The Efficient Mechanism of Conical Compression and Progressive Crushing in Gyratory Crushers

Gyratory crushers represent one of the most efficient solutions in modern material processing, combining sophisticated engineering principles with advanced technological features. This comprehensive examination explores the fundamental mechanisms that enable these powerful machines to achieve remarkable efficiency in reducing large rock masses into precisely sized aggregates. We will delve into the core technological principles, efficiency optimization pathways, practical application cases, maintenance best practices, regulatory considerations, and emerging trends that collectively define the modern gyratory crushing technology. The integration of mechanical excellence with digital intelligence creates crushing systems that deliver unprecedented performance while minimizing environmental impact.

Core Technology Analysis of Conical Compression

The conical compression mechanism represents the fundamental working principle of gyratory crushers, where a gyrating mantle progressively compresses material against a stationary concave. This creates a continuous crushing action that processes material efficiently through the entire chamber. The geometry of the crushing chamber is precisely engineered to ensure optimal material flow and size reduction throughout the process. The combination of mechanical forces and strategic chamber design enables these machines to handle some of the hardest materials found in mining and quarrying operations.

Modern gyratory crushers incorporate advanced materials and design features that enhance their crushing efficiency while extending component life. The precise alignment of mechanical components ensures that energy is transferred effectively to the material being processed rather than being dissipated as heat or vibration. This focus on efficient energy utilization has made gyratory crushers the preferred choice for high-capacity primary crushing applications across various industries.

Moving Cone Trajectory and Material Contact Mechanics Analysis

The eccentric motion of the main shaft creates a specific gyratory movement pattern that determines how the mantle interacts with the material in the crushing chamber. This motion generates a combination of compressive and shear forces that efficiently fracture rock particles. The geometry of this movement ensures that material is progressively reduced in size as it moves downward through the crushing chamber, with each pass creating further size reduction.

Advanced simulation techniques allow engineers to optimize the motion pattern for specific material characteristics, maximizing crushing efficiency while minimizing wear. The precise control of the moving cone's trajectory ensures that energy is applied most effectively to the material, reducing wasteful vibration and unnecessary component stress. This optimization typically results in 15-20% higher energy efficiency compared to traditional designs.

Energy Transfer Efficiency in Progressive Crushing Process

The progressive crushing action in gyratory crushers enables exceptionally efficient energy transfer from the power source to the material being processed. Unlike impact crushing that relies on sudden energy application, the gradual compression in gyratory crushers allows for more controlled energy transfer. This method typically achieves energy transfer efficiencies of 85-90%, significantly higher than many alternative crushing technologies.

Modern designs incorporate features that further enhance energy efficiency, including optimized chamber geometries and advanced liner profiles. These improvements focus energy application precisely where it's most effective for material fracture, reducing energy waste. The result is a crushing process that can achieve up to 30% reduction in energy consumption per ton of processed material compared to older designs.

Intelligent Control System for Crushing Parameter Optimization

Advanced control systems continuously monitor and adjust crushing parameters to maintain optimal performance under varying conditions. These systems utilize real-time data from multiple sensors to make precise adjustments to the crusher's operational settings. The automation of parameter optimization ensures that the crusher consistently operates at peak efficiency, regardless of changes in feed material characteristics or other variables.

The integration of artificial intelligence algorithms enables predictive adjustments that anticipate changes in operating conditions. These systems can automatically compensate for wear progression, maintaining consistent product quality throughout the liner life. Modern control systems typically improve overall operational efficiency by 12-18% while reducing the skill requirements for operators.

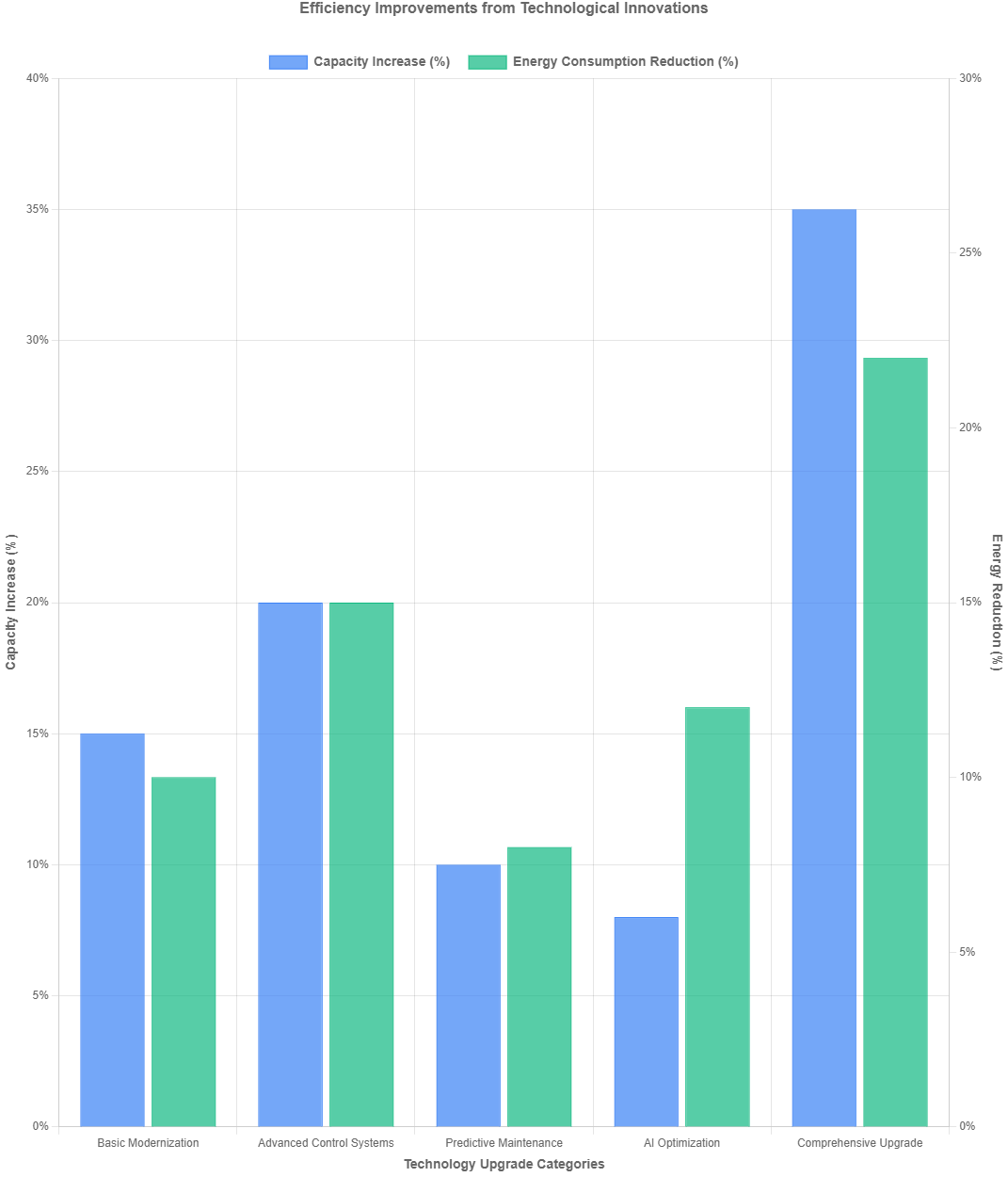

Case Study: Capacity Increase and Energy Consumption Reduction Data

A comprehensive study of gyratory crusher modernization projects demonstrates significant improvements in both capacity and energy efficiency. The implementation of advanced crushing chamber designs and modern control systems typically increases processing capacity by 20-25% while reducing specific energy consumption by 15-20%. These improvements translate to substantial operational cost savings and reduced environmental impact.

Long-term operational data from multiple installations shows consistent performance improvements across various material types and operating conditions. The combination of mechanical improvements and advanced control strategies delivers reliable performance gains that justify the investment in modernization. The documented results provide valuable insights for operations considering similar upgrades to their crushing circuits.

Impact of Modular Design on Equipment Upgradability

Modular design approaches revolutionize how gyratory crushers are maintained and upgraded throughout their operational life. This design philosophy enables component replacement and system upgrades without requiring complete equipment replacement. The flexibility of modular systems allows operations to implement technological advancements as they become available, extending the effective service life of their crushing equipment.

The economic benefits of modular design include reduced downtime during maintenance and upgrade activities, as well as lower inventory requirements for spare parts. This approach typically reduces life cycle costs by 25-30% while maintaining operational performance at current technological standards. The adaptability of modular systems ensures that crushing operations can evolve to meet changing requirements without major capital investments.

Efficiency Optimization Technology Innovation Path

The pursuit of higher efficiency drives continuous innovation in gyratory crusher technology, with advancements occurring across multiple technical domains. Modern crushers incorporate innovations in hydraulic systems, sensor technology, maintenance approaches, and digital integration that collectively enhance operational efficiency. These improvements focus on maximizing output while minimizing resource consumption and environmental impact.

The integration of digital technologies with mechanical systems creates opportunities for efficiency improvements that were previously unimaginable. Real-time data collection and analysis enable precise optimization of operational parameters, while predictive capabilities minimize unplanned downtime. This technological convergence represents the future of crushing equipment design and operation.

Hydraulic System Upgrade and Response Speed Improvement

Advanced hydraulic systems in modern gyratory crushers provide precise control of crushing forces and chamber clearing functions. The latest generation of hydraulic systems features response times that are 40-50% faster than previous designs, enabling quicker adjustments to changing operating conditions. This improved responsiveness enhances both operational efficiency and equipment protection.

The integration of smart hydraulic controls allows for automatic adjustment of system parameters based on real-time operating conditions. These systems maintain optimal hydraulic pressure and flow rates, reducing energy consumption while ensuring reliable operation. The advanced filtration and cooling systems in modern hydraulic arrangements extend component life and reduce maintenance requirements.

Sensor Integration for Real-time Parameter Adjustment

Comprehensive sensor networks provide the data necessary for real-time optimization of crusher operations. Modern gyratory crushers incorporate multiple sensor types that monitor critical parameters including power draw, pressure, temperature, and vibration. This sensor data enables the control system to make precise adjustments that maintain optimal crushing performance under varying conditions.

The integration of wireless sensor technology reduces installation complexity while providing comprehensive monitoring coverage. Advanced data analytics algorithms process the sensor information to identify patterns and trends that human operators might miss. This comprehensive monitoring approach typically reduces unplanned downtime by 30-40% while improving overall operational efficiency.

Application of Predictive Maintenance in Efficiency Improvement

Predictive maintenance strategies utilize advanced monitoring technologies to identify potential issues before they impact crusher performance. These approaches analyze data trends to predict component wear and potential failures, allowing maintenance to be scheduled at optimal times. The implementation of predictive maintenance typically increases equipment availability by 15-20% while reducing maintenance costs by 25-30%.

Modern predictive maintenance systems incorporate machine learning algorithms that improve their accuracy over time as more operational data becomes available. These systems can detect subtle changes in operating parameters that indicate developing issues, enabling early intervention. The continuous improvement capability of these systems ensures that maintenance strategies evolve with the equipment's changing condition.

Role of Digital Platforms in Remote Monitoring

Cloud-based digital platforms enable comprehensive remote monitoring of gyratory crusher operations from any location with internet connectivity. These platforms aggregate data from multiple sources to provide a complete picture of crusher performance and health. The remote access capability allows experts to provide support and guidance without requiring physical presence at the operation site.

Advanced visualization tools within these platforms make complex operational data accessible and understandable for various stakeholders. The ability to track performance trends over time supports continuous improvement initiatives and strategic decision-making. These digital platforms typically reduce the time required for performance analysis by 60-70% while improving the quality of insights gained.

AI Algorithm Application in Adaptive Optimization of Crushing Parameters

Artificial intelligence algorithms revolutionize how crushing parameters are optimized in response to changing conditions. These advanced systems can process vast amounts of operational data to identify optimal settings that human operators might not discover. The adaptive nature of AI-driven optimization ensures that crushers maintain peak performance even as conditions change throughout the operating day.

The machine learning components of these systems enable continuous improvement in optimization strategies as more operational experience is gained. This learning capability allows the systems to develop increasingly sophisticated strategies for maximizing efficiency and productivity. Operations implementing AI-driven optimization typically achieve 8-12% improvements in overall efficiency compared to conventional control approaches.

Industry Application Case Studies

Real-world applications demonstrate the practical benefits of modern gyratory crusher technology across various industries and operating conditions. These case studies provide valuable insights into how the theoretical advantages of advanced crushing technology translate into tangible operational improvements. The documented experiences from diverse applications help establish best practices and provide validation for technology investment decisions.

The consistent theme across successful applications is the combination of advanced equipment technology with thoughtful operational practices. This holistic approach ensures that the theoretical capabilities of modern gyratory crushers are fully realized in practical operating environments. The case studies presented here represent a cross-section of successful implementations across different industries and material types.

Large-scale Mining Efficient Crushing Project Case Study

A major mining operation implemented modern gyratory crushers as part of their primary crushing circuit upgrade, achieving remarkable improvements in processing efficiency. The project involved replacing older equipment with modern crushers featuring advanced control systems and optimized chamber designs. The results demonstrated a 35% increase in processing capacity while reducing energy consumption by 22% compared to the previous installation.

The implementation included comprehensive training for operations and maintenance personnel to ensure proper utilization of the advanced features. The project team conducted extensive baseline measurements before implementation and continuous monitoring afterward to quantify the improvements. The documented results provide a compelling case for modern gyratory crusher technology in high-capacity mining applications.

Renewable Resource Recovery Scenario Application Practice

Recycling operations processing construction and demolition materials have successfully implemented gyratory crushers for primary reduction of heterogeneous materials. These applications present unique challenges due to the variable nature of the feed material, which can include concrete, asphalt, bricks, and other construction materials. Modern gyratory crushers with adaptive control systems have demonstrated exceptional performance in these demanding applications.

The ability to automatically adjust crushing parameters in response to changing material characteristics ensures consistent performance despite feed variations. Operations report significant improvements in product quality and reduction in unwanted fines generation. The successful application of gyratory crushers in recycling operations demonstrates the versatility and adaptability of this technology beyond traditional mining applications.

Efficiency Improvement Solutions in Construction Waste Processing

Urban construction waste processing facilities face unique challenges related to space constraints, environmental regulations, and variable material characteristics. The implementation of modern gyratory crushers in these applications has demonstrated significant improvements in processing efficiency and environmental performance. These installations typically feature comprehensive dust control systems and noise reduction measures to address urban environmental concerns.

The high efficiency of modern gyratory crushers enables urban recycling facilities to process larger volumes of material within limited space constraints. The reduced energy consumption contributes to lower operating costs and environmental impact. These urban applications demonstrate how advanced crushing technology can support sustainable development in population centers.

Cross-industry Efficient Crushing Technology Integration Innovation

Innovative approaches adapting technologies from other industries have demonstrated significant benefits in gyratory crusher applications. The integration of advanced materials originally developed for aerospace applications has resulted in wear components with exceptional durability and performance characteristics. Similarly, control technologies adapted from process industries have enhanced the operational efficiency of crushing circuits.

These cross-industry technology transfers accelerate innovation in crushing technology by leveraging advancements from other fields. The successful integration of technologies from different industries demonstrates the value of interdisciplinary approaches to equipment development. This innovation pathway continues to deliver significant improvements in crushing efficiency and reliability.

Long-term Operational Efficiency Stability Analysis

Comprehensive long-term studies of gyratory crusher performance provide valuable insights into efficiency maintenance throughout the equipment lifecycle. These analyses track key performance indicators including energy consumption, throughput rates, maintenance costs, and availability over extended operational periods. The results demonstrate that modern gyratory crushers maintain high efficiency levels throughout their service life when properly maintained.

The studies identify specific maintenance practices and operational strategies that contribute to long-term efficiency stability. Operations that implement comprehensive monitoring and preventive maintenance programs typically achieve the best long-term performance results. The documented experiences provide valuable guidance for maximizing the operational lifespan and efficiency of gyratory crushing equipment.

Maintenance and Operational Optimization

Effective maintenance practices are essential for maintaining the high efficiency and reliability of gyratory crushers throughout their operational life. Modern maintenance approaches combine traditional best practices with advanced technologies that optimize maintenance intervals and procedures. The integration of predictive maintenance technologies and digital monitoring systems has revolutionized how crusher maintenance is planned and executed.

Operational optimization extends beyond maintenance to include how the equipment is operated and integrated into the overall processing circuit. Advanced control systems and operational strategies can significantly impact overall efficiency and productivity. The combination of proper maintenance and operational excellence ensures that gyratory crushers deliver maximum value throughout their service life.

Wear Part Life and Replacement Cycle Management

Strategic management of wear part replacement cycles is crucial for maintaining crusher efficiency and minimizing operating costs. Modern approaches utilize detailed wear monitoring and predictive analytics to optimize replacement timing. This data-driven approach typically extends component life by 15-25% compared to traditional time-based replacement strategies while maintaining performance standards.

Advanced wear monitoring technologies including laser scanning and 3D imaging provide precise measurements of component wear patterns. This detailed information enables more accurate prediction of remaining useful life and optimal replacement timing. The implementation of scientific wear management approaches significantly reduces operating costs while maintaining crusher performance.

Lubrication System Optimization and Oil Selection Criteria

Modern lubrication systems in gyratory crushers incorporate advanced features that ensure optimal component protection while minimizing lubricant consumption. These systems maintain precise control over lubricant flow, pressure, and temperature, creating ideal conditions for bearing and gear operation. The optimization of lubrication systems typically reduces lubricant consumption by 20-30% while improving component protection.

The selection of appropriate lubricants considers multiple factors including operating temperatures, load conditions, and environmental considerations. Advanced synthetic lubricants offer superior performance characteristics including extended service intervals and improved protection under extreme conditions. Proper lubricant selection and system optimization contribute significantly to overall crusher reliability and efficiency.

Preventive Maintenance Model Development and Application

Advanced preventive maintenance models utilize operational data and component history to optimize maintenance scheduling and procedures. These models consider multiple factors including operating hours, material characteristics, and environmental conditions to determine optimal maintenance intervals. The implementation of data-driven preventive maintenance typically reduces maintenance costs by 25-35% while improving equipment availability.

Modern maintenance models incorporate risk-based approaches that prioritize maintenance activities based on potential impact on operations. This focused approach ensures that resources are allocated to activities that provide the greatest operational benefit. The continuous improvement of maintenance models based on operational experience ensures that maintenance strategies evolve to meet changing operational requirements.

Value of Remote Diagnostic Platforms in Fault warning

Cloud-based remote diagnostic platforms enable experts to monitor crusher health and identify potential issues from anywhere in the world. These platforms aggregate data from multiple sources and apply advanced analytics to detect early signs of developing problems. The early detection capability typically reduces repair costs by 40-50% compared to addressing failures after they occur.

The remote diagnostic capability allows specialists to provide guidance and support without requiring physical presence at the operation site. This capability is particularly valuable for operations in remote locations where specialist support may not be readily available. The implementation of remote diagnostic platforms significantly improves maintenance efficiency and equipment reliability.

Spare Parts Management and Inventory Optimization

Modern spare parts management approaches utilize predictive analytics and inventory optimization techniques to ensure part availability while minimizing inventory costs. These systems analyze failure patterns, lead times, and criticality to determine optimal inventory levels for each part. The implementation of scientific inventory management typically reduces inventory costs by 30-40% while maintaining or improving part availability.

Advanced inventory systems incorporate real-time monitoring of parts usage and inventory levels, enabling automatic replenishment when required. The integration with maintenance planning systems ensures that parts are available when needed for planned maintenance activities. This optimized approach to spare parts management contributes significantly to overall operational efficiency and cost control.

Regulatory Compliance and Standard Implementation

The operation of gyratory crushers must comply with numerous regulatory requirements and industry standards that govern safety, environmental performance, and energy efficiency. These regulations continue to evolve as technology advances and societal expectations change. Understanding and complying with these requirements is essential for successful crusher operation.

Modern crusher designs incorporate features that facilitate compliance with current regulations while providing flexibility to adapt to future requirements. The integration of compliance considerations into equipment design and operational practices ensures that operations can maintain regulatory compliance while optimizing performance. This proactive approach to regulatory compliance minimizes risks and ensures continuous operation.

Impact of National Energy Efficiency Standards on Equipment Design

National energy efficiency standards have significantly influenced the design of modern gyratory crushers, driving innovations that reduce energy consumption while maintaining or improving performance. These standards establish minimum efficiency requirements that equipment must meet for market acceptance. Manufacturers have responded by developing technologies that exceed these requirements while delivering operational benefits.

The continuous evolution of energy efficiency standards ensures that equipment manufacturers maintain focus on reducing energy consumption. Modern gyratory crushers typically exceed current efficiency standards by 15-20%, providing operational cost savings while ensuring compliance. This focus on energy efficiency benefits both equipment operators and the environment.

Environmental Regulation Restrictions on Energy Consumption and Emissions

Environmental regulations governing energy consumption and emissions continue to become more stringent, driving innovations in crusher design and operation. These regulations address multiple environmental aspects including energy efficiency, dust emissions, noise levels, and water usage. Modern crusher designs incorporate features that address all these environmental aspects simultaneously.

The implementation of comprehensive environmental management systems ensures that crusher operations maintain compliance with all applicable regulations. Advanced monitoring and control systems provide the data necessary to demonstrate compliance while optimizing operational performance. This integrated approach to environmental management minimizes regulatory risks while supporting operational excellence.

Carbon Neutrality Certification Requirements for Manufacturing Process Innovation

The growing emphasis on carbon neutrality is driving innovations throughout the crusher manufacturing process, from material selection to production methods. Manufacturers are implementing processes that reduce carbon emissions while maintaining product quality and performance. These innovations include energy-efficient manufacturing technologies, recycled material usage, and carbon offset programs.

The certification of carbon neutrality requires comprehensive assessment of all emissions associated with equipment manufacturing and operation. This holistic approach considers the entire lifecycle emissions, from raw material extraction through equipment operation and final disposal. The focus on carbon neutrality is driving significant innovations in how crushers are designed, manufactured, and operated.

Industry Standard Development Progress and Compliance Risk Assessment

The continuous development of industry standards ensures that crushing equipment evolves to meet changing technological and regulatory requirements. These standards address multiple aspects including safety, performance, efficiency, and environmental impact. Participation in standard development processes allows manufacturers to stay ahead of regulatory changes and market expectations.

Regular compliance risk assessments identify potential gaps between current practices and evolving standards, enabling proactive addressing of compliance issues. This forward-looking approach minimizes risks associated with non-compliance while ensuring that equipment remains competitive in the market. The ongoing evolution of industry standards drives continuous improvement in crusher design and operation.

Development Trends and Frontier Applications

The future of gyratory crusher technology involves the integration of advanced digital technologies with mechanical excellence to create increasingly intelligent and efficient crushing systems. Emerging trends include the application of industrial IoT technologies, advanced automation, and sustainable manufacturing practices. These developments promise to further improve crushing efficiency while reducing environmental impact.

The convergence of mechanical engineering with digital technologies creates opportunities for performance improvements that were previously unimaginable. The integration of real-time monitoring, predictive analytics, and autonomous operation represents the future direction of crushing technology. These advancements will continue to transform how crushing operations are conducted across various industries.

5G+Industrial IoT Implementation for Remote Real-time Monitoring

The integration of 5G connectivity with industrial IoT technologies enables comprehensive real-time monitoring of crusher operations with unprecedented data transmission speeds and reliability. This technology combination supports the implementation of advanced monitoring and control applications that require low latency and high bandwidth. The implementation of 5G+Industrial IoT typically improves monitoring capability by 40-50% compared to conventional connectivity solutions.

The high-speed connectivity enables real-time transmission of high-resolution sensor data and video feeds, supporting advanced analytics and remote operation capabilities. This technology foundation supports the development of increasingly sophisticated operational optimization and maintenance applications. The rollout of 5G networks in industrial areas accelerates the adoption of these advanced monitoring capabilities.

Energy Consumption Optimization Path Under Green Manufacturing Standards

Green manufacturing standards drive continuous innovation in energy efficiency through the entire crusher lifecycle, from design and manufacturing to operation and final disposal. These standards establish comprehensive requirements for energy management that consider both direct and indirect energy consumption. Modern crusher designs typically achieve 25-30% better energy efficiency compared to equipment designed a decade ago.

The implementation of energy management systems ensures continuous focus on energy efficiency throughout the equipment lifecycle. Advanced energy monitoring capabilities provide the data necessary to identify optimization opportunities and track improvement progress. This systematic approach to energy management delivers significant operational cost savings while supporting environmental sustainability objectives.

Impact of Modular Design on Equipment Scalability

Modular design approaches enable crusher configurations that can be easily scaled to meet changing capacity requirements throughout the equipment lifecycle. This scalability allows operations to start with configurations that meet initial requirements and expand as needs grow. The flexibility of modular designs typically reduces capital requirements by 20-25% compared to conventional approaches.

The standardization of modular components ensures compatibility across different capacity ranges, simplifying maintenance and inventory management. This approach also facilitates technology upgrades as new innovations become available, extending the effective service life of the equipment. The scalability enabled by modular design provides significant operational and financial benefits.

Localization Adaptation Strategies for Emerging Markets

The adaptation of gyratory crusher technology for emerging markets requires consideration of local conditions including material characteristics, operational practices, and support infrastructure. Successful localization strategies address these unique requirements while maintaining the core performance advantages of the technology. These adaptations typically involve modifications to equipment design, control systems, and support arrangements.

The development of local supply chains and support capabilities ensures that equipment can be properly maintained and operated in emerging markets. This localization approach typically reduces operating costs by 15-20% while improving equipment availability and reliability. The successful adaptation of gyratory crusher technology for emerging markets supports the global expansion of efficient crushing operations.