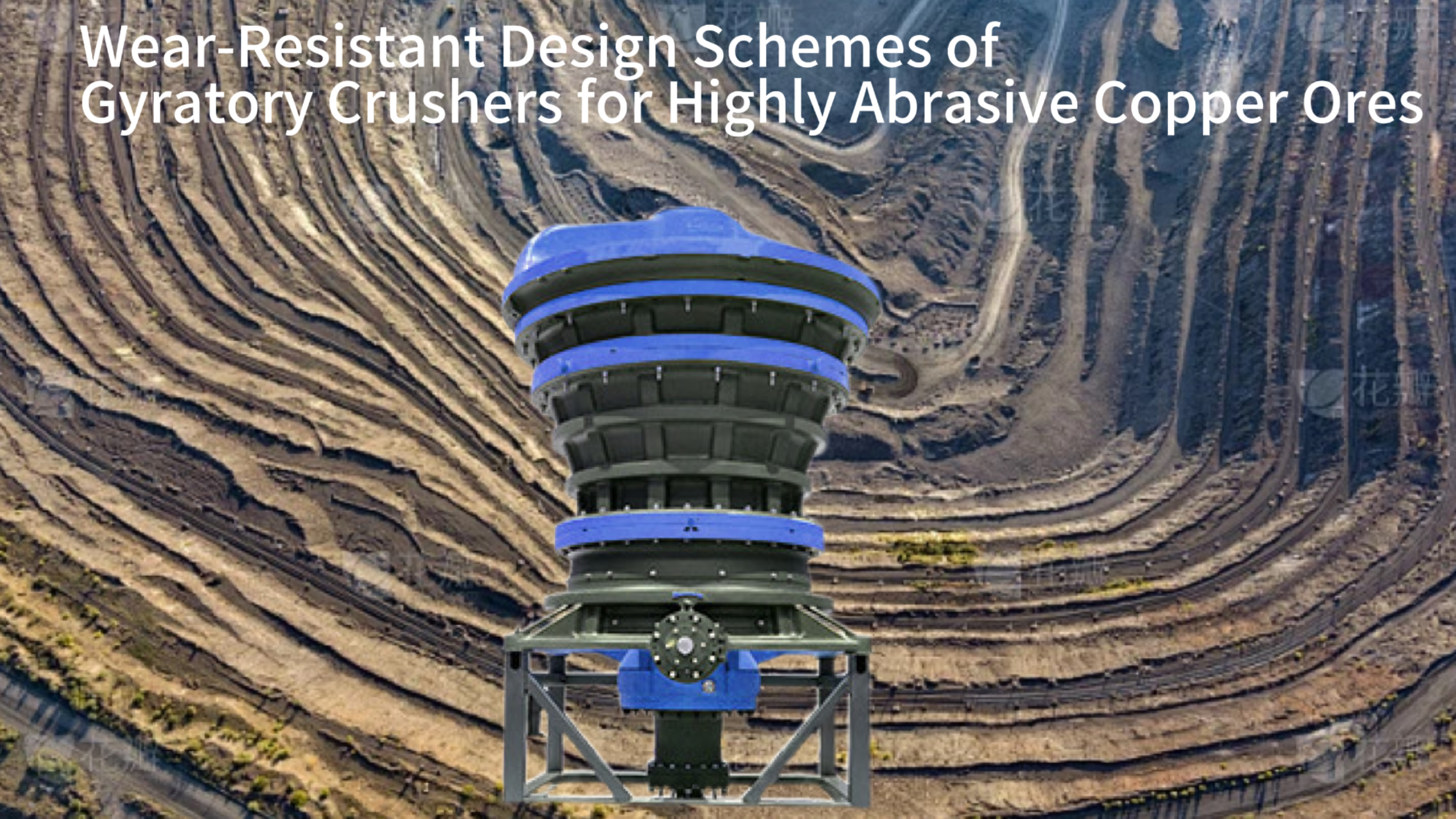

Wear-Resistant Design Schemes of Gyratory Crushers for Highly Abrasive Copper Ores

Processing highly abrasive copper ores presents exceptional challenges for gyratory crushers in mining operations worldwide. These robust machines face accelerated wear rates that can dramatically reduce operational efficiency and increase maintenance costs without proper design considerations. This comprehensive guide explores advanced wear-resistant strategies specifically developed for gyratory crushers handling tough copper ores with significant quartz content and abrasive characteristics. The following sections will examine material science innovations, structural design improvements, surface enhancement technologies, operational best practices, and comprehensive management systems that collectively extend component lifespan while maintaining crushing performance under extreme conditions. Mining professionals will discover practical approaches to transform their crushing circuits from high-maintenance liabilities into reliable, cost-effective assets through scientifically-backed wear protection methodologies.

Comprehensive Wear-Resistant Design Scheme for Gyratory Crushers

Ore Characteristics Analysis

Determine quartz content (30-60% typical range)

Measure abrasion indices (Bond, Yancy-Geer-Price)

Analyze mineral composition and hardness profiles

Material Selection

High-chromium cast iron (600-800 BHN) for severe abrasion

Bimetal composites for critical high-wear zones

Alloyed manganese steels for moderate conditions

Chamber & Structural Optimization

Curved profiles for uniform wear distribution

Interparticle crushing promotion design

Optimized stroke and speed parameters

Surface Enhancement

Automated hardfacing application

Laser cladding for precision protection

Controlled repair processes for worn components

Operational & Maintenance Systems

Advanced lubrication with condition monitoring

Optimized feed distribution systems

Total cost of ownership tracking

Monitoring & Continuous Improvement

Wear component lifecycle documentation

Personnel training programs

Smart sensors and predictive analytics

Implementation of this comprehensive scheme typically extends liner life by 30-40% in highly abrasive copper ore applications while reducing overall operational costs.

The Severe Challenges Posed by Highly Abrasive Copper Ores to Gyratory Crushers

Copper ores containing substantial quartz content create uniquely demanding environments for gyratory crushing equipment that require specialized understanding and preparation. The extreme abrasiveness of these materials accelerates component deterioration through multiple mechanical processes that collectively compromise crusher integrity and operational economics.

The Relationship Between Copper Ore Mineralogical Characteristics and Abrasiveness

Copper ores derive their abrasive properties primarily from quartz content that typically ranges between 30 and 60 percent in many economically significant deposits. Quartz particles possess a Mohs hardness of 7, significantly exceeding the hardness of most crusher liner materials under working conditions. This hardness differential creates a microscopic cutting action that progressively removes material from crusher surfaces through a process known as three-body abrasion. The angular fracture patterns of crushed quartz further exacerbate wear rates by creating fresh, sharp edges that continuously renew the abrasive action throughout the crushing process.

Additional mineralogical factors influencing wear rates include the presence of other hard minerals like feldspar and garnet, the cementation strength between mineral particles, and the overall rock structure. Massive sulfide ores typically present different wear challenges compared to porphyry copper deposits due to variations in mineral association and bonding characteristics. Understanding these geological factors enables mining operations to anticipate wear patterns and select appropriate countermeasures before commissioning new crushing circuits or processing different ore types from varying pit locations.

Identifying Key Wear Areas Inside Gyratory Crushers: From Mantle to Concave

Gyratory crushers experience concentrated wear in specific zones where rock compression and sliding actions are most intense. The mantle and concave surfaces endure the most significant material loss, with wear patterns following predictable trajectories based on the crusher's operational parameters and feed characteristics. The upper section of the crushing chamber typically demonstrates the highest wear rates as initial rock impact and coarse reduction occur in this region. Progressive wear moves downward through the chamber as material travels toward the discharge opening, creating distinctive wear profiles that can be monitored and managed.

Secondary wear areas include the spider arm shields, dust seal rings, and various internal protection plates that safeguard structural components from abrasive particles. Each of these zones requires specific consideration in wear protection strategies as they experience different types of mechanical action and material flow patterns. Comprehensive wear management involves not only addressing the primary crushing surfaces but also protecting these ancillary components that contribute to overall crusher reliability and prevent catastrophic failures that could result from unprotected wear in secondary areas.

The Cascading Negative Effects of Equipment Wear on Downstream Processes

Progressive wear in gyratory crushers initiates a chain reaction of operational challenges that extend far beyond the crushing circuit itself. As mantle and concave profiles change through wear, the crusher's product size distribution shifts toward coarser fractions that overload subsequent grinding stages. This size distribution alteration forces grinding mills to work harder to achieve target liberation sizes, increasing energy consumption by up to 15 percent in documented cases. The resulting coarser feed to milling circuits also accelerates wear in ball mill liners and grinding media, compounding maintenance costs across multiple process stages.

Additional downstream impacts include reduced recovery rates in flotation circuits due to inadequate mineral liberation, increased pumping costs for slurry transport, and greater reagent consumption in hydrometallurgical processes. These interconnected effects demonstrate that gyratory crusher wear management represents not merely a maintenance concern but a fundamental process optimization opportunity with implications for entire mineral processing plants. Progressive wear also increases the frequency of unplanned downtime events that disrupt continuous operation and reduce overall plant availability, creating production losses that often exceed direct maintenance expenses.

Quantifying Wear Costs: Beyond Component Replacement, What Are the Hidden Costs?

The true economic impact of gyratory crusher wear in copper ore applications extends far beyond the direct expenses of replacing mantles, concaves, and other consumable components. Comprehensive cost analysis must account for production losses during changeout periods, which typically range from 24 to 48 hours for major liner replacements in large gyratory crushers. These downtime events represent significant opportunity costs, particularly in operations running at full capacity where lost production cannot be recovered. Additional labor costs for maintenance crews, specialized equipment requirements for handling heavy components, and consumables like welding materials further contribute to the total expense.

Less apparent but equally significant are the energy penalties associated with operating crushers with worn components. Research indicates that worn crushing chambers can increase power consumption by 8-12 percent due to reduced crushing efficiency and increased material recirculation. The cumulative effect of these hidden costs often exceeds direct component replacement expenses by a factor of two to three, making comprehensive wear management economically imperative rather than merely desirable. Operations that track these total cost of ownership metrics typically discover that strategic investments in superior wear protection yield returns significantly exceeding their initial costs through extended component life and improved operational efficiency.

The Core of Wear Resistance: Advanced Materials and Alloy Technology

Material selection represents the foundational element in combating wear in gyratory crushers processing abrasive copper ores. Modern metallurgical science has developed specialized alloys and composite structures that dramatically outperform conventional materials in these demanding applications.

The Work Hardening Principle of Hadfield Manganese Steel and Its Limitations in Copper Ore Crushing

Traditional manganese steel derives its wear resistance from a unique capacity to work-harden under impact, transforming from an initial hardness of approximately 200 BHN to over 500 BHN through surface deformation during service. This characteristic makes it well-suited for applications involving significant impact forces, but proves less effective against the predominantly abrasive wear encountered in copper ore processing. The limited work-hardening response under pure abrasion leaves manganese steel vulnerable to rapid material loss when processing quartz-rich ores, particularly in the middle and lower sections of the crushing chamber where impact forces diminish.

Further limitations emerge from manganese steel's relatively low initial hardness, which permits substantial material removal before work-hardening occurs. In applications involving continuous processing of highly abrasive materials, this initial wear phase represents a significant portion of total component life. Modified manganese steels with carbide-forming additions like chromium and molybdenum have been developed to address these limitations, but still fall short of the performance achieved by more specialized alloy systems specifically engineered for abrasive ore processing.

The Advantages of New Generation High-Chromium Cast Iron and Bimetal Composite Liners

High-chromium white iron alloys represent a significant advancement in abrasion resistance for copper ore crushing applications. These materials achieve hardness levels between 600-800 BHN through the formation of hard chromium carbides distributed throughout a martensitic matrix. The carbide networks provide exceptional resistance to quartz abrasion while the tough matrix prevents catastrophic failure under operational stresses. Modern foundry techniques enable precise control of carbide size, distribution, and orientation to optimize both wear resistance and mechanical reliability in finished components.

Bimetal composite liners combine the superior surface hardness of high-chromium iron with the toughness and impact resistance of manganese or low-alloy steel substrates. These advanced components utilize metallurgical bonding techniques to create a seamless interface between materials, eliminating the weaknesses associated with mechanical attachments or weld overlays. The resulting composite structures provide targeted wear protection exactly where needed while maintaining structural integrity under the dynamic loading conditions inherent to gyratory crushing. This approach represents the current state-of-the-art in wear component design for the most demanding copper ore applications.

How to Select Liner Material Grades Based on Specific Copper Ore Abrasiveness Index

Material selection for gyratory crusher liners should correlate directly with the measured abrasiveness of the specific copper ore being processed. Standardized abrasion tests like the Bond Abrasion Index and the Yancy, Geer, and Price method provide quantitative data for making informed material decisions. Ores with abrasion indices below 0.300 typically perform adequately with premium manganese steel alloys, while indices between 0.300 and 0.500 warrant consideration of alloyed manganese steels with carbide-forming additions. For severely abrasive ores exceeding 0.500 on standard abrasion indices, high-chromium white irons or bimetal composites deliver substantially improved service life despite their higher initial cost.

Beyond simple abrasion indices, material selection must also consider the ore's compressive strength, moisture content, and feed size distribution, as these factors influence the type and intensity of wear mechanisms encountered. Operations processing variable ore types may implement different liner materials for different ore sources or employ zoned liner designs that place specialized materials in high-wear areas while using more economical options in less demanding locations. This strategic approach optimizes the economic balance between liner cost and service life across the complete range of processing conditions.

Material Certification and Quality Traceability: Ensuring You Receive Genuine Wear-Resistant Materials

The performance advantages of advanced wear-resistant alloys depend entirely on consistent material composition, proper heat treatment, and controlled manufacturing processes. Reputable suppliers provide comprehensive material certification documenting chemical composition, mechanical properties, and heat treatment parameters for each production batch. These certificates should reference internationally recognized standards and include results from destructive testing of witness samples to verify claimed properties. Operations processing highly abrasive copper ores should establish material certification as a mandatory requirement for all wear component purchases.

Quality traceability systems extend beyond initial certification to track components throughout their service life. Marking systems that survive the entire wear life enable correlation between specific production batches and field performance, creating valuable data for continuous improvement in material selection. Advanced operations implement digital tracking systems that record installation dates, operational hours, throughput tonnage, and measured wear patterns for each major component. This comprehensive approach transforms wear component management from a reactive replacement activity to a strategic optimization process based on empirical performance data.

Beyond Materials: Optimizing Crushing Chamber and Structural Design to Distribute Wear

Intelligent crusher design represents an equally important approach to wear management alongside material selection. Modern gyratory crushers incorporate sophisticated chamber profiles and structural features that actively manage wear patterns rather than simply resisting material loss.

Comparison of Different Chamber Design Profiles in Copper Ore Applications

Gyratory crusher chamber profiles significantly influence both performance characteristics and wear distribution patterns. Straight-profile chambers provide maximum capacity but concentrate wear in specific areas, leading to premature failure and irregular product size distribution as wear progresses. Curved chamber designs better match the natural flow path of material through the crusher, reducing unnecessary sliding and resulting in more uniform wear distribution. The optimal chamber profile balances capacity requirements with wear management objectives based on the specific characteristics of the copper ore being processed.

Modern chamber design utilizes sophisticated computer modeling to predict material flow and wear patterns before manufacturing. These digital simulations enable engineers to optimize chamber geometry for specific ore characteristics, creating custom profiles that maximize both performance and component life. Operations processing multiple ore types with significantly different abrasiveness characteristics may benefit from maintaining different chamber profiles optimized for each ore type, changing liners and profiles as ore sources shift. This strategic approach extends liner life significantly compared to using a single compromise design for all material types.

What Is Interparticle Crushing and Its Wear Resistance Benefits?

Interparticle crushing represents an advanced operating philosophy that leverages the abrasive ore itself to reduce wear on crusher components. This approach maximizes rock-on-rock compression by ensuring the crushing chamber remains adequately filled with material at all times. As particles compress against each other rather than sliding directly against liner surfaces, wear rates decrease dramatically while maintaining efficient size reduction. Properly implemented interparticle crushing can reduce liner wear by 30-40 percent while simultaneously improving energy efficiency and product shape characteristics.

Achieving optimal interparticle crushing requires precise control of crusher operating parameters including feed rate, closed-side setting, and crusher speed. Modern automated control systems continuously adjust these parameters to maintain the optimal material bed depth throughout the wear life of the liners. The transition to interparticle crushing represents a significant operational philosophy shift from traditional methods focused on maximizing throughput at any cost to a balanced approach that optimizes multiple performance indicators including wear rates, energy consumption, and product quality.

Optimizing Material Path Through the Crushing Chamber by Adjusting Stroke and Speed

The gyratory crusher's operational kinematics directly influence how material moves through the crushing chamber and consequently how wear develops on liner surfaces. Stroke characteristics determine how far the mantle moves toward and away from the concave during each cycle, influencing both the intensity of compression and the sliding distance between rock and liner surfaces. Optimal stroke settings balance adequate compression force for effective size reduction against excessive sliding that accelerates abrasive wear. Modern crushers offer adjustable stroke capabilities that enable operations to fine-tune this critical parameter for specific ore characteristics.

Crusher speed, measured in eccentric throws per minute, interacts with stroke to determine the overall material residence time within the crushing chamber. Higher speeds typically increase capacity but reduce interparticle crushing effectiveness and may increase wear rates through more frequent impact events. Lower speeds enhance interparticle crushing but may reduce throughput below economic targets. The optimal balance varies with ore characteristics, particularly abrasiveness and compressive strength. Operations processing highly abrasive copper ores typically benefit from slightly reduced speeds that promote interparticle crushing and reduce liner wear, accepting modest capacity reductions in exchange for significantly extended component life.

Case Study: How Chamber Optimization Increased Liner Life by Over 30 Percent

A major copper operation processing ore with 55 percent quartz content documented a comprehensive chamber optimization program that delivered exceptional results. The operation initially used standard straight-profile concaves with premium manganese steel construction, achieving an average service life of 650,000 tonnes between replacements. Detailed wear mapping revealed concentrated wear in the upper section of the crushing chamber that limited overall liner life despite significant remaining material thickness in lower regions.

The optimization program implemented a custom curved chamber profile specifically designed for the operation's ore characteristics and throughput requirements. The new profile distributed crushing action more evenly throughout the chamber depth, eliminating the concentrated wear zone that previously dictated replacement timing. Combined with a transition to bimetal composite concaves in the high-wear upper section, the redesigned chamber increased service life to 860,000 tonnes between replacements while maintaining product quality specifications. The 32 percent life extension reduced annual liner costs by approximately $185,000 while decreasing crusher downtime from 42 to 29 hours per year, delivering a complete return on investment in less than six months.

Surface Enhancement and Repair Technologies: Tools to Extend Component Service Life

Advanced surface treatments and repair methodologies provide additional weapons in the battle against wear, extending component life beyond inherent material capabilities through targeted enhancement of critical surfaces.

The Hardfacing Process Flow and Quality Control Essentials

Hardfacing applies wear-resistant alloys to crusher components through specialized welding processes, creating a protective surface layer that withstands abrasive wear far better than the base material. The process begins with thorough surface preparation including cleaning, preheating, and sometimes machining to create optimal conditions for deposit adhesion. Application typically employs automated welding equipment that ensures consistent deposit thickness, chemical composition, and microstructure throughout the treated surface. Post-weld heat treatment often follows to relieve residual stresses and optimize the metallurgical structure of both the deposit and the heat-affected zone.

Quality control in hardfacing focuses on three critical areas: bond integrity between deposit and base material, deposit microstructure, and final surface characteristics. Non-destructive testing methods including magnetic particle inspection and ultrasonic examination verify the absence of cracks, inclusions, or lack-of-fusion defects that could compromise performance. Metallographic analysis of witness samples confirms proper microstructure development with optimal carbide distribution and absence of detrimental phases. Final dimensional inspection ensures the hardfaced component will fit properly within assembly tolerances while providing the intended wear protection throughout its service life.

Performance and Cost Comparison Between Laser Cladding and Traditional Hardfacing Technologies

Laser cladding represents a technological evolution beyond traditional hardfacing methods, offering significant advantages for certain gyratory crusher applications. The process uses a high-power laser to create a small molten pool on the component surface into which precisely metered powder feedstock is injected. This controlled approach creates a metallurgically bonded layer with minimal dilution from the base material, preserving the full wear resistance of the deposited alloy. The extremely focused heat input minimizes thermal distortion and the extent of the heat-affected zone, reducing post-processing requirements and preserving the base material's mechanical properties.

Traditional hardfacing methods including submerged arc welding and open arc welding remain economically advantageous for large-area applications where the superior properties of laser cladding provide limited operational benefits. The decision between technologies involves careful consideration of component size, geometry, required wear resistance, and economic factors. Laser cladding typically commands a 40-60 percent cost premium over traditional methods but can extend service life by an additional 25-40 percent in severely abrasive applications. This economic equation favors laser technology for critical high-wear components where extended service life provides substantial operational benefits through reduced downtime and improved performance consistency.

Successful Liner Repair Case Study: Procedures, Results, and Key Considerations

A copper operation in South America implemented a comprehensive liner repair program that transformed their approach to wear management. The operation previously discarded concaves when wear reached approximately 60 percent of original thickness, following manufacturer recommendations. Analysis revealed that the discarded components still contained significant structural integrity and could be returned to service through proper repair methodologies. The implemented program begins with detailed inspection and measurement of worn components to identify repairable units meeting specific criteria regarding crack presence, deformation, and minimum remaining thickness.

Qualified components undergo a multi-step repair process starting with stress relief heat treatment followed by welding reconstruction of worn areas using specially developed filler metals matching the original material properties. The rebuilding process restores critical dimensions while incorporating design improvements identified through wear pattern analysis. Finished components undergo comprehensive quality verification including dimensional inspection, hardness testing, and non-destructive examination before being returned to service. The program extends average concave life from one campaign to three full service cycles, reducing component costs by approximately 65 percent while maintaining performance equivalent to new parts. This approach demonstrates how strategic repair initiatives can dramatically impact operational economics in copper ore processing.

Decision Guide: When Should Components Be Repaired Versus Replaced?

The repair-or-replace decision represents a critical economic determination in gyratory crusher wear management. Multiple factors influence this decision including the component's current condition, repair costs, expected extended service life, and operational considerations. Components with wear limited to specific areas while maintaining structural integrity generally present favorable repair economics. Conversely, components exhibiting widespread wear, significant cracking, or permanent deformation typically warrant replacement rather than attempted repair. The economic breakpoint typically occurs when repair costs approach 50-60 percent of replacement costs for similar remaining life expectancy.

Operational factors including crusher availability requirements, inventory levels, and planned maintenance schedules also influence the repair-or-replace decision. Operations with limited spare components may choose repair options even at marginally favorable economics to maintain operational flexibility. Conversely, operations with well-established maintenance cycles and adequate spares inventory may establish stricter economic criteria for repair authorization. Documented decision guidelines help maintain consistency in these determinations across multiple maintenance events and personnel changes, ensuring optimal economic outcomes over the long term.

Synergistic Operations: The Impact of Lubrication Systems and Equipment Operation on Wear Resistance

Proper operational practices and auxiliary systems significantly influence wear rates in gyratory crushers processing abrasive copper ores. These factors work synergistically with material and design approaches to deliver comprehensive wear protection.

More Than Lubrication: The Role of Lubricants in Wear Protection Systems

High-performance lubricants in gyratory crushers serve functions far beyond simple friction reduction. Modern specialty lubricants formulated for abrasive service conditions incorporate extreme pressure additives that form protective surface films on gear teeth and bearings, preventing metal-to-metal contact even under shock loading conditions. These lubricants also function as hydraulic fluids in adjustment systems, corrosion inhibitors on exposed surfaces, and most importantly as cleansing agents that remove abrasive particles from critical interfaces. The continuous filtration and cooling of lubricating oil represents one of the most effective methods for preventing three-body abrasion in crusher bearings and gears.

Advanced lubricant analysis programs provide early warning of abnormal wear conditions within the crusher. Regular oil sampling and analysis detects increasing metal content that indicates component degradation long before failure occurs. Additional testing reveals lubricant contamination from external sources including water and dust ingress, or internal degradation through oxidation or additive depletion. This predictive capability enables planned interventions during scheduled maintenance periods rather than emergency responses to unexpected failures. Operations that implement comprehensive lubricant management typically experience 15-20 percent longer component life in bearings and gears while reducing unscheduled downtime by up to 40 percent.

How Feed Hopper and Distributor Design Ensure Even Feeding and Prevent Waterfall Effect

Proper feed presentation to gyratory crushers significantly influences wear distribution and overall component life. The waterfall effect occurs when feed material falls directly onto specific areas of the mantle rather than distributing evenly around the crushing chamber. This concentrated feeding accelerates localized wear while leaving other areas underutilized, reducing overall liner life and creating irregular product size distribution. Modern feed systems incorporate engineered distributors that actively direct material into the crushing chamber in a controlled pattern that matches the crusher's natural material flow characteristics.

Feed hopper design works in conjunction with distributors to ensure consistent material delivery without segregation or interruption. Optimal hopper geometry prevents material bridging while promoting first-in-first-out flow that maintains consistent feed characteristics. The transition from hopper to distributor incorporates impact plates or rock boxes that absorb the energy of falling material, preventing direct impact damage to the distributor itself. Operations that have upgraded from simple chute arrangements to engineered feed systems typically report 20-30 percent improvements in liner life through more even wear distribution and elimination of localized impact damage.

Operating Parameter Settings: Optimal Matching of Discharge Setting and Power

The relationship between discharge setting and power consumption represents a critical operational balance in gyratory crusher performance and wear management. Operating with excessively tight settings maximizes reduction ratios but increases power demand, circulating load, and wear rates. Conversely, overly generous settings reduce power consumption and wear but produce coarser product that may overload downstream processes. The optimal balance varies with ore characteristics including abrasiveness, compressive strength, and feed size distribution. Modern control systems continuously adjust the closed-side setting in response to power draw and other operating parameters to maintain this balance throughout the liner wear cycle.

Advanced operations implement setting strategies that vary throughout the liner life to maintain consistent product quality as wear changes the effective crushing geometry. This approach typically begins with slightly more open settings when liners are new, progressively tightening as wear develops to maintain product size distribution. The specific adjustment schedule derives from historical wear pattern data correlated with product quality measurements. This proactive approach to setting management maintains more consistent performance throughout the liner life compared to fixed-setting operation while optimizing the trade-off between wear rates and product quality.

Using Lubricant Analysis as a Predictive Maintenance Tool for Wear Monitoring

Systematic lubricant analysis provides invaluable data for predicting wear progression in gyratory crushers long before component failure occurs. Regular sampling at predetermined intervals establishes baseline conditions when components are new or newly serviced, enabling detection of abnormal wear patterns as they develop. Increasing concentrations of specific metals indicate wear in particular components: iron from gears and housings, copper from bushings, and tin or lead from Babbitt bearings. The rate of increase in metal content often proves more significant than absolute concentrations, providing early warning of accelerating wear conditions.

Advanced lubricant analysis extends beyond simple elemental spectroscopy to include particle counting, ferrography, and analytical ferrography that provide detailed information about wear particle size, concentration, and morphology. These sophisticated techniques differentiate between normal rubbing wear and more severe cutting wear or fatigue spalling, enabling precise diagnosis of developing problems. Correlation of lubricant analysis data with operational parameters and component inspection findings creates a comprehensive understanding of crusher health that supports truly predictive maintenance strategies. Operations that fully implement these techniques typically reduce bearing-related failures by over 80 percent while extending average component life through early intervention at the first signs of abnormal wear.

Building a Comprehensive Wear Management System for Gyratory Crushers

Optimal wear resistance in gyratory crushers processing abrasive copper ores requires an integrated management approach that coordinates materials, design, operations, and maintenance into a cohesive system.

The Mindset Shift from Purchase Price to Total Cost of Ownership: Benefits Realized

The transition from evaluating crusher components based on initial purchase price to analyzing total cost of ownership represents a fundamental philosophical shift with substantial economic implications. Total cost of ownership calculations incorporate all expenses associated with components throughout their service life including purchase price, installation labor, operational energy consumption, maintenance requirements, and eventual removal and replacement. This comprehensive analysis frequently reveals that components with higher initial costs deliver significantly lower total costs through extended service life, reduced maintenance requirements, and improved operational efficiency.

Advanced operations implement total cost of ownership as the primary decision metric for all major wear component purchases. This approach requires systematic data collection including accurate service life records, detailed maintenance cost tracking, and operational parameter monitoring. The resulting database enables evidence-based component selection rather than reliance on supplier claims or historical preferences. Operations that have fully implemented this approach typically reduce their total crushing costs by 15-25 percent through optimized component selection and improved maintenance practices. The mindset shift also encourages longer-term strategic thinking about crusher management rather than short-term cost minimization.

Creating a Lifecycle Management File for Your Gyratory Crusher Wear Components

Systematic documentation of wear component performance forms the foundation of effective gyratory crusher management. A comprehensive lifecycle management file tracks each major component from receipt through final retirement, creating a valuable knowledge base for continuous improvement. The file begins with manufacturer documentation including material certifications, inspection reports, and dimensional verification records. Installation documentation captures critical pre-startup measurements, alignment verification, and bolt torque records that establish baseline conditions for future reference.

Operational tracking forms the core of the lifecycle file, recording throughput tonnage, operational hours, power consumption, and product quality measurements throughout the component's service life. Regular inspection records document wear progression through measurements and photographs, creating a visual history of wear patterns. Maintenance interventions including adjustments, repairs, and component rotations receive detailed documentation with associated costs and personnel records. Final retirement documentation includes comprehensive measurements of remaining dimensions, analysis of failure mechanisms if applicable, and recommendations for future improvements. This systematic approach transforms wear component management from a reactive maintenance activity to a strategic optimization process based on empirical data.

Training Operations and Maintenance Teams: The Human Factor as the Most Critical Element in Wear Management

Despite advanced materials and sophisticated monitoring systems, human operators and maintenance personnel remain the most critical factor in effective wear management. Comprehensive training programs ensure that all personnel understand how their actions influence crusher wear and performance. Operations teams require training on how feed control, setting adjustments, and operational parameter selection impact wear rates and patterns. Maintenance teams need detailed instruction on proper installation procedures, inspection methodologies, and repair techniques that preserve component integrity and performance.

Effective training extends beyond classroom instruction to include hands-on demonstrations, cross-training between operations and maintenance functions, and regular knowledge reinforcement through toolbox talks and operational reviews. Advanced operations implement simulator training that enables personnel to practice response to various operating scenarios without impacting actual production. The most successful programs also include elements of continuous improvement that encourage personnel to identify opportunities for wear reduction and operational optimization. Operations that invest comprehensively in personnel training typically achieve 20-30 percent better wear performance than comparable operations with similar equipment but less developed human resource programs.

Future Trends: The Application Outlook for Smart Sensors and AI in Wear Prediction

Emerging technologies promise to revolutionize wear management in gyratory crushers through unprecedented monitoring capabilities and predictive accuracy. Smart sensors embedded directly in liner materials enable real-time thickness monitoring at multiple points, providing continuous wear progression data without requiring crusher shutdown for manual measurements. These advanced monitoring systems detect not only gradual wear but also impact events that could cause premature damage, enabling immediate operational adjustments to prevent further component degradation.

Artificial intelligence systems analyze the vast datasets generated by modern monitoring equipment to identify subtle patterns preceding component failures. These systems learn from historical data to predict remaining useful life with increasing accuracy, enabling truly predictive maintenance scheduling that maximizes component utilization while preventing unexpected failures. The integration of operational data with maintenance records and component history creates a comprehensive digital twin of the crusher that simulates wear progression under various operating scenarios. This capability enables virtual testing of different operating strategies to identify approaches that optimize the balance between production targets and wear management objectives. The operations that pioneer these advanced technologies are establishing new benchmarks for crusher availability and operating costs in abrasive copper ore applications.