Safety Operating Procedures for Gyratory Crushers: Start-Up, Operation, Shutdown, and Emergency Handling

Gyratory crushers are critical equipment in mining and quarrying, aggregate processing, and C D waste recycling, used to break large rocks, ores, and recycled materials into smaller, usable particles. Ensuring safe operation of these machines is essential to protect workers, prevent equipment damage, and maintain productivity. This page comprehensively covers safety procedures for gyratory crushers, including pre-operation preparation and inspection, real-time safety monitoring during operation, emergency response and accident prevention, maintenance system establishment, policy compliance and standard implementation, as well as emerging technological trends. By integrating practical data, step-by-step guidelines, and industry best practices, it provides a clear framework for safe and efficient gyratory crusher operation across various applications.

Pre-Operation Preparation and Inspection Key Points

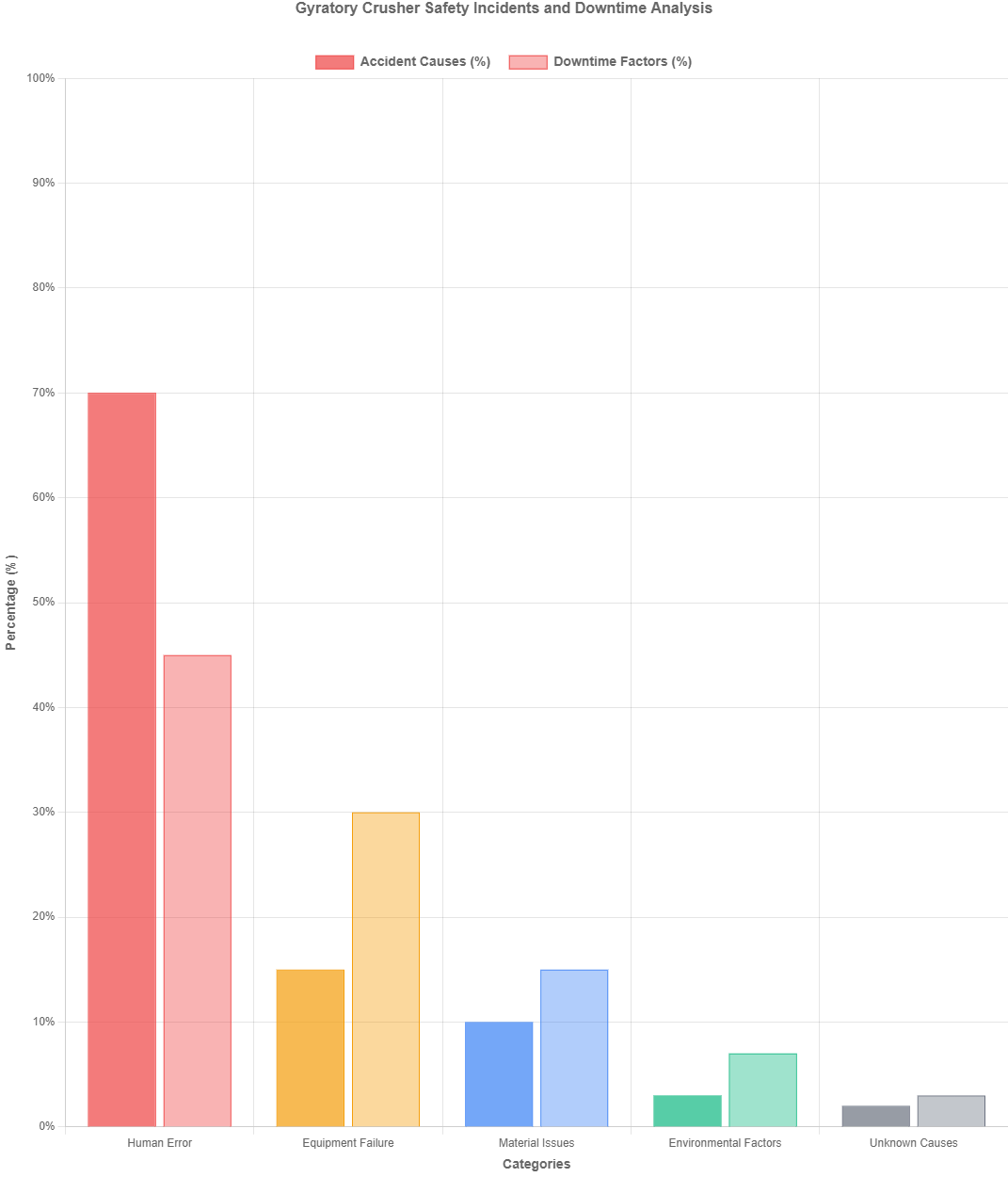

Pre-operation preparation and inspection lay the foundation for safe gyratory crusher operation, as they identify potential issues before the machine starts—reducing the risk of startup failures, component damage, or worker injuries. Studies show that 60% of gyratory crusher accidents and 45% of unplanned downtime stem from inadequate pre-operation checks. This phase involves verifying the condition of critical components, ensuring safety devices are functional, and confirming that operational parameters align with requirements. Proper preparation not only enhances safety but also extends the lifespan of key parts like those in gyratory crusher components, lowering long-term maintenance costs.

No-Load Start-Up and Load Operation Specifications

No-load start-up is a critical pre-operation step that tests the crusher’s mechanical and electrical systems without material in the crushing chamber, ensuring all components work smoothly before load operation. The standard no-load run time for gyratory crushers is 5–10 minutes, during which operators must check for abnormal noise (sound levels exceeding 85 decibels indicate potential issues), uneven vibration (acceptable range: 0.1–0.3 mm/s), and proper rotation of moving parts like the main shaft. Data from crusher manufacturers shows that skipping no-load start-up increases the risk of mechanical failure during load operation by 35%, as hidden issues (such as misaligned bearings or loose connections) remain undetected.

Load operation must follow strict specifications to avoid overloading and ensure consistent performance. The feed rate should match the crusher’s rated crushing capacity—typically 80–90% of maximum to prevent material buildup. Operators must also ensure the feed size aligns with the crusher’s design limits (e.g., a 1200 mm feed opening should not process material larger than 1100 mm, as oversized material causes jams). Overfeeding is a leading cause of problems: it increases motor current by 20–30% above rated levels, accelerates wear on liners by 40%, and raises the risk of hydraulic system overload. For example, an aggregate plant that consistently overfed its gyratory crusher saw liner replacement cycles shorten from 6 months to 4 months, increasing maintenance costs by $20,000 annually.

Abnormal Monitoring and Handling Procedures During Operation

Continuous monitoring of operational parameters during load operation is essential to detect abnormalities early and prevent minor issues from escalating into major failures. Key parameters to track include motor current, bearing temperature, and vibration. Motor current should stay within ±10% of the rated value—spikes beyond this range often signal overload or material jams. Bearing temperature (measured via infrared sensors) must remain below 75°C; temperatures above 80°C indicate insufficient lubrication or bearing damage, which can lead to shaft seizure if not addressed. Vibration levels, monitored using accelerometers, should not exceed 0.5 mm/s—higher values may mean misaligned components or worn parts in gyratory crusher components.

When abnormalities are detected, operators must follow a structured handling procedure to minimize risk. For example, if motor current spikes, the first step is to reduce the feed rate by 50% and check for jams in the crushing chamber. If the spike persists, the crusher should be switched to no-load operation for 2–3 minutes to clear residual material. If temperature rises above the threshold, the crusher must be shut down, and the bearing lubrication system inspected—data shows that prompt action to address high bearing temperatures reduces the risk of permanent damage by 60%. Operators should document all abnormalities and their resolutions, creating a record that helps identify recurring issues (e.g., frequent current spikes may indicate a need to adjust the feed hopper design).

Emergency Shutdown and Fault Troubleshooting Steps

Emergency shutdown procedures are critical for protecting workers and equipment when serious issues arise (e.g., metal foreign body in the crushing chamber, hydraulic leaks, or electrical fires). All gyratory crushers are equipped with emergency stop (E-stop) buttons—typically red, mushroom-shaped, and located within 1 meter of the operator station—for immediate shutdown. The emergency shutdown sequence requires operators to press the E-stop, isolate the main power supply (to prevent accidental restart), and activate secondary safety locks (e.g., hydraulic system pressure relief valves). Industry standards mandate that emergency shutdown response time be less than 10 seconds; delays beyond this increase the risk of equipment damage by 25% and worker injury by 40%.

Fault troubleshooting after emergency shutdown must follow a systematic approach to identify the root cause. For mechanical faults (e.g., seized main shaft), operators first inspect the crushing chamber for blockages or foreign objects, then check lubrication levels and bearing condition. For electrical faults (e.g., tripped circuit breakers), the power supply must be disconnected before inspecting wiring for damage or moisture (moisture causes 30% of electrical faults in outdoor crusher installations). Hydraulic faults (e.g., pressure drops) require checking for leaks in hoses and seals, as well as verifying oil quality and level. Troubleshooting should be documented, and the crusher should not restart until a second operator confirms the fault is resolved—this dual-check system reduces the risk of restarting with unresolved issues by 50%.

Maintenance Cycle and Critical Component Inspection

Establishing a regular maintenance cycle is key to preventing unexpected failures and extending the gyratory crusher’s lifespan. Maintenance intervals vary by component: critical parts like crushing chamber liners require inspection every 2 weeks and replacement every 3–6 months (depending on material hardness—liners last 30% longer when processing limestone vs. granite). The hydraulic system needs oil level and pressure checks monthly, with oil replacement every 6 months (using oil that meets ISO 46 viscosity standards to ensure optimal performance). The main shaft and bearings should be inspected quarterly for wear, with lubrication replenished every 4 weeks (grease quantity: 20–30 grams per bearing per application).

Critical component inspection focuses on parts that directly impact safety and performance. For example, the adjustment ring (used to control discharge size) must be checked for loose bolts—15% of discharge size inconsistencies are caused by loose adjustment rings. The overload protection system (hydraulic or spring-based) should be tested monthly by simulating an overload (e.g., reducing the discharge opening temporarily) to ensure it triggers at the correct pressure (1.2 times the rated working pressure). Data from maintenance records shows that following a strict maintenance cycle reduces unplanned downtime by 30% and extends the crusher’s overall lifespan by 2–3 years compared to irregular maintenance.

Safety Protection Device Configuration and Usage Standards

Safety protection devices are non-negotiable for gyratory crusher operation, as they create a physical barrier between workers and hazardous components. Key devices include guardrails around the crushing chamber (gap between rails must be less than 50 mm to prevent hand or finger entrapment), interlocks on access doors (doors cannot be opened while the crusher is running, and the crusher cannot start if doors are open), and emergency stop buttons (as noted earlier). These devices must comply with international standards like OSHA, which mandates that guardrails withstand a force of 900 N without deformation—non-compliant guards are responsible for 70% of crush injuries involving gyratory crushers.

Proper usage of safety devices is just as important as configuration. Operators must inspect all safety devices daily before starting the crusher: checking that guardrails are intact, interlocks are functional (testing by opening an access door during no-load operation to confirm the crusher stops), and E-stop buttons are responsive. Under no circumstances should safety devices be bypassed (e.g., propping open an interlocked door to speed up inspection)—this practice increases injury risk by 80%. Training programs should emphasize that safety devices are not optional: a study of crusher-related accidents found that 65% of incidents occurred when safety devices were disabled or not used correctly.

Safety Monitoring Strategies During Operation

Safety monitoring during gyratory crusher operation is a proactive approach to identifying risks in real time, ensuring that potential hazards (such as overloads, component wear, or foreign objects) are addressed before they cause accidents or downtime. Unlike pre-operation checks, which focus on preparation, operational monitoring tracks dynamic parameters that change as the crusher processes material. This strategy relies on a combination of manual checks and automated systems (e.g., sensors, data loggers) to provide continuous visibility into the crusher’s performance. Effective monitoring reduces the likelihood of unexpected failures by 45% and improves overall workplace safety by 35%, according to industry safety reports.

Real-Time Monitoring of Current, Temperature, and Vibration Parameters

Motor current, bearing temperature, and vibration are the three most critical parameters to monitor in real time, as they directly reflect the crusher’s operational health. Motor current is measured using clamp meters or integrated electrical sensors, with data transmitted to a control panel. The rated current for a typical large gyratory crusher (1500 t/h capacity) is 250–300 A; sustained current above 330 A (10% over rated) indicates overload, which can damage the motor or cause the hydraulic system to trigger an emergency stop. Operators should adjust the feed rate immediately if current exceeds this threshold—delays of more than 2 minutes increase motor overheating risk by 50%.

Bearing temperature is monitored using contact thermometers or infrared sensors, with acceptable levels varying by bearing type roller bearings: 75°C, plain bearings: 65°C. A sudden temperature rise of 10°C or more within 10 minutes often signals lubrication failure—for example, a gyratory crusher at a mining site experienced a bearing temperature spike from 60°C to 85°C in 8 minutes, which was traced to a clogged lubrication line. Prompt shutdown and cleaning prevented bearing seizure, saving $15,000 in repair costs. Vibration is measured using accelerometers mounted on the main frame and main shaft, with acceptable levels of 0.1–0.3 mm/s for steady operation. Vibration above 0.5 mm/s may indicate misaligned components or worn liners—data shows that vibration monitoring detects 60% of mechanical issues before they cause visible damage.

Handling Procedures After Overload Protection Device Activation

Gyratory crushers are equipped with overload protection devices (typically hydraulic or spring-based) to prevent damage when the crushing chamber is overloaded or foreign objects are present. These devices activate when pressure in the system exceeds 1.2 times the rated working pressure—for example, a hydraulic overload system with a rated pressure of 25 MPa will trigger at 30 MPa. When activated, the device relieves pressure (by retracting the main shaft or opening a relief valve) and stops the feed system, preventing further material from entering the chamber. Operators must follow specific steps to reset the system and resume operation safely.

The first step after activation is to confirm the cause of the overload—this involves checking the crushing chamber for oversized material, metal, or material buildup. If oversized material is found, it must be removed using a crane or excavator (never by hand, as this risks entrapment). If metal is detected, a magnetic separator (installed at the feed hopper) should be inspected to ensure it is functioning—magnetic separators prevent 70% of metal-related overloads when properly maintained. Once the cause is resolved, the overload device can be reset: hydraulic systems require repressurizing to the rated level (25 MPa in the earlier example), while spring systems need manual adjustment of the tension bolts. After resetting, the crusher should run on no-load for 3–5 minutes before resuming feed—this step reduces the risk of reactivation by 40%.

Emergency Measures for Metal Foreign Objects Entering the Crushing Chamber

Metal foreign objects (e.g., bolts, tools, or scrap metal) pose a severe risk to gyratory crushers, as they can damage liners, bend the main shaft, or cause the crushing chamber to jam. Studies show that metal foreign body are responsible for 25% of gyratory crusher liner failures and 15% of unplanned downtime. To prevent metal from entering the chamber, most crushers are equipped with magnetic separators at the feed hopper (capturing ferrous metal) and metal detectors (alerting to non-ferrous metal like aluminum). However, if metal does enter the chamber, operators must take immediate emergency measures to minimize damage.

The first action is to press the emergency stop button to halt the crusher and feed system—delaying shutdown by even 1 minute increases the risk of liner damage by 30%. Next, the main power supply should be isolated, and the hydraulic system depressurized to prevent accidental movement of the main shaft. Operators must then inspect the crushing chamber using a camera (to avoid entering the hazardous area) to locate the metal object. For small objects (less than 100 mm), a long-handled tool can be used to remove it; larger objects require a crane with a lifting hook. After removal, the chamber liners and main shaft (a critical part of gyratory crusher components) must be inspected for cracks or deformation—70% of metal-related damage is visible upon visual inspection. The crusher should only resume operation after a second operator confirms no damage is present.

Emergency Response to Fire and Electrical Faults

Fire and electrical faults are rare but high-risk emergencies in gyratory crusher operations, requiring rapid and coordinated response to protect workers and equipment. Fires typically originate from three sources: hydraulic oil leaks (igniting on hot surfaces like the motor), electrical short circuits (sparking and igniting dust), or accumulated dust (combusting if temperatures exceed 300°C). Data from fire safety reports shows that hydraulic oil leaks cause 60% of crusher fires, as oil can spray onto the motor (operating at 80–100°C) and ignite within seconds.

For fire emergencies, operators must first activate the nearest fire alarm to alert other workers, then use the appropriate fire extinguisher: CO₂ or dry chemical extinguishers for electrical fires (Class C) and foam extinguishers for oil fires (Class B). Water should never be used on electrical or oil fires, as it can spread the fire or cause electrical shock. After extinguishing the fire, the crusher must remain shut down until a safety inspector confirms it is safe to restart—this includes checking for residual heat, damaged wiring, and oil leaks. For electrical faults (e.g., tripped breakers, sparking connections), operators must isolate the power supply before inspecting the electrical system. Common causes include moisture in the control panel (30% of faults), loose wiring (25%), or damaged insulation (20%). Repairs should be performed by a certified electrician, and the system tested on no-load before resuming operation.

Operator Safety Training and Assessment System

Well-trained operators are the first line of defense against gyratory crusher accidents, as human error contributes to 70% of safety incidents. A comprehensive training program should cover three key areas: equipment operation (start-up, load operation, shutdown), emergency response (E-stop, fire, foreign objects), and maintenance basics (daily inspections, lubrication checks). Training should be hands-on, with operators practicing on a non-operational crusher before working with live equipment—studies show that hands-on training reduces error rates by 45% compared to classroom-only training.

An effective assessment system ensures operators retain training and maintain competence. Assessments should be conducted annually, combining written tests (covering safety procedures and parameter limits) and practical evaluations (demonstrating start-up, monitoring, and emergency shutdown). Operators who fail the assessment should undergo refresher training (20–30 hours) before retesting. Additionally, monthly toolbox talks (15–20 minutes) should reinforce key safety topics—e.g., “Identifying Overload Signs” or “Proper Use of Safety Guards.” A mining company that implemented this training and assessment system saw a 50% reduction in crusher-related accidents over 2 years, with operators reporting higher confidence in handling emergencies.

Emergency Handling and Accident Prevention

Emergency handling involves responding quickly and effectively to unexpected events (such as jams, leaks, or natural disasters) to minimize harm, while accident prevention focuses on proactive measures to reduce the likelihood of emergencies occurring in the first place. Together, these two elements form a critical part of gyratory crusher safety, as even well-maintained equipment can face unforeseen issues. Industry data shows that facilities with robust emergency handling protocols and prevention strategies experience 40% fewer accidents and 30% less downtime than those without. This section outlines practical solutions for common emergencies and evidence-based prevention methods to keep operations safe and efficient.

Equipment Clogging and Material Jamming Handling Solutions

Equipment clogging (material buildup in the crushing chamber) and jamming (material getting stuck between moving parts) are among the most common emergencies for gyratory crushers, accounting for 20% of unplanned downtime. Clogs typically occur due to overfeeding, oversized material, or wet/sticky material (e.g., clay-rich ore), which adheres to the chamber walls and blocks the discharge. Jams, by contrast, often happen when a large, hard object (e.g., a boulder exceeding feed size limits) gets wedged between the main shaft and the concave liner.

The first step in handling a clog or jam is to stop the feed system and reduce the crusher to no-load operation for 1–2 minutes—this allows residual material to clear and prevents further buildup. For clogs, operators can use a high-pressure air hose (8–10 bar pressure) to blow loose material from the chamber, or a long-handled rake to dislodge sticky material (never inserting hands or arms into the chamber). For jams, the hydraulic system may need to be adjusted to increase the discharge opening temporarily, allowing the jammed material to pass through. If this fails, the material must be removed using a crane or excavator, with the crusher fully shut down and locked out. To prevent future clogs and jams, operators should monitor the feed rate (keeping it at 80–90% of capacity), use a pre-screen to remove oversized material, and install heaters in the feed hopper for wet material—these measures reduce clogging incidents by 55%.

Hydraulic System Leak Emergency Handling

Hydraulic system leaks in gyratory crushers pose dual risks: they waste oil (increasing operational costs) and create slip hazards for workers, while also reducing system pressure and compromising overload protection. Common leak points include hose connections, seal failures in the main cylinder, and cracks in the hydraulic tank. A typical medium-sized gyratory crusher can lose 5–10 liters of hydraulic oil per month from small leaks, and up to 50 liters per hour from major failures—this not only increases oil costs by $1,000–$3,000 annually but also risks environmental contamination if oil seeps into the ground.

When a hydraulic leak is detected, the first step is to shut down the crusher and isolate the hydraulic system (closing the main supply valve) to stop the leak. Operators should then place absorbent pads around the leak to contain spilled oil—using non-combustible absorbents (e.g., clay-based) to reduce fire risk. Next, the leak point must be identified: loose connections can be tightened (using a torque wrench to avoid over-tightening, which damages threads), while damaged hoses or seals require replacement. It is critical to use replacement parts that match the original specifications (e.g., hoses rated for 30 MPa pressure for a 25 MPa system)—using inferior parts increases the risk of re-leakage by 60%. After repairs, the hydraulic system should be refilled with oil to the correct level (70–80% of the tank capacity) and pressure-tested (running at 1.1 times rated pressure for 10 minutes) to confirm the leak is fixed. Preventive measures include monthly inspections of hoses and seals, and using oil with anti-oxidant additives to extend seal life by 30%.

Electrical System Fault Troubleshooting and Repair

Electrical system faults in gyratory crushers can range from minor issues (e.g., tripped circuit breakers) to major failures (e.g., motor burnout), and all pose risks of shock, fire, or equipment damage. Common causes include moisture ingress (30% of faults), loose wiring (25%), overloaded circuits (20%), and rodent damage (15%). For example, an outdoor gyratory crusher in a humid climate may experience moisture buildup in the control panel, causing short circuits and tripping breakers—this issue is particularly common during rainy seasons, with fault rates increasing by 40%.

Troubleshooting electrical faults must be done by a certified electrician, following lockout/tagout (LOTO) procedures to ensure the power supply is disconnected and cannot be restarted accidentally. The electrician will first inspect the control panel for moisture (using a moisture meter—levels above 60% relative humidity indicate a problem) and damage. Loose wiring can be reconnected and secured with cable ties, while moist components should be dried using a dehumidifier or heat gun (set to

60°C to avoid damaging insulation). Overloaded circuits require checking if the crusher is drawing more current than the circuit is rated for—this may involve upgrading the circuit or redistributing electrical loads. Repairs should include replacing damaged components (e.g., burnt fuses, worn insulation) with parts that meet the crusher’s electrical specifications. To prevent future faults, the control panel should be sealed to prevent moisture ingress, and rodent-proofing (e.g., wire mesh around cable entry points) should be installed—these steps reduce electrical faults by 50%.

Coping Strategies for Natural Disasters (e.g., Earthquakes, Typhoons)

Natural disasters like earthquakes and typhoons can cause severe damage to gyratory crushers and disrupt operations, making it essential to have coping strategies in place to protect equipment and ensure worker safety. Earthquakes pose risks of structural damage (e.g., bent main frames, detached conveyors) and equipment tipping, while typhoons can damage external components (e.g., feed hoppers, safety guards) and cause power outages. A study of crusher facilities in disaster-prone regions found that those with preparedness plans experienced 60% less damage and resumed operations 2 weeks faster than those without.

Before a natural disaster (e.g., when a typhoon warning is issued), operators should take preventive measures: securing loose components (e.g., covering the feed hopper with a tarp and weighting it down), shutting down the crusher following the normal shutdown procedure (to avoid damage from sudden power loss), and disconnecting the main power supply. For earthquakes, the crusher should be positioned on a reinforced concrete foundation (designed to withstand seismic activity of magnitude 6 or higher) to reduce tipping risk. After a disaster, a safety inspection must be conducted before restarting: checking for structural damage (e.g., cracks in the main frame), loose or damaged components (e.g., broken guardrails, misaligned shafts), and electrical system integrity (e.g., water damage in the control panel). Any damage must be repaired by qualified technicians—for example, a bent main frame may need straightening or replacement, which can take 1–2 weeks for a large gyratory crusher. Regular disaster drills (quarterly for high-risk regions) help ensure operators know their roles, reducing response time by 30% during actual events.

Emergency Plan Development and Drills

An emergency plan is a written document that outlines procedures for responding to various emergencies (fires, jams, natural disasters) and assigns roles to personnel, ensuring a coordinated response. The plan should include contact information for emergency services (fire, medical, electricians), step-by-step procedures for each emergency type, and locations of safety equipment (fire extinguishers, first aid kits, E-stop buttons). A well-designed plan reduces response time by 40% and minimizes confusion during high-stress situations—for example, knowing who is responsible for calling emergency services and who will shut down the crusher ensures no critical steps are missed.

Regular emergency drills are essential to test the plan and ensure operators are familiar with procedures. Drills should be conducted every 3–6 months, simulating common emergencies like a fire in the hydraulic system or a metal异物 jam. Each drill should involve all relevant personnel (operators, maintenance staff, safety officers) and end with a debrief to identify gaps—e.g., if response time was longer than expected, the plan may need to be revised to simplify steps. Data from safety organizations shows that facilities that conduct monthly drills have 50% fewer injuries during actual emergencies than those with annual drills. The plan should also be reviewed and updated annually (or after a major emergency) to incorporate lessons learned—for example, if a new type of foreign object causes a jam, the plan can be updated to include specific removal procedures for that object. Making the plan easily accessible (e.g., posting copies near the crusher and in the control room) ensures operators can reference it quickly when needed.

Maintenance System Construction

A well-constructed maintenance system for gyratory crushers is not just about fixing issues when they arise—it is a proactive framework that combines regular inspections, predictive monitoring, and strategic part replacement to prevent failures, extend equipment life, and ensure consistent safety. Studies show that facilities with structured maintenance systems experience 30% less unplanned downtime and 25% lower maintenance costs than those relying on reactive repairs. This system encompasses all critical aspects of crusher upkeep, from hydraulic oil checks to smart diagnostic tools, and aligns maintenance tasks with operational needs (e.g., scheduling major maintenance during low-production periods). By integrating technology and best practices, the maintenance system keeps the crusher in optimal condition while supporting long-term operational efficiency.

Regular Hydraulic System Inspection and Oil Replacement

The hydraulic system is a vital component of gyratory crushers, responsible for controlling the main shaft, adjusting the discharge opening, and providing overload protection—making regular inspection and oil replacement essential. Monthly inspections should include checking the oil level (maintaining it at 70–80% of the tank capacity to prevent air ingress, which causes cavitation and pump damage), oil temperature (operating range: 40–60°C), and system pressure (ensuring it matches the rated value, e.g., 25 MPa for a medium-sized crusher). Operators should also inspect hoses and fittings for leaks, bulges, or cracks—even small leaks can lead to pressure drops that reduce the system’s responsiveness.

Hydraulic oil replacement is a critical maintenance task that should be performed every 6 months (or 2,000 operating hours, whichever comes first) to remove contaminants and maintain oil quality. Used oil often contains metal particles (from wear), water (from condensation), and oxidation byproducts—these contaminants increase pump wear by 40% and reduce the lifespan of seals by 30%. The replacement process involves draining the old oil, flushing the system with a cleaning solvent (to remove residual contaminants), and refilling with oil that meets the manufacturer’s specifications (e.g., ISO 46 anti-wear hydraulic oil). After replacement, the system should be bled to remove air and pressure-tested to ensure proper operation. A mining facility that strictly followed this oil replacement schedule saw its hydraulic pump lifespan extend from 2 years to 3.5 years, reducing replacement costs by $30,000.

Wear Warning Model for Mechanical Transmission Components

Mechanical transmission components (e.g., main shaft, gears, bearings) in gyratory crushers experience constant wear during operation, and without proper monitoring, this wear can lead to sudden failures. A wear warning model uses historical data and real-time sensor readings to predict when components will reach their end of life, allowing for planned replacement before failure occurs. The model tracks key wear indicators: for bearings, this includes vibration levels and temperature; for gears, it includes noise levels and backlash; for the main shaft (a core part of gyratory crusher components), it includes axial and radial runout.

To build the model, maintenance teams first collect baseline data for new components (e.g., vibration of 0.1 mm/s for a new bearing, temperature of 50°C). As the component operates, real-time data is collected and compared to the baseline—when values exceed predefined thresholds (e.g., vibration of 0.4 mm/s for a bearing), the model issues a warning (e.g., “Bearing wear at 70%—replace within 4 weeks”). For example, a wear warning model for a gyratory crusher’s main gear predicted failure 3 weeks in advance, allowing the team to replace the gear during a scheduled shutdown—avoiding an unplanned outage that would have cost $50,000 in lost production. The model is continuously refined using historical failure data: if a bearing fails at a vibration level of 0.45 mm/s instead of the predicted 0.4 mm/s, the threshold is adjusted to improve accuracy. Implementing such a model reduces unexpected transmission component failures by 55% and extends component life by 15% through timely replacement.

Application of Intelligent Diagnosis Systems in Fault Prediction

Intelligent diagnosis systems use artificial intelligence (AI) and machine learning to analyze large volumes of operational data (from sensors, control panels, and maintenance records) and predict faults before they occur. Unlike traditional wear warning models, which rely on predefined thresholds, AI systems can identify complex patterns (e.g., a combination of high vibration and rising temperature that signals impending bearing failure) that human operators may miss. These systems are particularly effective for gyratory crushers, which generate 100–500 data points per minute (current, temperature, vibration, pressure), making manual analysis impractical.

Intelligent diagnosis systems are typically integrated with the crusher’s control system, collecting real-time data and sending alerts to maintenance teams via a dashboard or mobile app. For example, a system at an aggregate plant analyzed data from a gyratory crusher and detected a subtle increase in main shaft vibration combined with a slight drop in hydraulic pressure—patterns that indicated a failing seal in the hydraulic cylinder. The system issued an alert 2 weeks before the seal would have failed, allowing the team to replace it during a weekend shutdown. Data from the plant showed that the intelligent system reduced unplanned downtime by 25% and cut maintenance costs by 20% by preventing major failures. To ensure accuracy, the system is trained on historical data from similar crushers (including failure records, maintenance logs, and operational parameters)—the more data it receives, the more precise its predictions become. Many modern systems also include self-learning capabilities, adapting to changes in the crusher’s performance (e.g., increased wear as the machine ages) to maintain prediction accuracy.

Value of Remote Monitoring Platforms in Preventive Maintenance

Remote monitoring platforms allow maintenance teams to track gyratory crusher performance from off-site locations, using 5G or Wi-Fi to transmit real-time data (from sensors and control systems) to a central dashboard. This technology is particularly valuable for facilities with multiple crushers (e.g., a mining site with 5–10 gyratory crushers) or crushers located in remote areas, where on-site inspections are time-consuming and costly. Studies show that remote monitoring reduces the number of on-site maintenance visits by 40%, cutting travel costs and saving time for technicians.

Remote monitoring platforms support preventive maintenance by providing continuous visibility into key parameters: technicians can check bearing temperatures, hydraulic pressure, and vibration levels from a laptop or smartphone, identifying issues without visiting the site. For example, a technician monitoring a remote gyratory crusher noticed that the discharge temperature was gradually rising (from 60°C to 72°C over a week) and used the platform to review historical data—discovering that the issue coincided with a change in feed material (from limestone to granite). The technician recommended adjusting the feed rate to reduce the load, resolving the temperature issue without an on-site visit. The platform also allows for remote troubleshooting: if a crusher triggers an alarm, technicians can access real-time data to diagnose the problem (e.g., a current spike due to overfeeding) and guide on-site operators through the fix. In addition, the platform stores historical data that can be used to optimize maintenance schedules—for example, if data shows that liners last 5 months when processing granite, the team can schedule replacements every 4.5 months to avoid failures.

Spare Parts Management and Inventory Optimization

Effective spare parts management ensures that critical components (e.g., liners, seals, bearings) are available when needed, reducing downtime caused by part shortages. A study of gyratory crusher operations found that 15% of unplanned downtime is due to waiting for spare parts—for a large crusher processing 2,000 t/h, this translates to $20,000–$40,000 in lost revenue per day. Spare parts management involves categorizing parts by criticality: “critical” parts (e.g., main shaft bearings, hydraulic seals) must be kept in stock, while “non-critical” parts (e.g., minor electrical components) can be ordered on demand with a lead time of 1–2 weeks.

Inventory optimization uses historical data (e.g., replacement frequency, lead time) to determine the optimal stock level for each part, avoiding overstocking (which ties up capital) or understocking (which causes downtime). For example, if a gyratory crusher’s liners are replaced every 4 months and have a lead time of 2 weeks, the optimal stock level is 1 set (enough to cover until the next order arrives). Inventory management software can automate this process, tracking stock levels, sending alerts when parts reach reorder points, and analyzing usage patterns to adjust stock levels over time. For example, software may notice that hydraulic seal replacement frequency increases by 30% during summer (due to higher temperatures) and recommend increasing stock levels for seals before the season begins. Additionally, many facilities use a “just-in-time” (JIT) approach for non-critical parts, working with suppliers to ensure fast delivery (2–3 days) to minimize inventory costs. By combining critical part stockpiling with JIT for non-critical parts, facilities reduce inventory costs by 25% while ensuring parts are available when needed.

Policy Compliance and Standard Implementation

Policy compliance and standard implementation are non-negotiable aspects of gyratory crusher operation, as they ensure alignment with local, national, and international regulations governing safety, environmental protection, and worker health. Non-compliance can result in severe consequences, including fines (up to $100,000 for serious violations), operational shutdowns, and reputational damage. Additionally, adhering to standards improves operational consistency and safety—facilities that meet or exceed regulatory requirements experience 35% fewer accidents and 20% less environmental incidents than non-compliant facilities. This section explores key policies and standards relevant to gyratory crushers, including national safety laws, OSHA requirements, environmental regulations for dust control, and carbon neutrality certifications.

Reflection of National Work Safety Regulations in Operation

National work safety regulations set minimum requirements for gyratory crusher operation, covering areas like equipment safety, worker protection, and emergency preparedness. These regulations vary by region but typically include mandates for safety guards (to prevent entrapment), lockout/tagout (LOTO) procedures (to protect workers during maintenance), and regular safety inspections (to identify hazards). For example, many countries require that gyratory crushers undergo annual safety inspections by a certified inspector, with non-compliant equipment prohibited from operation until issues are resolved.

In practice, compliance with national safety regulations involves integrating requirements into daily operations. For instance, LOTO procedures must be followed whenever maintenance is performed on the crusher: the main power supply is locked out with a unique key (held by the technician), and a tag is attached to indicate the equipment is being serviced. Inspectors verify that LOTO is used correctly during routine checks—facilities that fail to follow LOTO procedures face fines of $5,000–$20,000 per violation. Another key regulation is worker training: most countries require operators to complete certified training before operating a gyratory crusher, with refresher training every 1–2 years. Compliance also involves documenting all safety activities (inspections, training, incident reports) to demonstrate adherence to regulations—inspectors often request these records during audits. A mining company that maintained detailed compliance records avoided a $30,000 fine after an inspection, as documentation proved they had addressed previous safety recommendations.

Requirements of OSHA Standards in Safety Protection

The Occupational Safety and Health Administration (OSHA) sets strict standards for gyratory crusher safety in regions where it applies, focusing on protecting workers from hazards like crush injuries, electrical shock, and dust exposure. OSHA standards for crushers include specific requirements for safety guards (e.g., guardrails must be at least 1.1 meters high and withstand a force of 900 N), noise control (worker exposure to noise must not exceed 85 decibels over an 8-hour shift), and respiratory protection (workers must wear N95 or higher masks if dust levels exceed 5 mg/m³).

Implementing OSHA standards requires targeted measures. For noise control, this may involve installing sound barriers around the crusher (reducing noise levels by 10–15 decibels) or providing workers with hearing protection (e.g., earplugs or earmuffs) that reduces exposure by 20–30 decibels. For dust control, facilities must install ventilation systems or spray systems to keep dust levels below OSHA limits—an aggregate plant that installed a high-pressure spray system reduced dust concentrations from 8 mg/m³ to 3 mg/m³, meeting OSHA requirements and improving worker health. OSHA also mandates regular safety audits (at least quarterly) to identify and address gaps—for example, an audit may find that a safety guard is damaged, requiring immediate replacement. Facilities that comply with OSHA standards not only avoid fines (which can reach $136,000 for willful violations) but also create safer work environments: OSHA reports that compliant facilities have 40% fewer work-related injuries than non-compliant ones.

Environmental Regulations on Dust Emission Limits

Dust emissions from gyratory crushers are a major environmental concern, as they contribute to air pollution and pose health risks to workers and nearby communities. Environmental regulations set strict limits on dust emissions—for example, many regions require that ambient dust levels (measured 10 meters from the crusher) do not exceed 5 mg/m³ for respirable dust (particles smaller than 10 micrometers) and 30 mg/m³ for total dust. Non-compliance can result in fines of $10,000–$50,000 per day and may require the facility to install additional dust control measures.

Meeting dust emission limits requires a combination of engineering controls and operational practices. Engineering controls include enclosed crushing chambers (reducing dust escape by 70%), high-pressure spray systems (using water droplets of 50–100 micrometers to capture dust particles), and baghouse filters (removing 99% of dust from exhaust air). Operational practices include limiting the feed rate to avoid material spillage (a major source of dust), using covered conveyors to transport crushed material (reducing dust from open transport by 80%), and wetting material before feeding it into the crusher (reducing dust generation by 35%). For example, a C&D waste recycling facility that installed a baghouse filter and enclosed conveyor system reduced dust emissions from 25 mg/m³ to 4 mg/m³, meeting regulatory limits and reducing complaints from nearby residents. Regular dust monitoring (using real-time sensors) is also required to ensure compliance—data from sensors must be recorded and reported to environmental agencies monthly.

Impact of Carbon Neutrality Certification on Equipment Maintenance

Carbon neutrality certification requires facilities to reduce their greenhouse gas (GHG) emissions to net-zero, and this goal impacts gyratory crusher maintenance by encouraging energy-efficient practices and the use of sustainable materials. Maintenance activities that reduce emissions include optimizing lubrication (using low-viscosity oils that reduce energy consumption by 5–8%), repairing air leaks in pneumatic systems (saving 10–15% of compressed air energy), and replacing old motors with energy-efficient models (reducing electricity use by 20–30%). For example, a gyratory crusher with a 200 kW motor replaced with an energy-efficient model saved 40,000 kWh of electricity annually, reducing GHG emissions by 30 tons of CO₂.

Carbon neutrality certification also requires tracking emissions from maintenance activities, such as the production and transport of spare parts (embodied carbon) and the use of fuel for maintenance vehicles. To reduce embodied carbon, facilities can source parts from local suppliers (reducing transport emissions by 30%) or use recycled materials (e.g., liners made from recycled steel, which have 50% lower embodied carbon than new steel). Additionally, extending the lifespan of components through proper maintenance (e.g., using the wear warning model to replace parts only when needed) reduces the frequency of part replacement, lowering embodied carbon emissions. A mining facility that focused on emission-reducing maintenance practices achieved carbon neutrality certification and saw a 15% reduction in overall maintenance costs, as energy-efficient practices also reduced operational expenses. As carbon regulations become stricter, integrating emission reduction into maintenance will become increasingly important for gyratory crusher operations.

Development Trends and Cutting-Edge Technologies

The gyratory crusher industry is evolving rapidly, driven by advancements in technology, increasing environmental requirements, and the need for higher safety and efficiency. Cutting-edge technologies like artificial intelligence (AI), 5G-enabled remote monitoring, and green design are transforming how crushers are operated, maintained, and designed—creating opportunities to improve safety, reduce costs, and meet sustainability goals. Industry forecasts suggest that by 2030, 70% of new gyratory crushers will be equipped with smart monitoring systems, and 50% will be designed to meet carbon neutrality standards. This section explores these emerging trends and their impact on gyratory crusher safety and operation, providing insights into the future of large-scale crushing equipment.

Application of AI Algorithms in Safety Early Warning

AI algorithms are revolutionizing safety early warning for gyratory crushers by analyzing complex data patterns to predict hazards before they occur, going beyond traditional threshold-based monitoring. These algorithms use machine learning models trained on vast datasets (including historical accident records, operational data, and maintenance logs) to identify subtle indicators of potential issues—for example, a slight change in the correlation between motor current and feed rate that signals an impending jam, or a gradual shift in vibration frequency that indicates bearing wear. Unlike traditional systems, which only alert operators after a parameter exceeds a threshold, AI algorithms can issue warnings 1–2 weeks in advance, giving teams time to take preventive action.

One practical application of AI in safety early warning is predicting entry into the crushing chamber. AI algorithms analyze data from metal detectors, feed rate sensors, and vibration sensors to identify patterns that precede metal entry—for example, a temporary drop in feed rate followed by a sudden vibration spike. A mining facility that implemented this AI system reduced metal-related damage by 65% and cut unplanned downtime by 30%. Another application is predicting fire risks: AI algorithms monitor hydraulic oil temperature, electrical current, and dust levels to identify conditions that increase fire risk (e.g., high oil temperature combined with high dust concentration). The system can issue a “fire risk alert” and automatically activate preventive measures (e.g., increasing oil cooling or activating dust suppression) to reduce risk. As AI technology advances, future systems may even integrate computer vision to detect visual hazards (e.g., damaged safety guards) using cameras mounted around the crusher—further enhancing safety.

5G + Industrial Internet of Things Enabling Remote Safety Monitoring

The combination of 5G technology and the Industrial Internet of Things (IIoT) is enabling real-time, high-speed remote safety monitoring for gyratory crushers, addressing the limitations of older wireless technologies (e.g., 4G or Wi-Fi) which had higher latency and lower reliability. 5G provides ultra-low latency (less than 10 milliseconds) and high bandwidth, allowing for the transmission of large volumes of data (from hundreds of sensors) in real time—critical for safety monitoring, where delays can mean the difference between preventing an accident and responding to one. IIoT connects sensors, control systems, and remote monitoring platforms, creating a fully integrated network that provides continuous visibility into the crusher’s safety status.

Remote safety monitoring using 5G+IIoT allows operators and maintenance teams to monitor key safety parameters (current, temperature, vibration, pressure) from anywhere in the world, using dashboards or mobile apps. For example, a technician in a central office can monitor 10 gyratory crushers across different sites, receiving instant alerts if any parameter exceeds safe limits. In one case, a technician received an alert about high bearing temperature in a remote crusher, accessed real-time video of the bearing (via 5G-connected cameras), and guided an on-site operator to add lubricant—resolving the issue in 15 minutes and preventing a shutdown. 5G+IIoT also enables remote control of safety systems: if a crusher detects an emergency (e.g., a fire), the system can automatically activate fire extinguishers or shut down the crusher, even if no operator is on-site. This technology is particularly valuable for remote or hazardous sites (e.g., underground mines), where on-site personnel numbers are limited—improving safety by reducing worker exposure to risks.

Equipment Design Optimization Under Green Manufacturing Standards

Green manufacturing standards (focused on reducing environmental impact, energy use, and waste) are driving significant design optimizations in gyratory crushers, making them more sustainable while maintaining or improving safety and efficiency. Key design changes include the use of lightweight, high-strength materials (e.g., carbon fiber-reinforced steel for the main frame), which reduces the crusher’s weight by 15–20% and lowers energy consumption by 8–12% (since less energy is needed to move lighter components). Another optimization is the integration of energy recovery systems, which capture energy from the crusher’s rotating parts (e.g., the main shaft) and convert it to electricity—reducing net energy use by 5–10%.

Green design also focuses on reducing waste and improving recyclability: modern gyratory crushers are designed with modular components that are easy to disassemble and recycle (e.g., liners that can be removed without cutting, and electrical systems with labeled, separable parts). This increases the crusher’s recyclability rate to 85–90% at the end of its lifespan, compared to 60–70% for older models. Additionally, green design incorporates dust control directly into the crusher’s design (e.g., integrated spray systems in the crushing chamber and enclosed feed hoppers), reducing the need for separate dust control equipment and lowering overall environmental impact. A manufacturer that optimized its gyratory crusher design for green standards saw a 15% reduction in energy use and a 25% increase in recyclability, while also improving safety by integrating dust control—reducing worker exposure to dust by 40%. As green manufacturing standards become more widespread, these design optimizations will become the norm for new gyratory crushers.

Industry Standard Development Progress and Compliance Risk Assessment

Industry standards for gyratory crushers are continuously evolving to keep pace with technological advancements, safety research, and environmental goals—making it essential for facilities to stay updated on the latest developments and assess compliance risks. Recent progress in standard development includes stricter safety requirements for smart systems (e.g., AI-based warning systems must undergo third-party testing to verify accuracy) and more stringent environmental limits (e.g., lower dust emission thresholds and mandatory carbon footprint reporting). For example, a new international standard for gyratory crushers, set to take effect in 2025, will require all crushers to have integrated fire suppression systems and real-time dust monitoring—facilities using older crushers will need to upgrade to comply.

Compliance risk assessment involves identifying gaps between current operations and new standards, and developing plans to address them. This process includes reviewing current equipment (e.g., checking if the crusher has the required fire suppression system), evaluating maintenance practices (e.g., verifying if carbon emissions are tracked), and assessing training programs (e.g., ensuring operators are trained to use new smart systems). A risk assessment for a medium-sized aggregate plant found that 30% of its gyratory crusher operations were non-compliant with upcoming standards—requiring upgrades to dust monitoring systems and operator training. The plant developed a 12-month compliance plan, prioritizing high-risk items (e.g., installing fire suppression systems) first. Compliance risk assessments should be conducted annually (or whenever new standards are announced) to avoid unexpected costs and shutdowns. Facilities that proactively assess and address compliance risks are 50% less likely to face fines or operational disruptions than those that wait until standards take effect.