How to Choose the Right Impact Crusher Model Based on Material Hardness: A Comprehensive Guide

This guide provides a systematic explanation of the core logic behind selecting an impact crusher, focusing on the critical influence of material hardness on model selection. We will analyze six key dimensions to help you establish a scientific decision-making framework, ultimately achieving an optimal balance between crushing efficiency and equipment longevity. The discussion will cover material classification, working principles, key parameters, processing strategies, selection methodology, and maintenance optimization.

Material Hardness Classification and Crusher Adaptation Principles

The hardness of rock or ore is the primary factor determining the type of crushing force required. Materials are scientifically classified using scales like Mohs hardness, which ranks minerals from 1 (talc) to 10 (diamond). This classification is not merely academic; it directly dictates the kinetic energy and stress levels an impact crusher's rotor must generate. For instance, crushing soft limestone (Mohs 3-4) requires significantly less energy than processing abrasive granite (Mohs 6-7).

Beyond the hardness value itself, the material's toughness or brittleness plays an equally important role. Brittle materials like glass or certain slags shatter easily upon impact, making them ideal for impact crushing. Conversely, tough, ductile metals can absorb impact energy without fracturing cleanly, often requiring a different comminution method. Furthermore, natural material hardness is rarely consistent; fluctuations can cause uneven wear rates within the crushing chamber, a critical factor that must be accounted for during the model selection process to ensure consistent product size and reduce maintenance frequency.

The Reference Value of Mohs Hardness Scale in Crusher Selection

The Mohs scale provides a practical, albeit qualitative, reference for initial crusher assessment. It helps engineers quickly gauge the potential abrasiveness and required compressive strength of the crusher's components. A material rated above Mohs 5 typically necessitates a crusher built with high-chromium or manganese steel wear parts to withstand the accelerated degradation.

While not a direct input for precise engineering calculations, the Mohs value serves as a crucial first filter, preventing the grave error of deploying an under-powered or lightly-built crusher against a material it cannot effectively process, which would lead to rapid failure and operational losses.

Differences in Crushing Stress Requirements for Materials of Varying Hardness

Harder materials demand a higher applied stress to initiate and propagate cracks for successful fracturing. This translates directly to the need for a heavier rotor with higher rotational inertia or greater rotor speed to deliver the requisite impact force. The crusher's design must channel this stress efficiently to avoid energy loss and excessive wear.

The stress type is also pivotal. While pure impact is excellent for brittle materials, harder, tougher rocks might benefit from a combination of impact and compression, sometimes suggesting a hybrid approach or a different crusher type altogether for primary breaking before secondary impact crushing.

The Fundamental Difference in Crushing Brittle vs. Tough Materials

Brittle materials fail catastrophically at their elastic limit with little plastic deformation. An impact crusher excels here by transferring kinetic energy from the rotor to the feed material, causing it to fracture along its natural cleavage planes. This results in a well-shaped, cubic product ideal for aggregate production.

Tough materials, however, deform plastically, absorbing energy and resisting fragmentation. Attempting to impact-crush very tough feed can lead to high energy consumption, elevated wear on blow bars and impact plates, and an unsatisfactory, flaky product size distribution. Understanding this distinction is paramount for correct application.

The Influence Curve of Hardness Fluctuation on Crushing Chamber Wear Rate

Wear within the crushing chamber does not increase linearly with hardness; it often follows a more aggressive, exponential curve. A small increase in average material hardness can lead to a disproportionate surge in the wear rate of blow bars, impact plates, and liners. This relationship must be modeled to predict maintenance schedules and operating costs accurately.

Modern crushers are equipped with wear monitoring systems that track the performance drop or specific power consumption, providing operators with data to correlate real-time wear with feed material characteristics, allowing for proactive maintenance planning before wear compromises product quality.

The Necessity of Pre-Screening Systems in Hard Rock Crushing

Pre-screening, or scalping, is critical when processing hard and abrasive materials. It removes naturally fine material and undersized particles from the crusher feed, preventing them from occupying valuable space in the crushing chamber without being crushed. This allows the rotor to focus its energy on breaking the larger, harder rocks, improving efficiency.

Furthermore, by preventing fines from circulating within the chamber, pre-screening reduces the abrasive paste that accelerates wear on components. This simple step significantly extends the service life of wear parts and maintains a higher, more consistent throughput over time, protecting the crusher from unnecessary abrasion.

Core Working Principle Analysis of Impact Crushers

At its heart, an impact crusher accelerates the feed material into stationary impact plates using a high-speed rotor equipped with blow bars. The resulting fragmentation occurs through a transfer of kinetic energy, causing the rock to break upon impact. The adjustable gap between the rotor and the impact plates, along with the speed of the rotor, are the primary controls for the final product size.

The efficiency of this process is heavily dependent on the material's hardness and the rotor's tip speed. For soft materials, a lower speed might be sufficient, conserving energy. For hard, dense feed, the rotor must spin faster to impart more energy, ensuring a single impact event provides enough stress to cause fracture. This dynamic relationship between rotor velocity and material hardness is the cornerstone of impact crusher operation and optimization.

Dynamic Matching Model of Rotor Speed and Material Hardness

There exists an optimal rotor tip speed for any given material hardness. Too low a speed on hard rock results in inadequate fracture energy and poor reduction ratios. Excessively high speed on soft rock wastes energy, creates excessive fines, and accelerates wear unnecessarily. Advanced crusher models use programmable logic controllers (PLCs) to adjust rotor speed based on real-time motor amperage, providing a dynamic match to the feed material's characteristics.

This dynamic adjustment ensures the crusher operates at peak efficiency across a range of materials, maximizing throughput for the available power while simultaneously managing wear rates. It is a key feature in modern equipment designed for processing highly variable feed stocks.

Influence of Crushing Chamber Structure on Hardness Adaptability

The geometric design of the crushing chamber determines how material is impacted and how it flows through the crusher. Open, large-volume chambers are suitable for lower hardness, bulkier materials, allowing for higher throughput. For harder, more abrasive feed, a more enclosed and robust chamber design is employed to contain the higher energy impacts and direct the flow of material optimally across the wear parts.

Chamber designs that incorporate cascading material onto the rotor can also be used to create a rock-on-rock crushing action, which can reduce wear on metal components when processing very abrasive materials, making the crusher more adaptable to a wider range of hardness levels.

The Correspondence Between Blow Bar Material Selection and Hardness Grade

Blow bars are consumable items and their material composition is selected based directly on the hardness and abrasiveness of the feed. For low-abrasive, low-hardness materials, economical manganese steel offers good impact resistance. For highly abrasive hard rock, high-chromium iron blow bars are preferred for their superior wear resistance, despite being more brittle.

Manufacturers provide detailed guidelines matching blow bar metallurgy to application severity. Selecting the wrong material can lead to catastrophic failure; a hard but brittle blow bar might shatter on a very tough, uncrushable object, while a soft manganese bar would deform, potentially protecting the rotor from damage.

Mechanical Optimization Strategy for Impact Plate Adjustment Angle

The angle of the impact plates, or aprons, relative to the rotor's trajectory is a critical setting. A steeper angle creates a sharper impact, favoring fragmentation of smaller, harder pieces. A shallower angle creates a grinding/attrition effect, better for softer materials or for achieving a finer product size.

These aprons are often hydraulically adjustable, allowing operators to fine-tune the crushing action without stopping the machine. This flexibility is vital for operators facing changing feed materials, enabling them to optimize the product shape and discharge size for downstream processes in real-time.

Trigger Mechanism of Overload Protection Devices in Hard Material Processing

Hard feed and occasional uncrushable objects (tramp metal) pose a significant risk of overloading the crusher, potentially damaging the rotor, bearings, or drive system. Modern impact crushers are equipped with sophisticated overload protection. This can be mechanical, like a safety clutch, or hydraulic, where cylinders supporting the impact aprons allow them to retract, opening a wide gap for the uncrushable object to pass through.

Once the threat has passed, the system automatically resets, minimizing downtime. This feature is indispensable for processing hard, variable materials where the risk of blockages or overloads is high, protecting the machine's structural integrity and ensuring operational continuity.

Key Selection Parameters and Hardness Correlation Analysis

Selecting the correct crusher model involves analyzing several interdependent parameters, all of which are influenced by material hardness. The desired feed size and product size define the necessary reduction ratio, which in turn dictates the machine size and power requirements. Harder materials reduce the effective capacity of a given crusher model due to the need for lower throughputs to achieve adequate breakage and manage wear.

Power consumption is a direct function of the work required to break the rock, which increases with hardness. Therefore, a crusher processing granite will draw more power and have a lower hourly throughput than the same crusher processing limestone. Understanding these non-linear relationships is essential for avoiding under-sizing or over-sizing equipment for a specific hard rock application.

Balancing Feed Size Control and Discharge Size Requirements

The maximum feed size a crusher can accept is fixed by its inlet opening and rotor diameter. Feeding oversize material is a primary cause of blockages and damage. For hard materials, it is crucial to ensure the primary feeding device (e.g., a vibrating feeder) consistently delivers material within the crusher's design limits to maintain efficient operation and prevent stress on the drive system.

Conversely, the desired discharge size setting must be realistic for the material's hardness. Expecting a very fine product from a single impact crusher processing hard granite will drastically reduce capacity and exponentially increase wear. Often, a secondary crushing stage, like a cone crusher, is needed to achieve fine sizes in hard rock applications.

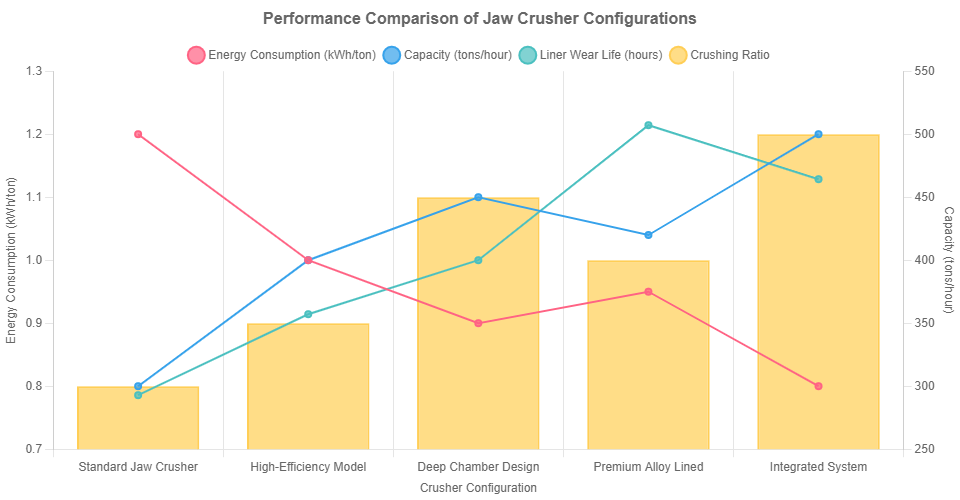

The Non-Linear Relationship Between Capacity (TPH) and Material Hardness

The advertised maximum capacity of an impact crusher is typically based on processing average limestone. This throughput number decreases significantly as material hardness increases. The reduction is not linear; moving from limestone to granite might reduce effective capacity by 30-50% for the same machine. This is due to the need for a higher number of impacts per particle to achieve fracture and the necessity to manage feed rate to control wear.

Therefore, selecting a model based solely on brochure capacity figures is a common mistake. Engineers must apply correction factors based on the specific material's hardness, abrasiveness, and desired reduction ratio to estimate the realistic tons per hour (TPH) a machine can achieve.

Power Consumption Variation Pattern with Increasing Hardness

The power drawn by the crusher's motor is a excellent indicator of the work being done. Harder materials require more energy to fracture, leading to higher amperage draw. Crushers are designed to operate at a certain load factor (e.g., 80-90% of motor nameplate amperage) under design conditions.

Processing a material harder than designed for will cause the motor to operate at or above its rated capacity, leading to overheating and potential failure. Conversely, a crusher operating well below its rated amperage on soft material is likely oversized, leading to inefficient energy use. Matching motor power to expected material hardness is a fundamental step.

Establishing a Predictive Model for Blow Bar Replacement Cycles

Predicting wear part life is critical for maintenance planning and cost control. Replacement cycles for blow bars and impact plates are primarily a function of material abrasiveness, hardness, and total throughput. Manufacturers provide wear rate indices (e.g., grams per ton crushed) for different materials.

By tracking actual production tons, operators can build a predictive model specific to their operation. For example, a set of blow bars might process 20,000 tons of soft sandstone but only 8,000 tons of hard abrasive basalt. This data allows for just-in-time ordering of parts and scheduling of maintenance windows, minimizing unexpected downtime.

Precision Requirement Grading for Hydraulic Adjustment Systems

The ability to adjust the gap between the rotor and impact aprons hydraulically is a standard feature on modern impact crushers. The precision required from this system increases with material hardness. For fine product sizing in hard rock applications, micron-level adjustments are necessary to compensate for wear and maintain product consistency.

Lower-precision systems may be adequate for primary crushing or soft materials where product size is less critical. However, for secondary or tertiary crushing of hard abrasive rock, a high-precision, reliable hydraulic system is indispensable for maintaining product quality and protecting the machine from damage caused by improper settings.

Comparison of Processing Solutions for Typical Hardness Materials

Different materials demand distinctly different processing strategies and crusher configurations. A one-size-fits-all approach leads to poor performance and high operating costs. The optimal setup for soft, non-abrasive limestone focuses on high capacity and low energy consumption. In contrast, a system for hard, abrasive granite must prioritize robust construction, advanced wear protection, and potentially multiple crushing stages.

Understanding these standard industry practices for common material types provides a solid foundation for selecting equipment. It also highlights the importance of consulting with application engineers who can recommend configurations proven in similar conditions, reducing project risk and ensuring the plant meets its production and cost targets.

Rapid Crushing Strategy for Low Hardness Materials (Limestone)

Limestone and other soft, low-abrasive materials are ideal for impact crushing. The strategy here is to maximize throughput and produce a well-shaped product with minimal wear. This often involves using a large-diameter rotor operating at a moderate speed to process high volumes efficiently. Wear parts can be made from more economical materials like standard manganese steel.

The focus is on achieving a high reduction ratio in a single stage, minimizing the number of crushing units in the plant layout. Energy efficiency is high, and maintenance intervals are long, making this a low-cost operation. Pre-screening might be used primarily to remove already-sized material, not for wear protection.

Wear-Resistant Configuration Scheme for Medium Hardness Materials (Iron Ore)

Iron ore presents a challenge due to its medium to high hardness and significant abrasiveness. The crushing strategy must balance capacity with wear management. Crushers are configured with heavier, more wear-resistant components. Blow bars and liners are typically high-chromium cast iron to extend service life.

Rotor speed may be optimized to provide sufficient energy for fracture without creating excessive fines or accelerating wear. A two-stage crushing circuit is common, with an impact crusher often serving as the primary or secondary unit. Close monitoring of wear part thickness is essential to prevent failure and maintain product sizing.

Reinforced Crushing Structure for High Hardness Materials (Granite)

Granite, basalt, and similar hard, abrasive rocks demand a heavily reinforced crusher structure. The machine's frame, rotor, and bearings must be designed to withstand the higher impact forces and vibrations. The rotor is often a solid, monolithic steel casting to provide the necessary mass and inertia for effective breakage.

Wear protection is paramount, utilizing the highest grade of wear-resistant alloys for all internal components. Capacities are lower, and power consumption is higher per ton of output. These crushers often operate in a secondary or tertiary position after primary jaw crushing, specializing in shaping the aggregate product.

Pre-treatment Process Combination for Ultra-Hard Materials (Basalt)

Some materials, like certain types of basalt or quartzite, approach the upper limits of what impact crushers can efficiently process. In these cases, a robust pre-treatment process is often necessary. This typically involves primary crushing with a jaw crusher specifically designed for hard rock, which applies compressive force rather than impact.

The jaw crusher performs the initial, high-force breakage, reducing the rock to a manageable size for the secondary impact crusher, which then refines the shape and size. This combination protects the more sensitive impact crusher from the extreme stresses of primary size reduction, making the overall process viable for ultra-hard materials.

Intelligent Sorting Technology for Mixed Hardness Feedstock

Recycling applications, like construction and demolition waste processing, often involve highly heterogeneous feed material with wildly varying hardness. Modern plants address this challenge with intelligent pre-sorting technology. Sensors (e.g., near-infrared, color, or laser) can identify and separate materials like wood, plastic, soft concrete, and hard natural rock before crushing.

This allows the crusher to be fed a more consistent stream of material, often of a specific hardness band. This consistency dramatically improves crushing efficiency, protects the machine from shock loads caused by uncrushables, and results in a higher quality, more consistent recycled aggregate product.

Selection Decision Process and Validation Methods

A scientific selection process moves beyond comparing brochure specifications. It begins with comprehensive material testing to gather definitive data on hardness, abrasiveness, and composition. This lab data must then be translated to real-world conditions using established correction factors that account for moisture, clay content, and feed gradation.

The next step is a critical analysis of supplier data, requesting performance guarantees based on your specific material. Finally, a detailed Total Cost of Ownership (TCO) model must be built, factoring in not just the purchase price, but also anticipated energy consumption, wear part costs, maintenance labor, and expected availability. This holistic approach ensures the selected crusher delivers the lowest cost per ton over its entire lifespan.

Key Data Collection Points During the Sample Testing Phase

Before selection, a representative sample of the material to be crushed must be tested in a laboratory. Key data points include the Los Angeles Abrasion (LAA) value, which quantifies abrasiveness, and the Mohs hardness. The sample's chemical composition is also analyzed to identify elements that might accelerate wear, such as high silica content.

The particle size distribution (PSD) of the feed and the desired PSD of the product define the required reduction ratio. Finally, tests for moisture content and the presence of clay are crucial, as these can cause clogging and significantly reduce capacity, factors that must be considered during crusher sizing.

Correction Factors Between Laboratory Data and Field Conditions

Laboratory crushers operate under ideal, controlled conditions that are difficult to replicate in a quarry or mine. Therefore, the performance data obtained from lab tests must be adjusted using industry-standard correction factors. These factors account for continuous operation, variations in feed size distribution, the presence of fines, and the overall efficiency of the full-scale machine.

An experienced application engineer will use these factors to scale up lab results and provide a realistic forecast of production capacity, power draw, and wear rates for the commercial-sized crusher, ensuring the selected model meets the plant's production targets.

Interpretation and Verification Techniques for Supplier Parameter Tables

Supplier brochures contain vital information but must be read critically. Key parameters like capacity are often given for a specific, easy-to-crush material. It is essential to request capacity curves that show performance across different discharge settings and for your specific material type.

Request references for installations processing similar materials and verify their performance claims. Scrutinize the standard and optional wear materials offered. A reputable supplier will be transparent with their data and provide performance guarantees based on your test results, forming part of the purchasing contract.

Key Elements for Building a Total Cost of Ownership (TCO) Model

The purchase price of the crusher is only a fraction of its lifetime cost. A comprehensive TCO model includes several key elements: initial capital investment (CAPEX), cost of wear parts (blow bars, liners) per ton crushed, energy consumption cost per ton, scheduled maintenance labor and parts, and the cost of unscheduled downtime.

By modeling these costs over a projected 5 or 10-year period, a clear financial picture emerges. Often, a slightly more expensive crusher with superior energy efficiency and longer wear part life presents a significantly lower TCO, making it the wiser financial choice in the long run.

Application of Digital Twin Technology in Selection Validation

Advanced manufacturers now utilize digital twin technology to validate crusher selection. A digital twin is a virtual, dynamic model of the physical crusher. Engineers can input the specific material properties from lab tests and run simulations to predict performance, product gradation, power usage, and even wear patterns.

This technology allows for virtual testing of different crusher models and configurations before a purchase is made, significantly de-risking the investment. It provides a data-driven forecast of how the machine will perform in the intended application, ensuring the selected model is optimally matched to the task.

Equipment Maintenance and Performance Optimization Strategies

Proactive maintenance is the key to maximizing the productivity and lifespan of an impact crusher, especially when processing hard materials. A structured approach involves regular inspection and monitoring of wear parts, tracking performance metrics like power draw and product size, and using data to predict maintenance needs rather than reacting to failures.

Optimization is an ongoing process. By analyzing operational data, adjustments can be made to rotor speed, feed rate, and crusher settings to find the perfect balance between product quality, throughput, and wear rate. Modern crushers with integrated automation systems provide the tools necessary for continuous performance improvement.

Phased Inspection Methodology for Blow Bar Wear

Blow bar wear should be monitored systematically. A common method is the "rule of thumb" inspection: when the wear profile on the blow bar creates a deep groove, reducing its effective weight by a certain percentage (e.g., 20%), it should be rotated or replaced. Uneven wear indicates issues with feed distribution or rotor balance.

Many operations use ultrasonic thickness gauges to measure remaining wear material accurately, moving from visual estimates to precise, data-driven replacement decisions. This prevents running blow bars to failure, which can damage the rotor and other components, leading to more extensive and expensive repairs.

Predictive Model for Crushing Chamber Liner Replacement Cycle

Like blow bars, the liners protecting the crushing chamber walls have a finite life. Their replacement cycle is typically longer but equally critical. Wear is monitored at scheduled intervals, and a predictive timeline for replacement is established based on the recorded wear rate and processed tonnage.

Replacing all liners simultaneously during a planned shutdown is far more efficient than replacing them piecemeal during unplanned stops. Keeping a history of liner life for different materials allows for increasingly accurate predictions and inventory planning, ensuring parts are available when needed.

Diagnostic Procedure for Hydraulic System Pressure Anomalies

The hydraulic system is crucial for adjustment and overload protection. Pressure anomalies are key diagnostic indicators. Low pressure might signal a leak or pump failure, while high pressure could indicate a blockage in the system or the crusher being overloaded.

Operators should be trained to recognize these signs. Modern crushers have sensors that monitor hydraulic pressure and can trigger alarms or automatically shut down the machine if parameters move outside a safe range, preventing damage to the hydraulic components and the main crusher structure.

Root Cause Analysis Path for Product Size Exceeding Specifications

When the product begins to contain oversized material, a structured root cause analysis is required. The first check is the wear on the blow bars and impact aprons; worn parts increase the gap, leading to a coarser product. The second is the feed rate and size; a sudden feed of larger rock can overwhelm the crusher.

Other causes include a decrease in rotor speed due to a drive belt issue or the accumulation of material blocking the adjustment mechanism's movement. A step-by-step diagnostic process ensures the true cause is found and rectified quickly, restoring product quality.

Intelligent Control Schemes for Energy Consumption Optimization

Advanced control systems can optimize a crusher's energy use. These systems constantly monitor the power draw of the main motor. If the crusher is operating below its target power range, the control system can signal the feeder to increase the feed rate, maximizing productivity.

Conversely, if the power draw approaches the motor's limit, the feed rate can be automatically reduced to prevent tripping. This "load-control" strategy ensures the crusher operates at its peak efficiency point, maximizing tons produced per kilowatt-hour of energy consumed, which is a major contributor to lowering operating costs.

Industry Application Cases and Selection Insights

Examining real-world applications provides invaluable insights into successful crusher selection logic. The requirements for a stationary aggregate quarry processing granite are vastly different from a mobile unit recycling concrete on a urban demolition site. Each application imposes unique constraints on capacity, mobility, product shape, noise, and dust emissions.

Understanding how leading operators in different sectors configure their crushing plants reveals best practices and common pitfalls. This knowledge helps in specifying not just the crusher itself, but the entire supporting system—feeders, screens, conveyors, and dust suppression—to create a cohesive and efficient processing circuit tailored to the material's hardness and the project's goals.

Equipment Selection Logic for Construction Waste Recycling Projects

Mobile impact crushers are the preferred choice for C&D waste recycling due to their mobility and ability to produce a well-shaped product. The key selection criteria here include the ability to handle a highly variable feed, built-in protection against uncrushable items (reinforced rotor, hydraulic overload), and advanced dust suppression systems to meet urban environmental regulations.

The crusher must be versatile, often equipped with a magnetic separator to remove rebar and a screening unit to separate fines. The hardness can vary from soft concrete and bricks to harder natural stone, so the machine must be robust yet efficient across this spectrum.

Special Requirements for Secondary Crushing in Metal Mines

In metal mining, secondary crushing prepares ore for further grinding. The feed is typically high-hardness, abrasive rock. Reliability and availability are paramount, as downtime stops the entire processing chain. Crushers are often configured with extra heavy-duty components and automated setting regulation to maintain a consistent product size for the grinding mills.

Wear part life is a major operating cost, so selecting a crusher known for easy and safe wear part replacement minimizes maintenance time. Often, these are large, stationary units designed for decades of continuous service under the most demanding conditions.

Stability Requirements for Raw Material Crushing in Cement Plants

Cement production requires a consistent and steady supply of correctly sized raw meal, often limestone and clay. Crushers in cement plants are selected for high availability and consistent performance rather than peak capacity. They must handle sometimes sticky materials without clogging.

The crushing process is a critical first step in controlling the chemistry of the cement, so a consistent product size is vital for the downstream raw mill and kiln processes. Reliability and minimal maintenance requirements are key to avoiding disruptions in the continuous production process.

Lightweight Design Trend in Mobile Crushing Stations

For mobile impact crushers, especially those mounted on tracks, there is a constant engineering push towards lightweighting without sacrificing strength. This is driven by the need to improve fuel efficiency, increase mobility, and comply with weight restrictions for transport on public roads.

This is achieved through advanced computer-aided design (CAD) for structural optimization and the use of high-strength steel alloys. This trend allows for powerful crushing capabilities to be deployed in remote or constrained locations, making them ideal for mining and quarrying operations that frequently change location.

Influence of Environmental Regulations on Crusher Configuration

Modern crushers are designed with stringent environmental regulations in mind. This primarily involves controlling dust and noise. Enclosed housing with sound dampening material is standard. Highly efficient dust suppression systems, which inject water mist into the crushing chamber and transfer points, are now a necessity, not an option.

In some regions, crushers may be required to operate within full enclosures with integrated baghouse filter systems to capture nearly 100% of particulate emissions. These environmental considerations are now fundamental design parameters that influence the overall layout, size, and cost of the crushing plant.