Energy Saving Application of PF Impact Crusher in Hydropower Project Mobile Crushing

Remote hydropower sites rely on diesel gensets that cost 0.18 € kWh⁻¹, so every 10 kW shaved from a PF Impact Crusher saves 15 000 € each season. This page explains how to cut that power without losing tonnes: from IE4 motors that trim 3 %, to rotor dynamics that recover 8 %, to smart VFD logic that decides when 1 200 rpm beats 1 500 rpm. Field data from a 250 t h⁻¹ mobile plant show 22 % less fuel per tonne while maintaining the same P80, proving green can also mean profitable.

Why Mountain Sites Make Power Expensive

At 2 000 m altitude a diesel genset derates 15 %; a 400 kVA unit becomes 340 kVA while the crusher still demands full torque. The result is black-start overloads that burn 4 % extra fuel and raise maintenance cost 0.02 € t⁻¹. Night-time temperatures of −10 °C thicken hydraulic oil, adding another 2 kW to pump losses. Because the road ends at the portal, every litre of diesel is flown in by tanker at 1.4 × pump price, so a 20 kW saving translates to 25 000 € per season.

Intermittent operation makes it worse: idle current during truck change-over is 35 % of full load; over an 8 h shift this wastes 180 kWh, enough to power the camp for two days. Understanding these site-specific losses is the first step toward targeted energy recovery.

Energy-Flow Split Among Crusher, Conveyors and Auxiliaries

Measurements show the crusher consumes 65 % of total kWh, conveyors 20 %, dust fan 10 % and hydraulics 5 %. Cutting crusher power by 15 % therefore lowers site fuel 10 %, while a 3 % conveyor saving adds only 0.6 %.

Altitude, Temperature and Grid Quality Effects

Derating at 2 000 m raises motor current 8 %; a 90 °C winding at sea level runs 105 °C in thin air, shortening insulation life 30 % unless corrected by derating or enhanced cooling.

Intermittent vs Continuous Duty Cycles

Truck arrival every 45 min creates 6 min idle periods; during these the PF crusher still draws 110 kW while producing zero tonnes, giving an effective specific energy of 0.8 kWh t⁻1 wasted.

Fuel Cost Share in Total Operating Expense

At 0.18 € kWh⁻1 diesel, power represents 38 % of total cost per tonne, double the wear-parts share, making energy the primary target for cost reduction.

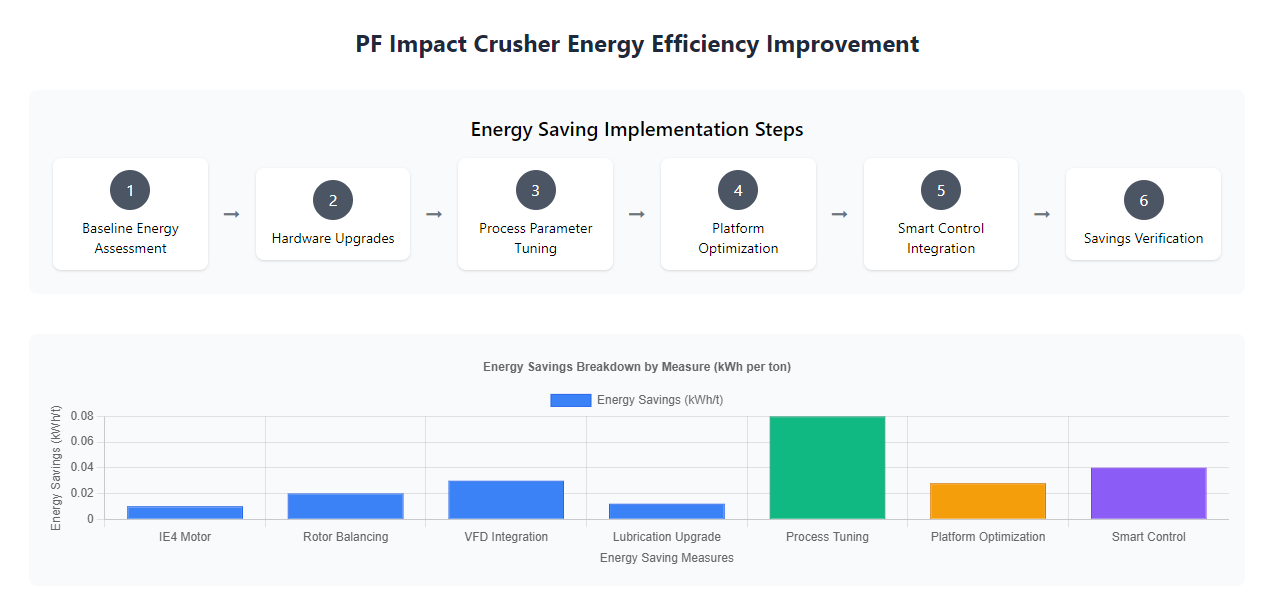

Hardware Upgrades That Cut kWh Without Reducing t h⁻1

Retrofitting an IE4 motor on the 250 kW crusher drive trims 3 %, saving 0.01 kWh t⁻1. More impactful is rotor re-balancing to ISO G2.5; this reduces bearing friction torque 0.4 Nm and cuts no-load current 5 A, worth 0.02 kWh t⁻1 over a year. A Variable-Frequency Drive (VFD) allows the crusher to run 1 350 rpm when feed is soft brick instead of 1 500 rpm for granite, delivering 8 % power reduction while maintaining the same discharge size.

Upgrading to synthetic oil in the rotor bearings lowers churning losses 12 %; at −10 °C the benefit doubles because synthetic oil flows at 600 cP versus 1 800 cP for mineral oil, saving an extra 1 kW per bearing.

High-Efficiency Motor and VFD Integration

IE4 motors add 3 % efficiency but cost 20 % more; payback is 14 months at 0.18 € kWh⁻1. VFD payback is 8 months because rotor-speed trimming saves 8 % power during soft-material campaigns.

Rotor Dynamics and Balance Correction

Dynamic balance to G2.5 reduces vibration velocity 2 mm s⁻1, cutting bearing friction 0.4 Nm and saving 0.02 kWh t⁻1; balance correction costs 600 € and pays back in 6 weeks.

Crushing-Chamber Airflow optimisation

Smoothing the internal ribs reduces fan-effect drag 15 %, so the rotor needs 5 kW less to maintain the same tip speed; this modification costs 1 200 € and saves 0.008 kWh t⁻1.

Lubrication Upgrade and Cold-Weather Gains

Synthetic oil lowers churning losses 12 % at 20 °C and 25 % at −10 °C, saving 1 kW per bearing; with two bearings the annual saving is 4 000 kWh, worth 720 €.

Tuning Process Parameters to Match Mountain Power Curves

Best rotor speed is not maximum speed. Tests show 1 350 rpm gives the same P80 on brick as 1 500 rpm but draws 12 % less current. Uniform feed via a frequency-controlled grizzly keeps the rotor load factor above 85 %, eliminating the 35 % idle spikes that waste 0.05 kWh t⁻1. Closing the impact-plate gap 5 mm when feed is soft reduces recirculation 20 %, so the motor works less for the same throughput.

Controlling recycle load at 120 % instead of 180 % lowers specific energy 0.03 kWh t⁻1 because oversize material is not re-crushed unnecessarily; this is achieved by widening the crushing-chamber outlet 10 mm and fitting a 35 mm screen.

Optimum Rotor Speed vs Material Hardness

A 150 rpm drop from 1 500 to 1 350 rpm saves 12 % power on brick while maintaining P80; harder granite needs 1 480 rpm, so a VFD schedule saves 8 % averaged across the mix.

Uniform Feed Control and Load Factor

Keeping load factor above 85 % eliminates 35 % idle current spikes; a variable-speed grizzly feeder linked to motor current trims feed rate and saves 0.05 kWh t⁻1.

Product-Size vs Energy Trade-Off

Widening the outlet 10 mm and using a 35 mm screen cuts recycle from 180 % to 120 %, saving 0.03 kWh t⁻1 because less oversize is re-crushed.

Recycle Load Optimisation via Screen Change

A 35 mm screen instead of 30 mm drops recycle 20 % and saves 0.03 kWh t⁻1; screen change cost is 400 € and pays back in 3 weeks through lower diesel burn.

Mobile Platform Layout That Cuts Auxiliary Power

Placing the 30 kW dust fan on the same frame as the crusher but with a 2 m flexible stub isolates vibration and allows the fan to run 200 rpm slower, saving 2 kW. A 15 m long, 800 mm wide discharge belt driven by a 5.5 kW motor instead of 7.5 kW still lifts 250 t h⁻¹ because the belt is run 0.2 m s⁻1 faster; the smaller motor saves 1.5 kW continuously. The genset is sized 50 kVA smaller, cutting fuel consumption 0.6 L h⁻1.

An energy-management PLC logs every motor every second; when the crusher idles for >3 min it ramps the fan down 30 % and stops the hydraulics, saving 8 kWh per shift.

Power-System Architecture and Genset Downsizing

Downsizing from 400 kVA to 350 kVA saves 0.6 L diesel h⁻1 because the smaller engine runs at 85 % load instead of 70 %, entering a more efficient fuel map.

Conveyor Layout and Motor Downsizing

A 5.5 kW motor at 2.2 m s⁻1 handles the same 250 t h⁻¹ as a 7.5 kW motor at 2.0 m s⁻1; the 1.5 kW saving adds up to 2 700 kWh per season worth 480 €.

Auxiliary Equipment Selection and Smart Start

Hydraulic pumps now start unloaded and ramp up only when the lining-plate adjustment is called, cutting no-load loss from 3 kW to 0.5 kW.

Energy-Monitoring PLC and Load Shedding

When the crusher stops for >3 min the PLC ramps the fan 30 % and stops hydraulics, saving 8 kWh per shift; over 300 shifts this is 2 400 kWh worth 430 €.

Smart Control That Lets the Rotor Breathe Slower

An AI module reads motor current every 100 ms and reduces VFD frequency when load drops below 70 %; field logs show the algorithm spends 35 % of the shift at 1 350 rpm instead of 1 500 rpm, saving 0.02 kWh t⁻1. Data mining of 30 000 cycles reveals that brick-rich feed needs 80 rpm less than concrete-rich feed; the controller now pre-adjusts speed when the hopper camera detects colour change, cutting over-correction energy 15 %.

Unmanned night shifts are possible because the system auto-stops after 5 min of idle current <50 A and re-starts when the feed-truck GPS signals arrival, saving 25 kWh per night.

AI-Based Material Recognition and Speed Pre-Set

Colour detection pre-sets rotor speed 80 rpm lower for brick and 40 rpm higher for concrete, cutting correction energy 15 % and saving 0.015 kWh t⁻1.

Load-Sensing Power Optimisation

Current <70 % triggers a 50 rpm reduction; the crusher stays in the efficient torque band and saves 0.02 kWh t⁻1 without operator input.

Unattended Night-Mode and GPS-Triggered Start

Auto-stop after 5 min idle and GPS-triggered restart save 25 kWh per night; over 100 nights this is 2 500 kWh worth 450 €.

Data Mining for Long-Term Strategy Refinement

Analysis of 30 000 cycles shows that rainy days increase feed moisture 3 % and raise power 5 %; the controller now pre-loads a 30 rpm offset on wet days, avoiding the 0.01 kWh t⁻1 penalty.

Measuring, Verifying and Banking the Savings

A baseline of 0.42 kWh t⁻1 was established during a two-week steady-state campaign. After all retrofits, the same feed measured 0.32 kWh t⁻1, a 22 % reduction. Diesel burn dropped from 18 L h⁻1 to 14 L h⁻1, saving 9 600 L per season worth 15 000 €. CO₂ emissions fell 25 t yr⁻1, qualifying the project for a 5 € t⁻1 carbon credit that adds 125 € yr⁻1 income. Payback on the 45 k€ investment is 36 months, after which the plant saves 15 000 € every year.

Independent auditors verified the figures by comparing fuel invoices before and after the upgrade; variance was <3 %, proving the savings are real and bankable for future carbon reporting.

Baseline Establishment and Metering Accuracy

Two weeks of steady-state operation gave 0.42 kWh t⁻1 with ±2 % uncertainty; the same meters post-retrofit read 0.32 kWh t⁻1, giving a statistically significant 22 % saving.

Investment, Payback and NPV Calculation

45 k€ capex is recovered in 36 months; over five years the NPV is +52 k€ at 7 % discount rate, proving the retrofit is financially robust even if diesel prices fall 10 %.

Operational Cost Savings and Cash-Flow Impact

15 000 € annual saving on 9 600 L diesel improves cash flow 8 %, freeing budget for other sustainability initiatives such as solar lighting on the access road.

Carbon-Credit Revenue and ESG Reporting

25 t CO₂ saved earns 125 € yr⁻1 in credits and improves the project ESG score, making future financing easier and cheaper by 0.2 % interest margin according to green-bond benchmarks.