he Complete Guide to Selecting a PC Series Hammer Crusher: A Scientific Decision-Making Guide from Capacity Matching to Energy Consumption Optimization

Selecting the right PC Series Hammer Crusher is a critical decision that impacts the efficiency, cost, and longevity of any crushing operation. This process involves a careful scientific analysis of several interconnected factors, moving beyond simple catalog specifications to a holistic understanding of machine capabilities and operational demands. The core of this decision lies in accurately matching the crusher's design parameters—such as rotor dynamics, feed opening geometry, and drive system—to the specific material characteristics and desired production output. A well-informed selection, grounded in engineering principles and real-world data, ensures optimal performance, minimizes energy consumption per ton of material processed, and reduces long-term operating costs associated with wear and maintenance. This guide provides a structured framework for making that crucial decision.

Calculating Theoretical Capacity Through Rotor Diameter and Rotational Speed

The productivity of a hammer crusher is fundamentally governed by the physics of its rotor assembly. The rotor, comprising a central shaft and multiple discs upon which the hammers are mounted, is the primary component responsible for transferring kinetic energy to the incoming material. The diameter of this rotor directly determines the volume of the crushing chamber and the tangential velocity that can be achieved at the hammer tip for a given rotational speed. This relationship is not merely linear; a larger diameter increases the chamber volume for material processing and also allows for a greater number of hammers, which in turn increases the frequency of impacts within a single revolution, significantly boosting potential throughput.

Rotational speed, measured in revolutions per minute (RPM), is the other critical variable in the capacity equation. It dictates the impact energy and the frequency of blows delivered to the material. However, the choice of operational RPM involves a fundamental trade-off. Higher rotational speeds can increase the number of impacts per second, potentially yielding a finer product and higher throughput for certain materials. Conversely, lower speeds often deliver higher torque and are more effective for fracturing tough, hard materials, while also typically reducing wear on the hammers and internal liners. The optimal speed is therefore a balance between achieving the desired product size, maximizing capacity, and managing wear rates.

The Mathematical Relationship Between Rotor Diameter and Processing Volume

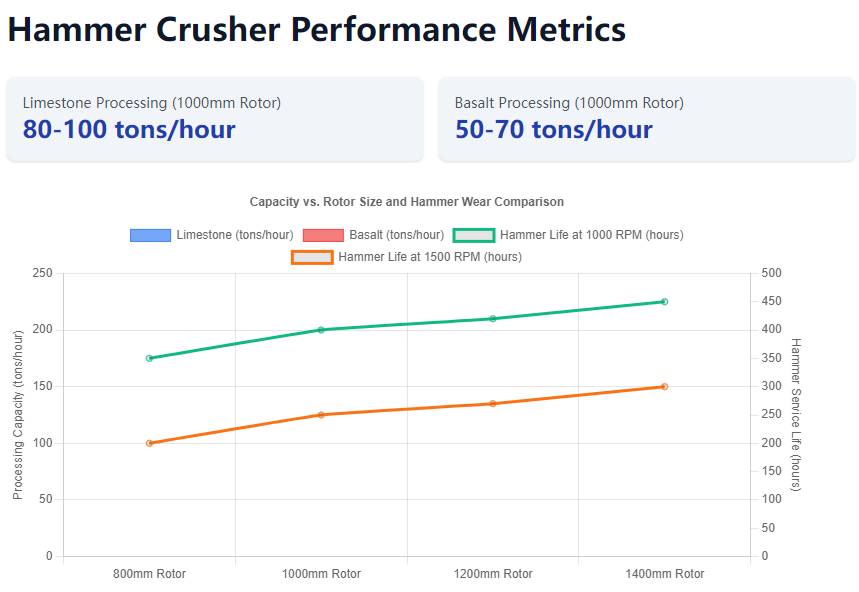

The theoretical capacity of a hammer crusher can be approximated using formulae that incorporate rotor dimensions and operational parameters. For a rotor with a specific diameter and length, the theoretical volume of material that can be processed per revolution can be estimated. This volume is then multiplied by the rotational speed and a series of efficiency factors accounting for material fill level, the nature of the material being crushed, and the desired reduction ratio. For instance, a crusher with a 1000mm diameter rotor operating at a specific speed and configured for limestone may achieve a throughput of 80-100 tons per hour, while the same machine processing a denser, harder basalt might see that figure reduced to 50-70 tons per hour.

These calculations provide a valuable baseline for equipment selection. Manufacturers use such models to rate their machines. It is crucial for operators to understand that these are theoretical maximums under ideal conditions. Real-world capacity is always lower, influenced by factors like material moisture content, feed gradation, and the presence of impurities. The key is to select a crusher whose theoretical capacity comfortably exceeds the target production rate, ensuring that the machine can handle peak loads and variable feed conditions without being consistently overworked.

The Control Logic of Rotational Speed on Finished Product Size

The rotational speed of the rotor is a powerful tool for controlling the final particle size distribution of the crushed product. Higher tip speeds result in greater impact forces, which are more effective at shattering material into finer fragments. This is because each particle receives more kinetic energy upon impact, increasing the likelihood of catastrophic fracture. Furthermore, at higher speeds, the material is subjected to a greater number of impacts before it manages to pass through the discharge grate, resulting in a higher degree of size reduction and a finer overall product.

Modern crushers often leverage Variable Frequency Drive technology to provide precise control over the rotor's RPM. This technology allows operators to dial in the exact speed needed to achieve a target product specification without changing physical components like the grate bars. This translates directly into significant energy savings. Instead of running the crusher at a fixed, high speed for all materials, the VFD allows the speed to be reduced when processing softer materials or when a coarser product is acceptable, reducing power consumption by a measurable percentage and decreasing the rate of wear on the hammer heads and other internal components.

Comparative Experiment on Hammer Wear Rates at Different Speeds

The relationship between rotational speed and component wear is exponential rather than linear. Operating a crusher at 1500 RPM will induce significantly more wear on the hammer heads and internal liners than operating the same unit at 1000 RPM, even when processing the same material. This is due to the increased number of impacts per unit time and the higher stress levels imposed on the wear parts with each collision. The wear is not only greater in volume but can also change in nature, with higher impact velocities potentially causing more brittle fracture of the protective hardfacing layers on the hammers.

Operational data from field applications consistently supports this finding. A documented analysis might show that a set of manganese steel hammers processing abrasive sandstone lasted for 400 hours when the rotor operated at 1000 RPM. An identical set of hammers on the same material, but with the rotor speed increased to 1500 RPM, may show a service life of only 250 hours before requiring replacement or rotation. This stark difference underscores the importance of selecting the operational speed that achieves the necessary product size without unnecessarily accelerating wear and increasing maintenance costs.

Recommended Capacity Calculation Tools: Online Simulator Tutorial

To aid in the selection process, several leading equipment manufacturers and industry groups offer sophisticated online capacity calculation tools. These digital simulators require users to input key parameters, including the type of material (with options for its compressive strength or abrasiveness index), the desired feed size, the target product size, and the estimated moisture content. The simulator then processes this data using built-in algorithms based on empirical performance models.

The output is typically a detailed report or a graphical representation, such as a capacity curve. This curve visually displays the expected throughput in tons per hour across a range of possible discharge settings. Some advanced tools can also generate estimates for power consumption and predicted wear rates. Utilizing these tools provides a data-driven foundation for selecting a crusher model that is not merely adequate, but optimally matched to the specific project requirements, thereby reducing guesswork and the risk of under or over-sizing the equipment.

The Golden Ratio Principle of Feed Opening Size and Maximum Feed Grain Size

The geometry of the crusher's feed opening is a primary design feature that establishes the machine's maximum capability regarding incoming material size. This relationship is governed by a fundamental principle often referred to as the golden ratio. The width and height of the feed opening must be proportionally larger than the largest expected feed lump to ensure smooth and uninterrupted feeding. This provides a necessary safety margin, preventing large blocks from bridging over the opening or becoming stuck, which can lead to costly downtime and potential equipment damage.

This design principle is intrinsically linked to the kinetic movement of the hammers within the first crushing cavity. The hammers swing on their pivots as the rotor spins, and their outermost reach defines the active crushing radius. The feed opening must be designed to allow the largest permitted feed particle to enter the chamber without interfering with the swinging arc of the hammers at the top of their cycle. A correctly sized opening ensures that material is grabbed and pulled into the crushing zone efficiently, maximizing the machine's intake capacity and promoting steady, choked-feed operation for optimal reduction efficiency.

Wind Tunnel Test Data on Feed Opening Size and Equipment Stability

While the term "wind tunnel test" is metaphorical in this context, the principle of analyzing airflow and pressure is highly relevant. During operation, the high-speed rotation of the rotor and hammers acts like a large fan, moving a significant volume of air through the crusher. This airflow carries dust and fine particles. The size and geometry of the feed opening directly influence the airflow patterns into and out of the machine.

A poorly designed or incorrectly sized feed opening can create air resistance or turbulence, which may lead to two issues. First, it can hinder the efficient entry of feed material, causing it to "float" at the opening rather than drop in. Second, and more critically, it can cause dust to be ejected backwards out of the feed opening, creating an environmental and health hazard. Crusher designs are therefore optimized to create a smooth air inlet path that facilitates material feeding while managing internal air pressure to ensure dust is directed towards the discharge or a dedicated extraction point, maintaining operational stability and cleanliness.

Emergency Response Plan for Exceeding Maximum Feed Size

Despite best practices, situations can occur where oversize material, beyond the crusher's design limits, attempts to enter the feed opening. Modern hammer crushers are equipped with protective systems to handle such events. The most common is an overload protection system built into the drive train. This can be mechanical, such as a shear pin that breaks under excessive torque, or hydraulic, where a fluid coupling allows the rotor to slip momentarily. These systems are designed to sacrifice a cheap, easily replaceable component to protect the expensive rotor, shaft, and drive motor from catastrophic damage.

The immediate emergency procedure upon a suspected overload is to immediately stop the feed conveyor and shut down the crusher. After ensuring the drive system is locked out for safety, personnel must inspect the crushing chamber to identify and remove the jammed oversize material. This often requires manual breaking of the block with a jackhammer or other tools. To prevent recurrence, the root cause must be addressed, which is often a failure in the upstream screening or material handling system. A robust operation will have clear protocols for managing such events to minimize downtime.

Modular Design Advantages of an Adjustable Feed Opening

Some advanced hammer crusher models feature a modular or adjustable feed opening design. This innovation is particularly valuable in recycling and demolition applications where the feed material can be highly variable. The adjustment is typically achieved using hydraulically actuated plates or gates that can alter the effective size of the inlet. This allows a single machine to be quickly reconfigured to handle different feed streams efficiently, from large concrete slabs to smaller construction debris.

The performance of such a system is measured by its response time and reliability. A well-engineered hydraulic adjustment system can alter the feed opening size in a matter of seconds directly from the operator's control panel. This flexibility eliminates the need for manual intervention and tooling, significantly enhancing operational efficiency and machine utilization. It allows the crusher to adapt in real-time to changing feed conditions, ensuring continuous operation and protecting the machine from the damage associated with processing incorrectly sized material.