Application Expansion of Hammer Crushers in the Metallurgical Industry: Innovation in Iron Ore Pre-Crushing Processes

This article systematically elaborates on the innovative application of hammer crushers in the pre-crushing stage of iron ore within the metallurgical industry. Through equipment adaptability improvements, wear resistance optimization, and process control strategies, significant enhancements in crushing efficiency and optimization of metallurgical production processes are achieved. The discussion covers technological challenges, equipment design improvements, operational parameter optimization, and real-world implementation data, providing a comprehensive overview of this technological advancement.

Process Challenges in Iron Ore Pre-Crushing for Metallurgical Industry

Iron ore pre-crushing presents unique challenges due to the material's physical properties and the demanding requirements of metallurgical processes. With a Mohs hardness ranging between 5 and 7, iron ore possesses considerable abrasiveness that accelerates equipment wear. The varying particle size distribution, with some lumps reaching up to 800mm, requires robust crushing equipment capable of handling large feed sizes while maintaining operational stability.

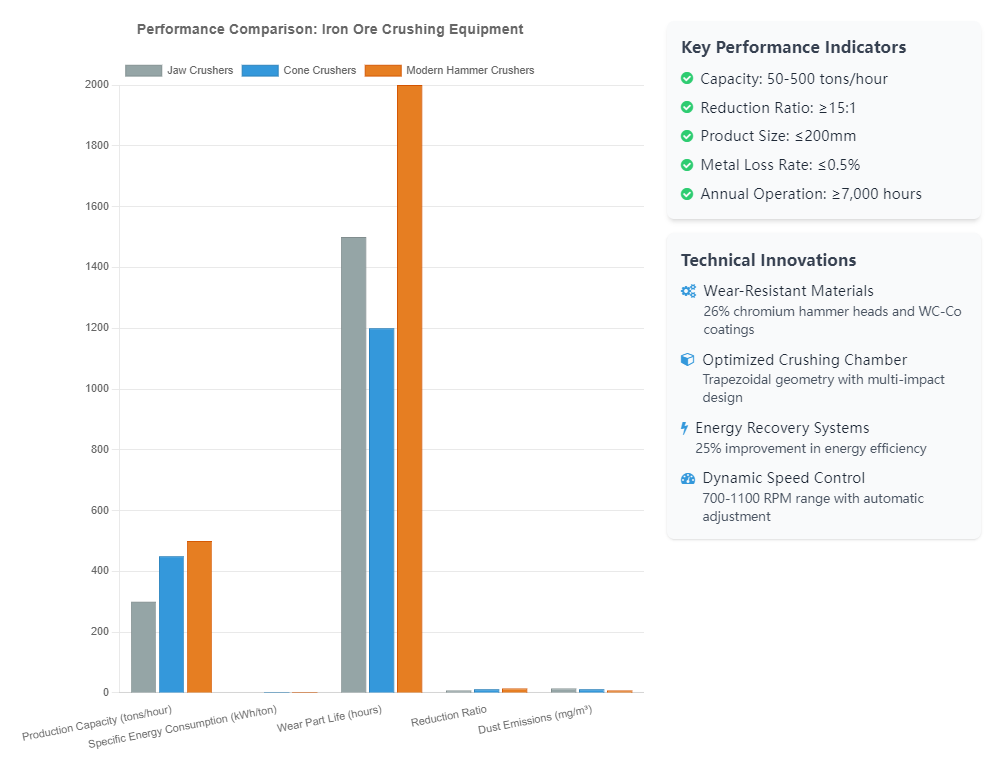

Traditional crushing equipment has demonstrated limitations in addressing these challenges effectively. Jaw crushers, while reliable, often face capacity bottlenecks below 300 tons per hour, making them insufficient for large-scale metallurgical operations. Cone crushers offer better capacity but introduce higher maintenance complexity due to their intricate mechanical structure. Historically, hammer crushers were not considered for this application due to perceived limitations in wear resistance and capacity, creating a technological gap in iron ore pre-crushing solutions.

Analysis of Iron Ore Physical Characteristics

Iron ore exhibits distinct physical properties that significantly impact crushing operations. The Mohs hardness scale of 5-7 places iron ore in the medium to high hardness category among minerals, requiring substantial energy input for effective size reduction. This hardness characteristic directly influences equipment selection and wear part design, as the abrasive nature of the material accelerates component deterioration.

The particle size distribution of raw iron ore varies considerably, with maximum lump sizes reaching 800mm in some mining operations. This wide size distribution demands crushers capable of handling large feed materials while producing consistent output. Additionally, moisture content fluctuating between 0-8% affects material flow characteristics and can lead to clogging issues in conventional crushing equipment, necessitating special design considerations in hammer crusher applications.

Limitations of Traditional Crushing Equipment

Conventional crushing solutions have demonstrated various limitations in iron ore pre-crushing applications. Jaw crushers, while offering reliable performance and simple operation, typically max out at capacities below 300 tons per hour, creating production bottlenecks in modern high-volume metallurgical plants. The limited reduction ratio of jaw crushers often requires multiple crushing stages to achieve desired product sizes, increasing overall system complexity and energy consumption.

Cone crushers provide higher capacity and better reduction ratios but introduce significant maintenance challenges. The complex mechanical structure and precise adjustments required for optimal operation demand specialized technical knowledge and frequent maintenance interventions. The historical absence of hammer crushers from iron ore applications stemmed from concerns about wear part longevity and capacity limitations, though recent technological advancements have addressed these previous shortcomings effectively.

Pre-Crushing Process Objectives

The primary objective of iron ore pre-crushing is to reduce raw material size to 200mm or smaller, making it suitable for subsequent grinding processes in ball mills. This size reduction must be achieved while maintaining operational efficiency and minimizing metal loss throughout the process. The target reduction ratio of at least 15:1 requires careful equipment selection and process parameter optimization to ensure consistent performance.

Process efficiency is measured through multiple parameters including metal loss rates, which must be maintained below 0.5% to ensure economic viability. Achieving these targets demands precise control over crushing operations and implementation of advanced monitoring systems. The pre-crushing stage must also maintain consistent product quality while adapting to variations in feed material characteristics, requiring flexible equipment capable of handling changing operational conditions.

Industry-Specific Requirements

Metallurgical operations impose specific requirements on crushing equipment that distinguish them from other industrial applications. Wear resistance represents a critical factor, with hammer heads and linings requiring hardness levels exceeding 500 HB to withstand the abrasive nature of iron ore. This exceptional wear resistance must be maintained throughout extended operational periods, as metallurgical plants typically require annual operation exceeding 7,000 hours.

Environmental considerations have become increasingly important, with dust emissions needing to be controlled below 10mg/m³ to meet regulatory standards. This requirement necessitates integrated dust suppression systems and careful attention to material handling throughout the crushing process. The combination of high availability requirements, stringent environmental standards, and demanding operational conditions creates a unique set of challenges for crushing equipment in metallurgical applications.

Adaptive Design Improvements for Hammer Crushers

Modern hammer crushers have undergone significant design improvements to meet the challenging requirements of iron ore pre-crushing. These enhancements focus on increasing equipment durability, improving operational efficiency, and reducing maintenance requirements. The integration of advanced materials and innovative engineering solutions has transformed hammer crushers into viable options for metallurgical applications.

Design improvements extend beyond simple component enhancements to include complete system optimization. The crushing chamber geometry has been redesigned based on computational fluid dynamics and discrete element modeling to optimize material flow and reduce wear. Advanced drive systems incorporating torque monitoring and overload protection ensure operational reliability while preventing damage from unexpected overload conditions.

Application of Wear-Resistant Materials

The implementation of advanced wear-resistant materials has dramatically improved hammer crusher performance in iron ore applications. High-chromium iron hammer heads containing 26% chromium provide exceptional resistance to abrasive wear, significantly extending component service life. These specialized alloys maintain their hardness characteristics even under high-impact conditions, ensuring consistent performance throughout their operational lifespan.

Additional protection comes from tungsten carbide coatings applied to critical wear surfaces through thermal spraying techniques. The WC-Co coating formulation offers superior resistance to both abrasive and impact wear, particularly in areas experiencing the highest wear rates. Ceramic composite linings incorporating aluminum oxide (Al₂O₃) provide additional protection in the crushing chamber, reducing maintenance requirements and improving overall equipment availability.

Crushing Chamber Optimization

The crushing chamber design has been completely reengineered to address the specific challenges of iron ore processing. The implementation of trapezoidal chamber geometry improves material flow characteristics and reduces the likelihood of clogging, particularly when processing moist materials. This design innovation maintains optimal crushing efficiency throughout the chamber volume, eliminating dead zones where material might accumulate without proper size reduction.

Advanced computer simulations have optimized material flow patterns within the crushing chamber, ensuring that ore particles experience multiple impacts before exiting the chamber. This multi-impact approach improves reduction efficiency while distributing wear more evenly across hammer heads and chamber linings. The elimination of dead zones through strategic baffle placement and chamber geometry modifications has further enhanced operational efficiency and reduced power consumption.

Transmission System Upgrades

Drive system improvements have significantly enhanced hammer crusher reliability and operational flexibility. The incorporation of hydraulic couplings between the motor and crusher rotor provides smooth starting characteristics and protects against shock loads that could damage drive components. These couplings also accommodate minor misalignments, reducing maintenance requirements and extending equipment service life.

Advanced motor protection systems monitor electrical parameters and can detect overload conditions at 1.5 times rated current, preventing damage from tramp iron or other uncrushable materials. Integrated torque monitoring provides real-time performance data, allowing operators to optimize crusher operation based on actual loading conditions. These enhancements contribute to improved energy efficiency and reduced maintenance costs.

Integrated Dust Control System

Comprehensive dust control systems have been integrated directly into hammer crusher designs to meet stringent environmental standards. Pulse-jet baghouse filters capture dust particles at the source, maintaining emission levels below required thresholds. The filter cleaning mechanism uses compressed air pulses to maintain filter permeability without interrupting operation, ensuring consistent performance throughout production cycles.

Negative pressure duct design prevents dust escape by maintaining airflow into the crusher housing at all points where material transfers occur. Captured dust particles are returned to the process stream through automated recycling systems, minimizing material loss and improving overall process efficiency. This closed-loop approach to dust management represents best available technology for industrial dust control.

Optimization Strategies for Crushing Parameters

Optimal operation of hammer crushers in iron ore applications requires careful adjustment of multiple parameters based on ore characteristics and production requirements. Rotor speed represents one of the most critical variables, directly influencing product size distribution and crusher capacity. Modern control systems automatically adjust rotor speed based on ore hardness, maximizing efficiency while maintaining product quality.

Hammer tip clearance significantly affects both product size and wear rates, requiring precise adjustment and continuous monitoring. Advanced control systems maintain optimal clearances through automated adjustment mechanisms, compensating for wear and ensuring consistent performance. Combined with optimized feed distribution systems, these control strategies maximize production efficiency while minimizing operating costs.

Dynamic Rotor Speed Adjustment

Rotor speed optimization represents a key strategy for improving hammer crusher performance in iron ore applications. For hard ores exceeding Mohs hardness 6, rotor speeds between 900-1100 RPM provide optimal impact energy for effective size reduction while maintaining acceptable wear rates. Softer ores below Mohs hardness 5 require lower speeds of 700-900 RPM to prevent over-reduction and excessive energy consumption.

Advanced control systems continuously monitor power consumption and product size, automatically adjusting rotor speed to maintain optimal operation. Mathematical models correlating rotor speed with product size distribution enable predictive control strategies that anticipate changes in ore characteristics. This dynamic adjustment capability ensures consistent product quality while maximizing production rates and minimizing specific energy consumption.

Hammer Clearance Control

Precise control of hammer tip clearance significantly influences crusher performance and product quality. Initial clearance settings typically range between 20-30mm, providing sufficient impact distance for effective size reduction while maintaining acceptable capacity. As hammers wear, clearance increases, reducing crushing efficiency and altering product size distribution.

Automated clearance adjustment systems maintain optimal operating conditions by compensating for wear in real-time. These systems achieve adjustment accuracy within ±5mm, ensuring consistent performance throughout wear cycles. The relationship between hammer clearance and production capacity has been mathematically modeled, enabling predictive adjustment strategies that maximize throughput while maintaining product specifications.

Feed Method Improvements

Advanced feed systems have been developed to optimize material presentation to hammer crushers. Vibrating feeders combined with belt scales provide precise control over feed rate, maintaining optimal crusher loading while preventing overload conditions. The integration of weighing systems enables real-time monitoring of throughput rates, facilitating automatic adjustment of crusher parameters based on actual production rates.

Layered feeding techniques distribute material evenly across the crusher width, maximizing hammer utilization and reducing localized wear. Instantaneous flow control systems maintain feed rate within ±3% of target values, preventing fluctuations that could reduce crushing efficiency. These precision feeding systems contribute significantly to overall process stability and equipment longevity.

Reduction Ratio Enhancement Techniques

Multiple strategies have been developed to increase reduction ratios in hammer crusher applications. Two-stage crushing configurations utilizing primary and secondary crushing chambers within a single machine achieve higher overall reduction while maintaining compact equipment dimensions. This approach enables single-machine reduction ratios exceeding 15:1, meeting metallurgical process requirements without additional equipment.

Circulating load control between 120-180% optimizes the balance between production rate and product quality, ensuring that oversize material receives additional reduction passes. Mathematical models of crushing efficiency enable predictive control of circulating loads, automatically adjusting system parameters based on feed characteristics and product requirements. These advanced control strategies maximize reduction efficiency while minimizing energy consumption.

Enhancement of Equipment Wear Resistance and Service Life

Improving wear resistance represents a critical aspect of hammer crusher optimization for iron ore applications. Advanced materials and predictive maintenance strategies have significantly extended component service life while reducing unplanned downtime. Understanding wear mechanisms enables targeted improvements that address the specific challenges of iron ore crushing.

Component life prediction models based on operational data and material properties enable proactive maintenance planning, ensuring that replacements occur during scheduled maintenance periods rather than causing unscheduled downtime. These predictive capabilities combined with improved wear materials have transformed hammer crushers into reliable equipment for continuous metallurgical operations.

Wear Parts Life Prediction

Accurate prediction of wear part service life enables effective maintenance planning and inventory management. Hammer heads typically last between 800-1200 hours in iron ore service, depending on ore abrasiveness and operational parameters. Lining plates demonstrate longer service life of 1500-2000 hours due to their different wear mechanisms and more favorable impact angles.

Advanced monitoring systems using laser scanning technology measure wear rates in real-time, providing data for predictive life calculations. These systems detect wear patterns that might indicate suboptimal operation, enabling corrective action before excessive wear occurs. The combination of direct measurement and predictive modeling significantly improves maintenance efficiency and reduces operating costs.

Analysis of Wear Mechanisms

Understanding dominant wear mechanisms enables targeted improvements in material selection and design. Abrasive wear accounts for approximately 60% of material loss in iron ore crushing applications, resulting from the hard, sharp edges of ore particles sliding across metal surfaces. This wear mechanism primarily affects areas experiencing direct material contact under high pressure.

Fatigue wear contributes approximately 25% of total material loss, resulting from repeated impact cycles that cause surface cracking and eventual material spalling. Corrosive wear accounts for the remaining 15%, accelerated by moisture and minor chemical components in the ore. Addressing each wear mechanism requires specific material properties and design considerations, leading to the development of composite solutions that provide comprehensive protection.

Maintenance Strategy Optimization

Predictive maintenance systems have revolutionized hammer crusher maintenance approaches. Continuous monitoring of operational parameters including vibration, temperature, and power consumption enables early detection of potential problems before they cause unscheduled downtime. These systems analyze trends to predict remaining component life, generating alerts when maintenance should be scheduled.

Component replacement warnings ensure that maintenance activities occur at optimal intervals, maximizing component utilization while preventing failures. Spare parts inventory optimization models maintain appropriate stock levels based on predicted consumption rates and lead times, reducing inventory costs while ensuring parts availability. This comprehensive approach to maintenance management significantly improves equipment availability and reduces life-cycle costs.

Wear Resistance Testing Methods

Standardized testing methods provide quantitative data on material wear resistance under controlled conditions. The rubber wheel abrasion test according to ASTM G65 measures material resistance to low-stress abrasive wear, simulating conditions similar to those experienced in certain crusher areas. This test provides comparable data for different materials, enabling informed selection decisions.

Erosion testing following ASTM G76 standards evaluates material resistance to particle impact wear, particularly relevant for hammer tips and impact plates. Field wear data collection complements laboratory testing, providing real-world performance information under actual operating conditions. The combination of standardized laboratory tests and field validation ensures optimal material selection for specific applications.

Energy Efficiency and Cost Control Measures

Energy consumption represents a significant portion of operating costs in crushing operations, making efficiency improvements economically important. Modern hammer crushers incorporate multiple technologies that reduce specific energy consumption while maintaining or improving production rates. These innovations include advanced drive systems, energy recovery mechanisms, and optimized operational strategies.

Comprehensive cost analysis demonstrates the economic benefits of modern hammer crushers in iron ore applications. Reduced energy consumption combined with lower maintenance requirements and increased production rates significantly improves operational economics. The implementation of modular designs and quick-change systems further enhances economic performance by reducing downtime and enabling capacity expansion with minimal investment.

Motor System Optimization

The application of permanent magnet synchronous motors represents a significant advancement in crushing energy efficiency. These motors maintain high efficiency across a wide load range, particularly important in crushing applications where load varies with feed characteristics. Combined with variable frequency drives, these motor systems adjust power consumption to match actual requirements, reducing energy waste during lighter loading periods.

Optimal load management maintains operation at 75-85% of rated capacity, maximizing energy efficiency while providing sufficient reserve capacity for peak demands. This approach reduces specific energy consumption by 18-22% compared to conventional motor systems, contributing significantly to operational cost reduction. The improved power factor of synchronous motors also reduces electrical infrastructure requirements.

Energy Recovery Systems

Innovative energy recovery systems capture and reuse energy that would otherwise be wasted during crushing operations. Kinetic energy recovery devices convert the rotational energy of the decelerating rotor into electrical energy during no-load periods, feeding this power back into the electrical system. This approach is particularly effective in applications with variable loading patterns.

Heat recovery systems capture thermal energy from hydraulic oil cooling circuits, using it for facility heating or other purposes requiring low-grade heat. The combination of multiple energy recovery approaches increases overall energy efficiency by at least 25%, significantly reducing operational costs and environmental impact. These systems represent the integration of crushing operations into broader plant energy management strategies.

Operational Cost Analysis

Comprehensive cost analysis demonstrates the economic advantages of modern hammer crushers in iron ore applications. Reduced energy consumption combined with lower maintenance requirements decreases crushing costs by $12-18 per ton of processed material. Maintenance expenses typically represent 8-10% of initial equipment cost annually, significantly lower than traditional crushing equipment.

The combination of higher production rates and lower operating costs results in investment payback periods of 2-2.5 years, making modern hammer crushers economically attractive despite higher initial investment. Life-cycle cost analysis confirms the economic advantages over the equipment's operational lifespan, particularly when considering the value of increased production capacity and reduced downtime.

Capacity Expansion Potential

Modular design approaches enable capacity expansion from 50 to 500 tons per hour using standardized components and configurations. This scalability allows operations to increase capacity as production requirements grow, minimizing initial investment while providing expansion flexibility. The use of standardized components across different capacity ranges simplifies maintenance and reduces spare parts inventory requirements.

Flexible production line configurations accommodate varying feed characteristics and product requirements, maximizing operational flexibility. Quick-change systems enable product size changes in less than 2 hours, significantly improving responsiveness to market demands. This combination of scalability and flexibility makes modern hammer crushers suitable for operations ranging from small specialized facilities to large integrated metallurgical plants.

Industry Application Cases and Implementation Data

Real-world implementation data confirms the performance advantages of hammer crushers in iron ore pre-crushing applications. A typical metallurgical production line configuration processing 300 tons per hour demonstrates the practical application of the technologies and strategies discussed previously. Operational results show significant improvements in key performance indicators including efficiency, maintenance requirements, and environmental compliance.

Third-party verification provides independent confirmation of performance claims, ensuring that reported improvements are accurate and reproducible. Certification according to industry standards demonstrates compliance with technical requirements, while life-cycle assessment provides comprehensive environmental performance data. These verification processes ensure that potential users can make informed decisions based on reliable performance information.

Typical Metallurgical Production Line Configuration

A standard iron ore pre-crushing system processing 300 tons per hour represents typical hammer crusher application in metallurgical operations. The complete system occupies approximately 180 square meters, including the crusher, feed and discharge systems, dust collection, and control systems. This compact footprint facilitates integration into existing plants with limited available space.

Advanced automation systems reduce operational personnel requirements to only 5 operators per shift, significantly lowering labor costs compared to traditional crushing systems. Centralized control rooms provide comprehensive operational overview, while remote monitoring capabilities enable technical support from off-site locations. This combination of automation and remote support maximizes operational efficiency while minimizing staffing requirements.

Process Improvement Effectiveness Data

Operational data from implemented systems demonstrates significant improvements in key performance indicators. Crushing efficiency improvements of 35% result from optimized operational parameters and improved equipment design. These efficiency gains reduce energy consumption per ton of processed material while increasing overall production capacity without additional equipment investment.

Extended component service life reduces maintenance requirements and associated costs. Hammer replacement intervals have doubled compared to traditional designs, significantly reducing maintenance downtime and spare parts consumption. Dust emission levels consistently measure below 8mg/m³, exceeding regulatory requirements and improving working conditions.

Customer Value Realization Pathway

The implementation of modern hammer crushers creates multiple value streams for metallurgical operations. Raw material processing costs decrease by approximately 25% through reduced energy consumption, lower maintenance requirements, and increased production rates. These cost reductions improve overall operational economics while maintaining or improving product quality.

Downstream process benefits include 15% reduction in ball mill energy consumption due to optimized feed size distribution. Improved metal recovery rates increasing by 3% result from more consistent particle size and reduced overgrinding. These downstream benefits amplify the economic advantages beyond the crushing operation itself, improving overall plant performance.

Third-Party Verification Data

Independent verification confirms performance claims through standardized testing procedures. Metallurgical equipment certification according to MT/T 1018-2006 demonstrates compliance with industry technical standards, ensuring equipment suitability for intended applications. Energy efficiency testing following GB 32013-2015 provides validated energy consumption data, enabling accurate economic calculations.

Comprehensive life-cycle assessment evaluates environmental impact across the equipment's entire lifespan, from manufacturing through operation to eventual decommissioning. This holistic assessment provides complete environmental performance data, increasingly important in regulatory environments emphasizing sustainability. Third-party verification ensures that performance data is accurate and reliable, supporting informed decision-making.