PC Series Hammer Crusher Hammer Head Life Management Guide: A Scientific System from Wear Monitoring to Replacement Decisions

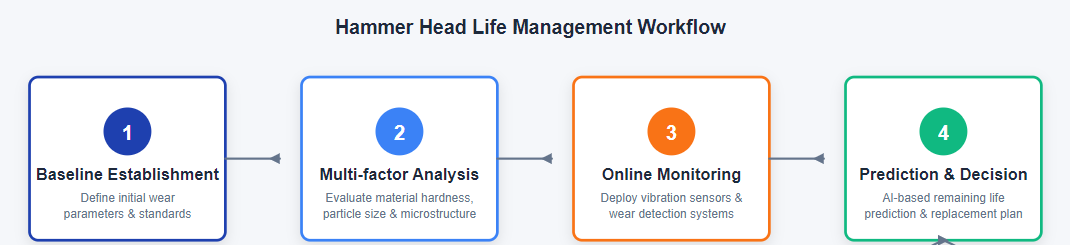

Maintaining optimal performance in a hammer crusher requires a deep understanding of its most critical wear component: the hammer head. Unplanned downtime for replacements and the cost of the hammers themselves represent a significant portion of operating expenses. A scientific approach to life management moves beyond simple hour-based schedules to a condition-based predictive model. This guide explores the multifaceted factors influencing wear rates, the deployment of advanced online monitoring systems, and the integration of data analytics to create a comprehensive framework for maximizing hammer life and making informed, cost-effective replacement decisions.

Analysis of Multiple Factors Influencing Hammer Head Wear Rate

The rate at which a hammer head wears down is not constant; it is the product of several interacting variables. The hardness of the processed material stands as the primary determinant, with wear increasing exponentially rather than linearly as hardness rises. An established exponential regression model describes this relationship, showing that processing material with a hardness of seven on the Mohs scale can cause wear rates more than double those observed with a hardness of five. This model allows operators to predict wear based on the known properties of their feed stock.

Beyond bulk hardness, the size distribution of the incoming feed plays a crucial role in localized wear patterns. A feed dominated by large, coarse particles delivers concentrated impact energy to specific points on the hammer head, rather than distributing the force evenly across its surface. This focused energy transfer accelerates the formation of grooves, notches, and deformation at these impact points, significantly shortening the component's effective service life compared to processing a well-graded feed with a variety of particle sizes that promote more uniform wear.

Material Hardness Classification Standards and Corresponding Wear Coefficient Table

To standardize wear predictions, materials are systematically classified by their abrasiveness and hardness. International standards provide clear classifications, and these are correlated with specific wear coefficients used in engineering calculations. For materials falling within the Mohs hardness range of five to seven, which includes many abrasive rocks and ores, detailed wear rate data has been compiled. This data shows a predictable increase in mass loss per ton of material processed, providing a quantitative basis for forecasting hammer head consumption and planning inventory.

The wear coefficient for a given material is not a single value but a range, accounting for variations in mineral composition and internal structure. For instance, a silicate rock at Mohs hardness six might exhibit a twenty percent higher wear rate than a carbonate rock of the same hardness due to differences in crystal structure and sharpness. These nuanced values are critical for creating accurate life expectancy models for hammer heads in specific applications, moving from rough estimates to precise forecasts.

Feed Particle Size CDF Curve and Wear Hotspot Prediction

The Cumulative Distribution Function curve of the feed material provides a statistical portrait of its size composition. Analyzing this CDF curve allows engineers to predict not just how fast a hammer will wear, but where that wear will be most severe. A feed curve skewed towards larger particles indicates a high probability of concentrated impact forces on the outer tips and leading edges of the hammers. This is where wear hotspots are most likely to develop.

Finite Element Analysis software is employed to model these impacts virtually. FEA simulates the kinetic energy transfer when a large particle strikes the hammer head at operational rotor speeds. The analysis reveals stress concentration points that are invisible during operation but are the initiation sites for cracks and material loss. By correlating the feed CDF with FEA results, maintenance teams can predict the location of wear hotspots and even schedule pre-emptive inspections or plan for targeted hardfacing repairs during maintenance windows, optimizing the use of the crushing chamber components.

Correlation Between Hammer Head Material Microstructure and Wear Mechanisms

The resistance of a hammer head to wear is fundamentally rooted in its microscopic structure. High-chromium iron and alloy steel hammers derive their properties from their heat-treated microstructure. The presence of martensite, a very hard and brittle phase, is crucial for resisting abrasion. Research has established a clear influence law: as the martensite content increases within a specific range, the material's resistance to abrasive wear improves significantly.

However, this relationship has limits. An excessively high martensite content, while maximizing hardness, can drastically reduce the material's toughness, making it susceptible to catastrophic impact fracture. The optimal microstructure is therefore a careful balance, often featuring a tough base material like tempered martensite with a dispersion of extremely hard carbides. This combination resists both the gouging caused by large impacts and the gradual scratching from abrasive minerals, ensuring the hammer body and head work in unison to withstand complex loading.

Wear Rate Prediction Algorithm Under Multi-Factor Coupling

Predicting wear in a real-world environment requires an algorithm that can process the coupling of multiple variables simultaneously. Simple models based on a single factor like material hardness are insufficient. Modern prediction algorithms incorporate data on feed size distribution, material moisture content, crusher rotor speed, and hammer head material properties. These factors are weighted and processed together to generate a dynamic wear rate prediction.

The most advanced systems employ machine learning models that are trained on historical operational data. These models continuously improve their accuracy by comparing their predictions against actual measured wear from inspections and sensor data. Validation studies have shown that such ML-based models can predict remaining useful life with an accuracy exceeding ninety percent, transforming maintenance from a reactive cost center into a predictable, planned operation. This allows for the optimal scheduling of replacements during planned shutdowns, avoiding costly unplanned downtime and ensuring consistent crushing capacity.

Deployment and Data Interpretation of Online Wear Monitoring Systems

The transition from theoretical wear models to practical management requires real-time data, which is provided by online monitoring systems. These systems use physical sensors attached to the crusher to continuously track its condition. The placement of these sensors is a science in itself, as their position directly affects their sensitivity to the subtle vibrational signatures that indicate wear. A sensor placed on a main bearing housing will capture different information than one mounted directly on the crusher's frame, each providing a unique piece of the diagnostic puzzle.

The core of these systems is the established quantitative relationship between measurable vibration characteristics and the physical wear of the hammer heads. As hammers wear down, their mass decreases and their balance changes, altering the dynamic forces acting on the rotor. These changes manifest as specific shifts in the vibration spectrum. A model correlates the amplitude of vibrations at specific frequencies with the degree of mass loss on the hammers, turning abstract vibration data into a concrete metric of remaining life and providing an early warning for the rotor assembly.

Optimal Layout Scheme for Triaxial Vibration Sensors

Triaxial vibration sensors, capable of measuring movement in three perpendicular directions, provide the most comprehensive data for condition monitoring. The optimal layout involves mounting sensors at key points on the crusher's main frame and bearing housings to capture the full range of forces generated by the rotating assembly. These locations are chosen based on structural dynamics to ensure the clearest transmission of signals from the source of the impact events within the crushing chamber.

The data from these sensors reveals distinct spectral energy distributions corresponding to different wear stages. In the early life of a new set of hammers, the vibration spectrum is characterized by specific harmonic frequencies of the rotor speed. As wear progresses, the spectrum evolves; the energy at the fundamental harmonics may decrease while new frequencies emerge, indicating imbalance and the development of asymmetric wear patterns. This evolution provides a clear fingerprint of the wear state, allowing for precise tracking of the degradation process over time.

Anti-Interference Design Essentials for Wireless Transmission Modules

In harsh industrial environments like coal mines or quarries, reliable data transmission from sensors is a significant challenge. Wireless transmission modules must be designed to operate reliably amidst powerful electromagnetic interference from large motors, variable frequency drives, and switching equipment. This requires robust anti-interference design, including shielded enclosures, frequency hopping spread spectrum technology, and error-correcting data protocols.

Rigorous testing under simulated and real-world conditions is essential. In underground coal mining applications, for example, modules are tested for data stability amidst the dense electromagnetic noise. Successful designs maintain a data packet success rate above ninety-nine point nine percent, ensuring that the critical information on hammer wear is transmitted faithfully to the control system without loss or corruption, enabling continuous protection of the crusher unit.

Cloud Analysis Platform Functions for Wear Monitoring Data

The raw data from vibration sensors is transmitted to a cloud-based analysis platform where its true value is unlocked. This platform aggregates data from multiple crushers across different sites, providing a centralized view of equipment health. Its core functions include advanced signal processing to filter out background noise, feature extraction to identify the key indicators of wear, and trend analysis to project future condition.

The most advanced feature is an AI algorithm that automatically generates replacement Early Warning Report. The logic behind this algorithm involves continuously comparing real-time vibration features against historical failure data and the wear prediction models. When the system detects a pattern that precedes a known failure mode or predicts that wear will exceed a critical threshold within a certain time frame, it automatically generates and disseminates an alert. This alert includes the specific diagnosis, the predicted remaining useful life, and a recommended action, enabling proactive maintenance planning.

Data Docking Process Between Monitoring System and ERP System

For the predictive data to drive business outcomes, it must be integrated into the company's Enterprise Resource Planning system. This integration creates a seamless workflow from condition detection to logistical action. The Docking Process begins when the cloud monitoring platform generates a high-confidence wear alert. This alert is not just an email; it is a structured data packet formatted specifically for the ERP's API.

Upon receipt, the ERP system can automatically trigger a pre-defined workflow. This workflow may include generating a purchase order for a replacement set of hammer heads, reserving the required inventory from stock, scheduling a maintenance window on the production calendar, and assigning the task to the appropriate maintenance crew. This automated trigger mechanism closes the loop between data and action, ensuring that a technical insight leads directly to a prepared response, minimizing downtime and streamlining the operational logistics for aggregate processing and other applications.