Technical Features and Application Scenarios of the PF Impact Crusher

The PF impact crusher is a well-established design known for its structural simplicity, reliability, and lower initial investment cost. It has been a popular choice for decades in various crushing applications, particularly for processing medium-hardness materials like limestone in aggregate production. Its straightforward mechanics make it a robust and predictable workhorse.

This crusher is often favored in smaller-scale projects or situations where capital expenditure is a primary concern. Its design is less complex than its modern counterparts, which can translate to easier maintenance for crews familiar with traditional machinery. However, this simplicity may come with trade-offs in automation and certain performance metrics.

Mechanical Adjustment and Manual Systems

Unlike its hydraulic-assisted counterparts, the PF crusher typically employs a mechanical system for adjusting the gap setting. This involves using tools to manually turn adjustment bolts that move the impact rack. While this method is mechanically sound and reliable, it requires operators to work in close proximity to the machine and can be more time-consuming.

The manual nature of this process means that changing the product size is not as swift or convenient. It may also lead to less frequent adjustments in practice, potentially resulting in a less consistent product gradation over time if the feed material characteristics change.

Impact Plate Design and Crushing Efficiency

The impact plate in a PF crusher is a critical wear component that defines the crushing path. Its angle and curvature are designed to create a high-speed impact zone where the material is shattered. The efficiency of this process is highly dependent on the feed size and the speed of the rotor.

While effective, the crushing action can sometimes produce a slightly higher proportion of flaky particles compared to more modern chamber designs. The efficiency is also closely tied to maintaining the correct geometry of the impact plate; as it wears, the crushing performance and product shape can gradually change.

Foundation Design and Installation Demands

The traditional PF impact crusher design generates significant dynamic forces during operation. As a result, when used in a stationary setting, it often requires a substantial concrete foundation to absorb these forces and maintain proper alignment. This adds to the initial installation time and cost for a fixed plant.

In a mobile crusher configuration, this challenge is addressed by the robust structure of the mobile chassis itself. The chassis must be engineered to withstand these dynamic loads without excessive flexing, ensuring the crusher remains stable and operates correctly while on the move.

Energy Consumption and Production Balance

The PF crusher operates with a direct and powerful impact principle. Its energy consumption is directly proportional to the hardness of the feed material and the desired reduction ratio. While generally efficient for its intended purpose, it may have a higher specific energy consumption per ton of output when processing very hard materials compared to newer designs.

The production balance is achieved through its robust construction, which allows for continuous operation. However, its overall throughput might be lower than a similarly sized EU crusher when tasked with producing a finely graded, high-quality product for sensitive applications like aggregate processing.

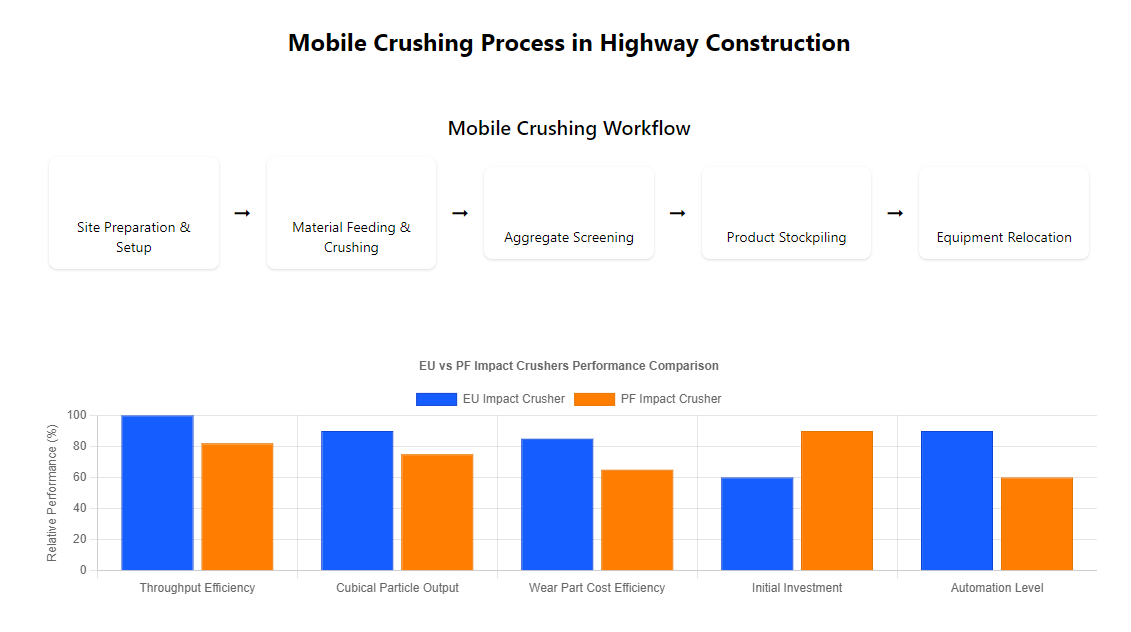

Key Performance Metrics Comparison

A direct comparison of performance indicators provides a clear, data-driven basis for selecting between EU and PF impact crushers. These metrics encompass not only pure output but also the quality of the product and the long-term cost of ownership. Evaluating these factors in the context of a specific project's goals is essential for making an optimal equipment choice.

Performance data is typically derived from standardized tests and real-world operational reports. Key figures include hourly production rates under specific settings, power draw measurements, and detailed analysis of the output material's physical properties. These quantifiable results remove subjectivity from the comparison process.

Crushing Efficiency and Production Output

In controlled conditions processing the same feed material, the EU impact crusher often demonstrates a higher throughput, sometimes by 15-20%, due to its optimized chamber geometry and high-inertia rotor. This increased efficiency is most noticeable when producing smaller, more precisely graded products. The energy consumed per ton of material processed can be lower, contributing to operational savings.

The PF crusher provides consistent and reliable production, particularly with medium-hard materials. Its output is dependable, though its peak capacity may be reached sooner than the EU model when pushing for finer product sizes or dealing with highly abrasive feed.

Final Product Shape and Gradation Curve

Laboratory analysis of the crushed aggregate consistently shows that the EU crusher produces a superior product shape. The percentage of cubical particles can exceed 90%, while the content of undesired flaky pieces is minimized. This results in a tighter and more predictable gradation curve, which is a critical specification for highway engineers.

The product from a PF crusher is generally acceptable for many applications but may contain a higher proportion of elongated particles. This can necessitate additional screening or crushing steps to meet strict specifications for high-value projects, potentially adding to the overall production cost.

Wear Parts Consumption and Operational Expenditure

The operational cost for wear parts is a significant long-term consideration. The advanced metallurgy used in EU crusher blow bars and impact plates typically grants them a longer service life. In abrasive applications, the cost of wear parts per ton of material produced can be 20-30% lower for the EU design, offsetting its higher initial price over time.

The wear parts for the PF crusher, while often less expensive per unit, may need replacement more frequently. The total cost of ownership must be calculated based on the specific abrasiveness of the material being processed, as this will determine the consumption rate and the associated downtime for changes.

Equipment Versatility and Adjustment Range

The EU impact crusher offers a wider dynamic range of operation. Its hydraulic adjustment system allows for quick and precise changes to the product size, making it highly adaptable to varying project requirements or changes in feed material. This flexibility is a major asset in mobile operations where conditions can change rapidly from one site to another.

The PF crusher is less versatile in this regard. Its manual adjustment system makes frequent changes impractical, so it is often set for a single product size for the duration of a task. It performs most reliably within a narrower band of feed size and product specifications.

Comparison of Mobile Crushing Integration Solutions

Integrating a crusher into a mobile platform involves more than simply mounting it on a chassis; it requires a holistic design approach to ensure all components function as a cohesive unit. The choice between an EU or PF crusher influences the design of the entire mobile plant, from the chassis selection to the control system architecture.

The integration must address power transmission, material flow, and operator accessibility. A well-integrated plant will have optimized conveyor lengths, centralized lubrication points, and a user-friendly control interface that allows a single operator to manage the entire crushing and screening process efficiently.

Chassis Compatibility and Weight Distribution

The heavier and more powerful EU crusher necessitates a correspondingly robust mobile chassis, often a multi-axle trailer with a reinforced frame. Engineers must carefully calculate the weight distribution to ensure safe and stable transport, as well as effective load transfer to the ground during operation to prevent sinking on soft terrain.

The PF crusher, being generally lighter, can be mounted on a slightly less heavy-duty chassis. This can sometimes result in a more compact overall mobile plant, which can be an advantage when navigating tight or constrained job sites commonly found in construction and demolition waste recycling projects adjacent to highways.

Power System Integration Schemes

Mobile plants can be configured with various power sources. The high power demand of the EU crusher is often met by a dedicated onboard diesel generator or through a direct connection to an external power supply if available on site. The electrical system must be designed to handle the high starting currents of the dual motors.

PF crusher plants can also use similar power schemes. The specific integration involves matching the generator's output to the crusher's motor power requirements, ensuring there is sufficient capacity for all simultaneous processes, including screening and conveying, without overloading the system.

Control System Integration and Automation Level

The modern EU crusher is designed with sophisticated programmable logic controller (PLC) systems that can be seamlessly integrated into the mobile plant's main control panel. This allows for automated startup and shutdown sequences, continuous monitoring of key parameters like bearing temperature and motor load, and remote troubleshooting capabilities.

The control integration for a PF crusher is typically more basic, focusing on start/stop functions and basic fault indication. While reliable, it offers a lower degree of automation and data feedback, which may require more direct operator supervision during the crushing process.

Quick-Connect Features and Maintenance Access Design

For rapid relocation, all service connections on a mobile plant, such as electrical cables and hydraulic hoses, should feature quick-disconnect couplings. The EU crusher's design, with its hydraulic opening mechanism, aligns well with this philosophy, allowing the entire upper housing to be swung open for maintenance without disassembling other plant components.

Maintenance access on plants featuring a PF crusher must be carefully planned. While the crusher itself is mechanically simple, ensuring clear and safe access to its adjustment points and wear parts for replacement is a key part of the mobile platform's design to minimize service time. The layout of other primary crushers on a multi-stage mobile plant also influences this design.

Economic Analysis and Return on Investment Assessment

The final selection between an EU and PF impact crusher is ultimately an economic decision based on a thorough analysis of costs and returns over the equipment's expected life cycle. This assessment must look beyond the initial purchase price to include all operational, maintenance, and residual value factors. The project's scale, duration, and financial constraints are the primary drivers of this evaluation.

A comprehensive economic model projects all cash flows associated with the equipment, from acquisition to disposal. This model helps determine the payback period and the overall return on investment, providing a clear financial justification for the capital allocation.

Analysis of Initial Investment Cost Structure

The initial investment for a mobile crushing plant with an EU crusher is typically higher. This cost includes the premium for the crusher's advanced technology, its integration into a capable mobile chassis, and the associated control systems. This represents a significant upfront capital outlay.

The PF crusher option presents a lower entry point. The initial investment is more accessible, making it an attractive option for contractors with budget limitations or for projects with a shorter timeline where a rapid payback is essential. The cost of auxiliary equipment like generators and conveyors is also generally lower.

Operational Costs and Energy Consumption

Operational costs accumulate over time and can surpass the initial investment. The EU crusher's higher efficiency often leads to lower fuel or electricity costs per ton of material produced. Combined with its longer wear part life, its operational expenditure profile is generally more favorable in high-volume, long-duration projects.

The PF crusher may have higher operating costs per ton in abrasive applications due to faster wear part consumption. Its energy efficiency is good but may not match the newer design, leading to marginally higher power costs over thousands of operating hours.

Equipment Residual Value and Secondary Market Performance

Technologically advanced equipment like the EU impact crusher tends to retain a higher residual value on the secondary market. Its modern features, automation capabilities, and reputation for producing high-specification aggregate make it desirable for used equipment buyers, potentially recouping a larger portion of the initial investment at resale.

The PF crusher also has a strong presence in the used market due to its simplicity and proven reliability. While its resale value may be a lower percentage of its original cost, its affordability and ease of repair ensure a consistent demand from smaller operators or those in developing markets. This is similar to the enduring market for robust hammer crushers in certain niches.

Payback Period and Return on Investment Calculation

The payback period is the time required for the net cash inflows from the equipment to equal the initial investment. For an EU crusher, the payback period might be longer due to the higher initial cost, but its superior production rate and lower operating costs can generate stronger positive cash flows thereafter, leading to a higher total return on investment over a five to seven-year period.

The PF crusher can achieve a faster payback because of its lower purchase price. Its ROI calculation is attractive for short-term projects or where the financing cost of a larger investment is prohibitive. The choice depends on the contractor's financial strategy and the specific mining and quarrying or construction workload anticipated.

Selection Guidelines and Field Application Recommendations

Choosing the right impact crusher requires a methodical evaluation of project-specific parameters rather than a one-size-fits-all approach. The optimal machine balances performance capabilities with practical constraints like budget, timeline, and available expertise. A careful site and material assessment forms the foundation of a sound selection.

Recommendations should be tailored to the contractor's operational model. A large contractor handling multiple, long-term highway projects will have different priorities than a smaller company focusing on short-duration subcontracts. The goal is to match the equipment's strengths to the project's most critical demands.

Recommendations for Matching Project Scale and Timeline

For large-scale, long-duration highway projects requiring high-quality aggregate and high availability, the EU impact crusher is generally the recommended choice. Its higher productivity and lower operating costs justify the initial investment over the project's life. Its ability to quickly adjust to different product specifications adds valuable flexibility.

For smaller projects, temporary sites, or situations with uncertain material supply, the PF impact crusher presents a lower-risk option. Its faster payback and mechanical simplicity make it suitable for contractors who need reliable performance without a long-term financial commitment or for those processing less abrasive materials like limestone.

Guidance for Material Properties and Product Requirements

When the primary feed material is very hard and abrasive, such as granite or trap rock, and the specification for particle shape is stringent, the EU crusher's advanced technology is necessary to achieve the required product quality economically. Its superior wear resistance is a key factor in controlling costs.

If the material is of medium hardness and the product specification is more forgiving, the PF crusher can perform admirably and at a lower overall cost. It remains a excellent choice for producing base course materials where a high percentage of cubical particles is beneficial but not as critically enforced as in surface layers.

Consideration of Operational Team Skill Level

The operation and maintenance of an EU impact crusher, with its hydraulic and electronic control systems, require a crew with corresponding technical skills. Training is essential to fully utilize its capabilities and perform troubleshooting. Contractors with a skilled maintenance team will extract the most value from this equipment.

The PF crusher is less demanding in terms of operator and mechanic expertise. Its straightforward mechanical systems can be maintained by personnel with general heavy equipment experience. This can be a significant advantage in regions where specialized technical support is not readily available.

Evaluation of After-Sales Service and Parts Supply

Before committing to an EU crusher, it is crucial to verify the manufacturer's or distributor's local support network. The availability of technical support, prompt parts supply, and service technicians is vital for minimizing downtime. A premium machine is only as good as the service behind it.

The widespread use of the PF crusher design often means that spare parts are readily available from multiple suppliers, which can reduce cost and lead time for replacements. Evaluating the reliability and responsiveness of the parts supply chain is a fundamental step in the selection process for any crushing equipment, much like one would for a specialized VSI crusher.