Innovative Application of Hammer Crushers in Building Materials: Optimizing Gypsum Board Raw Material Preparation

This article explores the innovative application of hammer crushers in the raw material preparation process for gypsum board production. By optimizing equipment selection, adjusting process parameters, and implementing quality control strategies, precise control of raw material particle size and significant improvements in production efficiency are achieved. The focus is on how technological advancements in crushing machinery meet the specific demands of modern building material manufacturing.

Innovative Application Scenarios of Hammer Crushers in the Building Materials Industry

The building materials industry constantly seeks efficient and reliable machinery for raw material processing. Hammer crushers have emerged as a versatile solution, particularly in the preparation of raw materials for gypsum board production. Their ability to handle moderately abrasive materials and achieve consistent particle size reduction makes them highly suitable for this application.

Unlike traditional crushing equipment, modern hammer crushers can be integrated with drying and screening systems, creating a more streamlined and efficient process. This integration is crucial for meeting the specific quality requirements of gypsum board raw materials, which demand precise control over fineness and moisture content. The adaptability of hammer crushers allows for these specific industrial needs to be met effectively. For more details on different crusher types, you can explore cone crusher applications.

Specific Requirements for Gypsum Board Raw Material Preparation

Gypsum board production imposes strict requirements on its raw material, known as gypsum stucco. The material must achieve a fine particle size, typically 200 micrometers or less, to ensure proper bonding and board strength. Furthermore, the moisture content needs to be meticulously controlled within an 8-12% range; excessive moisture can lead to longer drying times and weaker boards, while insufficient moisture can cause dust issues and poor crystallization during the board forming process.

The uniformity of the raw material is another critical factor. Inconsistent particle size distribution can directly compromise the final board's structural integrity, leading to reduced flexural strength. Therefore, the crushing process must not only reduce size but also produce a consistent and homogeneous powder to guarantee the high quality of the end product.

Adaptive Modifications of Hammer Crushers

To meet the stringent demands of gypsum processing, standard hammer crushers undergo specific modifications. The hammer heads are often fabricated from high-chromium cast iron, a material renowned for its exceptional wear resistance against moderately abrasive materials like gypsum. This significantly extends the service life of these critical wear parts and reduces maintenance frequency.

The crusher's design is also enhanced with a fully enclosed crushing chamber. This containment is vital for controlling dust, a major concern in gypsum handling, and for maintaining operational hygiene. Some advanced systems even integrate a drying apparatus within the crusher housing, allowing for simultaneous crushing and drying of the feedstock, which optimizes the entire preparation line.

Limitations of Traditional Crushing Equipment

Other crusher types, such as jaw crushers, are often ill-suited for this specific task. While excellent for primary crushing of large rocks, jaw crushers produce a relatively coarse output that requires further processing, adding complexity and cost to the production line. Their feed size acceptance is good, but control over the final product's fineness is limited.

Ball mills, another traditional option, can achieve the required fineness but are notoriously energy-intensive. They are also prone to over-grinding, which can negatively affect the gypsum's setting properties and lead to higher energy consumption per ton of processed material, making them less economical and efficient compared to modern hammer crusher systems.

Design of New Crushing Process Flows

The innovation lies not just in the machine itself but in the holistic design of the process flow. Modern systems are designed as integrated units combining crushing, drying, and screening into a single, continuous operation. This eliminates material handling between stages, reduces energy loss, and improves overall process control.

This integrated approach often includes a pre-processing system to handle raw gypsum rock of varying sizes and initial moisture content. By designing the entire line to work in harmony, manufacturers can achieve a significant boost in efficiency, product quality, and environmental performance, ensuring a steady supply of perfectly prepared raw material for the board production line.

Strategies for Optimizing Crushing Efficiency in Raw Material Preparation

Maximizing the efficiency of the crushing process is paramount for economic and operational success. This involves carefully balancing several factors, including the crusher's reduction ratio, its throughput capacity, and the configuration of its internal components. An optimized crusher operates at peak performance, consuming less energy per ton of material while delivering the desired product specification.

Efficiency gains are realized through mechanical adjustments, strategic component design, and the implementation of smart feeding and material handling systems. These optimizations work together to ensure the hammer crusher operates smoothly, minimizes downtime for maintenance, and consistently produces high-quality gypsum powder for the board manufacturing process. Understanding crushing capacity is key to this optimization.

Balancing Crushing Ratio and Processing Capacity

The crushing ratio, which defines the extent of size reduction from feed to product, is a fundamental parameter. For gypsum processing, an optimal ratio typically falls between 15:1 and 25:1. This range allows for effective size reduction to the target fineness without overloading the crusher or causing excessive wear. The processing capacity of a single machine for this application usually ranges from 30 to 80 metric tons per hour.

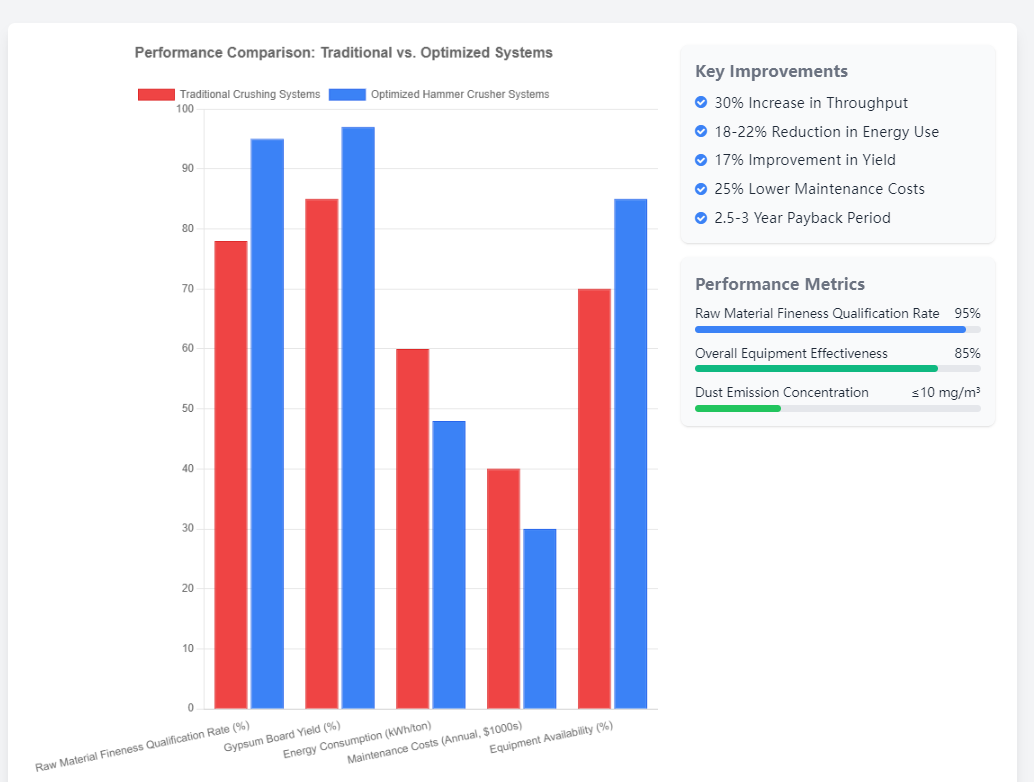

By precisely calibrating the crusher's operational parameters, such as rotor speed and grate clearance, plants can achieve a throughput increase of up to 30% without sacrificing product quality. This balance is crucial for meeting production targets while maintaining energy efficiency and the mechanical integrity of the crusher itself.

Hammer Configuration Optimization Plan

The arrangement and quality of the hammers are critical for efficient crushing. An optimized design often features three rows of hammers arranged in a staggered pattern on the rotor. This configuration ensures a more complete and uniform impact on the material bed, improving crushing efficiency and promoting a consistent product size distribution.

Maintaining tight weight tolerances for each hammer, typically within ±5 grams, is essential for rotor balance. An unbalanced rotor causes severe vibrations, leading to premature bearing failure and structural damage. Modern crushers may also include automated systems to adjust the hammer-to-liner clearance as the hammers wear, maintaining consistent performance throughout their operational life.

Improvement of Feeding Methods

Consistent and controlled feeding is the first step to efficient crushing. Utilizing a combination of a vibrating feeder and a belt weigh feeder ensures a steady, regulated flow of material into the crusher. The vibrating feeder handles material from the stockpile, while the weigh feeder provides precise mass flow data and control.

The feed material should also be pre-screened or sized to ensure no oversized rocks, typically larger than 80 mm, enter the crusher chamber, which could cause blockages or damage. Installing an instantaneous flow monitoring system allows operators to track feed rate in real-time and make immediate adjustments, preventing feeder overloads and ensuring optimal crusher operation.

Crushing Chamber Airflow Optimization

Managing airflow within the crusher is vital for controlling dust and moisture. A well-designed negative pressure dust removal system is installed to suction fine particles generated during crushing, preventing them from escaping into the plant environment. This maintains air quality and protects worker health.

The velocity of this airflow is carefully controlled, usually between 1.5 and 2.5 meters per second. This range is sufficient to carry away dust without removing an excessive amount of the valuable product. With proper airflow management, dust emission concentrations can be reliably maintained below 10 milligrams per cubic meter, meeting strict environmental standards.

Implementation of Precise Raw Material Particle Size Control Technology

Achieving and maintaining the target particle size distribution is the cornerstone of quality gypsum board production. This goes beyond simple crushing and involves integrated screening, real-time analysis, and sophisticated material handling logic. The goal is to create a closed-loop system that self-regulates to produce a consistently fine and uniform powder.

Precise size control directly influences the water demand during board formation, the setting time of the gypsum, and ultimately the mechanical strength of the dried board. Therefore, investing in advanced control technologies is not merely an operational improvement but a critical quality assurance measure. The integration of a fine crusher is often a part of this strategy.

Integrated Screening System Solutions

Following the crushing stage, the material is directed to a screening system, often a probability screen. These screens, with aperture sizes typically between 0.5 and 2 mm, are highly efficient at separating fine product from oversize material. The inclination angle of the screen deck, adjustable between 15 and 25 degrees, can be tuned to optimize material travel time and screening efficiency.

A well-designed and maintained screening system can achieve screening efficiencies exceeding 95%. This means that 95% of the undersized material is successfully separated and sent to the next process stage, while the oversize material is efficiently diverted for further processing, ensuring no合格 product is wasted.

Online Particle Size Detection Technology

Modern plants employ laser particle size analyzers installed directly in the product stream. These instruments provide real-time, continuous data on the full particle size distribution of the powder, rather than just a single point measurement. This data is crucial for immediate process adjustment.

This real-time analysis is fed into a central processing unit that forms part of a closed-loop control system. If the particle size begins to drift from the target specification, the system can automatically adjust crusher parameters, such as rotor speed or feed rate, to correct the issue before a large quantity of off-spec material is produced.

Design of the Return Material Recycling System

Oversize material from the screens is not wasted. It is automatically conveyed back to the inlet of the hammer crusher for further reduction. This returned material is known as circulating load. An optimal process operates with a circulating load ratio between 150% and 200%, meaning the crusher handles 1.5 to 2 times the amount of fresh feed.

Managing this cyclic load rate is key to stable operation. The system must be designed to handle this constant flow of return material without clogging. Engineers calculate the balance point between the crusher's capacity and the screen's efficiency to ensure the entire system operates smoothly and continuously without bottlenecks.

Measures to Ensure Raw Material Uniformity

Final product uniformity is guaranteed through multiple measures. A multi-point sampling and detection mechanism is implemented at the final product stage to continuously monitor quality. This involves automated samplers taking representative samples from the product stream at regular intervals for analysis.

Furthermore, the finished powder is often passed through a mixing or blending silo equipped with stirring devices. This step homogenizes powder from different production times, evening out any minor fluctuations and ensuring a perfectly uniform product batch. The variability in product quality, measured by the coefficient of variation (CV), is typically controlled to within 5%.

Energy Efficiency Improvement and Cost Control

In today's industrial environment, energy consumption represents a significant portion of operational costs. Therefore, optimizing the energy efficiency of crushing operations is a major focus for equipment manufacturers and plant operators alike. Strategies range from using high-efficiency motors to implementing smart energy management systems that adjust power use based on real-time load.

Beyond energy, controlling maintenance and wear part costs is essential for long-term profitability. This involves selecting longer-lasting materials, designing for easier maintenance, and adopting predictive maintenance strategies to avoid unplanned downtime. A holistic view of cost-per-ton is necessary for true optimization. The use of a hammer crusher is often central to this cost-effective approach.

Motor Power Matching Optimization

The application of Variable Frequency Drive (VFD) technology is a major step forward. Instead of running at a constant speed, the crusher's motor speed is adjusted by the VFD to match the actual feed load. This eliminates energy waste during low feed conditions and provides a soft start, reducing mechanical stress on the drive train.

Systems are designed to operate at an optimal motor load rate, typically between 75% and 85% of its full capacity. This avoids the inefficiency of underloading and the stress of overloading. Through such measures, plants have reported reductions in unit energy consumption of 18% to 22% per ton of processed gypsum.

Solutions for Extending Wear Part Life

Extending the operational life of wear parts like hammers and liners directly reduces operating costs and downtime. Hammer heads undergo surface treatments like carburization to create an extremely hard, wear-resistant outer layer while maintaining a tougher, shock-absorbing core.

The design of the chamber liners is also optimized. By curving the liners to match the material's trajectory, they promote a more efficient crushing action and reduce unnecessary wear. Through these material and design improvements, the replacement interval for key wear parts can be extended to six months or more, depending on production volume.

Maintenance Cost Optimization Strategy

Moving from reactive to predictive maintenance is a key strategy. Predictive maintenance systems use sensors to monitor the condition of key components like bearings and rotors, analyzing data like vibration and temperature to predict failures before they occur.

This allows maintenance to be scheduled during planned downtime, preventing costly unplanned stops and catastrophic damage. By addressing issues early and planning parts replacements, plants can reduce their annual maintenance expenses by approximately 25% and increase overall equipment availability.

Production Capacity and Investment Return Analysis

The investment in a modern, optimized hammer crusher system for gypsum preparation is significant but offers a compelling return. The payback period for such equipment typically ranges from 2.5 to 3 years based on operational savings and increased production.

These savings are realized through lower energy consumption, reduced maintenance costs, and higher throughput. The processing cost per ton of raw material can be reduced by $8 to $12. Furthermore, the overall line efficiency, measured as Overall Equipment Effectiveness (OEE), can see a dramatic increase, reaching levels of 85% or higher, indicating highly effective use of the machinery.