Breakthrough of Hammer Crushers in New Energy Material Preparation: Innovation in Lithium-ion Battery Raw Material Crushing Process

This article systematically elaborates on the latest technological breakthroughs of hammer crushers in the field of lithium-ion battery raw material preparation. Through material characteristic adaptation, process parameter optimization, and quality control system construction, high-purity raw material preparation and battery performance improvement are achieved. The focus is on how specialized crushing technology enables the production of consistent, high-quality materials essential for advanced battery manufacturing.

Analysis of Physicochemical Characteristics of Lithium-ion Battery Raw Materials

Lithium-ion battery materials possess unique physical and chemical properties that present distinct challenges for crushing operations. These materials require extremely precise processing conditions to maintain their electrochemical performance and structural integrity. Understanding these characteristics is fundamental to designing appropriate crushing equipment and processes that can meet the stringent requirements of battery manufacturers.

The production of electrode materials demands exceptional control over particle size distribution, contamination levels, and structural preservation. Even minor deviations from specifications can significantly impact battery performance, including capacity, cycle life, and safety characteristics. Therefore, crushing equipment must be specifically adapted to handle these sensitive materials while maintaining the highest standards of purity and consistency. This understanding is crucial for hammer crusher applications in the energy sector.

Typical Material Types and Requirements

Lithium-ion battery materials primarily consist of cathode compounds such as NCM (nickel-cobalt-manganese) and LFP (lithium iron phosphate), each with distinct processing requirements. These materials often have specific crystalline structures that must be preserved during size reduction to maintain their electrochemical properties. The crushing process must achieve the desired particle size without damaging these critical structural characteristics.

Anode materials, predominantly graphite and silicon-based compounds, present different challenges due to their layered structures and sensitivity to contamination. Additionally, electrolyte additives like VC (vinylene carbonate) and FEC (fluoroethylene carbonate) require specialized handling due to their chemical reactivity and sensitivity to processing conditions. Each material type demands specific crushing parameters and equipment configurations to optimize performance in the final battery application.

Key Indicators for Particle Size Control

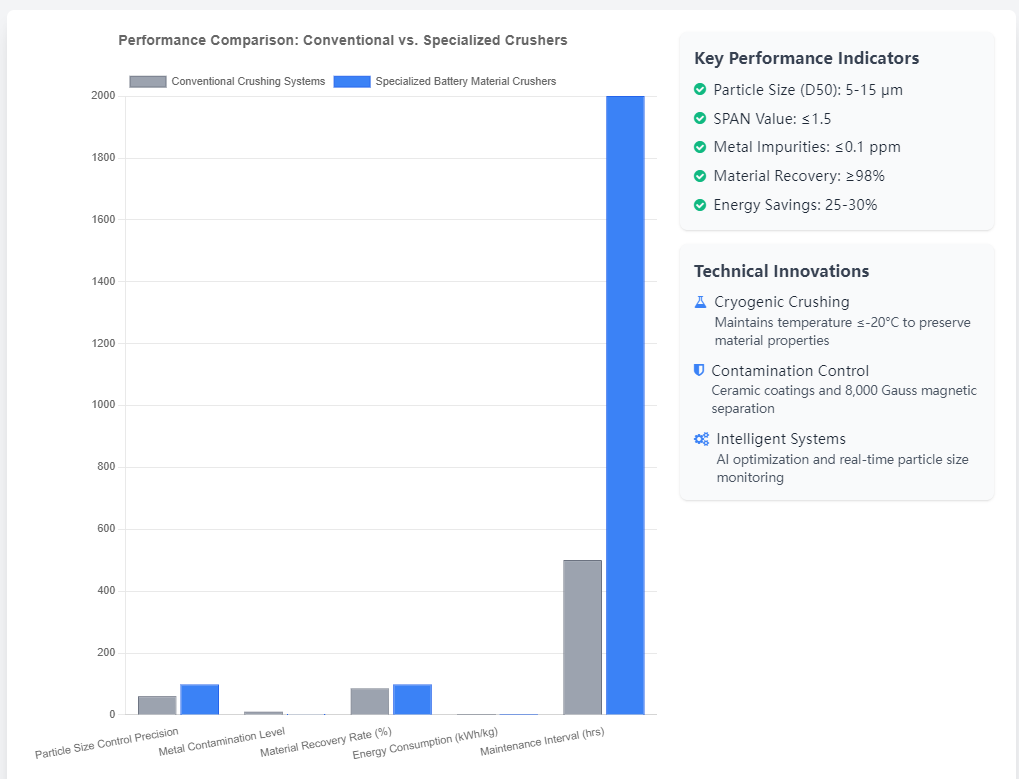

Particle size distribution is perhaps the most critical parameter in battery material preparation. The median particle size (D50) typically must fall between 5 and 15 micrometers to ensure optimal electrode packing density and ionic transport characteristics. This specific size range enables efficient lithium-ion movement while maintaining sufficient surface area for electrochemical reactions.

The width of the particle size distribution, often expressed as the SPAN value, must be controlled to 1.5 or less to ensure uniform electrode coating and consistent battery performance. Perhaps most importantly, metallic impurity content must be maintained at extremely low levels, not exceeding 0.1 parts per million, to prevent internal short circuits and thermal runaway in the finished batteries.

Challenges in the Crushing Process

The crushing of battery materials presents several significant technical challenges that must be carefully addressed. Preserving the material's microstructure is paramount, as mechanical damage to crystalline structures can degrade electrochemical performance. This requires precise control of impact forces and careful selection of crushing parameters to achieve size reduction without structural compromise.

Preventing metallic contamination is another critical challenge, as even minute metal particles can cause catastrophic battery failures. Additionally, controlling thermal effects during crushing is essential, with temperature rises typically limited to 30°C or less to prevent material degradation or unwanted chemical reactions that could affect battery performance and safety.

Special Requirements for Equipment Materials

Equipment construction materials must meet exceptionally high standards for battery material processing. Surface smoothness requirements are stringent, with surface roughness typically limited to 0.8 micrometers or less to prevent particle adhesion and facilitate cleaning. This high level of surface finish minimizes the risk of contamination and ensures consistent product quality.

Corrosion resistance is essential, particularly for equipment components that might contact electrolyte materials or their precursors. Additionally, magnetic substance control is critical, with requirements often specifying 50 parts per billion or less to prevent metallic contamination that could compromise battery safety and performance.

Innovative Adaptive Design of Hammer Crushers

Modern hammer crushers for battery material processing incorporate numerous innovative design features that address the unique challenges of these applications. These adaptations focus on contamination control, temperature management, and process monitoring to ensure the production of high-quality materials that meet stringent battery industry standards. The evolution of these specialized crushers represents a significant advancement in materials processing technology.

These design innovations include advanced materials selection, specialized cooling systems, and integrated monitoring technologies that work together to maintain product quality and process efficiency. By addressing the specific requirements of battery materials, these crushers enable manufacturers to produce consistent, high-performance materials essential for modern energy storage applications. The specialized crushing chamber designs are particularly important for maintaining product purity.

Metal Contamination Prevention Technology

Preventing metallic contamination is achieved through multiple complementary approaches. Ceramic-coated hammer heads with aluminum oxide content of 92% or higher provide excellent wear resistance while eliminating metal-to-material contact. These ceramic surfaces maintain their integrity under continuous operation, ensuring consistent performance without introducing metallic impurities.

Non-metal liner plates made from advanced polymers such as PEEK (polyether ether ketone) and PTFE (polytetrafluoroethylene) further reduce contamination risks. Additionally, integrated magnetic separation systems with field strengths of 8,000 Gauss or more provide final assurance by removing any ferrous particles that might have entered the process stream, ensuring the highest levels of product purity.

Low-Temperature Crushing Technology

Temperature control during crushing is critical for heat-sensitive battery materials. Liquid nitrogen cooling systems are integrated into the crusher design to maintain processing temperatures at -20°C or lower. This cryogenic approach prevents thermal degradation of sensitive materials and preserves their electrochemical properties.

The controlled low-temperature environment also reduces the reactivity of materials during processing, minimizing unwanted side reactions. For particularly temperature-sensitive compounds, this technology enables processing that would be impossible at ambient temperatures, expanding the range of materials that can be effectively processed using mechanical crushing methods.

High-Cleanliness Design Features

Maintaining exceptional cleanliness standards requires comprehensive design approaches. Fully enclosed crushing chambers prevent external contaminants from entering the process while containing fine particles within the system. This containment is essential for both product quality and operator safety in battery material processing.

Inert gas protection systems using nitrogen or argon create an oxygen-free environment that prevents oxidation of sensitive materials. Additionally, integrated cleaning-in-place (CIP) systems enable thorough cleaning between product batches without disassembling equipment, reducing downtime while maintaining the highest hygiene standards required for battery material production.

Intelligent Monitoring Systems

Advanced sensor systems provide real-time monitoring of critical process parameters. Laser diffraction particle size analyzers continuously measure particle size distribution, allowing for immediate adjustment of crushing parameters to maintain product specifications. This real-time monitoring ensures consistent product quality and reduces the need for offline testing.

X-ray detection systems identify and quantify metallic contaminants with high sensitivity, providing an additional layer of quality assurance. These monitoring systems are integrated with process control systems that automatically adjust operational parameters based on sensor inputs, creating a closed-loop control system that maintains optimal processing conditions despite variations in feed material characteristics.

Crushing Process Optimization Strategies

Optimizing the crushing process for battery materials requires a holistic approach that addresses multiple aspects of system design and operation. These strategies focus on achieving the desired product characteristics while maximizing efficiency, minimizing energy consumption, and ensuring process stability. The implementation of these optimization strategies has proven essential for economic production of high-quality battery materials.

Process optimization involves careful consideration of system configuration, parameter control, energy management, and operational stability. By addressing each of these areas systematically, manufacturers can achieve significant improvements in product quality, production efficiency, and operational costs. These optimizations are particularly important given the stringent quality requirements and competitive nature of the battery materials market. Understanding the crushing ratio is fundamental to this optimization process.

Multi-Stage Crushing System Design

Multi-stage crushing systems provide graduated size reduction that optimizes efficiency and product quality. Initial coarse crushing reduces material to 20 millimeters or less, followed by intermediate crushing to 5 millimeters, and final fine crushing to 1 micrometer or less. This stepped approach allows for optimized energy use at each reduction stage and prevents overgrinding of material.

The circulation load rate is carefully optimized between 150% and 200% to ensure efficient operation without overloading the system. The crushing ratio is dynamically adjusted between 10:1 and 25:1 based on material characteristics and product requirements, allowing for flexible operation across different material types and production targets.

Intelligent Parameter Adjustment Technology

Advanced control systems enable precise adjustment of operational parameters in real time. Rotor speed is controlled between 800 and 1500 RPM based on material characteristics and desired product size. This variable speed control allows operators to optimize energy consumption and product quality for different materials and production requirements.

Automatic hammer gap calibration maintains precise clearances between 5 and 20 micrometers, ensuring consistent product size distribution despite wear on crushing components. Feed rate is matched to crusher capacity, typically between 20 and 100 kilograms per minute, to maintain optimal loading conditions and prevent system overload while maximizing throughput.

Energy Efficiency Improvement Solutions

Energy consumption is optimized through multiple approaches. Variable frequency drives on motors maintain load rates between 75% and 85% of capacity, optimizing energy use across varying production conditions. This approach significantly reduces energy consumption compared to fixed-speed operation, particularly during partial load conditions.

Energy recovery systems capture kinetic energy from the crushing process and convert it to electrical energy, reducing net power consumption. Through these and other efficiency measures, specific energy consumption (energy per unit of product) is typically reduced by 25% to 30% compared to conventional crushing systems, contributing significantly to production economics and environmental performance.

Process Stability Control Measures

Maintaining process stability is essential for consistent product quality. Vibration monitoring systems track equipment condition with sensitivity to 2 millimeters per second or better, detecting potential mechanical issues before they affect product quality or cause unscheduled downtime. This predictive approach to maintenance improves overall equipment reliability.

Temperature warning mechanisms alert operators when processing temperatures approach 40°C, allowing for corrective action before material properties are affected. Automatic shutdown systems activate when abnormal conditions are detected, preventing equipment damage and ensuring product quality is maintained even during unexpected process upsets.

Economic Benefits and Environmental Impact Assessment

The application of specialized hammer crushers in battery material production delivers significant economic and environmental benefits. These advantages stem from improved process efficiency, reduced resource consumption, and enhanced product quality that commands premium prices in the market. The economic case for these advanced crushing systems continues to strengthen as battery production scales globally.

Environmental benefits include reduced energy consumption, decreased waste generation, and lower carbon emissions compared to conventional processing methods. These environmental advantages align with the sustainability goals of battery manufacturers and their customers, creating additional value beyond direct economic benefits. The combination of improved economics and environmental performance makes these systems increasingly attractive for battery material production. Many of these benefits are realized through advanced fine crusher technologies.

Resource Utilization Improvement

Advanced crushing systems achieve remarkable material utilization rates, with raw material recovery rates of 98% or higher. This high efficiency reduces waste and minimizes the consumption of valuable raw materials. By-product utilization rates reach 85% or more, further enhancing the overall efficiency of the production process and reducing environmental impact.

The carbon footprint of processing is significantly reduced, with typical reductions of 0.5 kilograms of carbon dioxide equivalent per kilogram of processed material compared to conventional methods. This reduction stems from improved energy efficiency, reduced material waste, and optimized process conditions that minimize overall environmental impact.

Operational Cost Optimization

Processing costs are substantially reduced through multiple mechanisms. Per-ton processing costs typically decrease by 30-50 currency units due to improved energy efficiency, reduced maintenance requirements, and higher throughput rates. These cost reductions significantly improve production economics and competitiveness in the battery materials market.

Maintenance intervals are extended to 2,000 hours or more through improved wear resistance and predictive maintenance approaches. The investment payback period for these advanced systems typically ranges from 1.5 to 2 years, making them economically attractive despite their higher initial cost compared to conventional crushing equipment.

Production Capacity Expansion Potential

Modular design approaches enable flexible capacity expansion from 50 to 500 kilograms per hour, allowing producers to scale operations according to market demand. This scalability is particularly valuable in the rapidly evolving battery industry, where production requirements can change quickly based on market conditions and technological developments.

Production line flexibility allows for quick changes between different material types, enhancing operational flexibility. Rapid changeover systems enable product transitions in 30 minutes or less, reducing downtime and improving overall equipment utilization. These capabilities provide significant competitive advantages in dynamic market conditions.

Policy Incentive Utilization

New energy subsidies and incentives can significantly improve project economics for battery material production facilities. These financial incentives reduce the effective cost of equipment and accelerate return on investment. Producers who implement advanced crushing technologies often qualify for these programs due to their improved energy efficiency and environmental performance.

Carbon trading mechanisms provide additional revenue streams, with annual carbon credit revenues potentially exceeding 500,000 currency units for typical production facilities. Green factory certification benefits enhance corporate image and provide additional market advantages, particularly when supplying environmentally conscious customers in the electric vehicle and energy storage markets.

Technical Development Trends and Frontier Exploration

The field of battery material crushing continues to evolve rapidly, driven by advancing battery technologies and increasing performance requirements. Emerging trends include greater automation, advanced materials, and innovative process approaches that promise further improvements in efficiency, product quality, and environmental performance. Staying abreast of these developments is essential for maintaining competitiveness in the battery materials sector.

Future directions include intelligent systems that optimize processes in real time, novel materials that enhance equipment performance and longevity, and circular economy approaches that maximize resource utilization. These advancements will likely transform battery material production in the coming years, enabling higher performance at lower cost with reduced environmental impact. These innovations are particularly relevant for recycling applications in the battery sector.

Intelligent Technology Applications

Artificial intelligence is increasingly applied to process optimization, using machine learning algorithms to identify optimal operating parameters based on material characteristics and product requirements. These AI systems continuously improve performance through operation, potentially achieving efficiencies beyond human operators' capabilities.

Digital twin technology creates virtual replicas of crushing systems, enabling simulation and optimization without disrupting actual production. Predictive maintenance algorithms analyze equipment data to forecast maintenance needs before failures occur, reducing downtime and maintenance costs while improving overall equipment reliability.

New Material Application Breakthroughs

Nanoceramic coatings offer enhanced wear resistance and contamination control compared to conventional materials. These advanced coatings maintain their integrity under extreme operating conditions, extending component life and improving product purity. The nanoscale structure of these materials provides unique properties that are particularly beneficial for battery material processing.

Self-lubricating materials reduce maintenance requirements and eliminate potential contamination from external lubricants. Biodegradable components offer environmental advantages at end-of-life, supporting circular economy principles and enhancing the overall sustainability of battery material production systems.

Circular Economy Model Innovation

Integrated crushing-recycling-regeneration systems create closed-loop processes that maximize resource utilization. These systems enable efficient recovery of valuable materials from production waste and end-of-life batteries, reducing reliance on virgin materials and minimizing environmental impact. The development of these circular approaches is critical for sustainable battery production.

Battery full-lifecycle management systems track materials from production through use and recycling, enabling efficient resource recovery. Urban mining concepts aim to recover valuable materials from electronic waste, creating new material sources while addressing growing waste management challenges associated with portable electronics and electric vehicles.