The Recycling Revolution in Construction Waste: How the PC Series Hammer Crusher Achieves Cost Reduction and Efficiency Gains in Aggregate Production

The construction industry generates vast amounts of waste, presenting both a disposal challenge and a significant opportunity. Traditional methods of dealing with demolished concrete and bricks are increasingly unsustainable. Modern hammer crushers, specifically the PC series, are engineered to transform this waste into valuable recycled aggregates. This process not only conserves natural resources but also offers substantial economic benefits. This article explores the advanced technological features that allow these robust machines to efficiently process complex construction debris, control final product quality, and operate with remarkable adaptability and intelligence.

The Impact of Construction Waste Composition on Crushing Processes

Construction and demolition waste is not a uniform material. Its variable composition directly influences the crushing technique required for efficient processing. Concrete chunks possess high compressive strength, often exceeding 30 megapascals, demanding significant impact energy to fracture. In contrast, brick materials are more abrasive but less resistant to shear forces. This fundamental difference necessitates a crusher capable of delivering multiple types of mechanical stress.

Beyond the mineral components, metal contaminants like reinforcing bar and wire present a major challenge. These metallic elements accelerate wear on internal components, particularly the hammer heads. The continuous impact and abrasion from these impurities can lead to premature failure of critical parts, increasing operational costs and downtime. Effective processing must therefore account for both the hardness variance and the presence of damaging contaminants.

Concrete Block Crushing and Lamination Theory in Hammer Design

Concrete fragmentation benefits greatly from the layer crushing principle. This theory posits that material is best reduced in size through successive applications of concentrated impact forces rather than a single massive blow. PC series crushers utilize a multi-hammerhead design that applies this theory, creating a cascading crushing effect within the crushing cavity. This method promotes inter-particle contact, where pieces of concrete break each other down, significantly improving efficiency and reducing energy consumption per ton of material processed.

The strategic arrangement of the hammers on the rotating drum is critical for controlling the final particle size distribution. By carefully calculating the trajectory and tip speed of each hammer, engineers can direct the flow of material to ensure consistent exposure to impact forces. This controlled environment prevents the formation of excessive fine powder, maximizing the yield of desirable, coarse aggregate fractions between 5 and 40 millimeters, which are essential for new concrete production.

Shear Force Application and Energy Consumption Optimization for Brick

Brick, being more brittle than concrete, responds better to combined impact and shear forces. The crusher's design incorporates features that exploit this material property. Rather than relying solely on high rotational speeds, the PCZ-type hammer crusher operates with a low-speed, high-torque rotor system. This configuration allows the hammers to engage with the brick material for a slightly longer duration, effectively applying a cleaving or shearing action that splits the bricks along their natural planes of weakness.

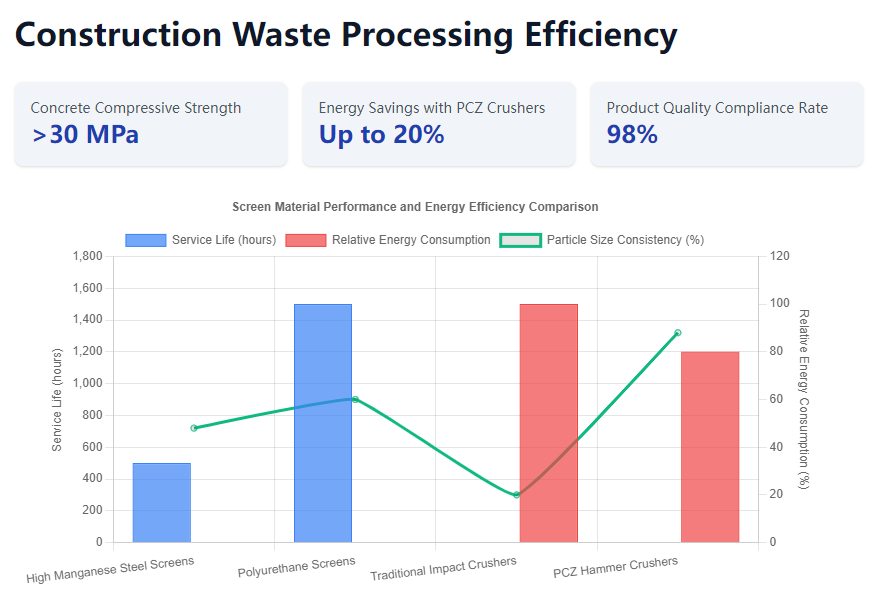

This operational philosophy directly translates to lower energy consumption. Verified performance data indicates that this low RPM, high-torque approach can reduce power requirements by up to twenty percent compared to conventional high-speed impact crushing when processing clay brick materials. The reduction in speed also decreases the wear rate on the hammer heads and interior liners, as the abrasive brick material is processed with less violent, more controlled force, contributing to lower operating costs over the equipment's lifespan.

Metal Impurity Detection and Integrated Automatic Sorting Systems

The economic viability of recycling operations depends on protecting the crushing machinery from metal contamination. An integrated sorting system is therefore a critical component. The process begins with a primary rotor that performs an initial liberation of embedded metals, followed by a powerful overhead suspended electromagnetic separator. This magnet can generate fields strong enough to extract ferrous metals like rebar and wire from a deep burden of material on a conveyor belt, ensuring purity before the crushed product reaches the final screening stages.

For non-ferrous metals such as aluminum or copper, which are not attracted to magnets, an eddy current separator is employed downstream. This device uses a rapidly alternating magnetic field to induce electrical currents in conductive metals, effectively turning them into temporary magnets that are repelled from the source and ejected from the main material stream. The synergistic logic between the electromagnetic and eddy current systems ensures a comprehensive removal of metallic contaminants, safeguarding the crusher's integrity and enhancing the quality of the final recycled aggregate product.

Process Self-Adaptation Strategies for Fluctuating Waste Composition

The heterogeneous nature of construction debris means that the feed material entering the crusher is never constant. To maintain stable operation and consistent product quality, modern plants rely on sophisticated programmable logic controller systems. These automated brains continuously monitor key operational parameters such as motor amperage, which indicates the load on the crusher, and the level of material in the feed hopper.

Upon detecting a surge of hard concrete or a drop in material volume, the PLC can dynamically adjust the feed rate via variable speed conveyors and feeders. This real-time modulation prevents the crusher from being overloaded, which can cause blockages and damage, or running empty, which wastes energy and causes unnecessary wear on components. This adaptive strategy ensures the crusher operates at its peak efficiency point regardless of incoming material variations, optimizing throughput and protecting the machinery.

Key Technical Parameters for Controlling Recycled Aggregate Particle Size

Producing high-quality aggregate requires precise control over the final particle size distribution. This is primarily governed by the configuration of the discharge grate at the bottom of the crushing chamber. The size and shape of the openings in this grate act as a final sizing screen; material remains in the chamber until it is broken down small enough to pass through. A well-established linear relationship exists between the sieve aperture and the top size of the product, allowing operators to accurately select the grate needed to meet specific grading requirements.

Another crucial parameter is the gap between the tips of the rotating hammers and the surface of the sieve grate. A smaller clearance results in more intensive grinding of the material, producing a finer product but also increasing the generation of unwanted fines and accelerating wear. A larger gap reduces wear and fines production but may allow oversized particles to discharge. Optimizing this hammer-to-screen distance is therefore essential for suppressing over-crushing and achieving the target yield of valuable coarse aggregates, which command a higher market price.

Screen Material Selection: A Comparison of High Manganese Steel and Polyurethane Lifespans

The choice of screen material is a critical economic decision that impacts maintenance downtime and operating costs. Traditional high manganese steel screens offer exceptional resistance to impact and shock loading, making them suitable for the initial coarse crushing stages where large, heavy blocks of concrete are present. However, in highly abrasive environments, such as those with a sand content exceeding thirty percent, the wear rate on steel screens can be significant, requiring frequent replacement.

Polyurethane screens present a modern alternative, particularly in secondary or final crushing stages. Laboratory and field tests under controlled conditions with thirty percent abrasive content have demonstrated that polyurethane screens can exhibit a wear life up to three times longer than their steel counterparts. This extended service life is due to the material's inherent elasticity and resistance to abrasion. While the initial cost may be higher, the reduction in change-out frequency and associated labor costs often results in a lower total cost of ownership, making polyurethane a compelling choice for specific applications within the crushing chamber.

Capacity Matching Calculation Methods for Multi-Stage Screening Systems

To achieve a precise separation of aggregates into different size fractions, a multi-stage screening system is deployed after the crushing unit. The design of this system requires careful capacity matching to ensure efficiency. For a target product like 30-80mm coarse aggregate, the screen surface area, mesh aperture, and vibration characteristics must be calculated based on the crusher's output tonnage and the expected size distribution of its discharge.

The optimization of screening efficiency involves analyzing the material's travel speed across the screen deck and the probability of a particle passing through an aperture. If the screen is undersized for the crusher's capacity, material will not have sufficient residence time on the deck, leading to misplaced particles and a blurred separation between size fractions. Properly matching the screen capacity to the crusher's output ensures a sharp, efficient classification, maximizing the yield of on-spec product and reducing the need for re-crushing off-spec material, which is a key factor in the overall crushing ratio and plant economics.

Precision Control of Hammer Screen Gap Adjustment via Hydraulic Systems

Maintaining the optimal gap between the hammer tips and the screen is vital for consistent product sizing. Modern crushers are equipped with precision hydraulic systems that allow for this adjustment to be made quickly and accurately without manual intervention. These systems can control the position of the screen assembly or the rotor with an accuracy within half a millimeter.

The impact of this precise control on product quality is measurable. Statistical analysis of output material has shown that maintaining a consistent gap within this tight tolerance can reduce the standard deviation of the product's particle size distribution by over fifteen percent. This means the final aggregate is more uniform, with fewer oversized rocks and less fine powder. This level of consistency is highly valued in downstream applications like concrete batching, where predictable aggregate properties are essential for structural integrity and mix design accuracy, directly influencing the control over the final discharge size.

Application Case of Intelligent Control Systems in Particle Size Stability

The integration of artificial intelligence and machine learning with traditional PLC controls marks the next step in optimizing crusher performance. These intelligent systems go beyond simple feedback loops; they use historical operational data to predict optimal settings for changing material conditions. By analyzing trends in power consumption, feed rate, and product size, the system can proactively adjust parameters to maintain a steady state.

A practical application of this technology was demonstrated at a large-scale recycling plant. After implementing an AI-driven control system on their hammer crusher circuit, the plant reported a dramatic improvement in product consistency. The proportion of output material meeting the specified size gradation, known as the quality合格率, increased to ninety-eight percent. This improvement was achieved by the system's ability to make micro-adjustments to the rotor speed and feed conveyor rate in real-time, compensating for subtle variations in the hardness and size of the incoming demolition waste. This high level of automation ensures the crusher contributes effectively to the broader goals of C&D waste recycling.