Hammer Crusher Applications in Mine Tailings Processing: Comprehensive Technical Solutions and Case Studies

Mine tailings management represents a critical challenge and opportunity in modern mining operations, requiring innovative approaches to transform waste materials into valuable resources. This comprehensive analysis explores the application of hammer crushers in tailings processing, covering material characteristics, equipment selection, system design, operational performance, and economic viability. The integration of hammer crusher technology enables mining operations to address environmental concerns while creating new revenue streams from previously discarded materials.

Global mining operations generate approximately 10-15 billion metric tons of tailings annually, creating significant storage challenges and environmental liabilities. Hammer crushers offer a robust solution for tailings processing due to their high-impact crushing mechanism, adaptability to varying moisture content, and ability to produce controlled particle sizes for different applications. The technology has demonstrated particular effectiveness in processing brittle tailings materials common in metallic and industrial mineral operations.

Physical Characteristics and Processing Challenges of Mine Tailings

Mine tailings possess unique physical and chemical properties that differentiate them from primary ores and conventional construction materials. Understanding these characteristics is essential for designing effective processing systems and selecting appropriate equipment configurations. The heterogeneous nature of tailings requires specialized approaches to ensure efficient processing and optimal product quality.

Tailings materials typically exhibit wide variations in particle size distribution, moisture content, and mineral composition depending on the original ore characteristics and beneficiation processes employed. These variations directly influence processing equipment selection and operational parameters, necessitating thorough characterization before system design.

Particle Size Distribution and Moisture Content Characteristics

Tailings particles generally range from coarse sand-sized materials measuring 2-0.5 mm to fine silt and clay particles below 0.075 mm. The specific distribution varies significantly between operations, with some tailings streams containing up to 60% fines content. Moisture levels typically range from 15-25% in thickened tailings to 40-60% in conventional slurry deposits, directly impacting processing approaches and equipment selection.

The presence of moisture affects material handling properties and crushing efficiency, requiring equipment capable of processing damp materials without clogging. Hammer crushers demonstrate particular effectiveness in handling materials with moderate moisture content due to their impact-based crushing action and self-cleaning characteristics. The equipment's ability to process materials with moisture content up to 15% without significant efficiency loss makes it suitable for many tailings applications.

Mineral Composition and Abrasive Wear Mechanisms

Tailings often contain significant quantities of hard minerals including quartz, feldspar, and various metal oxides that contribute to equipment wear. Quartz content frequently ranges between 20-40% in metallic ore tailings, with hardness values of 7 on the Mohs scale. These abrasive components accelerate wear on crushing elements, necessitating robust materials and strategic design to maintain operational efficiency.

The wear mechanism in hammer crushers involves both impact abrasion from direct particle contact and erosion from fine particles moving at high velocity. Hammer heads and liner plates experience the most significant wear, with service life typically ranging from 500-1500 operating hours depending on material abrasiveness. Advanced wear-resistant materials including high-chromium iron alloys can extend component life by 30-50% compared to standard manganese steel.

Adhesive Properties and Equipment Clogging Risks

Clay minerals present in many tailings deposits, particularly those from weathered ore bodies, create adhesive challenges during processing. Montmorillonite and illite clays can absorb significant moisture, increasing material viscosity and promoting adherence to equipment surfaces. This adhesion potential necessitates specialized design features to prevent material buildup and maintain continuous operation.

Hammer crushers address adhesion challenges through several design features including large crushing chambers, optimized hammer geometry, and strategic screen plate configurations. The centrifugal action created by rotor rotation helps prevent material accumulation, while impact forces break apart agglomerated particles. These characteristics make hammer crushers particularly suitable for processing tailings with clay contents up to 15-20%.

Particle Shape Requirements for Resource Utilization

Different tailings utilization pathways impose specific requirements on crushed product characteristics. Construction applications including brick manufacturing typically require cubical particles with controlled fines content, while backfill operations may prioritize specific size distributions for optimal compaction. The particle shape produced by hammer crushers generally exhibits higher angularity compared to other crushing technologies, enhancing interlocking in compacted applications.

The impact crushing mechanism of hammer crushers produces particles with fractured surfaces that improve bonding characteristics in cementitious applications. This feature proves particularly valuable for tailings destined for construction materials, where particle morphology influences final product strength and durability. Controlled crushing parameters can optimize these characteristics for specific end-use requirements.

Technical Advantages and Applicability of Hammer Crushers for Tailings Processing

Hammer crushers offer distinct technical benefits for tailings processing applications, combining high reduction ratios with operational flexibility and reliability. The technology's fundamental operating principles align well with the physical characteristics of most tailings materials, enabling efficient processing across diverse applications.

The versatility of hammer crushers allows adaptation to varying feed conditions and product requirements, making them suitable for both fixed plant installations and mobile processing operations. This flexibility proves particularly valuable in tailings reprocessing scenarios where feed characteristics may change throughout the project lifecycle.

High-Speed Impact Crushing for Efficient Liberation of Brittle Tailings

The operating principle of hammer crushers involves high-velocity impact between rotating hammers and feed material, generating sufficient energy to fracture particles along natural cleavage planes. Rotor tip speeds typically range between 35-45 m/s, creating impact forces adequate for liberating valuable minerals from gangue materials in tailings. This mechanism proves particularly effective for siliceous and other brittle tailings common in hard rock mining operations.

Impact crushing produces higher reduction ratios per processing stage compared to compression-based technologies, often achieving 15:1 to 20:1 in a single pass. This characteristic reduces the number of processing stages required to achieve target product sizes, simplifying system layout and reducing capital investment. The rapid fracture mechanism also minimizes overgrinding, preserving particle integrity for downstream applications.

Adjustable Grate for Precise Product Size Control

Hammer crushers incorporate adjustable grate assemblies that control product size by determining the retention time of material within the crushing chamber. Grate openings can typically be adjusted between 3-30 mm depending on crusher size and application requirements. This adjustability enables operators to produce different product specifications from the same feed material, enhancing operational flexibility.

The grate design also influences crusher capacity and power consumption, with smaller openings increasing retention time and reducing throughput. Modern hammer crushers feature quick-adjustment mechanisms that enable operators to modify product size specifications within minutes, facilitating rapid response to changing production requirements. This capability proves valuable in tailings processing operations targeting multiple product markets.

Moisture Tolerance and Anti-Clogging Structural Design

Hammer crushers demonstrate superior performance in processing materials with elevated moisture content compared to other crushing technologies. The combination of impact forces and air movement created by rotor rotation helps prevent material agglomeration and adhesion to internal surfaces. Specialized designs incorporating oversized discharge areas and reduced dead zones further enhance wet material processing capability.

Anti-clogging features include reversible rotors that enable rotation direction reversal to clear potential blockages, and segmented grate plates that can be removed individually for maintenance. These design elements reduce downtime and maintenance requirements, improving overall operational availability in challenging tailings processing environments. The robust construction ensures reliable operation even with abrasive, damp materials.

Wear-Resistant Material Technology for Extended Component Life

Advanced materials significantly enhance the service life of critical hammer crusher components operating in abrasive tailings applications. High-chromium iron alloys containing 20-30% chromium demonstrate hardness values of 58-65 HRC with exceptional wear resistance. These materials maintain their protective properties through extensive service, reducing replacement frequency and associated downtime.

Composite materials incorporating ceramic inserts or hardfacing overlays provide additional wear protection in high-impact areas. The economic analysis of material selection must consider both initial cost and total life cycle expense, with premium materials often delivering lower cost per ton processed despite higher initial investment. Proper material selection can reduce operating costs by 15-25% in highly abrasive applications.

Selection and Configuration of Tailings-Specific Hammer Crushers

Optimal hammer crusher selection for tailings applications requires careful consideration of multiple technical parameters and operational requirements. The configuration must align with specific processing objectives while accommodating the unique characteristics of tailings materials.

Professional equipment selection involves balancing capital investment with operational efficiency, maintenance requirements, and product quality objectives. The comprehensive approach ensures the selected equipment delivers sustainable performance throughout the project lifecycle.

Rotor Specifications and Speed Parameter Matching Principles

Rotor diameter and width determine crusher capacity and product size distribution, with larger diameters providing greater impact energy and wider rotors increasing throughput. For tailings applications, rotor diameters typically range from 800-2000 mm depending on processing requirements, with rotational speeds between 500-1500 rpm. The specific combination influences product gradation and power consumption.

The peripheral speed of hammers directly impacts crushing efficiency and wear rates, with optimal speeds typically between 35-45 m/s for most tailings materials. Higher speeds increase reduction ratios but accelerate component wear, requiring careful balance based on material characteristics and economic considerations. Engineering calculations incorporate these factors to determine the optimal configuration for specific applications.

Hammer Arrangement Patterns and Quantity Optimization

Hammer arrangement on the rotor significantly influences crushing efficiency, wear distribution, and power consumption. Various patterns including staggered, helical, and symmetrical arrangements offer different performance characteristics. Staggered arrangements provide more uniform wear distribution, while helical patterns enhance material flow through the crushing chamber.

The number of hammers balances impact frequency against available clearance, with higher numbers providing more crushing events but reducing kinetic energy per impact. PCZ-type heavy hammer crushers typically feature fewer but larger hammers that deliver greater impact force, making them suitable for processing tougher tailings materials. The optimal configuration depends on feed size, material hardness, and target product specifications.

Grate Structure Design and Gap Adjustment Mechanisms

Grate assemblies in hammer crushers perform multiple functions including product size control, material retention time management, and discharge facilitation. Curved grate designs promote material flow and reduce plugging potential, while segmented construction enables replacement of worn sections without complete assembly replacement. The gap between hammers and grate surface influences crushing efficiency and product gradation.

Modern adjustment mechanisms incorporate hydraulic or mechanical systems that enable precise gap control during operation. These systems maintain optimal clearance as components wear, ensuring consistent product quality throughout the operating cycle. The ability to make rapid adjustments proves particularly valuable when processing tailings with varying characteristics or producing multiple product specifications.

Process Flow Design and Equipment Integration for Tailings Treatment

Effective tailings processing requires integrated system design that coordinates multiple unit operations into a cohesive workflow. Hammer crushers function as central components within these systems, interacting with feeding, screening, and material handling equipment to achieve overall processing objectives.

System design must consider both technical performance and practical operational requirements, including equipment accessibility, maintenance provisions, and future expansion potential. The comprehensive approach ensures sustainable operation throughout the project lifecycle.

Preprocessing Section and Feed Equipment Configuration

Feed systems for tailings processing must accommodate varying material characteristics while ensuring consistent supply to downstream equipment. Vibrating feeders with variable speed control provide regulated material flow, while grizzly screens remove oversize material that could damage crusher components. Metal detection and removal systems protect processing equipment from tramp metal contamination.

Feed hopper design incorporates features to prevent bridging and rat-holing common with cohesive tailings materials. Hopper geometry, internal lining materials, and vibration systems work together to ensure consistent material flow. Proper feed system design improves overall system efficiency and reduces operational disruptions caused by feed-related issues.

Crushing Section Process Layout and Material Transportation

Process layout optimization minimizes material handling distances while maintaining adequate access for operation and maintenance. Open-circuit crushing configurations provide simplicity and lower capital cost, while closed-circuit systems with product screening deliver tighter product size control. The selection depends on product quality requirements and economic considerations.

Material transport between processing stages typically employs belt conveyors designed for specific capacity and incline requirements. Conveyor design incorporates features to control dust generation and material spillage, addressing environmental concerns associated with fine tailings materials. Proper transport system design ensures reliable material movement throughout the processing circuit.

Screening Equipment and Closed-Circuit Crusher Configuration

Vibrating screens integrated with hammer crushers enable closed-circuit operation that improves product quality and system efficiency. Screen selection considers material characteristics, capacity requirements, and separation efficiency. Multi-deck screens provide simultaneous production of multiple product fractions, enhancing operational flexibility.

Closed-circuit configurations return oversize material to the crusher for further reduction, ensuring all product meets specification requirements. Control systems monitor crusher power consumption and adjust feed rates to maintain optimal operation. This approach maximizes system efficiency while ensuring consistent product quality for downstream applications.

Practical Application Cases and Operational Performance Analysis

Real-world applications demonstrate the effectiveness of hammer crushers in diverse tailings processing scenarios. Performance data from operating installations provides valuable insights for new project planning and equipment selection.

Case studies illustrate how hammer crusher technology addresses specific processing challenges while delivering economic and environmental benefits. The documented performance enables prospective users to evaluate potential applications in similar contexts.

Iron Ore Tailings Processing for Brick Manufacturing

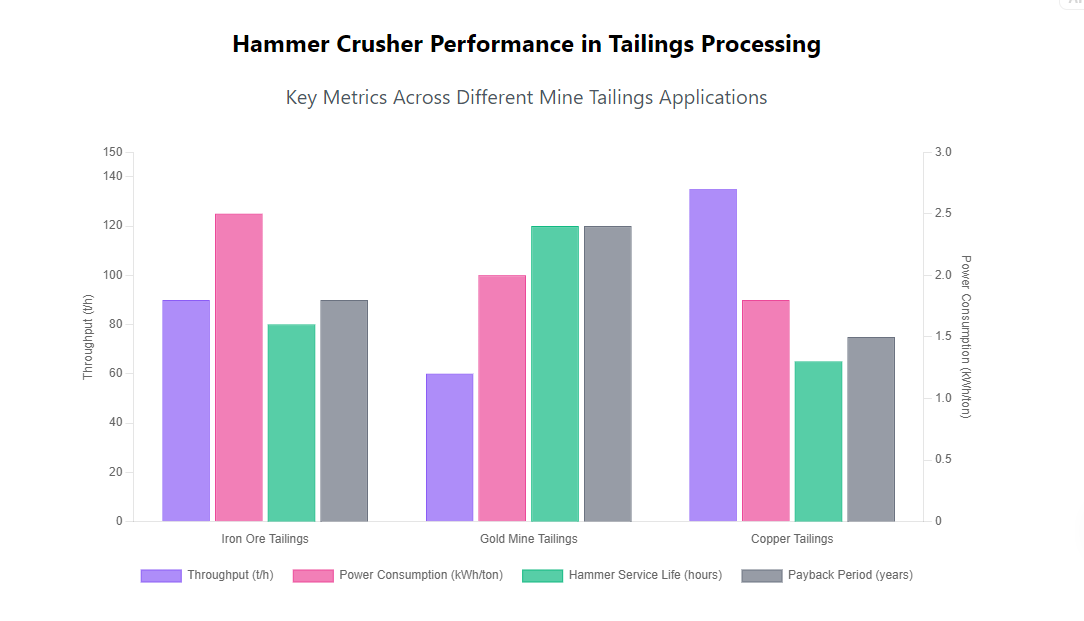

A major iron ore operation implemented hammer crushers to process tailings for brick production, achieving throughput rates of 80-100 tons per hour with product sizes between 0-5 mm. The crushing system reduced tailings storage requirements while creating saleable construction materials. Product quality met industry standards for compressive strength and water absorption.

The installation demonstrated economic viability with payback periods under three years based on brick sales revenue and reduced tailings management costs. Operational data indicated hammer service life of approximately 800 hours between replacements, with total operating costs representing 15-20% of product value. The success prompted expansion to process additional tailings volumes.

Gold Mine Tailings Treatment for Backfill Material Production

A gold mining operation employed hammer crushers to process historical tailings for underground backfill applications. The system produced 50-70 tph of classified material meeting particle size distribution requirements for cemented paste backfill. The operation reduced surface tailings storage while providing economic backfill material for ongoing mining operations.

Performance monitoring documented power consumption of 1.8-2.2 kWh per ton processed, with availability exceeding 85% during continuous operation. The project demonstrated significant environmental benefits through tailings volume reduction and improved resource utilization. The technical approach has been replicated at similar operations facing comparable challenges.

Copper Tailings Processing for Construction Aggregate Production

Copper tailings containing significant silica content were processed through hammer crushers to produce construction sand meeting ASTM C33 specifications. The operation achieved production rates of 120-150 tph with consistent product quality. The manufactured sand demonstrated excellent performance in concrete applications, with testing confirming compliance with relevant standards.

The project created new revenue streams while addressing long-term tailings management challenges. Market analysis indicated strong demand for construction aggregates in the region, ensuring economic sustainability. The success illustrates how proper processing can transform mining waste into valuable construction materials.

Comprehensive Economic and Environmental Benefit Assessment

Tailings processing projects require thorough evaluation of both financial returns and environmental impacts to demonstrate overall project viability. The assessment methodology must capture direct economic benefits alongside indirect environmental and social advantages.

Comprehensive evaluation provides decision-makers with complete information for project approval and prioritization. The integrated approach recognizes the multifaceted value proposition of tailings reprocessing initiatives.

Investment Cost Analysis and Payback Period Calculation

Capital investment for hammer crusher-based tailings processing systems typically ranges between $500,000-$2,000,000 depending on system capacity and complexity. Major cost components include crushing equipment, material handling systems, electrical infrastructure, and civil works. Accurate estimation requires detailed engineering analysis specific to each application.

Payback periods generally range from 2-5 years for well-conceived projects, with returns influenced by product market conditions, transportation costs, and processing efficiency. Projects incorporating mining and quarrying solutions often demonstrate stronger economics due to integration with existing operations. Financial modeling should incorporate sensitivity analysis to evaluate project robustness under varying market conditions.

Operational Cost Structure and Optimization Opportunities

Operating costs for tailings processing include power consumption, wear part replacement, labor, and maintenance supplies. Power consumption typically represents 40-50% of operating costs, with wear parts accounting for 25-35%. Labor requirements vary with system automation level, with modern installations achieving outputs of 500-1000 tons per operator shift.

Optimization opportunities include predictive maintenance programs that reduce unplanned downtime, wear material selection that extends component life, and process control strategies that maximize energy efficiency. Continuous improvement programs typically achieve 10-15% operational cost reduction within the first two years of operation through systematic optimization.