Comprehensive Guide to Bearing Health Management for PC Series Hammer Crushers: A Full-Curation Maintenance Strategy from Vibration Analysis to Lubrication Optimization

Maintaining the operational integrity of industrial machinery requires a meticulous approach to component health, particularly for critical elements like bearings in hammer crushers. This guide provides a thorough exploration of advanced monitoring and maintenance strategies, focusing on vibration analysis and lubrication optimization. These methodologies form the cornerstone of predictive maintenance, enabling the early detection of faults and the extension of component lifespan. The subsequent sections will delve into the technical specifics of interpreting vibration signatures and implementing real-time lubrication monitoring systems, offering a holistic framework for ensuring crusher reliability and efficiency.

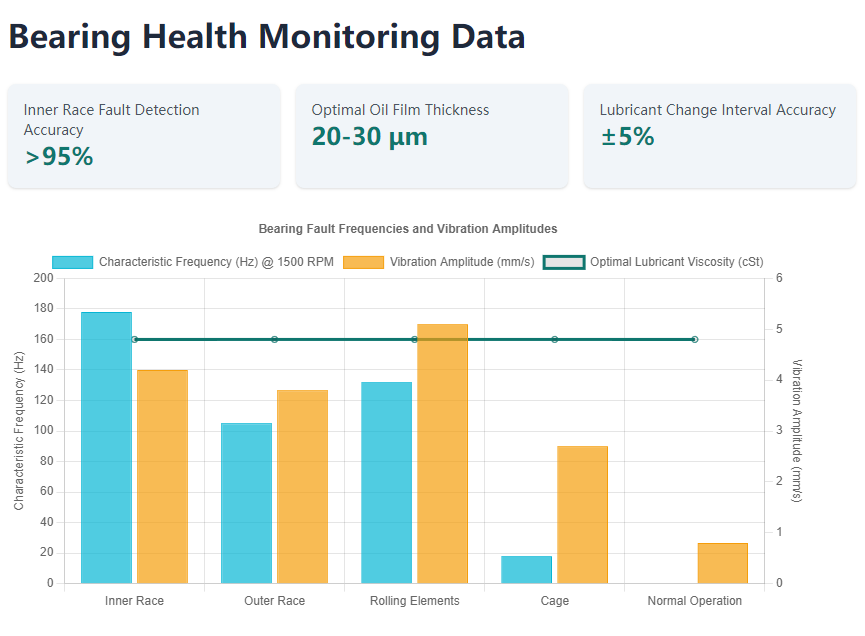

Vibration Spectrum Analysis for Bearing Faults

Vibration analysis serves as a powerful diagnostic tool for identifying impending bearing failures in hammer crushers. The unique vibrational signatures generated by damaged components provide early warnings long before catastrophic breakdowns occur. By examining the frequency spectrum of these vibrations, maintenance teams can pinpoint the exact nature and location of a fault, whether it lies on the inner race, outer race, or among the rolling elements.

Significant differences exist between the spectral patterns of inner and outer race faults. Inner race defects typically produce high-frequency signals modulated by the rotation speed of the crusher's rotor assembly, while outer race faults often generate more constant vibrational echoes. Cage damage introduces its own distinct modulation patterns, which can be identified through careful spectral analysis. Mastering the interpretation of these differences is fundamental to proactive maintenance of any hammer crusher.

Calculation Formulas for Rolling Bearing Fault Characteristic Frequencies

Every type of bearing has specific geometric properties that determine its characteristic fault frequencies. These frequencies can be precisely calculated using established formulas that account for the number of rolling elements, their diameter, the pitch diameter, and the contact angle. For instance, the fundamental train frequency, or cage frequency, is derived from the rotational speed and the bearing dimensions.

Taking a standard NU220E bearing as a reference, its fault frequency table reveals distinct values for inner race, outer race, ball spin, and cage frequencies relative to the shaft speed. These calculated values provide the baseline against which measured vibration data is compared. Any deviation or amplification at these specific frequencies indicates the initiation of a corresponding fault, allowing for precise diagnostic conclusions.

Interpreting Sideband Frequencies in Spectrum Analysis

Sidebands are frequency components that appear symmetrically around a dominant frequency peak in a vibration spectrum. Their presence often indicates amplitude or frequency modulation, typically caused by a recurring impact from a damaged component. In the context of a hammer crusher, the interplay between bearing fault frequencies and other machine frequencies, like gear mesh, can create complex sideband patterns.

A thorough analysis requires decoupling these interactions. For example, a faulty bearing located near a gearbox might produce sidebands around the gear mesh frequency, spaced at the bearing's fault frequency. Correctly interpreting these patterns is crucial to avoid misdiagnosis and to accurately identify the primary source of the vibration, ensuring that maintenance efforts are directed appropriately.

The Impact of Vibration Sensor Mounting Angle on Signal Quality

The quality and clarity of vibration data are profoundly influenced by how and where the sensor is mounted on the crusher housing. The orientation of the sensor determines its sensitivity to different force vectors generated by the rotating assembly. An accelerometer mounted in the axial direction will capture different data than one mounted radially, either horizontally or vertically.

Comparative experiments consistently demonstrate that signal-to-noise ratios vary significantly with mounting angle. Vertical mounting often provides the clearest signal for detecting imbalances, while horizontal mounting may be more sensitive to misalignment. Axial mounting is critical for capturing thrust-related issues. Selecting the optimal mounting position is therefore a prerequisite for acquiring high-fidelity data that can be trusted for accurate fault diagnosis.

Rapid Diagnostic Procedure with Portable Vibration Analyzers

Portable vibration analyzers empower maintenance personnel to conduct swift and effective condition assessments directly on the crusher floor. The process begins with the strategic placement of the sensor on pre-defined measurement points on the crusher's bearing housings. The instrument then captures a time waveform and converts it into a frequency spectrum for analysis.

A proven five-step methodology guides the user from data acquisition to fault localization. This involves recording baseline spectra, comparing them to historical data, identifying anomalous peaks at characteristic frequencies, analyzing sideband patterns for confirmation, and finally, correlating the findings to pinpoint the exact faulty component. This streamlined process transforms complex data into actionable maintenance insights.

Real-Time Monitoring Technologies for Bearing Lubrication State

Optimal lubrication is the lifeblood of any bearing system, directly influencing its temperature, wear rate, and ultimate failure point. Real-time monitoring technologies move beyond scheduled lubrication towards a condition-based approach, ensuring that lubricant is always present in the correct quantity and quality. This proactive strategy prevents both the starvation that causes wear and the over-lubrication that leads to excessive heat and churning losses.

The dynamic relationship between oil film thickness and the coefficient of friction is central to this process. A sufficient film thickness separates the metal surfaces completely, resulting in low friction and minimal wear. As the film thins due to degradation or contamination, boundary lubrication occurs, friction increases, and the risk of adhesive wear rises dramatically. Continuous monitoring of these parameters is essential for crushers operating under heavy load conditions.

Installation and Calibration of Ultrasonic Lubrication Monitors

Ultrasonic lubrication monitors detect high-frequency acoustic emissions generated by the friction between components, emissions that are inaudible to the human ear. These sensors are typically mounted on the crusher's bearing housing using a magnetic base or adhesive, positioned to have a direct path to the lubricant. Proper installation is critical to avoid signal attenuation or interference from external noise sources.

Calibration involves creating a baseline correlation between the amplitude of the ultrasonic signal and the actual lubricant film thickness. This is achieved by taking measurements under known conditions of optimal lubrication and starvation. The resulting calibration curve allows the monitor to translate raw acoustic emission data into a meaningful quantitative value for oil film thickness, providing a clear indication of the current lubrication state.

Sensor Selection for Online Lubricant Viscosity Detection

Selecting the appropriate sensor for online viscosity monitoring depends on the operating environment and the specific lubricant used in the crusher's bearings. Modern in-line viscometers operate on various principles, including vibrational, mechanical, and optical methods. These sensors are integrated directly into the lubrication system, providing continuous real-time data on lubricant health.

A key consideration in interpretation is understanding the relationship between different viscosity measurement scales. While some sensors may output a value related to cone penetration, the industry standard for grease, others report kinematic viscosity. Understanding the conversion factors between these units is vital for accurately assessing whether the lubricant remains within its specified operational window and for making informed decisions about its remaining useful life.

Preparation and Microscopic Observation of Ferrography Analysis Slides

Ferrography analysis is a detailed technique for assessing wear by examining the particles suspended in a lubricant sample. The process begins with preparing an analysis slide, where a diluted oil sample is drawn across a specially treated substrate under a magnetic field. This field aligns ferrous particles according to size, depositing them onto the slide for examination.

Under a microscope, these particles reveal a wealth of information. Their size, shape, concentration, and composition are diagnostic of specific wear modes. Small, rubbing wear particles indicate normal operation, while larger, fatigue chunks or severe sliding platelets signal advanced and abnormal wear stages. This analysis provides a direct window into the condition of the bearing surfaces, far beyond what viscosity alone can indicate.

Dynamic Adjustment Algorithm for Lubrication Maintenance Cycles

Fixed-interval lubrication schedules are often inefficient, either wasting resources or leading to premature failures. Dynamic adjustment algorithms offer a smarter alternative by continuously calculating the optimal lubricant change interval based on real-time operating parameters. These algorithms process data from various sensors, including temperature, load, vibration, and moisture levels.

The core of the algorithm is a predictive model that estimates the rate of lubricant degradation under the current crusher operating conditions. By integrating this data, the system can accurately forecast the remaining useful life of the oil or grease. This enables maintenance to be performed precisely when needed, maximizing the use of the lubricant while guaranteeing that the bearing is never at risk due to degraded lubrication, a critical function for machinery in mining and quarrying.