Adaptability Research of Hammer Crushers in Chemical Raw Material Crushing: Handling Solutions for Corrosive Materials

This article provides a systematic investigation into the adaptability of hammer crushers in chemical raw material processing, with a focus on solving the challenges of crushing corrosive substances. Through material compatibility analysis, equipment anti-corrosion design, and process optimization strategies, the study aims to achieve efficient and safe crushing of chemical raw materials while maintaining equipment integrity and longevity.

Physicochemical Characteristics of Corrosive Chemical Raw Materials

Understanding the nature of corrosive chemical materials is fundamental to selecting and designing appropriate crushing equipment. These materials present unique challenges that go beyond simple size reduction, as their chemical properties can actively degrade standard industrial equipment. The interaction between material chemistry and equipment surfaces dictates the service life and maintenance requirements of any processing machinery.

Chemical raw materials vary widely in their corrosive potential, ranging from mildly abrasive to highly reactive substances that can compromise structural integrity. Factors such as pH level, moisture content, and temperature fluctuations all contribute to the overall corrosiveness of a material. A comprehensive analysis of these properties enables engineers to develop specialized crushers that can withstand these harsh operating conditions. This understanding is crucial for hammer crusher applications in the chemical sector.

Classification of Typical Corrosive Raw Materials

Corrosive chemical materials can be broadly categorized into several groups based on their chemical composition and behavior. Acidic substances, including various sulfates and chlorides, represent one major category that requires special handling. These materials can rapidly degrade standard steel components through chemical attack, particularly in the presence of moisture.

Alkaline materials such as sodium hydroxide and carbonates constitute another significant category of corrosive substances. These compounds can cause different types of deterioration compared to acidic materials, often leading to surface degradation and weakening of metallic structures. Additionally, crystalline salt materials present unique challenges due to their abrasive nature combined with chemical reactivity, creating a combined wear-corrosion effect on equipment surfaces.

Analysis of Material Chemical Activity

The chemical activity of materials is quantified through various measurements, with pH value being one of the most significant indicators. Chemical raw materials can exhibit pH values ranging from extremely acidic (pH 2) to highly alkaline (pH 12), representing a substantial challenge for equipment compatibility. Each point on the pH scale represents a tenfold difference in acidity or alkalinity, meaning materials at the extremes can be highly corrosive.

Beyond pH, the electrochemical corrosion tendency of materials determines how readily they will participate in redox reactions with equipment surfaces. Some materials have a strong tendency to donate or accept electrons when in contact with metals, accelerating the corrosion process. Understanding these electrochemical properties is essential for selecting appropriate construction materials that will resist chemical attack in specific processing environments.

Influence of Physical State on Processing

The physical state of chemical raw materials significantly impacts their processing characteristics and corrosive potential. Humidity-sensitive materials that readily absorb moisture from the atmosphere can create highly corrosive environments within the crusher. This moisture absorption can dissolve soluble components, creating concentrated corrosive solutions that attack metal surfaces.

Particle size distribution also plays a crucial role in material behavior. Fine powders present different handling challenges compared to large lumps or crystals, affecting dust generation, flow characteristics, and corrosion mechanisms. Temperature variations during processing can cause expansion and contraction cycles that may accelerate material degradation through thermal stress, particularly in composite materials with different thermal expansion coefficients.

Equipment Material Erosion Mechanisms

Corrosive materials attack equipment through several distinct mechanisms that often work in combination. Uniform corrosion occurs when material degradation happens at approximately the same rate over the entire exposed surface, leading to general thinning of components. This type of corrosion is somewhat predictable and can be accounted for in design through corrosion allowances.

More problematic are localized corrosion forms such as pitting, which creates small, deep holes in the material surface that can lead to sudden failure. Stress corrosion cracking represents another dangerous mechanism where the combined action of tensile stress and a corrosive environment causes crack propagation. Perhaps the most challenging scenario is the synergistic effect of wear and corrosion, where mechanical abrasion removes protective surface layers, exposing fresh material to chemical attack.

Adaptive Design Strategies for Hammer Crushers

Designing hammer crushers for corrosive chemical applications requires a multifaceted approach that addresses material selection, structural configuration, and operational parameters. The goal is to create equipment that maintains its crushing efficiency while resisting the degrading effects of corrosive substances. This involves rethinking traditional crusher design from first principles with corrosion resistance as a primary consideration.

Modern adaptive designs incorporate advanced materials, improved sealing technologies, and smart monitoring systems to extend equipment life in harsh chemical environments. These design strategies work together to create crushers that can handle the dual challenges of mechanical size reduction and chemical resistance. The success of these designs is measured not just by throughput capacity but by maintenance intervals and total cost of ownership in corrosive applications. Proper design must consider the entire crushing chamber environment.

Application of Specialized Materials

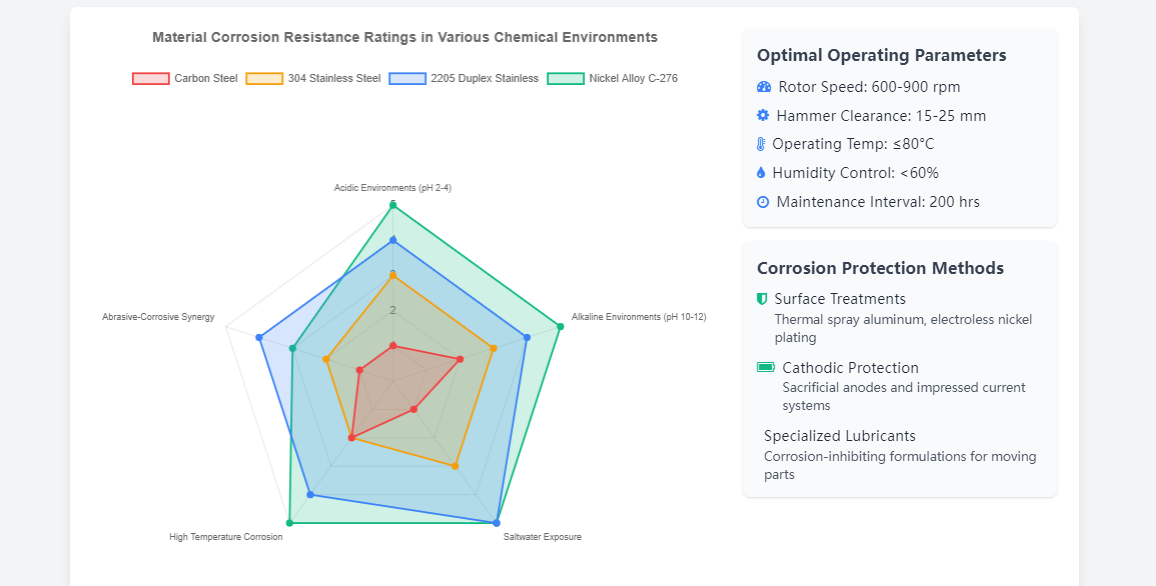

The selection of construction materials represents the first line of defense against corrosive attack in chemical processing equipment. Duplex stainless steels, particularly grades 2205 and 2507, offer an excellent balance of strength and corrosion resistance for many chemical applications. These materials combine the benefits of austenitic and ferritic stainless steels, providing good resistance to stress corrosion cracking.

For extremely corrosive environments, nickel-based alloys such as C-276 and C-22 provide superior performance against a wide range of chemical attacks. These advanced alloys maintain their integrity even in the presence of strong oxidizing agents and acidic conditions. Additionally, ceramic composite coatings can be applied to critical wear surfaces, providing exceptional resistance to both abrasion and chemical attack while extending component life significantly.

Structural Design Optimization

Beyond material selection, the structural design of hammer crushers can be optimized to minimize corrosion vulnerability. The strategic application of corrosion-resistant liner plates protects the main housing from direct exposure to corrosive materials. These liners can be replaced independently of the main structure, reducing long-term maintenance costs.

Sealing systems represent another critical area for design improvement. Upgrading to double mechanical seals prevents the ingress of corrosive vapors and liquids into bearing assemblies and other sensitive areas. Furthermore, design modifications to minimize fluid冲刷, or fluid冲刷, patterns can reduce the erosive component of wear-corrosion synergy, particularly in areas where high-velocity particle streams impact surfaces.

Adjustment of Crushing Parameters

Operational parameters can be optimized to reduce the corrosive impact on crusher components. Controlling rotor speed within a range of 600-900 rpm can minimize the generation of heat and fine dust particles that might accelerate corrosion processes. This moderate speed range maintains efficient crushing while reducing mechanical stress and temperature rise.

The clearance between hammers and liner plates, typically maintained at 15-25 mm, can be optimized to balance crushing efficiency against wear rates. Improved feed methods, such as layered feeding, ensure a more consistent material flow that prevents localized overloading and reduces the potential for corrosive material buildup in the crushing chamber.

Process Monitoring Systems Implementation

Advanced monitoring systems provide critical data for managing corrosion in real-time. Online corrosion rate detection systems can track material degradation continuously, allowing for predictive maintenance before failures occur. These systems use electrical resistance or polarization resistance techniques to measure corrosion rates accurately.

Integrated temperature and humidity sensors provide additional data points for process optimization, as these factors significantly influence corrosion rates. Warning system designs incorporate these data streams to alert operators when conditions approach corrosive thresholds, enabling proactive adjustments to process parameters or material handling procedures.

Material Compatibility Testing and Data Analysis

Determining the compatibility between construction materials and processed chemicals requires rigorous laboratory testing and data analysis. This empirical approach provides the foundation for informed material selection and equipment design decisions. Without this scientific basis, equipment manufacturers would be forced to rely on anecdotal evidence or worst-case assumptions.

Compatibility testing follows standardized methodologies that simulate real-world conditions while accelerating degradation processes to obtain actionable data within reasonable timeframes. The results of these tests enable engineers to predict equipment lifespan, plan maintenance schedules, and select the most cost-effective materials for specific applications. This scientific approach transforms material selection from guesswork to calculated decision-making. The testing often considers how materials will perform under specific crushing ratios and operational conditions.

Laboratory Corrosion Testing Methods

Standardized test methods provide reproducible data for comparing material performance in corrosive environments. Salt spray testing following ASTM B117 standards subjects materials to a controlled corrosive atmosphere to evaluate surface degradation and protective coating performance. This accelerated test provides comparative data on material resistance to chloride-induced corrosion.

Electrochemical impedance spectroscopy (EIS) offers a more sophisticated approach to evaluating corrosion mechanisms and rates by measuring the electrical response of materials in corrosive solutions. Stress corrosion cracking (SCC) tests evaluate how materials perform under combined mechanical stress and corrosive exposure, identifying susceptibility to this dangerous failure mode.

Testing of Typical Material Combinations

Comparative testing of material combinations provides practical data for equipment design decisions. Evaluations typically compare carbon steel, 304 stainless steel, and 2205 duplex stainless steel to establish performance benchmarks across different material grades and cost points. These comparisons help determine the most economical material that will provide adequate service life.

Elastomer materials such as rubber liners versus polyurethane liners are tested for both corrosion resistance and abrasion performance. The influence of ceramic coating thickness on protection effectiveness is another important area of investigation, as insufficient thickness may provide inadequate protection while excessive thickness may compromise adhesion or economic feasibility.

Comparative Analysis of Test Results

Test results are quantified using standardized metrics that enable objective comparison between materials. Mass loss rate, measured in milligrams per square centimeter per hour, provides a direct measurement of material degradation in specific environments. This metric allows for direct comparison between different material options.

Corrosion depth, expressed in micrometers per year, translates mass loss into a more practical measurement for engineering design calculations. Life prediction models, such as L10 life estimates, combine test data with operational parameters to forecast component lifespan with statistical confidence, enabling proactive maintenance planning and inventory management.

Compatibility Matrix Development

The culmination of compatibility testing is the development of practical guidance for material selection. A comprehensive compatibility matrix matches material types with equipment components, providing clear recommendations based on chemical environment and operational parameters. This matrix serves as a quick reference for engineers making material decisions.

The matrix typically includes a corrosion rating scale from 1 to 5, with 1 indicating excellent compatibility and 5 indicating severe incompatibility. Based on these ratings, specific maintenance cycle recommendations are provided for different material combinations, enabling plants to optimize their maintenance schedules for both safety and economic efficiency.

Anti-Corrosion Treatment Processes and Maintenance Strategies

Implementing effective anti-corrosion treatments and maintenance strategies is essential for maximizing equipment life in chemical processing environments. These approaches complement appropriate material selection by providing additional layers of protection and establishing maintenance practices that detect and address corrosion before it leads to equipment failure.

A comprehensive corrosion management program includes surface treatments that enhance inherent material resistance, active protection systems that counteract electrochemical corrosion processes, and maintenance protocols that systematically address wear and degradation. Together, these elements form a multi-faceted defense against the costly effects of corrosion in chemical processing equipment. These strategies are particularly important for maintaining components in the feed size regulation system.

Surface Treatment Technologies

Advanced surface treatments can significantly enhance the corrosion resistance of base materials. Thermal spray aluminum coatings create a protective barrier that sacrifices itself to protect the underlying substrate, particularly effective in atmospheric corrosion applications. These coatings can be applied to large structures and complex geometries.

Electroless nickel-phosphorus plating provides a uniform, hard coating with excellent corrosion resistance, even on complex parts with internal surfaces. Micro-arc oxidation creates a ceramic-like coating on aluminum and magnesium alloys, offering exceptional hardness and corrosion resistance for specific component applications.

Cathodic Protection Systems

Cathodic protection systems actively counteract the electrochemical processes that cause corrosion. Sacrificial anode systems use metals such as zinc that are more electrochemically active than the protected structure, causing the anode to corrode instead of the equipment. These systems are simple to implement and maintain.

Impressed current cathodic protection systems use external power sources to reverse the electrochemical potential that drives corrosion, providing protection for larger structures and more aggressive environments. Potential monitoring systems ensure that cathodic protection systems are operating within their design parameters, maintaining optimal protection levels.

Lubrication System Improvements

Specialized lubrication strategies address corrosion in moving components and bearing surfaces. The selection of corrosion-resistant lubricants is critical for equipment operating in chemically aggressive environments. These lubricants often contain additives that provide both lubrication and corrosion protection.

Optimized lubrication cycles ensure adequate protection while minimizing consumption and potential environmental contamination. Leak monitoring devices detect lubrication system failures before they lead to equipment damage, allowing for prompt corrective action and preventing costly secondary damage from inadequate lubrication.

Standardization of Maintenance Operations

Establishing standardized maintenance procedures ensures consistent and effective corrosion management. Corrosion severity classification standards provide technicians with clear criteria for assessing equipment condition and determining appropriate responses. These standards help prioritize maintenance activities based on actual equipment condition.

Component replacement threshold settings establish objective criteria for when parts should be replaced based on measurable corrosion indicators rather than subjective assessment. Preventive maintenance plans incorporate these standards and thresholds to create scheduled maintenance activities that address corrosion before it impacts equipment reliability or safety.

Technical Development Trends and Frontier Exploration

The field of corrosion-resistant crushing technology continues to evolve with advancements in materials science, monitoring technologies, and process integration. These developments promise to further enhance the performance and economics of chemical processing equipment in corrosive environments. Staying abreast of these trends is essential for maintaining competitive advantage in chemical processing operations.

Future directions include novel materials with enhanced inherent resistance, intelligent systems that predict and prevent corrosion damage, and holistic process approaches that minimize corrosive impacts through design innovation. These advancements represent the cutting edge of corrosion engineering as applied to industrial crushing applications. Many of these innovations are being developed for various fine crusher applications as well.

Research and Development of New Anti-Corrosion Materials

Material science research continues to develop increasingly effective solutions for corrosive environments. Graphene-enhanced composite materials show promise for creating ultra-thin yet highly effective barrier coatings that resist both chemical penetration and mechanical abrasion. These advanced materials could significantly extend component life in harsh processing conditions.

Self-healing polymer coatings represent another innovative approach, containing microcapsules that release corrosion inhibitors when the coating is damaged, automatically repairing small defects before they lead to significant corrosion. Nanostructured corrosion layers engineered at the molecular level offer potentially revolutionary improvements in corrosion resistance through precise control of material structure and composition.

Application of Intelligent Monitoring Technology

Advanced sensor technologies are transforming corrosion monitoring from periodic inspection to continuous, real-time assessment. Fiber optic corrosion sensors can be distributed throughout equipment to provide detailed spatial mapping of corrosion conditions, identifying problem areas before they become critical.

Machine vision systems can automate visual inspection tasks, using image analysis algorithms to detect and quantify corrosion with greater consistency and objectivity than human inspectors. Big data analytics platforms correlate corrosion data with operational parameters to identify patterns and predictors of corrosion, enabling truly predictive maintenance approaches.