Gyratory Crushers in Copper Ore Crushing: Process Flow Design and Optimization Strategies

This article provides a detailed exploration of the role and optimization of gyratory crushers within the copper ore processing circuit. We will examine the fundamental properties of copper ore that dictate crushing requirements, the strategic positioning of gyratory crushers in the comminution workflow, and the critical operational parameters for efficient size reduction. Furthermore, the discussion will extend to advanced optimization strategies, real-world project considerations, and a look at future technological trends aimed at enhancing efficiency and sustainability in copper ore crushing operations.

Physical Characteristics of Copper Ore and Crushing Requirements Analysis

The successful crushing of copper ore is fundamentally guided by its inherent physical properties. A primary characteristic is its Mohs hardness, which typically ranges from 3 to 4, classifying it as a medium-hard ore. This hardness directly influences the selection of crushing equipment and the wear rates on components like mantles and concaves. Beyond hardness, the structural composition, including the presence of fractures and the brittleness of the mineral, affects how the ore responds to compressive crushing forces.

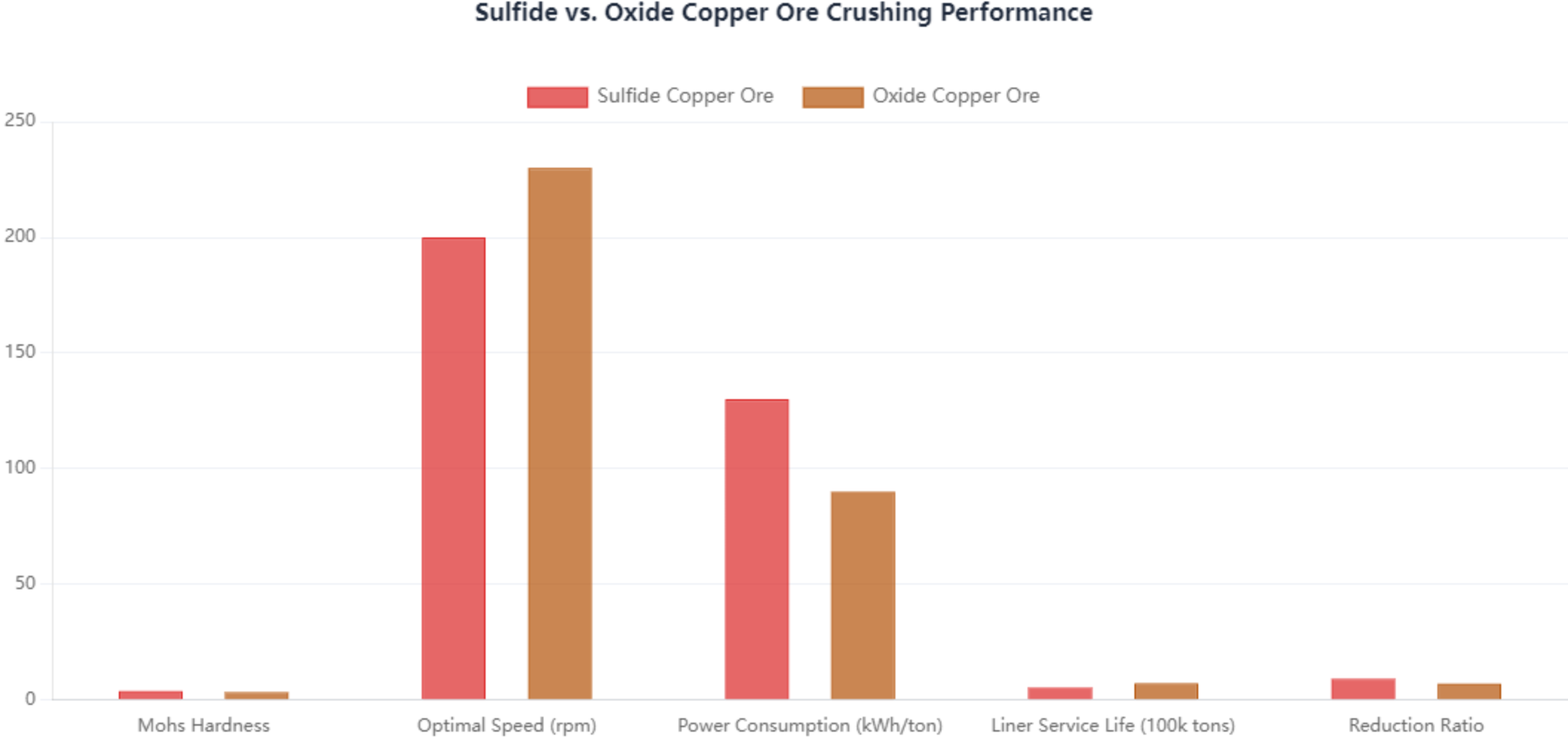

Furthermore, a crucial distinction must be made between sulfide and oxide copper ores. Sulfide ores, often harder and more abrasive, demand robust crushing solutions and high-wear-resistance materials. Oxide ores can be softer but sometimes clay-rich, leading to potential issues like material packing or clogging within the crushing chamber. The target product size from the primary crushing stage is usually controlled to be 200mm or less, a specification designed to optimally feed subsequent secondary crushing or grinding circuits. The reduction ratio, which is the ratio of the feed size to the product size, is a critical factor as it determines the liberation degree of copper minerals from the gangue, impacting the overall recovery rate in the beneficiation plant.

Study on Hardness Distribution of Gangue Minerals in Copper Ore

Copper ore is never pure; it is a mixture of valuable copper minerals and worthless gangue. Common gangue minerals include quartz (Mohs hardness 7), various feldspars (6-6.5), and clay minerals (1-2.5). This wide variation in hardness presents a significant challenge. The presence of hard quartz can accelerate liner wear, while soft clay minerals can cause damp, sticky feed that hinders material flow and reduces throughput. Understanding the specific hardness distribution within a deposit is essential for crusher selection and predicting maintenance schedules.

The average hardness of the ore blend dictates the specific energy required for crushing. For instance, an ore body with a higher proportion of quartz will consume more power and cause more wear on the concave liners compared to an ore body dominated by softer minerals. This data is crucial for designing the entire crushing circuit and selecting the appropriate type of gyratory crusher.

Treatment Strategy for Surface Oxidation Layer of Copper Ore by Wet Crushing

Wet crushing is an effective strategy employed to handle ores with significant surface oxidation, which often leads to dust generation and potential clogging. By introducing a controlled amount of water into the gyratory crusher feed, dust is effectively suppressed, creating a safer working environment and reducing material loss. This practice is particularly common in arid regions or with ores that have a high fines content.

Moreover, the moisture helps to wash away fine particles that might otherwise pack into the crushing chamber, maintaining a consistent feed flow and preventing choke-fed conditions that can lead to unnecessary strain on the crusher. However, the water volume must be carefully optimized; excessive moisture can lead to slurry formation, which may cause issues in downstream material handling on conveyor belts.

Optimization of Copper Mineral Liberation Degree during Crushing

The primary goal of the crushing stage is not merely to reduce size but to achieve a degree of liberation where the copper mineral particles are separated from the gangue matrix. Inadequate crushing will result in composite particles, lowering the efficiency of the flotation process and ultimately the metal recovery. The product size distribution from the gyratory crusher is, therefore, a key parameter.

Optimization involves balancing the crushing force and the reduction ratio to create a product where a high percentage of particles are sufficiently liberated. This often requires operating the crusher with a specific closed-side setting (CSS) and ensuring a consistent feed size to promote inter-particle crushing and optimal liberation without generating excessive fines, which are undesirable for subsequent processes.

Adaptive Adjustment of Crushing Process to Seasonal Copper Grade Fluctuation

The grade of ore fed to a crusher can vary seasonally or as mining moves through different zones of a deposit. A change in ore grade often correlates with changes in hardness and abrasiveness. The crushing circuit must be adaptable to these variations. When harder, higher-grade ore is processed, the crusher's power draw may increase, and wear rates will accelerate, potentially requiring adjustments to the crusher's operational parameters.

Modern automated control systems can help manage these fluctuations. By monitoring power draw and pressure in the hydraulic system, the control system can automatically adjust the crusher's setting or the feed rate to maintain optimal performance and protect the equipment from damage, ensuring a consistent product size despite variations in ore characteristics.

Stage Positioning of Gyratory Crushers in the Copper Ore Crushing Process

Gyratory crushers are quintessential primary crushers, representing the first and most robust stage of size reduction in a mineral processing plant. They are designed to handle the largest feed material directly from the mine, typically up to 1.5 meters in diameter. Their primary function is to reduce the run-of-mine (ROM) ore to a manageable size, usually around 200-250 mm, suitable for conveying and feeding secondary crushing units. Their high capacity and ability to handle variable and coarse feed make them indispensable in large-scale copper mining operations.

The strategic placement of the gyratory crusher often involves a primary crushing station located in close proximity to the mine pit to minimize haulage distances for the massive haul trucks. The crushed product is then transported via conveyor belts to the next stage of comminution. It is estimated that the crushing stage, primarily led by the gyratory crusher, can account for approximately 35% of the total energy consumption of the comminution circuit, underscoring its significance in the overall energy footprint of the operation.

Matching Principle of Gyratory Crusher Feed Opening Size and Copper Ore Lump Size

The feed opening of a gyratory crusher is a critical design parameter. It must be significantly larger than the largest expected ore lump to ensure uninterrupted feeding and prevent bridging. A common rule is that the feed opening width should be at least 20% greater than the largest piece of ore. This ensures that even the largest boulders can enter the crushing chamber without causing blockages at the feed hopper, thus maintaining a steady and efficient crushing process.

Control Logic of Crusher Chamber Discharge Opening Size on Copper Ore Particle Size

The size of the final product from a gyratory crusher is primarily controlled by the setting of the discharge opening, known as the closed-side setting (CSS). A smaller CSS produces a finer product but reduces the crusher's throughput capacity and increases power consumption. Conversely, a larger CSS increases capacity but results in a coarser product. For copper ore processing, the CSS is carefully selected to produce the optimal feed size for the subsequent secondary cone crushers, balancing capacity and particle size distribution requirements.

Capacity Linkage Design between Belt Conveyor and Gyratory Crusher

The material handling system must be perfectly synchronized with the crushing unit. The belt conveyor following the gyratory crusher must have a capacity that exceeds the crusher's maximum throughput to avoid becoming a bottleneck. This is managed through coordinated control systems. The speed of the apron feeder supplying the crusher and the operation of the crusher itself are often linked to the load on the discharge conveyor, ensuring a smooth and continuous flow of material without overloading any component of the system.

Dust Control and Environmental Requirements in the Crushing Process

Crushing is a significant source of dust generation, which poses health risks and environmental challenges. Modern copper mines implement comprehensive dust control strategies at the primary crusher station. These include encapsulation of the crusher itself, water spray systems at transfer points on conveyors, and sometimes baghouse filtration systems to capture airborne dust. Compliance with strict occupational health and safety regulations is mandatory, making effective dust suppression a non-negotiable aspect of crusher operation.

Core Parameters of Gyratory Crushers and Their Adaptation to Copper Ore Crushing

The efficient reduction of copper ore requires the precise configuration of the gyratory crusher's core mechanical parameters. The diameter of the main shaft and mantle (often ranging from 1200mm to 1600mm in large mines) directly determines the physical capacity of the machine to process ore. The eccentric throw, which controls the gyrating motion of the mantle, defines the stroke and consequently the crushing force applied to the ore particles. This force must be sufficient to fracture the hard copper ore without causing undue stress on the crusher's components.

Furthermore, the hydraulic system that controls the crusher's setting and provides overload protection must be calibrated to operate within a specific pressure range, typically 200 to 300 bar, to match the compressive strength of the ore. The selection of the crushing chamber profile—whether a standard, deep, or shallow chamber—is another critical decision based on the feed size and the desired reduction ratio for a specific copper ore type.

Wear Resistance Verification of Manganese Steel Liners in Copper Ore Crushing

The concaves and mantle, collectively known as the liners, are subjected to extreme abrasive wear. High manganese steel is the traditional material of choice due to its unique work-hardening property; its surface becomes harder under impact, providing excellent resistance to abrasion. In copper ore applications, the lifespan of these liners is a major operational cost. The wear rate is continuously monitored, and the data is used to predict replacement schedules and evaluate the performance of different liner metallurgies or designs for specific ore conditions.

The Relationship between Gyratory Crusher Speed (150-250 rpm) and Copper Ore Crushing Efficiency

The operational speed of the crusher, measured in revolutions per minute of the eccentric bushing, influences the number of crushing cycles per minute. A higher speed can increase capacity but may not allow sufficient time for the broken material to discharge from the chamber, leading to over-crushing and higher energy consumption. For copper ore, an optimal speed is found that maximizes throughput while achieving the desired product size and minimizing power draw, typically falling within the 150-250 rpm range for most large machines.

Life Extension Effect of Automated Lubrication Systems

The massive bearings and gears in a gyratory crusher operate under immense load. A reliable, automated lubrication system is vital for ensuring a continuous supply of clean oil at the correct temperature and pressure to these critical components. This prevents metal-to-metal contact, reduces friction and wear, and significantly extends the service life of expensive parts like the eccentric assembly and main shaft bearings. Modern systems provide real-time monitoring of oil condition and flow, alerting operators to any potential issues before they lead to failure.

Response Mechanism of Overload Protection Devices (Hydraulic/Spring) in Copper Ore Crushing

Uncrushable material, like tramp metal or extremely hard mining tools, can occasionally enter the crusher. To protect the machine from catastrophic damage, overload protection systems are installed. In a hydraulic system, the supporting piston and hydraulic pressure allow the mantle to move down, widening the discharge opening to let the uncrushable object pass. Once cleared, the system automatically returns to its original setting. This rapid response is crucial for avoiding downtime and expensive repairs in the harsh environment of copper ore crushing.

Optimization Strategies and Technology Applications in Copper Ore Crushing Process

The drive for greater efficiency and lower operational costs has led to the adoption of sophisticated optimization strategies in copper ore crushing. Digital modeling techniques, such as Discrete Element Method (DEM) simulations, allow engineers to visualize and analyze the flow of ore and the crushing action inside the chamber without the need for physical prototypes. This enables the optimization of liner profiles and crusher operational parameters for a specific ore type.

Furthermore, the integration of Variable Frequency Drives (VFDs) on crusher motors allows for dynamic adjustment of the crusher's power and speed, enabling operators to fine-tune performance in real-time based on feed conditions. The overarching goal of these technological advancements is not only to increase throughput but also to achieve a significant reduction in energy consumption, often targeting a decrease of 20% or more from baseline operations.

Remote Monitoring System for Crusher Status Based on the Internet of Things

IoT sensors placed on key crusher components (bearings, motor, hydraulic system) continuously collect data on vibration, temperature, pressure, and power draw. This data is transmitted to a central platform where it is analyzed. Operators and engineers can monitor the health and performance of the crusher from anywhere in the world, enabling proactive maintenance and rapid response to any abnormal conditions, thereby maximizing availability and preventing unexpected failures.

Intelligent Feed Control Algorithm for Copper Ore Crushing

Advanced control systems use the crusher's power draw as a key input variable. The algorithm is designed to maintain the crusher operating at or near its peak power capacity without overloading it. By regulating the feed rate from the apron feeder based on real-time power consumption, the system ensures the crushing chamber is always optimally filled (choke-fed), which maximizes throughput and efficiency while producing a consistent product size.

Detection and Exclusion Technology for Metal Tramp in the Crushing Process

Metal detectors and metal separators (like magnets) are installed ahead of the primary crusher to identify and remove tramp metal from the ore stream. This is a critical protective measure. Even small pieces of steel from drilling equipment or shovel teeth can cause significant damage to the crusher's liners and internal components. Removing them beforehand prevents costly damage and unplanned downtime, protecting the crusher's integrity.

Integrated Automation Scheme for Crushing-Screening-Transportation System

Modern crushing plants are fully integrated automated systems. The primary gyratory crusher, secondary crushers, screens, and conveyors are all controlled by a single Plant Control System (PCS). This system coordinates all units to work in harmony. For example, if a screen downstream becomes overloaded, the PCS can automatically reduce the feed rate to the primary crusher to prevent a bottleneck, ensuring smooth and efficient operation of the entire circuit.

Process Design and Implementation of Typical Copper Ore Crushing Projects

The design of a crushing circuit for a copper mine is a complex engineering task tailored to the specific characteristics of the ore body and the geographical constraints of the site. In a large open-pit mine, the primary gyratory crusher is often housed in a massive concrete structure at the edge of the pit. The crusher may be fed directly by haul trucks or via a stationary apron feeder from a dump pocket. The layout focuses on minimizing truck haulage cycles and ensuring a steady, reliable feed to the crusher.

For underground mines, space is a significant constraint. The primary crushing station is located underground, often directly beneath the ore passes. The crusher must be designed for compactness and ease of maintenance in a confined environment. The crushed ore is then hoisted to the surface for further processing. In high-altitude locations, crushers and their motors may require derating or special cooling systems to compensate for the thinner air and reduced cooling efficiency.

Analysis Method for Capacity Bottlenecks in Copper Ore Crushing Process

Identifying and eliminating bottlenecks is key to increasing overall plant throughput. Engineers use techniques like time-and-motion studies on haul trucks, mass flow balancing across the circuit, and data analysis from the control system to pinpoint constraints. A bottleneck might be the crusher itself, the capacity of the feed conveyor, or the availability of haul trucks. Once identified, targeted solutions, such as increasing the crusher's power, upgrading a conveyor, or optimizing truck dispatch, can be implemented.

Relationship Model between Crusher Liner Replacement Cycle and Copper Ore Hardness

Liner wear is directly proportional to the abrasiveness of the ore and the total tonnage processed. By analyzing historical data on ore hardness (e.g., from drill core samples) and correlating it with actual liner wear measurements, mines can develop predictive models. These models forecast the remaining life of liner sets, allowing maintenance to be planned during scheduled shutdowns, thus avoiding unexpected failures and maximizing the utilization of the liners.

Dust Collection and Resource Utilization in the Crushing Process

Beyond simple suppression, some advanced operations collect the dust extracted from the crusher station. This dust, which often contains fine copper particles, can be agglomerated or mixed with water and fed back into the process stream. This not only improves environmental performance by eliminating a waste stream but also recovers valuable metal that would otherwise be lost, contributing to the overall recovery and economics of the operation.

Noise Control and Occupational Health and Safety Specifications

Gyratory crushers are significant sources of industrial noise. Protecting workers requires a multi-faceted approach including engineering controls (acoustic enclosures around the crusher, sound-damping materials on conveyors), administrative controls (limiting time spent in high-noise areas), and the mandatory use of personal hearing protection. Compliance with strict OHS standards is essential for ensuring a safe and sustainable working environment.

Future Technology Trends and Innovation Directions

The future of copper ore crushing is oriented towards smarter, more autonomous, and more sustainable technologies. The concept of the intelligent crusher involves machines with self-diagnosing and self-optimizing capabilities. These crushers would use AI and real-time sensor data to continuously adjust their operational parameters (like CSS and speed) to adapt to changing ore conditions, always seeking the point of maximum efficiency and minimum wear.

Energy sustainability is another major focus. The integration of renewable energy sources, such as large-scale solar power installations with energy storage systems, to power crushing plants is being explored to reduce the carbon footprint of mining operations. Furthermore, there is a growing interest in highly compact, integrated process designs that combine crushing and initial sorting or grinding stages to reduce the physical footprint and energy intensity of mineral processing.

Application of 3D Printing Technology in Crusher Liner Customization

Additive manufacturing, or 3D printing, is revolutionizing the production of complex wear parts. It allows for the creation of liner designs with optimized internal cooling channels or complex geometries that are impossible to achieve with traditional casting. This enables the production of custom liners tailored to the specific wear patterns of a particular crusher and ore type, potentially extending service life and improving crushing performance.

Research and Development Progress of Hydrogen Energy-Driven Crushers

As the industry moves towards decarbonization, alternative power sources for heavy equipment are being investigated. Hydrogen fuel cells represent a promising zero-emission technology. While still in early stages for application in massive equipment like gyratory crushers, R&D is ongoing to develop hydrogen-powered haul trucks and auxiliary power units, which could eventually extend to the primary crushing infrastructure, significantly reducing the greenhouse gas emissions associated with mining.

Integration of Blockchain Traceability Technology in the Crushing Process

Blockchain technology could be implemented to create a tamper-proof digital record of the entire processing journey of a copper ore batch. From the specific block in the mine where it was extracted, through the crushing and grinding stages, and onto final smelting, each step could be recorded. This provides unparalleled traceability for quality control, process optimization, and verifying the source of "green" copper produced with high environmental and ethical standards.

New Technologies for Resource Utilization of Copper Crushing Waste

The leftover material from crushing, particularly the fine wastes and dust, is increasingly seen not as waste but as a potential resource. Research is focused on new methods to extract residual metals from these tailings. Furthermore, there is growing interest in repurposing this rocky material as construction aggregate, for mine backfill, or even in agricultural applications, moving the industry closer to a goal of zero waste.