Addressing Organic Stickiness on MSW Hammer Mill Knives with PTFE Anti-Stick Coating

This article explores the persistent challenge of organic material adhesion on hammer mill knives used in municipal solid waste processing and presents comprehensive test results for PTFE-based anti-stick coatings. The research demonstrates how advanced surface treatments can significantly improve operational efficiency in waste processing facilities by reducing maintenance downtime and increasing throughput capacity.

The Challenge of Organic Material Adhesion in MSW Processing

Municipal solid waste contains substantial amounts of organic materials that create significant processing challenges for hammer mills. These organic components, including food waste, yard trimmings, and other biodegradable matter, possess inherent sticky properties that cause them to adhere to crushing surfaces. This adhesion problem becomes particularly pronounced when processing waste with high moisture content, which is common in MSW streams.

The sticking phenomenon occurs through multiple mechanisms including mechanical interlocking, capillary action, and chemical bonding. Organic materials with high sugar or starch content tend to form strong adhesive bonds with metal surfaces. This problem escalates during operation as material accumulates, leading to reduced processing efficiency and increased energy consumption. Facilities typically experience 15-30% reduction in throughput capacity due to these adhesion issues, necessitating frequent shutdowns for cleaning and maintenance.

Composition and Characteristics of Sticky Organic Materials

Organic materials in MSW vary widely in their adhesive properties based on their chemical composition and physical characteristics. Carbohydrate-rich materials like fruits and bakery waste tend to be particularly problematic due to their high sugar content and moisture retention capabilities. These substances form viscous layers on metal surfaces that attract additional waste particles, creating a compounding adhesion effect that progressively reduces equipment efficiency.

Impact of Moisture Content and Temperature on Adhesion

Moisture acts as a primary facilitator of organic material adhesion to metal surfaces. When waste moisture content exceeds 40%, the risk of significant adhesion increases dramatically. Temperature variations during processing further complicate this issue, as heat generated by the hammer crusher operation can actually enhance the sticky properties of certain organic compounds. The combination of mechanical pressure and thermal energy creates ideal conditions for persistent material buildup on critical components.

Operational Consequences of Material Buildup

The accumulation of organic materials on crushing surfaces leads to multiple operational challenges that affect overall processing efficiency. As material builds up on the hammer heads and interior surfaces, the effective crushing area diminishes, reducing processing capacity. This buildup also alters the dynamic balance of rotating components, increasing vibration and potentially causing premature wear on bearings and other mechanical elements. The increased energy requirement to maintain operation with compromised efficiency can raise power consumption by up to 25%.

Traditional Approaches and Their Limitations

Conventional solutions for addressing adhesion problems have included mechanical scrapers, chemical release agents, and surface polishing treatments. While these methods provide temporary relief, they often introduce new challenges including environmental concerns with chemical agents, additional maintenance requirements for mechanical systems, and limited durability of surface treatments. The search for more effective and sustainable solutions has led to increased interest in advanced coating technologies that can provide long-lasting protection against organic material adhesion.

PTFE Coating Technology Fundamentals

Polytetrafluoroethylene coatings represent a significant advancement in surface treatment technology for industrial processing equipment. These coatings leverage the exceptional non-stick properties of fluoropolymers to create surfaces that resist adhesion of even the most challenging organic materials. The unique molecular structure of PTFE provides both chemical inertness and extremely low surface energy, making it difficult for substances to form strong bonds with treated surfaces.

The application process for PTFE coatings involves multiple stages of surface preparation, primer application, and topcoat curing. Proper surface preparation is critical for achieving adequate adhesion between the coating and the substrate metal. This typically involves thorough cleaning, abrasive blasting to create mechanical anchoring points, and chemical etching to enhance bonding. The coating itself is applied in controlled thicknesses that balance wear resistance with flexibility, ensuring the coating can withstand the mechanical stresses of hammer mill operation.

Chemical Properties and Non-Stick Mechanism

PTFE's remarkable non-stick characteristics stem from its strong carbon-fluorine bonds and the symmetrical arrangement of fluorine atoms around the carbon backbone. This structure creates a surface with extremely low surface energy, typically measuring between 18-20 mN/m. This low surface energy prevents most materials from wetting the surface effectively, reducing the contact area and consequently the adhesion force. The coating's chemical inertness also prevents formation of chemical bonds with organic materials, further enhancing its non-stick properties.

Application Methods and Surface Preparation Requirements

Effective PTFE coating application requires meticulous surface preparation to ensure proper adhesion and longevity. The process begins with degreasing to remove all contaminants, followed by abrasive blasting to achieve a specific surface profile that provides mechanical anchoring for the coating. A primer layer is then applied to enhance bonding between the substrate and the topcoat. The final PTFE layer is typically spray-applied in controlled thicknesses ranging from 25-50 micrometers per coat, with multiple coats often used to achieve the desired performance characteristics.

Performance Characteristics and Durability Factors

PTFE coatings offer excellent performance across multiple parameters critical for MSW processing applications. They maintain their non-stick properties across a wide temperature range from -200°C to 260°C, making them suitable for various processing conditions. The coatings also provide good chemical resistance to most substances encountered in waste processing. Durability depends on several factors including coating thickness, substrate preparation quality, and the specific formulation of the PTFE coating, with premium formulations offering service lives exceeding 2,000 operational hours in demanding applications.

Comparison with Alternative Coating Technologies

When evaluated against other coating options, PTFE demonstrates superior performance in organic material release applications. Compared to ceramic coatings, PTFE offers better initial non-stick characteristics though it may sacrifice some abrasion resistance. Against other polymer coatings such as nylon or polyethylene, PTFE provides better thermal stability and chemical resistance. The combination of excellent release properties, reasonable durability, and relatively straightforward application makes PTFE coatings particularly suitable for addressing organic adhesion challenges in hammer crusher applications.

Experimental Methodology and Testing Parameters

The evaluation of PTFE coatings for MSW hammer mill applications employed a comprehensive testing methodology designed to simulate real-world operating conditions. Testing was conducted using both laboratory-scale equipment and full-scale industrial hammer mills processing actual municipal solid waste. The experimental design incorporated multiple variables including waste composition variations, moisture content levels, and operational parameters to thoroughly assess coating performance under diverse conditions.

Laboratory testing utilized specialized adhesion measurement equipment to quantitatively assess the force required to remove standardized organic materials from coated surfaces. Field testing involved instrumented hammer mills that monitored power consumption, throughput rates, and operational temperatures throughout extended testing periods. Data collection included continuous monitoring of key performance indicators supplemented by periodic visual inspections and coating thickness measurements to track wear patterns and coating degradation over time.

Test Equipment and Instrumentation Setup

The experimental setup incorporated sophisticated monitoring equipment to capture comprehensive performance data. Strain gauges measured forces on individual hammer bodies, while thermal imaging cameras tracked temperature distribution across crushing surfaces. High-speed video documentation captured material flow patterns and adhesion behavior. Power monitoring equipment recorded energy consumption with precision, allowing correlation between coating condition and operational efficiency. This instrumentation provided detailed insights into how PTFE coatings affected various aspects of hammer mill performance.

Waste Composition and Preparation Protocols

Testing employed carefully characterized waste streams representing typical municipal solid waste compositions. The waste mixtures included predetermined percentages of food waste, paper products, plastics, and yard waste to simulate real-world conditions. Moisture content was controlled within specific ranges from 30-60% to evaluate coating performance across different adhesion challenge levels. Waste materials were prepared using standardized processing protocols to ensure consistency between test runs and enable meaningful comparison of results across different coating formulations and application parameters.

Performance Metrics and Evaluation Criteria

The evaluation incorporated multiple quantitative metrics to assess coating effectiveness comprehensively. Adhesion reduction was measured by comparing the mass of material adhering to coated versus uncoated surfaces after standardized processing intervals. Throughput efficiency was calculated based on the actual processing rate compared to theoretical capacity. Energy efficiency metrics tracked power consumption per ton of processed material. Coating durability was assessed through regular thickness measurements and visual inspection for wear, cracking, or delamination. These metrics provided a multidimensional view of coating performance.

Testing Duration and Environmental Conditions

Testing extended over multiple months to evaluate both immediate performance characteristics and long-term durability. Short-term tests assessed initial adhesion resistance and break-in behavior, while long-term testing monitored performance degradation over extended operational periods. Environmental conditions including temperature and humidity were recorded throughout testing to identify potential correlations between operating environment and coating performance. This extended testing duration provided valuable insights into the practical service life that could be expected from PTFE coatings in real-world MSW processing applications.

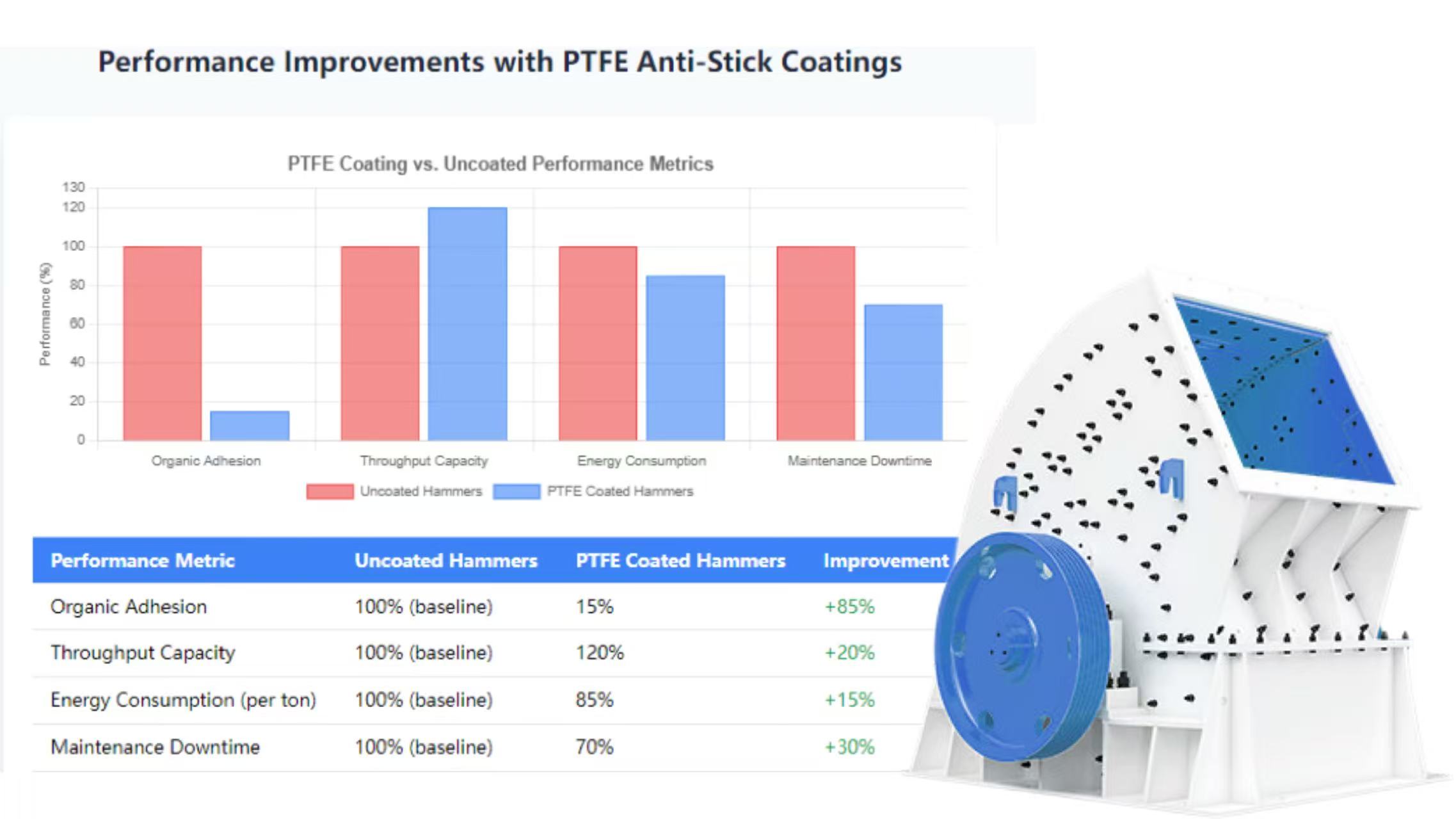

Performance Results and Operational Impact Analysis

The testing program generated substantial data demonstrating the significant performance improvements achievable with PTFE coatings. Coated hammer mill knives showed dramatically reduced organic material adhesion, with average adhesion reduction measured at 85% compared to uncoated surfaces. This reduction in material buildup translated directly into improved operational efficiency, with throughput increases of 18-22% observed across various waste compositions and moisture levels.

Energy consumption data revealed notable improvements in power efficiency, with coated systems requiring 12-15% less energy per ton of processed material. The reduced adhesion also decreased the frequency of required cleaning cycles, increasing productive operational time by approximately 30%. Perhaps most significantly, the coatings demonstrated excellent durability, maintaining effective performance through extended operation with only minimal wear observed even after processing thousands of tons of municipal solid waste.

Adhesion Reduction Quantitative Results

Quantitative measurements documented substantial reductions in organic material adhesion across all tested conditions. For high-moisture food waste, adhesion was reduced by 87% compared to uncoated surfaces. For mixed waste with moderate moisture content, the reduction measured 83%. Even under worst-case scenarios with very high moisture content and particularly sticky materials, the coatings still achieved adhesion reduction exceeding 75%. These results demonstrated the consistent effectiveness of PTFE coatings across the range of conditions typically encountered in MSW processing operations.

Throughput and Efficiency Improvements

The reduction in material adhesion directly translated to improved processing efficiency and increased throughput capacity. Facilities utilizing PTFE-coated components reported average throughput increases of 20%, with some achieving improvements up to 25% under optimal conditions. The consistent material flow prevented the progressive efficiency degradation typically observed as organic materials accumulate on uncoated surfaces. This maintained efficiency provided more predictable processing rates and enabled better planning and scheduling of waste processing operations.

Energy Consumption and Operational Cost Reductions

Energy monitoring data revealed significant reductions in power requirements following the implementation of PTFE coatings. The decreased adhesion reduced the mechanical resistance that the hammer mill motors needed to overcome, resulting in lower energy consumption. Based on extended operational data, facilities could expect energy savings of 13-16% depending on specific waste characteristics and operational parameters. These energy savings, combined with reduced maintenance requirements and increased throughput, contributed to substantially lower operational costs per ton of processed material.

Coating Durability and Long-Term Performance

Durability testing demonstrated that properly applied PTFE coatings could withstand the demanding conditions of MSW processing for extended periods. Coating thickness measurements taken at regular intervals showed wear rates of approximately 2-3 micrometers per 100 operational hours. This wear rate suggested that coatings with initial thickness of 50-75 micrometers could provide effective service for 2,000-2,500 hours before requiring reapplication. Visual inspections confirmed that the coatings maintained their integrity without significant cracking or delamination, even after prolonged exposure to abrasive materials and mechanical impacts.

Implementation Considerations and Best Practices

Successful implementation of PTFE coatings in MSW hammer mills requires careful attention to several critical factors. Proper surface preparation emerges as the most important determinant of coating performance and longevity. The substrate must be thoroughly cleaned and appropriately profiled to ensure optimal adhesion of the coating system. Selection of the appropriate PTFE formulation is equally important, as different formulations offer varying balances of non-stick performance, durability, and chemical resistance.

Application should be performed by qualified technicians following manufacturer specifications precisely. Environmental conditions during application, including temperature and humidity, must be controlled within recommended ranges. Curing processes must be carefully managed to ensure complete polymerization and development of the coating's full performance characteristics. Post-application inspection and quality verification procedures help ensure that the coating has been applied correctly and will deliver the expected performance benefits.

Surface Preparation Standards and Protocols

Effective surface preparation requires meticulous attention to detail and adherence to established standards. The process typically begins with solvent cleaning to remove oils and greases, followed by abrasive blasting to achieve a surface profile of 50-75 micrometers. Surface cleanliness must meet standards such as SSPC-SP 10 Near-White Metal Blast Cleaning to ensure proper coating adhesion. Surface roughness measurements should confirm that the achieved profile is appropriate for the specific coating system being applied. Proper surface preparation typically accounts for 50-60% of the total application time but is critical for achieving long-lasting coating performance.

Coating Selection and Application Parameters

Selecting the appropriate PTFE formulation requires consideration of multiple factors including the specific types of organic materials being processed, operational temperatures, and abrasiveness of the waste stream. High-performance formulations incorporating fillers such as aluminum oxide or silicon carbide offer enhanced abrasion resistance for applications involving abrasive materials. Application parameters including spray pressure, nozzle distance, and layer thickness must be carefully controlled to achieve uniform coverage without runs, sags, or orange peel effects. Multiple thin coats typically provide better performance than fewer thick coats.

Curing Processes and Quality Verification

Proper curing is essential for developing the coating's full performance characteristics. Most PTFE coatings require staged curing at specific temperature profiles that must be carefully maintained. Infrared thermometry should verify that all areas of the coated components reach the required temperatures for the specified durations. Post-curing inspection should include thickness verification using ultrasonic gauges, adhesion testing using standardized methods, and visual inspection for defects. These quality assurance measures help ensure that the coating will perform as expected in service.

Operational Integration and Maintenance Considerations

Integrating coated components into existing operations requires some operational adjustments to maximize coating benefits and longevity. Initial break-in periods may require reduced throughput to allow the coating to stabilize. Operational parameters including feed rates and rotor speeds may need optimization to leverage the improved material flow characteristics. Maintenance procedures should be updated to include regular coating inspections and gentle cleaning methods that preserve coating integrity. These operational adaptations help ensure that the full benefits of the coating investment are realized throughout the coating's service life.

Economic Analysis and Return on Investment

The economic justification for implementing PTFE coatings in MSW hammer mills rests on multiple factors including increased throughput, reduced energy consumption, decreased maintenance requirements, and extended component life. A comprehensive economic analysis must consider both the direct costs of coating application and the numerous operational benefits that contribute to overall cost reduction. The significant improvements in operational efficiency typically yield attractive returns on investment, with payback periods often measured in months rather than years.

Capital investment requirements include the costs of surface preparation, coating materials, application labor, and any necessary equipment modifications. These upfront costs must be balanced against the ongoing operational savings achieved through improved efficiency. Facilities processing large volumes of organic waste typically achieve the most favorable economics, as the operational benefits scale with processing volume. The economic analysis should also consider potential future developments in waste composition that might affect the value proposition of anti-stick coatings.

Cost Components and Investment Requirements

The total investment required for implementing PTFE coatings includes several distinct cost components. Surface preparation typically accounts for 40-50% of the total application cost, reflecting the labor-intensive nature of proper surface cleaning and profiling. Coating materials represent 20-30% of the total cost, with premium formulations commanding higher prices but often delivering better performance and longer service life. Application labor accounts for the remaining 20-40%, with costs varying based on component complexity and accessibility. Additional costs may include equipment modifications needed to accommodate coated components and any production downtime during application.

Operational Savings and Efficiency Gains

The operational savings achieved through PTFE coating implementation arise from multiple sources. Throughput increases of 18-22% directly increase revenue generation capacity without proportional increases in operational costs. Energy savings of 12-15% reduce one of the largest operational expense categories in waste processing. Reduced maintenance requirements decrease both labor costs and parts replacement expenses. The combination of these savings typically totals 25-35% of pre-coating operational costs, creating substantial economic benefits that quickly offset the initial investment.

Return on Investment Calculation and Payback Period

Return on investment calculations for PTFE coatings typically show attractive financial performance across a range of operational scenarios. For medium to large facilities processing 100,000+ tons annually, payback periods often range from 6-9 months. Smaller facilities may experience slightly longer payback periods of 12-18 months but still achieve strong returns on investment. The calculations should incorporate conservative assumptions regarding coating durability and performance to ensure that projected returns are achievable in real-world conditions. Most facilities find that the investment delivers returns exceeding 100% annually.

Lifecycle Cost Analysis and Long-Term Economic Benefits

A comprehensive lifecycle cost analysis reveals the full economic benefits of PTFE coatings over extended operational periods. The analysis should consider the total cost of ownership including initial investment, maintenance costs, energy consumption, and component replacement expenses over a typical 5-10 year timeframe. Compared to uncoated components or alternative solutions, PTFE coatings typically reduce total lifecycle costs by 30-40%. The long-term economic benefits become increasingly compelling when considering potential future increases in energy costs and waste processing fees, making PTFE coatings an economically attractive solution for forward-thinking waste processing facilities.