Pre-Granulation Crushing of Dried Poultry Manure: Hammer Mill Screen Size and Temperature Control

This article details the crushing process for dried poultry manure before granulation, emphasizing hammer mill screen size selection and temperature management—key factors for achieving optimal discharge size and maintaining material quality. Proper practices ensure the crushed manure meets granulation requirements, directly impacting pellet strength and production efficiency.

Characteristics of Poultry Manure and Crushing Process Requirements

Dried poultry manure is a complex material with fibrous content (5-15%) and variable hardness (depending on drying degree), requiring a crusher that balances shearing and impact forces. It must be crushed to a specific size range (1-3 mm) to facilitate efficient granulation—too fine, and dust issues arise; too coarse, and granulation fails due to poor binding. This size requirement demands precise control of the hammer mill’s crushing ratio to avoid over- or under-crushing.

Temperature control during crushing is critical to prevent organic matter degradation: high temperatures (>60°C) can cause protein denaturation or loss of volatile nutrients (e.g., nitrogen), reducing the manure’s fertilizing value. Dust and odor must also be managed—enclosed hammer mills with dust collection systems protect operators from inhalation risks, while odor suppressants maintain workplace safety. Understanding these requirements guides the selection of hammer mills and operation parameters for pre-granulation crushing.

Hardness and Brittleness Analysis of Dried Manure

Dried manure is brittle but may contain tough fibers (e.g., feather fragments) that resist crushing. This requires a hammer mill with both impact and cutting capabilities to ensure uniform size reduction.

Relationship Between Fiber Content and Crushing Difficulty

High fiber content (>10%) can wrap around hammer mill rotors or block screens, increasing downtime. Crushers with anti-wrapping rotor designs handle fibrous manure more effectively.

Influence of Target Particle Size on Pelletization Rate and Pellet Strength

Particles between 1-3 mm promote optimal binding during granulation, yielding pellets with 90%+ strength retention. Uniform sizes reduce reprocessing and improve granulator throughput.

Dust and Odor Control Requirements During Crushing

Enclosed hammer mills with negative-pressure dust collection systems capture fine particles. Biofilters or chemical odor neutralizers manage ammonia-based odors, complying with environmental standards.

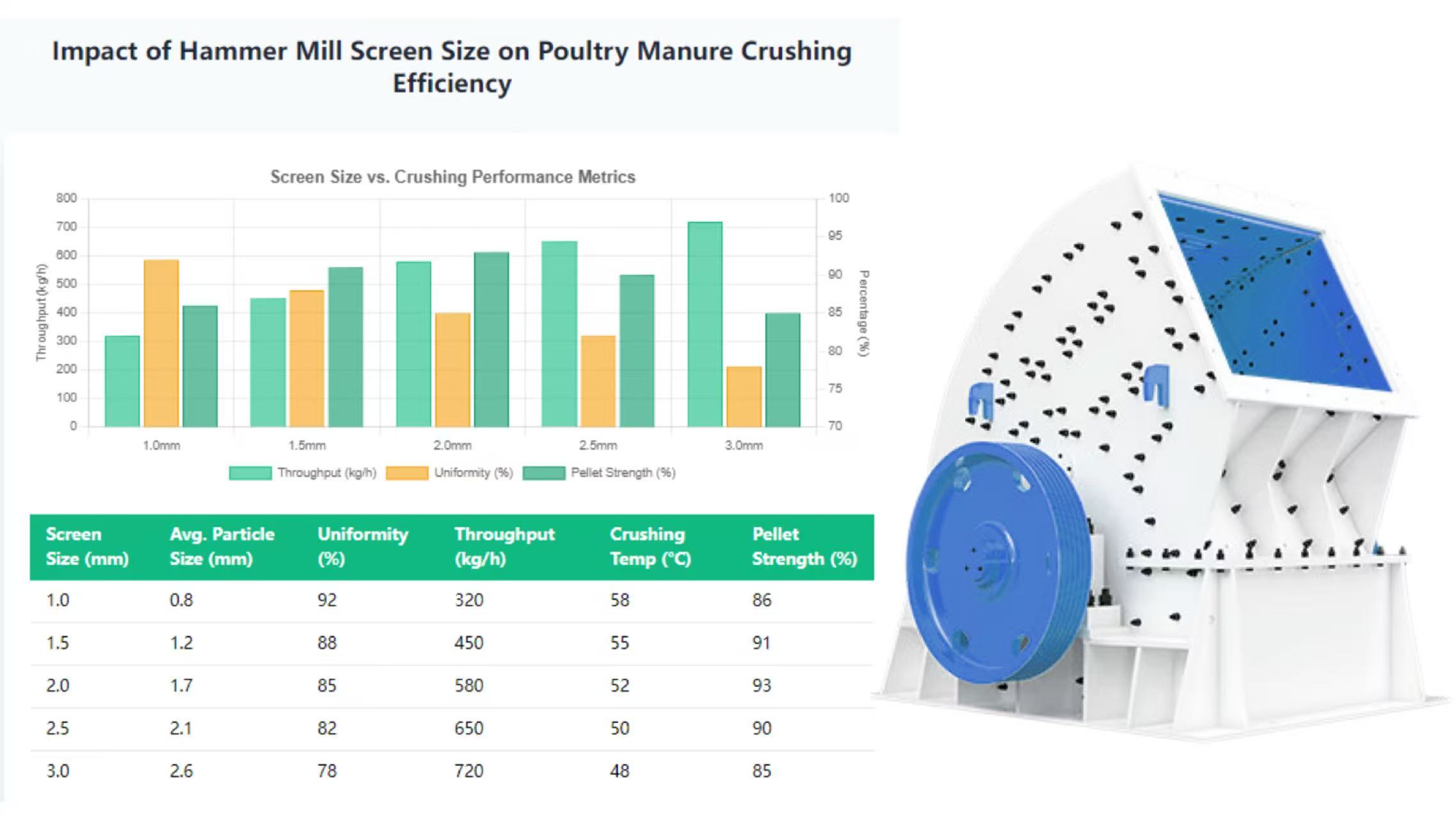

Principles for Selecting Hammer Mill Screen Size

Screen size in hammer mills directly determines the discharge size of crushed manure—larger screen openings (3-4 mm) produce coarser particles, while smaller openings (1-2 mm) yield finer materials. The screen’s open area (percentage of total screen area occupied by holes) also impacts performance: higher open areas (40-50%) increase throughput by allowing more material to pass, but require careful matching to the manure’s feed size (typically 5-10 mm for dried manure) to avoid clogging.

Material selection for screens is equally important: stainless steel screens resist corrosion from manure’s acidic components (pH 6.0-7.5) and are easier to clean than carbon steel. Wear-resistant coatings (e.g., chromium plating) extend screen life, especially for high-volume operations. Regular inspection (e.g., checking for hole deformation or fiber buildup) and replacement (when hole size deviates by >20%) prevent size drift, ensuring the crushed manure meets granulation standards.

Correspondence Between Screen Aperture and Crushing Size

Screen hole diameter directly limits maximum particle size—e.g., a 2 mm screen produces particles ≤2 mm, with 80% falling in the 1-2 mm range due to attrition in the mill.

Impact of Open Area on Capacity and Energy Consumption

Screens with 45% open area handle 20-30% more manure than those with 30% open area, but require 5-10% more power to maintain rotor speed. Balancing open area with energy use optimizes efficiency.

Screen Material and Wear Resistance Requirements

304 stainless steel screens resist corrosion and manure adhesion. For heavy use, 316 stainless steel with 0.1 mm hard chrome plating extends service life by 50%.

Frequency and Standards for Screen Replacement

Screens are replaced when hole edges become rounded (reducing size control) or when 10% of holes are clogged with hardened manure. Monthly inspections ensure timely replacement.

Importance and Methods of Crushing Temperature Control

Temperature rise during crushing (caused by friction between manure, hammers, and screen) can damage organic materials—keeping temperatures below 60°C preserves the manure’s nutrient content and granulation performance. One key method is adjusting rotor speed: slower speeds (1200-1500 rpm) reduce friction-based heating, though they may require longer residence time in the mill to achieve target size.

Air cooling systems further manage temperature: axial fans mounted on the mill housing blow ambient air through the crushing chamber, dissipating heat and reducing moisture (critical for preventing manure clumping). Temperature sensors (e.g., infrared probes) mounted near the discharge track surface temperatures in real time, sending data to a control system that adjusts fan speed or rotor speed automatically. These measures ensure consistent temperature control, even during long production runs.

Impact of Temperature Rise on Material Nutrient Content

Temperatures >60°C cause 5-10% nitrogen loss via volatilization. Maintaining temperatures at 45-55°C preserves nutrients while ensuring effective crushing.

Relationship Between Rotor Speed and Crushing Heat Generation

Rotor speeds >1800 rpm increase friction, raising chamber temperatures by 15-20°C. Speeds of 1300-1600 rpm balance heat control and size reduction efficiency.

Design and Installation Points for Air Cooling Systems

Fans with adjustable speed (500-1500 rpm) direct air across the screen and rotor. Ducting with adjustable dampers ensures even air distribution, avoiding cold spots that cause moisture condensation.

Infrared Temperature Measurement and Automatic Control Systems

Infrared sensors with ±1°C accuracy monitor chamber temperatures. PLC systems adjust fan speed or feed rate if temperatures exceed 58°C, preventing overheating.

Operational Strategies to Prevent Adhesion and Clogging

Even dried poultry manure (moisture 8-12%) can be slightly sticky, leading to screen clogging and reduced throughput. Anti-clogging designs in hammer mills include self-cleaning hammers with curved edges that scrape manure from the screen during rotation, and tapered screen holes (wider on the inlet side) that prevent material from wedging. Internal chamber surfaces are polished to Ra 0.8 μm to reduce adhesion, minimizing buildup on walls.

Operational practices further reduce clogging: controlled feed rates (matched to mill capacity) prevent overloading, while periodic "reverse air blasts" (10-15 seconds every 30 minutes) clear fine manure from screen holes. After shutdown, thorough cleaning with compressed air (5-7 bar) removes residual manure—this prevents hardening of residues that can cause blockages in subsequent runs. These strategies maintain continuous operation and consistent particle size for granulation.

Anti-Clogging Design: Self-Cleaning Hammers and Tapered Screens

Hammers with 15° curved edges sweep material from screens. Tapered holes (2 mm inlet, 1.8 mm outlet) reduce wedging and improve material flow.

Polishing and Anti-Stick Coatings for Internal Walls

Chamber walls are polished to mirror finish, reducing manure adhesion by 30%. Food-grade Teflon coatings (applied annually) further minimize buildup.

Regular Cleaning and Inspection Procedures

Operators inspect screens hourly for clogging, using soft brushes to remove surface buildup. Daily shutdowns include full chamber cleaning with compressed air and screen hole verification.

Humidity Monitoring and Auxiliary Drying Measures

Hygrometers in the mill inlet track manure moisture. If moisture exceeds 12%, auxiliary hot-air dryers (50-60°C) pre-dry the manure before crushing, reducing stickiness.

Synergistic Optimization Between Hammer Mill and Subsequent Granulation

The hammer mill must be integrated with the granulation process to ensure efficiency—crushed manure size must match the granulator’s die hole size (typically 3-5 mm) to avoid jamming or poor pellet formation. A buffer silo between the mill and granulator smooths material flow, preventing surges that disrupt granulator operation and ensuring consistent crushing capacity alignment with granulation speed.

Recycling oversize particles (from granulator screening) back to the hammer mill improves overall yield: a closed-loop system routes 5-10% of oversize material (4-6 mm) for re-crushing, reducing waste and ensuring uniform feed to the granulator. Automation links the two processes: granulator load sensors send data to the hammer mill’s control system, adjusting rotor speed or feed rate to maintain optimal particle size—if the granulator slows, the mill reduces output to prevent overflow, and vice versa.

Matching Crushing Size with Granulator Die Holes

Crushed manure size should be 60-80% of the die hole diameter—e.g., 2 mm manure for 3 mm die holes—to ensure proper compaction and pellet strength.

Material Handling and Buffer System Design

Buffer silos with 1-2 hours of capacity absorb fluctuations in mill output. Screw conveyors with variable speed control feed manure to the granulator at a steady rate.

Recycling and Crushing of Return Materials

Oversize particles from granulator screening are crushed with a 2.5 mm screen, then blended with fresh crushed manure (1:5 ratio) to maintain size consistency.

System Automation Control and Data Linkage

PLC systems integrate mill and granulator data, adjusting mill speed based on granulator throughput. HMI dashboards display real-time particle size, temperature, and feed rate for operators.

Environmental, Safety, and Hygiene Compliance Requirements

Processing poultry manure requires strict adherence to environmental and safety standards—enclosed hammer mills with sealed lower housings prevent manure dust escape, while centralized dust collection systems (e.g., baghouses with HEPA filters) capture 99.9% of fine particles, complying with occupational exposure limits (OELs) for organic dust (<10 mg/m³).

Odor control is managed via biofilters: air from the mill and granulator is passed through a bed of compost or activated carbon, reducing ammonia and hydrogen sulfide levels by 80-90%. Equipment hygiene is critical—weekly washdowns with hot water (80°C) and food-grade disinfectants prevent pathogen growth (e.g., Salmonella, E. coli), ensuring the final fertilizer product meets safety standards. Operators wear personal protective equipment (PPE): dust masks, gloves, and eye protection minimize exposure to manure dust and odors.

Enclosed Crushing and Dust Collection Systems

Enclosed mills with negative pressure (-50 Pa) prevent dust leakage. Baghouses with 5 μm filters capture fine particles, which are recycled back to the mill to reduce waste.

Odor Control and Biological Safety Protection

Biofilters with 1.5 m depth of compost media treat 1000 m³/h of air, reducing odor intensity by 85%. UV disinfection systems post-treat air to kill pathogens.

Equipment Cleaning and Disinfection Procedures

Monthly deep cleaning includes disassembly of mill screens and hammers, with soaking in 5% sodium hypochlorite solution. Daily wipe-downs with quaternary ammonium disinfectants prevent microbial buildup.

Operator Health and Safety Protection

Operators use N95 dust masks, nitrile gloves, and face shields. Annual air quality testing ensures compliance with OELs, and health screenings monitor respiratory health.