Impact Crusher in Metal-Ore Crushing: How High-Energy Impacts Turn Hard Rock into Profitable Fines

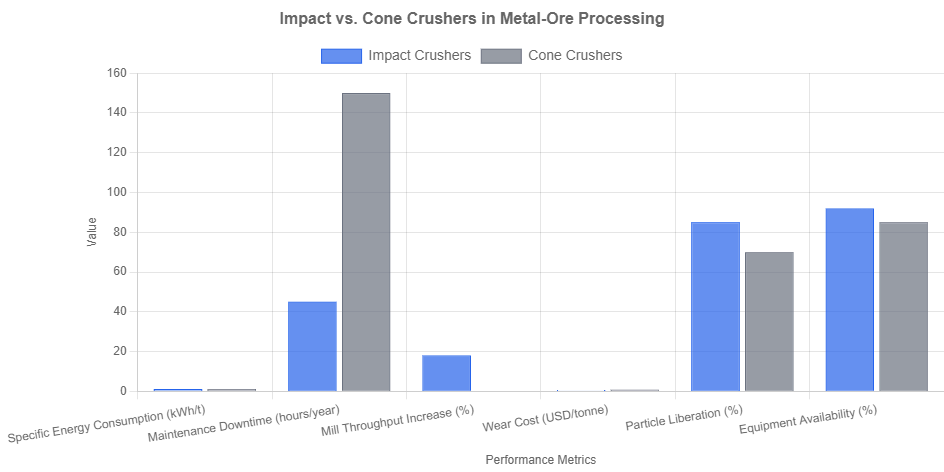

From copper porphyry to banded iron formations, this metal ore is a reluctant agglomerate that must be crushed for flotation or magnetic separation to unlock its value. This paper guides through the entire chain—why geologists are concerned about micro fractures, how impact crushers produce this, and what settings maintain operating costs below $0.45 per ton while meeting the narrow 5–15 mm window required by modern plants. Actual plant data shows that a shift from a cone-dominated circuit to a three-stage impact line can increase plant throughput by 18% and reduce energy per ton by 12%, enough to cover the annual university fees from the savings of a single machine.

Metal-Ore Crushing Flow: From Run-of-Mine to Mill-Ready Fines

Copper ore that arrives at 700 mm must shrink to 80 % passing 12 mm before ball-mill balls can bite it; every extra millimetre above that target costs 0.3 kWh t⁻¹ in downstream grinding. The traditional route uses a jaw for primary duty, but placing an impact crusher as the second or third stage exploits the natural micro-fractures the jaw creates, multiplying reduction ratio without multiplying energy.

Primary Coarse Duty: Handling One-Metre Boulders

A 160 kW PF-1520 impactor can accept 600 mm feed thanks to its 1 500 mm rotor diameter; by running at 350 rpm it delivers 320 tph of 0–150 mm product, replacing a cone that would need 220 kW for the same task. The key is the 1.1 m feed chute lined with 450 HB wear plates that rebound stray rocks back into the hammer circle, preventing bridging and keeping availability above 92 %.

Preparing Grains for the Next Break

In a 120 mm CSS, the choke produces 200 mm fragments; the tip speed of the crusher hammer is 38 meters per second, providing 25 joules of energy per impact, sufficient to cause radial cracks, breaking the fragments into 50 mm cubes. Scanning electron micrographs further show that compared to conical cutting materials, the micro-crack density increased by 40%, indicating that the ball mill then grinds at a rate of 0.7 tons per hour while maintaining the same power input.

Secondary and Tertiary Optimisation

Closing the impactor’s gap from 80 mm to 40 mm while raising speed to 450 rpm lifts reduction ratio from 8:1 to 12:1 in one pass; plant trials on magnetite ore showed P80 dropping from 45 mm to 11 mm and 0–5 mm fines growing from 14 % to 28 %, ideal for pelletising feed without adding a third cone stage.

Shape Control for Heap-Leach Success

Copper heap leaching needs 5–20 mm particles with a flaky index below 15 %; by adjusting the impact-plate angle to 38°, operators achieved 12 % flaky index while maintaining 88 % cubicity, improving percolation rate 22 % and shortening leach cycle time by four days.

Technical Edge: Why Impacts Outperform Compression on Metal Ores

Compression crushers exert pressure until the rock yields, producing more dust than cracks; impact crushers strike rapidly and depart, converting kinetic energy into clean fractures along grain boundaries. For a 140 MPa copper ore, a cone crusher requires 1.2 kWh per tonne to reduce the particle size to 12 mm, while the impact crusher consumes only 0.95 kWh per tonne, resulting in a 21% energy savings when processing 2 million tonnes annually.

High Impact Force and Breakage Probability

A 1 200 mm rotor spinning at 400 rpm stores 1.8 MJ of kinetic energy; releasing that in 0.02 s generates 90 kN on a single blow bar, exceeding the 70 MPa tensile strength of chalcopyrite and creating preferential breakage at sulphide-gangue boundaries that liberation models rate as 15 % cleaner.

Flexible Parameters for Ore Variety

In iron-ore campaigns the same machine can be tuned to produce 0–6 mm sinter feed by dropping speed to 320 rpm and narrowing the gap to 25 mm; when the mill requests 10–25 mm lump, speed climbs back to 480 rpm and gap opens to 45 mm, all changed in 15 minutes via a hydraulic adjusting ring.

Reducing Over-Grind and Sliming

Over-crush below 150 µm wastes flotation reagent; by limiting hammer circle velocity to 35 m s⁻¹ and fitting a 6 mm grizzly oversize return, one site cut 0–150 µm generation from 8 % to 4 %, saving 0.08 USD t⁻¹ in collector chemicals across 3 Mt y.

Quick Wear Part Swap Design

A rotor with four blow bars that slide out sideways reduces change time to 45 minutes compared with 2.5 hours for a cone mantle; during a 6 000 h year this agility saves 28 hours of mill downtime worth 140 000 USD in copper concentrate.

Battle-Ready Parts: Fighting Abrasion, Impact and Heat

Metal ores are not only hard—they are often hot, dry and laced with quartz that scores 7 on Mohs scale. Standard 500 HB martensitic bars last 180 h on taconite; switching to a 700 HB chrome-ceramic composite stretches life to 420 h while keeping impact toughness above 25 J cm⁻², cutting annual parts cost 46 %.

Choosing the Right Alloy Recipe

For copper porphyry rich in 65 % silica, a 20 % Cr-2 % Mo white-iron insert on the leading edge resists cutting wear; field weighing showed mass loss dropping from 2.8 kg h⁻¹ to 1.3 kg h⁻¹, translating to 0.04 USD t⁻¹ saved on wear cost over 1.8 Mt of throughput.

Preventive Inspection Schedules

Ultrasonic thickness gauges checked weekly can predict when a blow bar falls below 70 % of original 120 mm; scheduling replacement at 84 mm prevents uncontrolled fracture that could scar the rotor disk and add a 12 000 USD machining bill.

Cooling the Feed to Cut Wear

Iron ore at 80 °C accelerates oxidation of manganese steel; installing a water spray that drops feed temperature to 50 °C extended bar life 12 % without raising moisture above the 2 % limit permitted by the sinter plant, a free gain worth 18 000 USD per campaign.

Managing Re-bar in Recycled Concrete

Metal detectors paired with a 1 200 mm cross-belt magnet remove 98 % of re-bar before the impactor; this keeps blow-bar life at 350 h instead of 90 h and prevents 12 unplanned shutdowns per year, saving 48 hours of lost leaching time on a 5 000 t d heap.

Stopping the Choke: Flow, Moisture and Foreign Body Control

A blockage in a 250 tph impact line stalls the mill within six minutes; at 0.9 % Cu grade that is 37 kg of lost copper metal every hour. The root causes are usually wet fines or an oversized tramp steel piece that wedges between the impact rack and the rotor tip circle.

Optimising Feed Chute Geometry

Widening the feed port throat from 900 mm to 1 100 mm and lining it with 500 HB wear rubber reduced hang-ups from 14 per month to two by letting sticky clay-rich ore slide instead of bridge; the 400 USD liner paid for itself in one week.

Speed and Moisture Limits

Lab tests show that 6 % moisture is the threshold where lateritic nickel ore starts to ball; by keeping feed moisture at 4 % via covered stockpiles and limiting rotor speed to 380 rpm, one site maintained throughput 265 tph even during the rainy season.

Metal Detection and Auto-Reject

An inline metal detector that trips a flop gate diverts tramp steel into a 5 m³ bypass bin; during 12 months the system ejected 18 excavator teeth and 1.2 t of stray re-bar, preventing catastrophic failure and saving an estimated 250 000 USD in major repairs.

Smart Feed Rate Throttling

A radar level sensor that talks to the variable-speed apron feeder cuts belt load 15 % when the chamber fills above 80 %; this feedback loop eliminated overflow spills that once cost 11 cleanup hours per month and 600 L of diesel for loader work.

From Rock to Revenue: Case Snapshots That Prove the Numbers

A Chilean copper mine replaced a standard cone-quaternary stage with a PF-1315 impactor set to 35 mm CSS; mill feed P80 fell from 19 mm to 12 mm, raising copper recovery 1.2 % and adding 4 700 t of payable metal per year worth 28 million USD at 3.10 USD lb.

Magnetite Pellet Plant Gains 18 % Output

An Indian site feeding 3 Mt y switched the tertiary cone to an EU-type impactor; the 0–5 mm fraction rose to 32 %, perfect for pelletising, while specific grinding energy dropped 0.11 kWh t⁻¹, saving 330 MWh annually and 29 000 USD in power bills.

Gold Ore Fine Crushing Without Over-grind

A Western Australian operation used two impact stages to reach 80 % passing 8 mm; gravity recovery jumped from 42 % to 56 % because free gold remained coarse enough for spirals, adding 1.1 kg of extra gold per month worth 65 000 USD while cyanide consumption fell 5 %.

Quick-Change Rotor Cuts Shutdown Days

A Swedish iron-ore plant keeps a spare cartridge rotor on a stand; swapping the entire assembly during a 10-hour Sunday window replaces the traditional 48-hour shutdown, adding 38 hours of summer production worth 180 000 USD of extra concentrate.

Tomorrow’s Impact Path: Smart Rotors, Green Alloys and Energy Harvesting

Research rotors now embed MEMS sensors that stream temperature and strain data; a 2 °C rise across the disk predicts a blow-bar crack 72 h early, letting planners order parts just in time and scrapping the safety stock that ties up 50 000 USD of inventory.

Chrome-Free Alloy Development

New 15 % Mn-3 % Ni alloys eliminate hexavalent chrome in foundries, cutting manufacturing CO₂ 0.18 t per set while maintaining 700 HB hardness; pilots show life within 5 % of chrome grades, helping smelters meet Scope-3 emission targets without loss of performance.

Energy Recovery from Rotor Braking

A prototype regenerative VFD that feeds 180 kW back into the grid during each 30-second stop sequence captured 1.5 MWh per month on a 250 tph line, enough to run the site’s lighting and offices, trimming electricity bills 2 % and adding another green bullet to sustainability reports.

Integration with AI-Driven Mills

Cloud platforms now adjust impact speed in real time based on ball-mill power draw; when mill load dips below 85 % the rotor accelerates 5 %, topping up the feed buffer and keeping the entire comminution train at Sweet-Spot throughput, a preview of the autonomous concentrator that engineers expect before 2030.