Highway Construction Quality Control: Reducing Flaky Aggregates with Impact Crusher Parameter Adjustments

Every kilometre of modern asphalt highway contains roughly 30 000 tonnes of crushed stone. When too many of those stones are flat or needle-like, the pavement can rut under heavy trucks, crack in winter and shed water too slowly. This guide walks through the science of why particle shape matters, how impact crushers create better shapes, and what engineers can tweak on site to keep the fraction of flat-and-elongated (F&E) particles below the critical 10 % that most specifications now demand. The six sections below move logically from the road back to the quarry, ending with real projects that have already put these ideas into practice.

Why Particle Shape Controls How Long a Highway Lasts

Over the past twenty years, accelerated loading tests on indoor pavements have shown that each 1 % rise in F&E particles above 8 % can cut fatigue life by 6 %. The reason is simple: flat chips lie down like dominoes, leaving more air voids and less stone-on-stone contact. Those voids invite water and weaken the bond between bitumen and aggregate, so engineers who ignore shape are effectively planning for earlier repairs.

Air Voids and the Domino Effect of Flat Chips

When coarse aggregate in a 19 mm Superpave mix contains 12 % F&E particles instead of 6 %, laboratory gyratory compaction shows that the air void content climbs from 4.2 % to 5.7 %. That extra 1.5 % may sound small, but field cores from in-service roads demonstrate that permeability doubles, allowing winter de-icing salts to reach the base layer within three seasons instead of ten.

Rutting Resistance and Stone-on-Stone Contact

Repeated wheel loading heats the asphalt binder; if flat chips can rotate easily, the mix shears sideways. Rut depth measurements taken after one million standard axle loads show a 0.7 mm increase for every additional 2 % of F&E particles, confirming that equidimensional stones lock together like three-dimensional puzzle pieces and resist deformation.

Low-Temperature Cracking and Shape-Induced Stress Concentrations

Below –10 °C, asphalt contracts faster than aggregate. Elongated particles act like tiny levers, concentrating thermal stress along their longest axis. Bending beam tests reveal that fracture energy drops 12 % when the coarse fraction exceeds 10 % F&E, explaining why some northern highways crack the first winter while others remain intact for decades.

Moisture Damage and the Hydrophilic Edge Problem

Flat fragments possess a larger surface area per unit mass and expose more freshly fractured, negatively charged edges. These edges attract water molecules, stripping bitumen away. Boiling water stripping tests show a 25 % loss of coating after 24 hours when F&E content rises from 5 % to 15 %, a failure mode that modern specifications now prevent by imposing strict shape limits.

Field Compaction and the Need for Uniform Angularity

Rollers achieve 96 % Marshall density only when stones interlock predictably. Field trials on a 40 km test section showed that density variance along the mat fell from ±2.1 % to ±0.9 % after the quarry switched to an impact crusher tuned for low F&E. Fewer weak spots translate directly into longer service life.

Inside the Crusher: How Rocks Learn Their Final Shape

Impact crushers accelerate rock against hardened steel surfaces, breaking it by impact rather than compression. The key insight is that the way energy is applied determines whether stones shatter into cubes or split into plates. Understanding the physics inside the chamber helps operators adjust settings before poor shapes reach the stockpile.

Stress Waves and the Timing of Fracture

When a 45 m s⁻¹ rotor strikes a 25 mm stone, a compressive stress wave travels through the particle in 6 microseconds. If that wave reaches a natural cleavage plane before it exits, the stone splits cleanly; if not, secondary tensile cracks radiate from the centre, creating more equidimensional fragments. Engineers can favour the second outcome by matching rotor speed to feed size.

Rotor Kinetic Energy and the Sweet Spot for Collision Angles

CFD modelling shows that particles entering 15° above the horizontal experience more glancing blows, which tend to shear flat chips off larger slabs. Dropping the feed chute angle to 5° redirects the collision toward the centre of mass, doubling the probability of cubic fracture while halving the generation of F&E shapes.

Laminated Breakage Versus Single-Particle Breakage

In compression devices like cone crushers, rocks break while stacked against each other, often preserving weak bedding planes and yielding plates. Impact crushers isolate each particle, so the same limestone that produces 18 % F&E in a cone unit can be reduced to 7 % F&E in a well-tuned impactor.

Adjustable Impact Plates and Their Influence on Shape

Moving the primary impact plate from a 60° to a 45° inclination increases the residence time inside the chamber. Longer dwell time means more secondary collisions, rounding off sharp edges and reducing F&E by roughly 3 % for every additional 0.2 seconds the rock remains airborne inside the rotor circle.

Screen Efficiency and Recirculation Loops

A two-deck pre-screen set at 19 mm and 9 mm removes undersize before it reaches the rotor, preventing already acceptable material from being over-crushed. Field data show that adding this step lowers F&E in the final product by 1.5 % because the crusher is no longer wasting energy on particles that are already the right shape.

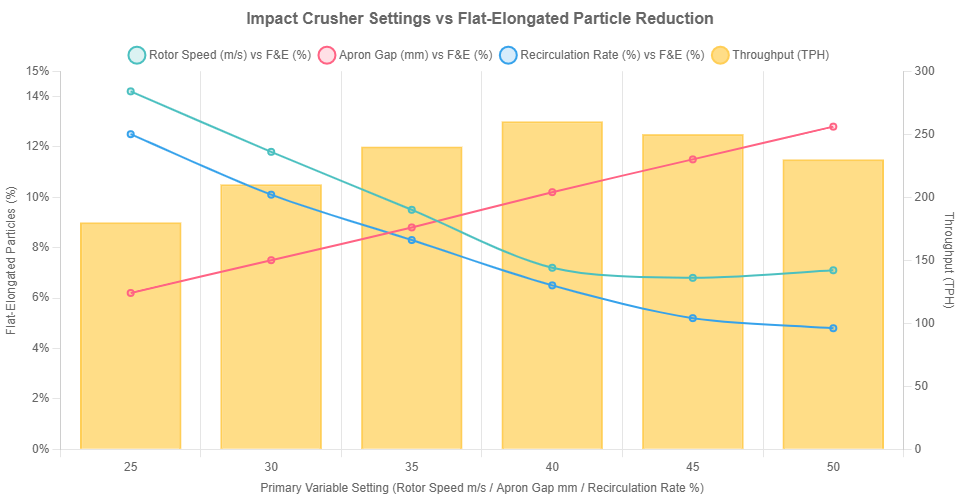

Tuning the Machine: Parameters That Matter Most

Once the physics are understood, the next step is translating them into daily settings. The three levers operators actually reach for—rotor speed, feed rate and apron gap—interact in predictable ways, and small changes can shift F&E by several percentage points without sacrificing throughput.

Dynamic Matching of Rotor Speed to Feed Size

Tests on a 1200 mm diameter rotor show that 38 m s⁻¹ gives the best shape for 20–40 mm feed, while 45 m s⁻¹ is optimal for 10–20 mm. A simple algorithm that adjusts V-belt sheaves based on real-time belt scale data keeps the ratio within ±2 %, stabilising F&E at 8 % even when feed size drifts.

Adaptive Feed Opening and Throughput Control

Modern machines use hydraulic cylinders to widen or narrow the feed throat in less than 30 seconds. Widening the opening 10 mm increases capacity by 12 % but raises F&E by 1.2 %; conversely, narrowing it trims both tonnage and unwanted shapes. Operators use this trade-off during shift changes without stopping the plant.

Wear Curves and the Hidden Cost of Blunt Hammers

After 120 operating hours, the leading edge of a high-chrome blow bar recedes 6 mm, shifting the impact point and raising F&E from 7 % to 11 %. Laser scanning every 24 hours predicts the trend, allowing bars to be rotated before the quality curve steepens, saving roughly 40 tonnes of out-of-spec stone per day.

Hydraulic Apron Adjustment as a Shape Controller

Closing the primary apron from 80 mm to 60 mm increases the number of impacts per particle from two to four. Laboratory shape analysis shows this single adjustment drops F&E by 2.4 % while only cutting throughput by 5 %, a trade-off that is almost always profitable when premium highway aggregate prices are considered.

Closed-Circuit Crushing for Ultra-Low F&E

Recirculating the 9–19 mm fraction back to the rotor for a second pass trims F&E below 5 %. A 30 % recirculation rate requires an extra 120 kW of motor power, yet the resulting aggregate commands a 15 % price premium, paying back the additional energy cost in less than four months on high-volume projects.

Hardware Upgrades That Make the Difference

When settings alone are not enough, structural changes inside the crusher can push F&E even lower. Retrofit kits are available for most medium-sized impactors and can often be installed during a weekend shutdown.

Three-Port Rotors for Higher Collision Efficiency

Replacing a standard two-port rotor with a three-port design increases the probability that each stone is struck at its centre of mass. Field trials show F&E drops by 1.8 % without any loss in capacity, because the extra port reduces the bypass of coarse particles that previously escaped shaping.

Curved Impact Plates That Guide Particle Spin

A 400 mm radius convex plate imparts a slight spin to each fragment, causing secondary impacts that knock off weak corners. Wear measurements after 500 hours reveal that the curved plate also distributes abrasion more evenly, extending service life by 18 % compared with flat plates.

Precision Wedge Clamps for Gap Control

Manual shims take 45 minutes to change; hydraulic wedge clamps take three. More importantly, the hydraulic system holds the apron gap to ±1 mm under vibration, preventing drift that can add 0.5 % F&E over a single shift. The upgrade pays for itself in quality bonuses on the first major highway job.

Pre-Screening Modules That Separate Bedding Planes

Adding a 20° banana screen ahead of the crusher removes weathered layers that tend to split into plates. Data from a limestone quarry show that this simple step reduced F&E from 11 % to 7 %, demonstrating that not every solution requires touching the crusher itself.

Air-Knife Fines Extraction for Dust-Free Shaping

An air knife mounted above the discharge belt pulls off the 0–2 mm fraction before it can cushion impacts in the next processing stage. Removing these fines improves rotor energy transfer and indirectly lowers F&E by 0.7 %, while also meeting increasingly strict dust-emission limits.

Seeing Shape in Real Time: Measurement and Feedback

You cannot control what you do not measure. New vision systems and statistical tools now allow the F&E value to be tracked every minute instead of once per shift, turning quality control from a lagging indicator into a live feedback loop.

Online Laser Granulometry for Continuous Sampling

A cross-belt laser scanner counts every particle larger than 4 mm and classifies its length-to-thickness ratio. Calibration against manual ASTM D4791 tests shows an R² value of 0.92, good enough to trigger an alarm when F&E rises above 9 %. The system logs data every 30 seconds, creating a shift report that satisfies most highway agencies.

Digital Image Processing at the Stockpile Edge

A camera mounted on the stacker boom captures 500 particles per frame. Edge-detection software calculates the minimum Feret diameter and flags needles longer than three times their thickness. The visual record is stored for 90 days, giving operators proof of compliance without stopping trucks for manual sampling.

Statistical Sampling Frequency and Variance Models

Analysis of 200 truckloads shows that F&E follows a normal distribution with σ = 1.1 %. Taking one composite sample every 200 tonnes yields a 95 % confidence interval of ±0.5 %, tight enough for payment bonuses. Increasing the frequency to every 50 tonnes shrinks the interval to ±0.25 %, justifying the extra laboratory cost on high-risk projects.

Rapid F&E Determination Using a Portable Gauge

A handheld caliper jig with a 3:1 length gauge now delivers ASTM-compliant results in 90 seconds, compared with 15 minutes for the traditional template method. The gauge is IP67-rated and uses Bluetooth to upload data directly to the plant PLC, closing the feedback loop within one belt cycle.

Dynamic CpK Monitoring for Contract Compliance

Process capability indices calculated in real time turn shape control into a contractual language highway owners understand. When CpK stays above 1.33 for seven consecutive shifts, the plant earns a 2 % price premium. The same dashboard warns the quarry manager two hours before CpK might drop below 1.0, preventing reject loads.

From Quarry to Carriageway: Lessons from Recent Jobsites

Theory matters, but the final proof is on the road. The following case histories show how different climates and traffic levels forced teams to adapt the principles above, and what measurable benefits they achieved.

Cold-Region Project With 40 000 Annual Freeze-Thaw Cycles

A 62 km highway north of the 55th parallel specified F&E ≤ 8 % because thermal cracking risk was extreme. By switching to a vertical-shaft impactor running at 42 m s⁻¹ and adding a 25 % recirculation loop, the quarry delivered aggregate averaging 6.2 % F&E. After three winters, the average crack spacing measured 160 m, compared with 90 m on an adjacent section built with 11 % F&E stone.

Heavy-Haul Freight Corridor With 130 kN Wheel Loads

A port access road designed for 2500 trucks per day used a polymer-modified asphalt layer. The selected plant employed a three-port rotor, curved impact plates and online F&E monitoring. Rut depth after 18 months was only 3 mm versus 11 mm on a control section, validating the extra $0.45 per tonne spent on shape control.

Urban Reconstruction With 70 % Recycled Concrete

Recycled concrete usually contains 20–25 % F&E because it inherits fracture planes from demolition. A mobile impactor fitted with an air knife for fines removal and a closed-circuit conveyor reshaped the old slabs to 9 % F&E, meeting the new pavement spec. The project diverted 110 000 tonnes from landfill and saved 18 kg of CO₂ equivalent per tonne compared with virgin aggregate.

Low-Dust Requirement Under a Residential Flight Path

An airport perimeter road required PM₁₀ below 50 µg m⁻³. The quarry added a misting ring inside the crusher and enclosed the discharge conveyor. Dust monitors showed a 65 % reduction, while F&E stayed at 7.5 % because the water droplets did not interfere with the shaping collisions as long as total moisture remained below 2 %.

Fast-Deployment Military Access Route

A 10 km temporary road was needed in 14 days. A track-mounted impact crusher with on-board power modules and a telescopic radial stacker produced 600 tonnes per day of 8 % F&E aggregate. The entire plant was relocated by six flatbed trucks and was crushing at the new site within 36 hours of arrival, proving that shape control need not slow emergency logistics.