Avoiding Pitfalls in Selecting Impact Crushers for Small and Medium-Sized Gravel Plants

This guide provides a systematic analysis of the common mistakes small and medium-sized quarries make when selecting an impact crusher. It addresses core dimensions such as equipment suitability, space constraints, and budget control to offer a scientific selection framework. Through an exploration of seven key modules, this resource aims to help quarry operators maximize equipment efficiency and achieve an optimal balance in operational costs, ensuring a profitable and sustainable operation.

Core Requirement Analysis for Small and Medium-Sized Quarries

The selection process for an impact crusher in a smaller operation begins with a thorough understanding of its unique constraints and goals. Unlike large-scale mining operations, these quarries often operate with limited capital, restricted physical space, and a need for operational flexibility. The primary objective is to identify a machine that delivers reliable performance at a scale that matches their production targets, without incurring unnecessary capital or operational expenses.

A critical first step is a realistic assessment of the annual and daily production requirements. This involves forecasting demand for various aggregate products and understanding the seasonal fluctuations that may affect production schedules. The chosen crusher must have a crushing capacity that aligns with these targets, providing enough headroom for growth without being excessively oversized, which leads to inefficient energy use and higher upfront costs.

Matching Principle of Production Scale and Equipment Processing Capacity

Selecting a crusher with the correct throughput capacity is a delicate balancing act. An undersized machine will operate at maximum capacity constantly, leading to accelerated wear, frequent breakdowns, and an inability to meet demand. Conversely, an oversized crusher represents a significant and unnecessary capital investment and will operate inefficiently at low loads, consuming more energy per ton of material processed.

A prudent approach is to choose a crusher model where the planned production rate sits at approximately 70-80% of its maximum rated capacity. This provides a crucial buffer to handle unexpected surges in feed, variations in material hardness, and ensures the machine operates within its most efficient and durable range, thereby protecting the investment.

Impact Mechanism of Raw Material Hardness Fluctuations on Equipment Lifespan

The hardness of quarried rock, often measured on the Mohs scale, is not always consistent. Even within a single quarry face, pockets of harder material like basalt or quartzite can be encountered. These fluctuations have a dramatic and non-linear impact on the wear rate of crusher components, particularly the blow bars and liners.

A crusher that is perfectly adequate for soft limestone may suffer catastrophic wear when processing unexpectedly hard rock. Therefore, the selection must be based on the maximum anticipated hardness, not the average. This ensures the structural integrity of the rotor, the quality of the bearings, and the wear resistance of the components are all suited to the toughest conditions the quarry may present.

Demand for Compact Equipment Design Under Site Space Constraints

Small and medium quarries frequently operate on limited land, making the physical footprint of the crushing plant a major consideration. The layout must integrate the crusher, feeders, screens, and conveyors into a compact and logical flow that minimizes the need for extensive civil works and long-distance conveying, which adds cost.

Manufacturers offer modular and compact designs for this very market. These designs focus on a smaller footprint, sometimes utilizing vertical space with stacked screening units. The ease of access for maintenance within this compact layout is also a critical factor, as cramped spaces should not hinder routine checks and part replacements.

Weight Balance Between Equipment Procurement and Long-Term Maintenance in Budget Allocation

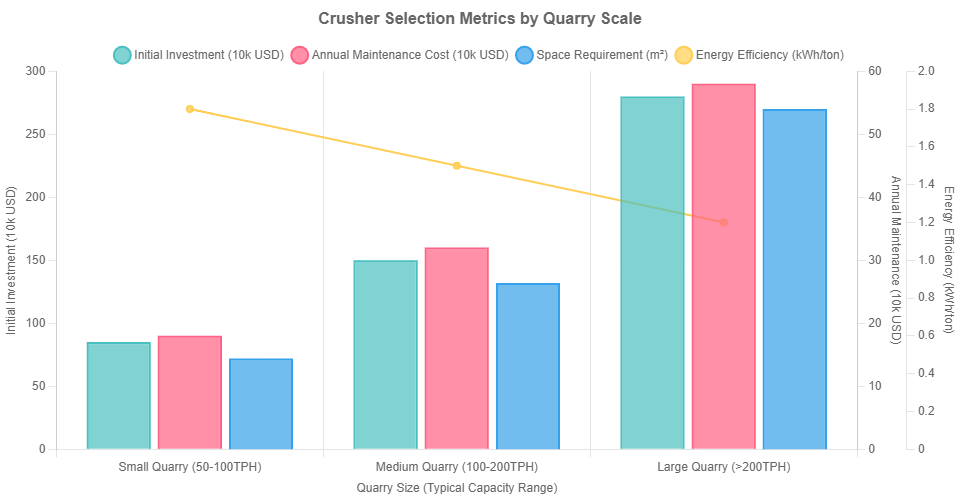

The initial purchase price of the crusher is only a portion of its total lifetime cost. A common error is to allocate the entire budget to the procurement phase, leaving insufficient funds for the inevitable maintenance and operational costs. A more strategic approach involves analyzing the Total Cost of Ownership (TCO).

TCO includes the initial investment, anticipated costs of wear parts like blow bars, energy consumption, and planned maintenance labor. A slightly more expensive crusher known for its energy efficiency, ease of maintenance, and longer wear part life will often yield a significantly lower TCO over a 5-year period than a cheaper, less robust alternative.

Mandatory Environmental Policy Requirements for Equipment Emission Standards

Modern quarry operations must adhere to stringent environmental regulations concerning dust and noise emissions. Regulatory bodies often impose strict limits on particulate matter released into the air. Therefore, the selected crusher must be equipped with effective and integrated dust suppression systems, which typically involve water spray nozzles at key transfer points and enclosed loading zones.

Furthermore, noise pollution is a key concern, especially for quarries near residential areas. Crushers designed with sound-dampening enclosures and vibration isolation pads are essential. Non-compliance can result in hefty fines and operational shutdowns, making environmental compatibility a non-negotiable criterion in the selection process.

In-Depth Analysis of Common Selection Mistakes

The path to selecting the right crusher is fraught with potential errors in judgment, often stemming from short-term thinking or a lack of technical understanding. These mistakes can lock an operation into a cycle of high operating costs, low availability, and poor product quality. Recognizing these pitfalls beforehand is the most effective strategy for avoiding them.

These errors range from financial miscalculations, such as focusing solely on the cheapest upfront price, to technical missteps, like ignoring the fundamental properties of the material to be crushed. A methodical and informed selection process, which views the crusher as a long-term production partner rather than a simple commodity, is vital for success.

Mistake 1: Pursuing Low Prices Leading to Soaring Comprehensive Costs

The allure of a low initial purchase price is powerful but often deceptive. Crushers offered at rock-bottom prices frequently compromise on the quality of materials and craftsmanship. This can manifest in lighter-grade steel for the frame and rotor, inferior bearings, and less effective wear components.

In operation, these shortcomings lead to higher energy consumption, a shorter operational lifespan, more frequent and expensive breakdowns, and a higher cost per ton of material produced. The initial savings are quickly erased, often multiple times over, by these excessive operational and maintenance expenses.

Mistake 2: Neglecting the Adaptability Between Equipment and Raw Material Hardness

Perhaps the most critical technical mistake is selecting a crusher that is not matched to the abrasiveness and compressive strength of the feed material. Using an impact crusher designed for medium-hard rock to process very hard, abrasive granite will result in disastrously short wear part life and potential damage to the rotor itself.

The crusher's capabilities, including the rotor mass, the rotational speed, and the quality of its wear parts, must be aligned with the material's properties. Suppliers provide application guidelines that specify the suitable material hardness range for each model; ignoring these guidelines is a guarantee of poor performance and financial loss.

Mistake 3: Failing to Reserve Buffer Space for Production Fluctuations

Quarry production targets are not static. Market demand can increase, or a new contract might require higher output. Selecting a crusher that operates at its absolute maximum capacity under normal conditions leaves no room for this growth. To increase production, the entire crusher would need to be replaced, representing a massive secondary investment.

As previously mentioned, selecting a crusher with a rated capacity about 20-30% higher than the current need provides this essential buffer. It allows the quarry to capitalize on new opportunities without the downtime and expense of a major equipment replacement project.

Mistake 4: Believing Online Promotions Without Physical Performance Verification

Marketing materials and online specifications are designed to highlight a product's strengths. However, they may not fully represent its performance in a specific application. Relying solely on this information without independent verification is a significant risk.

It is essential to request contact information for existing customers who are processing similar materials. Visiting these sites to see the crusher in operation, discussing maintenance costs and machine reliability with the owners, provides invaluable real-world data that can confirm or refute the manufacturer's claims.

Mistake 5: Overlooking the Maintenance-Friendly Design of Equipment

The ease with which routine maintenance can be performed directly impacts the crusher's availability and the safety of the maintenance crew. A design that requires hours of disassembly to access a routine service point like a grease bank or to inspect a wear part will result in excessive downtime.

Modern crushers are designed with maintenance in mind, featuring hydraulic opening systems for the upper frame, easy-access doors, and sliding mechanisms for wear part replacement. Overlooking these features in favor of a simpler, cheaper design can lead to prolonged and costly maintenance shutdowns throughout the machine's life.

Equipment Compatibility Optimization Strategy

Optimizing a crusher for a specific application involves fine-tuning its various systems to work in harmony with the material properties and production goals. This goes beyond mere model selection and delves into the configuration of the machine itself. A well-optimized crusher operates efficiently, produces a consistent, high-quality product, and minimizes wear.

This optimization encompasses the geometric design of the crushing chamber to suit the material's breakage characteristics, the selection of metallurgy for wear parts to balance toughness and abrasion resistance, and the use of intelligent systems to monitor and adjust operations in real-time for peak performance.

Matching Model of Raw Material Hardness and Crushing Chamber Structure

The shape and size of the crushing chamber influence how material is reduced. For softer, less abrasive materials, a larger chamber may be optimal for high-volume processing. For hard, abrasive rock, a more robust and enclosed chamber design is necessary to withstand higher impact forces and to guide the material flow in a way that maximizes the rock-on-rock crushing action, which protects the wear parts.

Some crusher models offer different chamber options. Selecting the correct chamber geometry for the primary material type ensures efficient fragmentation, optimal product shape, and the longest possible service life for the liners and blow bars.

Feed Size Control and Graded Crushing Process Design

Consistent control of the feed size is crucial for an impact crusher. Feeding oversized blocks can cause blockages, damage the rotor, and lead to unsafe operating conditions. Implementing a pre-screening stage (scalping) to remove fines and oversized material before the crusher ensures it receives a consistent and optimal feed.

For very hard rock, a two-stage crushing process is often necessary. A primary jaw crusher first reduces the large quarry rock to a manageable size, which is then fed to the secondary impact crusher for further reduction and shaping. This graded approach protects the impact crusher from excessive stress and improves the overall efficiency of the crushing circuit.

Blow Bar Material Selection and Replacement Cycle Prediction

Blow bars are the primary consumable in an impact crusher. Their material composition must be carefully chosen. For less abrasive rock, manganese steel offers good impact resistance. For highly abrasive material, high-chrome iron bars provide superior wear resistance despite being more brittle.

By tracking production tonnage and monitoring wear, operators can build an accurate model to predict replacement cycles. This allows for just-in-time ordering of new blow bars and planned maintenance shutdowns, avoiding unexpected failures that disrupt production and potentially damage the crusher.

Precision Control of Hydraulic System Pressure Adjustment

The hydraulic system is responsible for adjusting the setting of the impact aprons and providing overload protection. Precise control over the apron position is key to maintaining a consistent product size. Modern systems allow for remote adjustment, enabling operators to fine-tune the product gradation from the control room.

Furthermore, the hydraulic system's pressure settings determine the force required to trigger the overload protection. Setting this correctly ensures the system activates when an uncrushable object enters the chamber, protecting the crusher from damage, but does not activate unnecessarily under normal high-load conditions.

The Value of Intelligent Monitoring Systems in Equipment Compatibility

Modern crushers can be equipped with sensors and monitoring systems that provide real-time data on operation. These systems can track power draw, bearing temperature, vibration levels, and hydraulic pressure. This data is crucial for optimization.

For example, a sudden drop in power draw could indicate a loss of feed, while a spike could signal a blockage. Monitoring vibration can provide early warning of bearing failure or rotor imbalance. This intelligence allows for proactive maintenance and operational adjustments, ensuring the crusher always operates within its ideal parameters for the given material.