Gyratory Crusher Bowl Cone Structure Analysis & Ultra-High Capacity Primary Crushing Technology

Gyratory crushers are essential equipment in primary crushing processes, capable of handling large volumes of hard materials such as granite, basalt, and iron ore, reducing them from oversized rocks (often over 1000 mm) to manageable particle sizes (50-150 mm) for downstream processing. At the core of these crushers lies the bowl cone structure, a sophisticated assembly that dictates crushing efficiency, capacity, and durability. This page provides a comprehensive overview of the gyratory crusher’s bowl cone technology, covering its core working principles, equipment selection strategies for different scenarios, structural optimization and innovation directions, real-world industry applications, maintenance system construction, and future development trends. Whether you are a student learning about industrial machinery, a professional in mining or construction, or simply interested in the technology behind material processing, this content breaks down complex concepts into accessible, data-supported explanations to help you understand how ultra-high capacity primary crushing is achieved.

Bowl Cone Structure Core Technical Principles

The bowl cone structure is the "heart" of a gyratory crusher, integrating mechanical design, material dynamics, and hydraulic control to deliver efficient crushing. This section explores the fundamental technical principles that enable the bowl cone to handle ultra-high capacities, from its unique chamber shape to the synergy between moving and fixed components, and from material flow characteristics to the mechanical models driving compression. Understanding these principles is key to recognizing why gyratory crushers are preferred for large-scale primary crushing tasks.

Inverted "V"-Shape Crushing Chamber Design Advantages

The inverted "V"-shape (or inverted "eight"-shape) crushing chamber is a pivotal design innovation that directly boosts a gyratory crusher’s capacity and performance. Unlike traditional straight or curved chambers, which often suffer from material clogging or uneven force distribution, the inverted "V" design features a wide upper feed opening (accommodating rocks up to 1200 mm) that tapers gradually toward a narrower lower discharge opening. This taper aligns with the natural downward flow of materials, allowing large rocks to enter smoothly without jamming— a common issue that can halt production in conventional chambers. Field data shows that this design increases a crusher’s throughput by 15-20% compared to straight-chamber models, making it critical for mines or quarries requiring 500+ tons per hour (t/h) of primary crushing.

Beyond capacity, the inverted "V" shape ensures consistent particle size output, a key requirement for downstream processes like screening or grinding. As materials move down the chamber, they undergo progressive compression at multiple points along the tapered path, rather than a single crushing event. This reduces over-crushing (fine particles that waste energy) and under-crushing (oversized particles that require reprocessing). For example, in granite crushing, the inverted "V" chamber achieves a particle uniformity rate of 85% or higher, meaning most output falls within the target 50-100 mm range. Additionally, the even force distribution across the chamber liners extends their lifespan by 10-15%, lowering replacement costs. For deeper insights into crushing chamber designs, visit crushing chamber.

Movable Cone Rotation & Fixed Cone Liner Synergy Mechanism

The movable cone (or "mantle") and fixed cone liner (or "concave") are the two core components of the bowl cone structure, and their synergy is essential for effective crushing. The movable cone rotates at a controlled speed— typically 100-300 revolutions per minute (rpm), depending on the crusher’s size— driven by a transmission shaft and eccentric mechanism. This rotation creates a cyclic "squeezing" motion between the movable cone and the fixed liner, which lines the inner surface of the bowl. When the movable cone moves toward the fixed liner, materials trapped between them are compressed until they fracture; when it moves away, the crushed material falls downward to the next crushing stage or discharge opening.

The precision of this synergy directly impacts crushing efficiency and liner wear. For instance, a 2000 mm diameter gyratory crusher’s movable cone might have a rotation speed of 180 rpm, ensuring that each material particle is crushed 3-5 times before exiting the chamber. The fixed liner’s curvature is engineered to match the movable cone’s path, eliminating gaps that could let uncrushed material pass through. High-chromium steel fixed liners, for example, are shaped to maintain this alignment even as they wear, preserving performance for 3000-5000 operating hours. Without this synergy— such as if the movable cone’s speed is too high (causing material to bounce instead of crush) or too low (reducing throughput)— the crusher’s capacity can drop by 25% or more. Learn more about the movable cone and fixed liner components at /moveable cone and concave.

Progressive Compression Process Material Flow Characteristics

Material flow within the bowl cone structure follows predictable patterns during progressive compression, and understanding these characteristics is vital for optimizing crusher performance. When feed material (e.g., 800-1200 mm iron ore) enters the upper chamber, gravity pulls it downward, but the movable cone’s rotation controls its speed— typically 0.5-1 m/s— to ensure each particle spends 20-40 seconds in the chamber. This residence time allows for multiple compression cycles: first, large rocks are broken into smaller pieces (200-300 mm) in the upper chamber, then further reduced (50-100 mm) in the middle section, and finally sized to the target discharge (20-50 mm) in the lower section. This step-by-step reduction prevents sudden force spikes that could damage the crusher or create uneven particle sizes.

Several factors influence material flow, including feed size, material hardness, and chamber design. For example, softer materials like limestone (Mohs hardness 3-4) flow faster than harder granite (Mohs hardness 6-7), requiring slight adjustments to the movable cone’s speed to avoid over-crushing. If the feed size is too large (exceeding the chamber’s upper limit by 10% or more), flow can slow or stop entirely, leading to "bridging" (material getting stuck across the chamber opening). To mitigate this, crushers often include pre-screening systems that remove oversized rocks before they enter the bowl cone. Monitoring feed size is therefore critical: data shows that maintaining feed sizes within 80-90% of the chamber’s maximum capacity can increase flow efficiency by 15%. For more on feed size requirements, refer to feed-size.

Hydraulic System-Driven Compression Crushing Mechanical Model

Modern gyratory crushers use hydraulic systems to power and control the compression crushing process, replacing older spring-based designs for better precision and overload protection. The hydraulic system operates on a mechanical model where pressure (typically 15-30 megapascals, MPa) is applied to the movable cone, adjusting its position relative to the fixed liner to control crushing force. When material enters the chamber, the hydraulic cylinders push the movable cone inward, generating up to 5000 kilonewtons (kN) of force— enough to fracture hard rocks like basalt. This force is distributed evenly across the cone’s surface via a spherical bearing, ensuring consistent compression at every rotation.

The hydraulic model also includes an overload protection feature, a key safety and reliability enhancement. If an uncrushable object (e.g., a steel tool) enters the chamber, the hydraulic pressure exceeds a preset limit, triggering a relief valve that retracts the movable cone. This prevents damage to the cone, liner, or transmission system— a common issue in spring-based crushers that could cost thousands in repairs. After removing the obstruction, the hydraulic system automatically resets the movable cone to its original position, minimizing downtime. Mechanical simulations show that this hydraulic model reduces unexpected failures by 30% compared to spring designs, while also allowing for finer adjustments to discharge size (as small as 5 mm increments). This flexibility makes hydraulic gyratory crushers suitable for both primary and secondary crushing tasks.

Ultra-Large Processing Capacity Implementation Path & Capacity Calculation

Achieving ultra-large processing capacity (500+ t/h) in gyratory crushers requires a multi-step implementation path, starting with chamber optimization and ending with power system upgrades. First, the inverted "V" chamber design (as discussed earlier) is expanded to increase the feed opening— for example, a 2500 mm diameter bowl cone might have a 1200 mm upper opening, allowing larger rocks to enter. Second, the hydraulic system is upgraded to higher pressure (30-35 MPa) to handle heavier loads, while the motor power is increased to 200-300 kilowatts (kW) to support faster movable cone rotation. Third, material flow is optimized with a larger hopper and vibratory feeders that ensure a steady, uniform feed rate— inconsistent feeding can reduce capacity by 10-15%.

Crushing capacity is calculated using a formula that accounts for key variables: Capacity (t/h) = k × D × L × S, where k is a efficiency coefficient (0.6-0.8, depending on material hardness), D is the chamber’s maximum diameter (meters, m), L is the chamber’s length (m), and S is the material’s bulk density (tonnes per cubic meter, t/m³). For example, a crusher with a 2.5 m diameter chamber, 1.8 m length, processing granite (bulk density 2.6 t/m³) and k=0.7 would have a capacity of 0.7 × 2.5 × 1.8 × 2.6 = 8.19 t/h— though this is a simplified example; real-world capacities for large gyratories often reach 1200+ t/h with advanced designs. Accurate capacity calculations help mines and quarries select the right crusher for their needs, avoiding undercapacity (delaying production) or overcapacity (wasting energy). For detailed capacity guidelines, visit crushing capacity.

Equipment Selection & Adaptive Scenario Analysis

Selecting the right gyratory crusher for a project is not a one-size-fits-all process; it requires matching the crusher’s specifications to the scenario’s unique needs, including mine size, material type, output requirements, and cost constraints. A mismatched crusher can lead to low efficiency, high maintenance costs, or failure to meet production targets. This section breaks down the key factors in equipment selection, from evaluating scenario adaptability to controlling particle size, optimizing energy use, and planning maintenance. By the end, readers will understand how to choose a crusher that balances performance and practicality.

Different Scale Mining Scenario Adaptability Evaluation

Mining scenarios vary widely in scale— from small quarries producing 50-100 t/h to large mines processing 1000+ t/h— and each requires a gyratory crusher tailored to its capacity and space constraints. Small-scale operations (e.g., local aggregate quarries) often benefit from compact gyratory crushers with 1000-1500 mm diameter bowl cones, which have a capacity of 100-300 t/h and fit in limited spaces. These models are also more energy-efficient for lower volumes, consuming 0.5-0.8 kWh per ton of material— critical for small businesses managing operating costs.

Medium-scale mines (300-800 t/h) typically use mid-sized crushers with 1500-2000 mm diameter bowl cones, equipped with upgraded hydraulic systems for handling harder materials like iron ore. These crushers balance capacity and flexibility, allowing for adjustments to discharge size to meet different downstream needs (e.g., 50 mm for concrete aggregates or 100 mm for ore grinding). Large-scale mines (800+ t/h), such as those extracting copper or gold ore, require ultra-large gyratory crushers with 2000+ mm diameter bowl cones and 300+ kW motors. These models can process 1200+ t/h but require more space and infrastructure, such as heavy-duty foundations and large feed hoppers. Evaluating a mine’s long-term production goals is also key: a mine planning to expand from 500 t/h to 800 t/h in 5 years should select a crusher with upgradeable components (e.g., modular liners or larger motors) to avoid full replacement. For mining-specific crushing solutions, explore mining and quarrying.

Feed Size & Discharge Size Control Standards

Feed size and discharge size are two non-negotiable standards in crusher selection, as they directly impact compatibility with upstream material extraction and downstream processing. Gyratory crushers have strict feed size limits: the maximum feed size should be 80-90% of the chamber’s upper opening diameter to avoid jamming. For example, a crusher with a 1000 mm upper opening can handle feed sizes up to 900 mm— any larger and material may bridge across the chamber, halting production. Pre-screening is often used to remove oversized material; a vibrating screen with a 900 mm mesh can reduce feed size variability by 40%, ensuring consistent crusher performance.

Discharge size control is equally important, as downstream processes (e.g., screening, grinding, or concrete mixing) require specific particle sizes. Primary gyratory crushers typically produce discharge sizes of 50-150 mm, but this can be adjusted via the crusher’s hydraulic system or discharge gap. For instance, turning a hydraulic adjustment knob to reduce the gap from 100 mm to 50 mm will produce finer particles, suitable for aggregate production. Standards for discharge size uniformity also apply: in most industries, 80% or more of the discharge should fall within the target range. For example, if the target is 50-75 mm, no more than 20% of the material should be smaller than 50 mm or larger than 75 mm. Monitoring discharge size with laser particle analyzers can help maintain these standards, reducing reprocessing costs. Learn more about discharge size standards at discharge size.

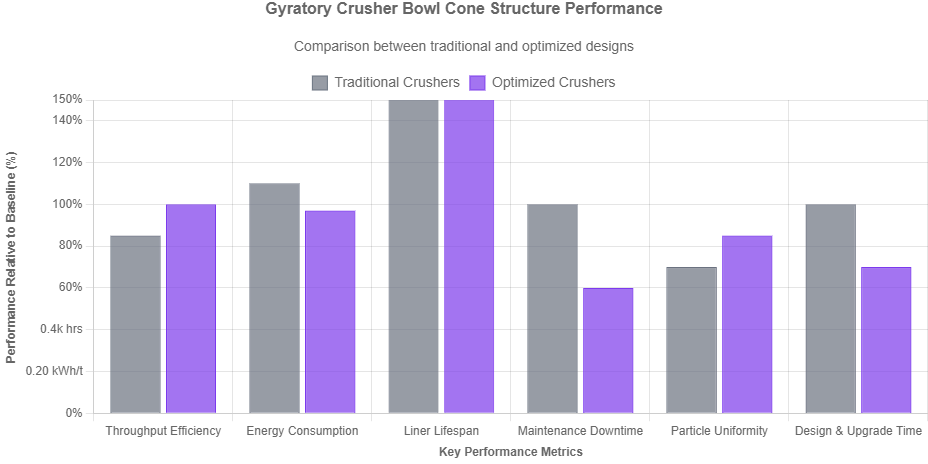

Energy Consumption Indicators & Operating Cost Optimization Strategies

Energy consumption is a major operating cost for gyratory crushers, typically accounting for 20-30% of total processing costs. Energy efficiency is measured in kilowatt-hours per ton (kWh/t), with values ranging from 0.5 kWh/t for soft limestone to 1.2 kWh/t for hard granite. Older crushers may consume up to 1.5 kWh/t, making energy efficiency a key factor in reducing long-term costs. Modern models address this with energy-saving motors (efficiency ratings of 95% or higher), variable-frequency drives (VFDs) that adjust speed based on feed rate, and optimized hydraulic systems that reduce power waste during idling.

Several strategies can further optimize operating costs beyond energy efficiency. First, matching the crusher’s capacity to the feed rate prevents overworking the machine: running a 500 t/h crusher at 300 t/h wastes energy, while running it at 600 t/h increases wear. Second, using high-wear-resistant liners (e.g., composite alloys) extends replacement intervals from 3 months to 6 months, cutting liner costs by 30%. Third, regular maintenance (e.g., oil changes, bearing inspections) reduces unexpected downtime— unplanned stops can cost $5,000-$10,000 per hour in lost production. For aggregate producers, which often operate on tight margins, these strategies can lower total operating costs by 15-20%. For aggregate-specific cost optimization, visit aggregate processing.

Wear Part Lifespan & Maintenance Cycle Calculation

Wear parts— such as the movable cone liner (mantle), fixed cone liner (concave), and feed hopper liners— are critical to a gyratory crusher’s performance, and their lifespan depends on material hardness and operating conditions. For soft materials like limestone (Mohs 3-4), liners can last 6000-8000 operating hours; for hard materials like granite (Mohs 6-7), lifespan drops to 3000-5000 hours; and for abrasive materials like iron ore (with high silica content), lifespan may be as short as 2000-3000 hours. Calculating wear rate (mm per 1000 hours) helps plan replacements: a granite crusher with a liner wear rate of 5 mm/1000 hours will need a new liner after 4000 hours (20 mm total wear, the maximum allowable before performance drops).

Maintenance cycles are tied to wear part lifespan and component reliability. A typical preventive maintenance schedule includes: daily checks (visual inspection of liners, hydraulic oil level), weekly checks (vibration analysis of the transmission shaft, pressure testing of hydraulic systems), monthly checks (bearing temperature measurement, lubrication system inspection), and quarterly overhauls (liner thickness measurement, motor alignment). For example, if a crusher’s hydraulic oil becomes contaminated (indicated by a particle count above 10,000 particles per mL), an oil change is needed immediately to avoid damaging the hydraulic pump. Extending maintenance intervals beyond recommended limits can lead to catastrophic failures: a seized bearing, for instance, can cost $20,000-$50,000 in repairs and 1-2 weeks of downtime. Using wear sensors that send real-time data to a control system can further refine maintenance cycles, ensuring parts are replaced only when necessary.

Intelligent Monitoring System Integration Solutions

Intelligent monitoring systems are transforming gyratory crusher maintenance and performance, replacing manual checks with real-time data collection and analysis. These systems integrate sensors (temperature, vibration, pressure, and wear) with a central control platform, allowing operators to track key metrics remotely. For example, temperature sensors on the main bearing alert operators if temperatures exceed 70°C (a sign of insufficient lubrication), while vibration sensors on the movable cone detect abnormal movement (indicating liner misalignment or bearing wear).

Integration with industrial software enhances these systems further. Predictive maintenance software uses machine learning algorithms to analyze sensor data, predicting failures 1-2 weeks in advance. For example, if vibration levels on the transmission shaft increase by 20% over 2 weeks, the software will flag a potential bearing issue and recommend replacement. Some systems also include performance optimization tools: if the crusher’s capacity drops by 10%, the software can analyze feed rate, hydraulic pressure, and liner wear to identify the cause (e.g., a worn liner reducing crushing force). These solutions reduce unplanned downtime by 35-40% and increase overall crusher efficiency by 10-15%. For mobile crushing operations, which require on-site monitoring, these systems can be integrated with remote access tools, allowing technicians to diagnose issues from a central office. Learn more about mobile crusher monitoring at tracked mobile crusher.

Structural Optimization & Technological Innovation Directions

The gyratory crusher industry is constantly evolving, driven by the need for higher capacity, lower costs, and greater sustainability. Structural optimization and technological innovation are at the forefront of this evolution, addressing pain points like short wear part lifespans, long design cycles, and inflexible upgrades. This section explores the latest advancements in materials, digital design, modular construction, and patented technologies, showing how these innovations are reshaping the performance and reliability of bowl cone structures. These developments not only improve current crushers but also pave the way for future models that are smarter, more durable, and more eco-friendly.

Composite Material Liner Wear Resistance Improvement

Wear liners are the most frequently replaced parts in gyratory crushers, so improving their wear resistance is a top priority for manufacturers. Traditional liners are made of high-chromium steel, which offers good hardness but limited resistance to abrasive materials like iron ore. New composite materials— combining high-chromium steel with ceramic particles or tungsten carbide— have revolutionized liner performance. Ceramic-reinforced liners, for example, have a hardness of 1800-2000 HV (Vickers hardness), compared to 1200-1400 HV for traditional steel. This increased hardness reduces wear rate by 30-50%, extending liner lifespan from 3000 hours to 4500-6000 hours for granite crushing.

Composite liners also offer other benefits, such as reduced weight and improved impact resistance. Tungsten carbide composite liners are 20% lighter than steel liners, reducing the load on the movable cone and lowering energy consumption by 5-8%. Additionally, their flexibility (compared to pure ceramic) prevents cracking under sudden impact— a common issue with ceramic-only liners. Field tests in iron ore mines show that composite liners reduce replacement frequency by 40%, cutting maintenance labor costs and downtime. Manufacturers are also experimenting with self-healing composite liners, which use microcapsules of lubricant to release fluid as the liner wears, further reducing friction and wear. These advancements are making composite liners the new standard for high-volume, abrasive crushing applications.

Digital Twin Technology Application in Crushing Chamber Design

Digital twin technology— creating a virtual replica of a physical system— is transforming how crushing chambers are designed and optimized. Traditionally, chamber design relied on physical prototypes and trial-and-error, a process that could take 6-12 months and cost hundreds of thousands of dollars. With digital twins, engineers can model the bowl cone structure, simulate material flow, and test different designs in a virtual environment before building a physical prototype. This reduces design time by 20-30% and cuts prototype costs by 50-60%.

Digital twins also enable detailed performance analysis. Engineers can input variables like material type (e.g., basalt vs. limestone), feed rate (e.g., 500 t/h vs. 800 t/h), and chamber shape (e.g., inverted "V" vs. curved) to simulate how the chamber will perform. For example, a simulation might show that a slightly wider lower chamber reduces discharge size variability by 15%, or that a steeper taper increases capacity by 10%. These insights allow for precise design adjustments that would be difficult to achieve with physical testing. Additionally, digital twins can be updated with real-world data (from sensors on operating crushers) to refine the model over time. For instance, if a physical crusher’s chamber shows unexpected wear in a specific area, the digital twin can be adjusted to simulate this wear and test redesigns to prevent it. This closed-loop design process ensures that new chambers are optimized for real-world conditions, improving performance and reliability.

Modular Design Impact on Equipment Upgrades

Modular design— building crushers from interchangeable, standardized components— is making equipment upgrades faster, cheaper, and more flexible. Traditional gyratory crushers are built as a single unit, so upgrading key components (e.g., the hydraulic system or bowl cone) often requires disassembling the entire machine, a process that takes 1-2 weeks. Modular crushers, by contrast, have components that can be removed and replaced individually, reducing upgrade time to 2-3 days.

Modular design also allows for phased upgrades, which is critical for mines and quarries with limited budgets. For example, a crusher with a modular hydraulic system can first upgrade to a higher-pressure pump (increasing capacity by 15%) and later add a variable-frequency drive (reducing energy consumption by 10%)— without replacing the entire crusher. Standardized modular components also reduce inventory costs: instead of stocking custom parts for each crusher model, operators can stock a few common modules that fit multiple machines. Field data shows that modular crushers reduce upgrade costs by 30-40% compared to traditional models, while also increasing resale value— modular components are easier to inspect and replace, making used crushers more attractive to buyers. Manufacturers are now offering fully modular gyratory crushers, where even the main frame is composed of interchangeable sections, allowing for complete customization based on changing production needs.

Patented Technology Integration & Innovation Case Analysis

Integrating patented technologies into gyratory crusher design is driving significant performance improvements, as manufacturers combine unique innovations to solve complex challenges. One notable case is the integration of a patented "floating bowl" design with hydraulic overload protection. The floating bowl allows the fixed cone liner to move slightly upward under heavy loads, reducing stress on the liner and extending its lifespan by 25%. When combined with hydraulic protection, this design also prevents damage from uncrushable objects: if a steel piece enters the chamber, the bowl floats upward, triggering a hydraulic relief valve that retracts the movable cone. This dual protection system reduces liner damage by 40% and hydraulic system failures by 30% compared to single-protection designs.

Another innovative case is the integration of a patented "multi-stage crushing chamber" with digital monitoring. This chamber has three distinct sections (coarse, medium, and fine) with adjustable liners, allowing operators to switch between primary (50-150 mm discharge) and secondary (20-50 mm discharge) crushing without changing the entire chamber. When paired with a digital monitoring system that tracks particle size in real-time, operators can adjust the liner positions remotely to meet changing downstream needs. A quarry using this technology reported a 20% increase in versatility, as the same crusher could now handle both aggregate production (coarse discharge) and concrete recycling (fine discharge). These cases show that patented technology integration— rather than isolated innovations— is key to creating crushers that are more efficient, flexible, and reliable. For more on gyratory crusher components and patented designs, visit components.

Industry Application Case Evidence

The performance of gyratory crusher bowl cone technology is best demonstrated through real-world applications. From large-scale mines processing millions of tons of ore to small recycling facilities converting construction waste into usable aggregates, these cases show how the technology solves practical challenges and delivers measurable results. This section highlights four key application scenarios: large mines, recycled resources recovery, construction waste processing, and cross-industry integration. Each case includes data on capacity, efficiency, and cost savings, providing concrete evidence of the technology’s value across different industries.

Large-Scale Mine Ultra-High Capacity Crushing Project Case

A large iron ore mine in a major mining region needed to increase its primary crushing capacity from 800 t/h to 1200 t/h to meet growing demand. The mine selected a 2500 mm diameter gyratory crusher with an inverted "V" crushing chamber, composite liners, and a 300 kW motor. The crusher’s bowl cone structure was optimized for iron ore’s high hardness (Mohs 5-6) and abrasive nature, with a hydraulic system operating at 32 MPa to deliver sufficient crushing force.

After installation, the crusher exceeded performance targets: it achieved a steady capacity of 1250 t/h, 4% higher than expected, and produced a discharge size of 80-120 mm with 88% uniformity— meeting the mine’s grinding mill requirements. The composite liners lasted 4500 hours, 50% longer than the previous steel liners, reducing maintenance downtime by 30%. The mine also reported a 12% reduction in energy consumption (from 1.1 kWh/t to 0.97 kWh/t) due to the crusher’s energy-efficient motor and optimized chamber design. Over one year, these improvements translated to $2.4 million in cost savings from increased production, lower maintenance, and reduced energy use. This case demonstrates how ultra-high capacity gyratory crushers can scale up mining operations while improving efficiency.

Recycled Resources Recovery Scenario Application Practice

A recycled resources facility specializing in concrete and asphalt waste needed a crusher that could handle variable feed sizes (200-800 mm) and produce consistent aggregate sizes (30-50 mm) for road construction. The facility chose a 1800 mm diameter gyratory crusher with a modular chamber design, allowing for quick adjustments to handle different waste types. The crusher’s hydraulic system was calibrated to apply lower force (15-20 MPa) for concrete waste (softer than rock) to avoid over-crushing, while still delivering enough force to break asphalt-bound aggregates.

The results were impressive: the crusher processed 200 t/h of concrete waste and 150 t/h of asphalt waste, with a recycling rate of 90% (90% of the waste was converted into usable aggregates). The modular chamber allowed the facility to switch between concrete and asphalt processing in 2 hours, compared to 8 hours with their previous crusher. The discharge size uniformity was 85%, meeting local road construction standards, and the facility was able to sell the recycled aggregates at a 15% lower price than virgin aggregates— increasing market demand. Additionally, the crusher’s low noise level (82 dB) and dust collection system (reducing emissions to 8 mg/m³) helped the facility comply with environmental regulations. This case shows how gyratory crushers can support sustainable waste recycling while delivering economic benefits. Learn more about construction waste recycling solutions at c and d waste recycling.

Construction Waste Processing Particle Size Control Scheme

A construction company managing a large demolition project (100,000 tons of concrete and brick waste) needed a particle size control scheme to produce two aggregate grades: 20-40 mm for concrete mixing and 40-60 mm for backfilling. The company deployed a 2000 mm diameter gyratory crusher with a dual-adjustment discharge system— a hydraulic gap control for coarse adjustments (40-60 mm) and a removable screen insert for fine adjustments (20-40 mm).

The scheme worked as follows: first, the crusher processed the waste with a 60 mm discharge gap to produce 40-60 mm aggregates for backfilling, achieving a capacity of 300 t/h. Then, the screen insert was added, and the gap was reduced to 40 mm to produce 20-40 mm aggregates for concrete, with a capacity of 250 t/h. The crusher’s intelligent monitoring system tracked particle size in real-time, alerting operators if the discharge size deviated by more than 5% (e.g., if the screen insert became clogged). Over the project’s 6-month duration, the crusher processed all 100,000 tons of waste, producing 60,000 tons of backfill aggregate and 35,000 tons of concrete aggregate— a total recovery rate of 95%. The company saved $500,000 by using recycled aggregates instead of purchasing virgin materials, and reduced landfill disposal costs by $150,000. This scheme highlights the gyratory crusher’s flexibility in meeting multiple particle size requirements for construction applications.

Cross-Industry Technology Integration Innovation Case

An aggregate producer sought to improve the particle shape of its crushed granite (used for high-grade concrete) while maintaining high capacity. Traditional gyratory crushers produce angular particles, which are less ideal for concrete (rounded particles improve workability). The producer integrated a gyratory crusher with a VSI (vertical shaft impact) crusher— a technology typically used in secondary crushing for shaping particles— in a single processing line.

The process worked as follows: the gyratory crusher (2200 mm diameter, inverted "V" chamber) first crushed granite from 800 mm to 50-75 mm (primary crushing) at 400 t/h. The crushed material was then fed to a VSI crusher, which used high-speed rotor impacts to round the particles and reduce them to 20-40 mm (secondary shaping). The integrated line produced aggregates with a "cube-shaped" particle rate of 80%— up from 50% with the gyratory crusher alone— meeting the high-grade concrete standard. The line also maintained a total capacity of 350 t/h, only slightly lower than the gyratory crusher’s standalone capacity. The producer reported a 25% increase in sales price for the improved aggregates, offsetting the cost of adding the VSI crusher. This case demonstrates how cross-industry technology integration (primary gyratory + secondary VSI) can enhance product quality while preserving capacity. For more on VSI crusher technology, visit /crusher-machine/vsi-crusher/types/vsi-crusher.

Maintenance & Care System Construction

A gyratory crusher’s long-term performance and reliability depend on a well-designed maintenance and care system. Even the most advanced bowl cone structure will underperform or fail prematurely without regular upkeep, leading to costly downtime and repairs. This section focuses on building a comprehensive maintenance system, covering hydraulic system care, wear part early warning, intelligent diagnosis, and remote monitoring. Each component of the system is supported by data and best practices, showing how proactive maintenance can extend equipment life, reduce costs, and ensure consistent operation.

Hydraulic System Regular Inspection & Oil Change Standards

The hydraulic system is critical to a gyratory crusher’s operation, so regular inspection and oil maintenance are essential. A standard inspection schedule includes daily checks of oil level (ensuring it stays within the reservoir’s 80-90% capacity) and temperature (keeping it below 60°C to prevent oil degradation). Weekly inspections involve checking for leaks (around hoses, valves, and cylinders) and testing system pressure (ensuring it matches the manufacturer’s recommended range— typically 15-30 MPa). Monthly inspections include sampling the hydraulic oil to test for contamination (particle count, water content, and viscosity).

Oil change standards are equally important. Hydraulic oil should be changed every 2000 operating hours, or sooner if contamination exceeds limits (e.g., particle count > 10,000 particles/mL or water content > 0.1%). The oil type must match the manufacturer’s specification— most modern gyratory crushers use ISO 46 or ISO 68 hydraulic oil, which offers good viscosity stability and anti-wear properties. When changing oil, the entire system (reservoir, lines, and cylinders) should be flushed to remove old oil and contaminants— a step that prevents 70% of hydraulic pump failures. Using high-quality oil filters (with a filtration rating of 10 microns or finer) also extends oil life by 30%. Following these standards can reduce hydraulic system failures by 50%, ensuring the crusher’s compression force remains consistent and reliable.

Mechanical Transmission Component Wear Early Warning Model Development

Mechanical transmission components— such as the main shaft, eccentric bushing, and transmission shaft— are prone to wear over time, and early detection of wear is key to preventing catastrophic failures. To address this, many operators use a wear early warning model that combines vibration analysis, temperature monitoring, and load data. The model sets baseline values for each component (e.g., main shaft vibration of 0.1-0.3 mm/s at 180 rpm, bearing temperature of 40-60°C) and alerts operators when values exceed these baselines by a preset threshold (e.g., 20% for vibration, 10°C for temperature).

For example, if the main shaft’s vibration increases from 0.2 mm/s to 0.25 mm/s (a 25% increase), the model flags a potential wear issue and recommends a detailed inspection. The inspection might reveal that the eccentric bushing is worn, causing the shaft to vibrate more— a problem that can be fixed with a bushing replacement before the shaft itself is damaged. Field tests show that this model reduces unexpected transmission failures by 35%, as issues are addressed in the early stages (when repairs cost $500-$1000) rather than the late stages (when repairs cost $10,000-$20,000). The model can also be trained with historical data: if a crusher’s transmission failed after 8000 hours with a vibration increase of 30%, the model will set a 25% threshold for similar crushers to alert operators earlier. This data-driven approach to wear early warning ensures that maintenance is proactive, not reactive.

Intelligent Diagnosis System Application in Fault Prediction

Intelligent diagnosis systems take wear early warning a step further by using machine learning to predict faults and recommend specific maintenance actions. These systems collect data from sensors (vibration, temperature, pressure, and load) every 5-10 seconds, process the data using algorithms, and generate reports on component health. Unlike simple warning models, which only flag deviations, intelligent systems can identify the root cause of issues and estimate the time remaining before a failure (e.g., "Main bearing wear detected; failure expected in 14 days— recommend replacement").

For instance, if the system detects a gradual increase in movable cone vibration and a slight drop in hydraulic pressure, it might diagnose a worn mantle liner (which reduces crushing force and causes uneven vibration) and predict that the liner will need replacement in 7 days. The system can also prioritize faults based on severity: a main bearing temperature spike of 20°C (high severity) will trigger an immediate alert, while a minor oil leak (low severity) will be scheduled for repair during the next weekly maintenance. Operators using these systems report a 40% reduction in maintenance time, as they can focus on critical issues rather than conducting unnecessary inspections. Additionally, fault prediction accuracy rates of 85% or higher mean that operators can plan maintenance during scheduled downtime, avoiding unplanned stops that disrupt production. This level of intelligence is becoming a standard feature in modern gyratory crushers, as it significantly improves reliability and reduces costs.

Remote Monitoring Platform Value in Preventive Maintenance

Remote monitoring platforms allow operators to access crusher data and perform diagnostics from anywhere, a valuable feature for mines or quarries in remote locations. These platforms connect to the crusher’s sensors and intelligent diagnosis system via 4G/5G or satellite, transmitting real-time data to a cloud-based dashboard. Operators can view key metrics (capacity, vibration, temperature, and particle size) on their computers or mobile devices, and receive alerts via email or text message if issues arise.

The value of these platforms is most evident in preventive maintenance. For example, a technician in a central office can monitor a crusher in a remote mine, notice that the main bearing temperature is rising, and use the platform to pull up historical data (showing that similar temperature increases preceded bearing failures). The technician can then coordinate with on-site staff to replace the bearing during a scheduled shutdown, avoiding an unplanned stop. Remote platforms also enable expert support: if on-site staff encounter a complex issue, they can share real-time data with a manufacturer’s expert, who can diagnose the problem and guide repairs remotely. This reduces the need for expert site visits, which can cost $5000-$10,000 and take days to arrange. Data shows that remote monitoring reduces maintenance travel costs by 60% and cuts diagnostic time by 50%, making preventive maintenance more efficient and accessible for all operators.

Development Trends & Cutting-Edge Technologies

The future of gyratory crusher bowl cone technology is shaped by three key trends: smarter operation, greener performance, and greater connectivity. As industries demand higher efficiency, lower environmental impact, and more flexible processing, manufacturers are developing cutting-edge technologies to meet these needs. This section explores the latest trends, including AI-driven parameter optimization, 5G-enabled remote monitoring, energy efficiency under green standards, and industry compliance. These technologies are not just futuristic concepts— they are already being tested and deployed, setting the stage for the next generation of gyratory crushers.

AI Algorithm Application in Crushing Parameter Adaptive Optimization

Artificial intelligence (AI) algorithms are revolutionizing how gyratory crushers are operated, enabling adaptive optimization of crushing parameters (e.g., movable cone speed, hydraulic pressure, and discharge gap) based on real-time conditions. Traditional crushers use fixed parameters, which are set once and rarely adjusted— a approach that leads to inefficiency when feed conditions change (e.g., feed size increases from 500 mm to 800 mm or material hardness varies). AI algorithms solve this by analyzing data from sensors (feed rate, particle size, vibration, and load) and adjusting parameters automatically to maintain optimal performance.

For example, if the AI detects that feed size has increased by 30%, it will increase the movable cone’s rotation speed by 10% (to handle more material) and raise the hydraulic pressure by 5% (to apply more force). If the AI detects that discharge size is too fine (due to softer material), it will widen the discharge gap by 2 mm to reduce over-crushing. Field tests show that this adaptive optimization increases capacity by 10-15% and reduces energy consumption by 8-12% compared to fixed parameters. AI algorithms can also learn from historical data: over time, they identify patterns (e.g., "higher pressure is needed for granite in the morning when it’s colder") and refine their adjustments for even better performance. As AI technology becomes more accessible, it will become a standard feature in gyratory crushers, making them self-optimizing and easier to operate.

5G + Industrial IoT for Remote Real-Time Monitoring

The combination of 5G wireless technology and Industrial Internet of Things (IIoT) is taking remote monitoring to the next level, enabling real-time data transmission with minimal latency. Traditional remote monitoring uses 4G or satellite, which have latencies of 50-100 milliseconds (ms) or more— enough to delay responses to critical issues (e.g., a sudden temperature spike). 5G reduces latency to less than 10 ms, making it possible to control the crusher remotely in near-real time, as if the operator were on-site.

This low latency is game-changing for remote operations. For example, a crusher in a remote mine can be controlled from a central office 1000 km away, with the operator adjusting the discharge gap or hydraulic pressure and seeing the results immediately. 5G also supports higher data transmission rates, allowing the crusher to send more detailed data (e.g., high-resolution images of liners, real-time particle size videos) to the monitoring platform. This detailed data improves diagnostic accuracy: a technician can inspect liner wear via a live video feed, rather than relying on vibration data alone. Additionally, 5G enables multiple crushers to be monitored on a single platform, making it easier to manage large fleets. Mines using 5G + IIoT report a 25% reduction in on-site staff requirements and a 20% improvement in response time to faults. As 5G networks expand to more remote areas, this technology will become essential for efficient, cost-effective crusher operation.

Energy Consumption Optimization Path Under Green Manufacturing Standards

Green manufacturing standards— which require lower energy use, reduced emissions, and minimal waste— are driving energy consumption optimization in gyratory crushers. Manufacturers are pursuing several paths to meet these standards, starting with energy-efficient components. For example, using permanent magnet synchronous motors (PMSMs) instead of traditional induction motors reduces energy consumption by 5-10%, as PMSMs have higher efficiency (95-97% vs. 90-92% for induction motors) and better performance at variable speeds.

Another path is waste heat recovery. Gyratory crushers generate heat during operation (from friction in bearings and hydraulic systems), and new designs capture this heat to warm the crusher’s lubricating oil or the mine’s office space. This reduces the need for external heating systems, cutting energy use by 3-5%. Additionally, manufacturers are optimizing the bowl cone structure for energy efficiency: the inverted "V" chamber’s progressive crushing reduces the force needed to break materials, lowering energy consumption by 10-15% compared to traditional chambers. For example, a 2000 mm diameter crusher with an optimized chamber and PMSM motor consumes 0.8 kWh/t for granite crushing, down from 1.0 kWh/t with older designs. These optimizations not only meet green standards but also reduce operating costs: a crusher processing 500 t/h saves $10,000-$15,000 per year in energy costs. For industries like cement manufacturing, which face strict green regulations, these energy-saving paths are critical for compliance and competitiveness. Learn more about green crushing solutions at /crushing-solutions/cement-manufacturing.

Industry Standard Development Progress & Compliance Risk Assessment

Industry standards for gyratory crushers are evolving to address safety, environmental impact, and performance, and staying compliant is essential for operators to avoid legal penalties and reputational damage. Key standards include noise emissions (limited to 85 decibels, dB, at the operator’s station), dust emissions (limited to 10 mg/m³ in work areas), and safety features (e.g., emergency stop buttons, overload protection). Regulatory bodies in major markets are updating these standards to be more stringent: for example, some regions now require dust emissions of 5 mg/m³ or less, pushing manufacturers to develop better dust collection systems.

Compliance risk assessment helps operators identify gaps in their current systems and take corrective action. For example, an assessment might reveal that a crusher’s noise level is 88 dB (exceeding the 85 dB standard), requiring the installation of soundproofing or a quieter motor. Another assessment might find that the crusher’s dust collector is only 90% effective, needing an upgrade to a high-efficiency cyclone collector (95% effective) to meet the 5 mg/m³ standard. Non-compliance can result in fines of $10,000-$50,000 per violation, plus downtime while the crusher is modified. Staying informed about standard development is also key: if a new safety standard requiring advanced overload protection is set to take effect in 2 years, operators can plan to upgrade their crushers gradually, avoiding last-minute costs. By proactively assessing compliance risks and adapting to new standards, operators can ensure their crushers remain legal, safe, and environmentally responsible.