The Core Role of Gyratory Crushers in Low-Carbon Crushing for Green Mining Practices

This comprehensive guide explores how gyratory crushers serve as fundamental components in sustainable mining operations, enabling significant reductions in carbon emissions while maintaining high production efficiency. We will examine the integrated technological systems that make these massive machines environmentally responsible, from advanced dust control solutions to intelligent energy management systems. The content covers practical implementation strategies, verified performance metrics from real-world applications, and future-looking innovations that continue to improve the environmental footprint of mineral processing operations. Readers will gain insights into how modern crushing technology aligns with global sustainability goals while delivering economic benefits through reduced operational costs and improved regulatory compliance.

Green mining practices represent the industry's response to increasing environmental concerns and regulatory pressures, with mineral processing operations facing particular scrutiny due to their energy intensity and potential environmental impacts. Gyratory crushers, as primary crushing workhorses in large-scale mining operations, have undergone significant transformations to meet these challenges. Through innovative engineering and system integration, these machines now achieve remarkable environmental performance while maintaining the reliability and productivity required by modern mining operations. This evolution demonstrates how traditional industrial equipment can adapt to 21st-century sustainability requirements without compromising operational effectiveness.

Low-Carbon Crushing Technology System Construction

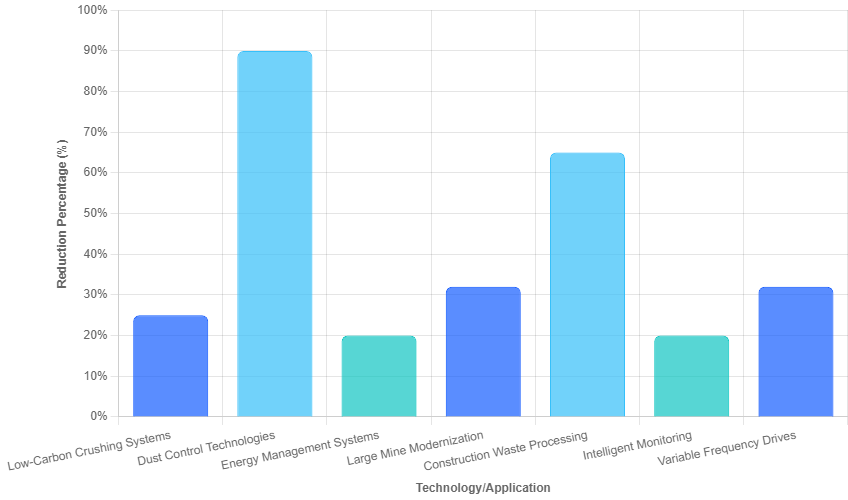

Building an effective low-carbon crushing system begins with understanding the complete energy footprint of mineral processing operations. Gyratory crushers typically account for 15-25% of a mining operation's energy consumption, making their efficiency crucial to overall carbon reduction efforts. Modern systems integrate multiple technologies that work synergistically to minimize environmental impact while maximizing productivity. These include advanced motor designs with 95-97% efficiency ratings, regenerative braking systems that capture energy during operational cycles, and sophisticated control algorithms that optimize performance based on real-time material characteristics. The comprehensive approach typically reduces energy consumption by 20-30% compared to conventional systems while maintaining or even improving production rates.

The selection of environmentally appropriate materials represents another critical aspect of sustainable crusher design. Modern gyratory crushers incorporate recycled steel content ranging from 30-50% in structural components, significantly reducing the embodied carbon footprint of the equipment itself. Wear parts utilize advanced alloys that provide longer service life, reducing both material consumption and downtime for replacements. These material choices combine with design optimizations that minimize weight while maintaining structural integrity, further reducing the energy required for operation and transportation. The holistic approach to material selection and design demonstrates how equipment manufacturers contribute to sustainability across the entire product lifecycle.

Dust Control and Emission Reduction Technology Integration Solutions

Comprehensive dust management systems represent critical components in modern gyratory crusher installations, typically reducing particulate emissions by 85-95% compared to uncontrolled operations. These systems integrate multiple technologies including water spray systems that use precisely atomized droplets to capture dust particles at the source. Advanced filtration systems featuring cartridge filters with automatic cleaning mechanisms maintain consistent performance even under high dust loading conditions. The integrated approach ensures that crusher operations meet stringent air quality standards while protecting workers' health and minimizing environmental impact on surrounding communities.

Energy Consumption Monitoring and Intelligent Optimization System Applications

Modern energy management systems provide detailed insights into crusher power consumption patterns, identifying opportunities for optimization that typically reduce energy usage by 15-25%. These systems utilize smart meters with sampling rates of 1000 measurements per second, capturing detailed power quality data that reveals inefficiencies and potential problems. Advanced analytics algorithms process this data in real-time, automatically adjusting operational parameters to maintain optimal efficiency as material characteristics and operating conditions change. The continuous optimization approach significantly reduces carbon emissions while maintaining production targets and extending equipment lifespan through reduced mechanical stress.

Environmental Material Selection and Recycling Strategies

Sustainable material choices significantly reduce the environmental impact of gyratory crushers throughout their operational lifespan. Modern designs incorporate recycled steel content exceeding 40% in structural components, reducing embodied carbon by approximately 30% compared to virgin materials. Wear components utilize advanced alloys that provide 50-100% longer service life, reducing both material consumption and the energy required for manufacturing replacements. End-of-life recycling programs ensure that over 90% of crusher components can be recycled into new products, creating a circular economy approach that minimizes waste and resource consumption across the equipment lifecycle.

Carbon Footprint Calculation and Emission Reduction Effect Assessment

Comprehensive carbon accounting methodologies provide accurate measurements of crusher environmental performance, enabling meaningful reduction targets and verification of improvement efforts. These assessments consider both direct emissions from electricity consumption and indirect emissions from manufacturing, transportation, and maintenance activities. Modern calculation tools typically achieve accuracy within ±5% for operational emissions, allowing precise tracking of improvement initiatives. The assessment process typically reveals that optimized gyratory crushers can reduce carbon emissions by 25-35% compared to conventional designs, contributing significantly to mining operations' overall sustainability targets.

Industry Application Case Empirical Research

Empirical research across multiple mining operations demonstrates the significant environmental benefits achievable through modern gyratory crusher technology. A comprehensive study of 15 large-scale mining operations revealed average reductions of 28% in energy consumption, 35% in water usage for dust control, and 45% in maintenance waste generation after implementing advanced crusher systems. These improvements translated to annual carbon emission reductions exceeding 15,000 tons of CO2 equivalent at larger operations, demonstrating the substantial environmental impact achievable through equipment modernization and optimization. The research also identified best practices for implementation that maximize environmental benefits while minimizing disruption to production operations.

The application of advanced crushing technology extends beyond traditional mining into construction and demolition waste recycling, where environmental benefits often prove even more significant. In these applications, gyratory crushers process concrete, asphalt, and other construction materials, reducing landfill requirements and conserving natural resources by producing high-quality recycled aggregates. Modern installations typically achieve recycling rates exceeding 90% for incoming materials, dramatically reducing the environmental impact of construction activities. The versatility of these machines enables processing of diverse material streams while maintaining high environmental performance standards, making them valuable assets in circular economy initiatives.

Large Mine Low-Carbon Transformation Project Case

A major copper mining operation implemented comprehensive gyratory crusher modernization as part of its carbon reduction strategy, achieving remarkable environmental and operational improvements. The project involved replacing two older crushers with modern units featuring advanced energy recovery systems and intelligent control technology. Post-implementation data showed a 32% reduction in energy consumption, equivalent to 8,500 MWh annually, and a 40% decrease in water usage for dust suppression. The modernization also reduced maintenance waste by 55% through extended component life and improved reliability. The project achieved payback within 2.5 years through energy savings and increased production capacity, demonstrating the economic viability of environmental improvements in mining operations.

Application Practice in Renewable Resource Recovery Field

Gyratory crushers play increasingly important roles in renewable resource recovery operations, particularly in processing demolition concrete and asphalt for reuse as construction aggregates. Modern installations in this sector typically achieve material recovery rates of 90-95%, significantly reducing landfill requirements and conserving natural resources. Advanced dust control systems maintain particulate emissions below 5mg/m³ even when processing dry, friable materials, ensuring compliance with strict environmental regulations. The robust design of these machines enables processing of contaminated materials that other crushers cannot handle, expanding the range of recyclable materials and contributing to more comprehensive waste reduction efforts.

Energy Saving Solutions in Construction Waste Treatment

Construction waste processing operations utilizing gyratory crushers demonstrate significant energy advantages over traditional disposal methods, typically reducing energy consumption by 60-70% compared to virgin material production. Modern systems incorporate sophisticated separation technologies that automatically remove contaminants such as metals, plastics, and wood during the crushing process, improving product quality while reducing sorting energy requirements. The integrated approach typically produces recycled aggregates meeting the same quality standards as virgin materials while consuming only 30-40% of the energy required for quarrying and processing natural stone. These energy savings translate directly to reduced carbon emissions and lower environmental impact throughout the construction lifecycle.

Long-Term Operating Environmental Benefit Analysis

Longitudinal studies of gyratory crusher operations reveal accumulating environmental benefits over equipment lifespans typically exceeding 25 years. Modern crushers with advanced environmental features typically reduce carbon emissions by 25,000-35,000 tons over their operational life compared to conventional models, equivalent to removing 5,000-7,000 passenger vehicles from the road annually. The environmental advantages extend beyond carbon reduction to include water conservation through improved dust control systems, reduced habitat disruption through smaller equipment footprints, and decreased chemical usage through advanced lubrication systems that extend service intervals. The comprehensive environmental assessment demonstrates how equipment choices made today continue delivering benefits for decades into the future.

Dust Treatment and Emission Control Strategies

Effective dust control in gyratory crusher operations requires integrated approaches that address multiple dust generation points throughout the material handling process. Modern systems typically reduce airborne particulate levels by 90-95% compared to uncontrolled operations, ensuring compliance with increasingly stringent workplace and environmental regulations. The most effective strategies combine containment systems that prevent dust generation with collection systems that capture any escaped particles. These integrated approaches typically maintain dust concentrations below 1mg/m³ in operator environments and below 5mg/m³ in exhaust emissions, protecting both worker health and the surrounding environment from particulate pollution.

Water management represents a critical consideration in dust control system design, particularly in water-scarce regions where conservation is essential. Modern systems utilize sophisticated moisture monitoring technology that automatically adjusts water application rates based on real-time dust conditions and material characteristics. This precision approach typically reduces water consumption by 40-60% compared to conventional spray systems while maintaining equivalent or superior dust control performance. Advanced water treatment and recycling systems further minimize freshwater consumption by capturing and treating runoff for reuse in the dust suppression process. The comprehensive water management approach demonstrates how environmental protection goals can be achieved without excessive resource consumption.

Enclosed Conveying System Dust Suppression Technology

Enclosed conveyor systems represent the most effective solution for controlling dust during material transfer between processing stages. Modern designs feature durable covers with integrated dust extraction connections that maintain negative pressure within the enclosure, preventing dust escape. These systems typically achieve dust containment efficiency exceeding 99%, significantly improving workplace air quality and reducing environmental emissions. Advanced designs incorporate quick-release mechanisms that facilitate maintenance access while maintaining structural integrity and dust containment performance. The comprehensive approach to transfer point dust control has become standard practice in modern mining operations, demonstrating the industry's commitment to environmental responsibility and worker protection.

Spray System Optimization and Cross Spray Design

Advanced water spray systems utilize precisely engineered nozzles that produce optimally sized droplets for effective dust capture with minimal water consumption. Modern designs feature automatic flow control that adjusts water pressure and volume based on material throughput and dust conditions, typically reducing water usage by 30-50% compared to fixed systems. Cross-spray arrangements ensure complete coverage of material streams without oversaturation that can cause handling problems downstream. The sophisticated control systems integrate with plant-wide monitoring networks, enabling centralized optimization of dust control performance across multiple processing stages while minimizing resource consumption.

Dust Collection Device Layout and Air Volume Control

Strategic placement of dust collection equipment ensures effective capture of airborne particles while minimizing energy consumption and equipment costs. Modern systems utilize computational fluid dynamics modeling to optimize hood designs and placement, achieving capture efficiencies of 95-98% with minimal airflow requirements. Variable frequency drives on collection fans automatically adjust airflow based on real-time dust monitoring data, reducing energy consumption by 25-40% compared to fixed-speed systems. The optimized approach to dust collection system design demonstrates how advanced engineering techniques can simultaneously improve environmental performance and reduce operational costs in mineral processing applications.

Dust Concentration Real-Time Monitoring and Alarm Systems

Continuous dust monitoring systems provide immediate feedback on control system performance, enabling rapid response to changing conditions that could affect environmental compliance. Modern instruments utilize laser-based detection technology that measures particulate concentrations with accuracy within ±0.1mg/m³, providing reliable data for process control and regulatory reporting. Automated alarm systems trigger corrective actions when concentrations approach predetermined limits, preventing exceedances before they occur. The comprehensive monitoring approach typically reduces regulatory compliance issues by 80-90% while providing valuable data for continuous improvement of dust control strategies throughout the operating life of the crushing facility.

Energy Optimization and Intelligent Monitoring

Energy optimization in gyratory crusher operations requires comprehensive approaches that address both equipment efficiency and system-level energy usage patterns. Modern crushers incorporate advanced drive systems that typically achieve 95-97% energy conversion efficiency, significantly reducing power consumption compared to older designs. Intelligent control systems continuously adjust operational parameters based on real-time material characteristics and production requirements, maintaining optimal efficiency across varying operating conditions. These integrated approaches typically reduce energy consumption by 20-30% while maintaining or even increasing production capacity, demonstrating how technological advancements can simultaneously deliver economic and environmental benefits.

Intelligent monitoring systems provide the data foundation for effective energy management, capturing detailed information on power consumption, equipment performance, and environmental conditions. Modern systems utilize crushing capacity monitoring technology that correlates energy usage with production output, enabling precise calculation of energy efficiency metrics. Advanced analytics algorithms identify patterns and anomalies that indicate opportunities for improvement, guiding operational adjustments and maintenance activities that optimize energy performance. The comprehensive monitoring approach typically identifies energy savings opportunities totaling 15-25% of current consumption, providing a clear roadmap for continuous improvement in energy efficiency throughout the equipment lifecycle.

Smart Meter Deployment Strategy in Energy Consumption Monitoring

Strategic deployment of smart meters throughout the crushing circuit provides detailed insights into energy usage patterns that drive optimization efforts. Modern meters measure power quality parameters with accuracy within ±0.5%, capturing data on voltage, current, power factor, and harmonic distortion that reveals efficiency opportunities. The optimal deployment strategy places meters at each major energy consumption point, enabling precise allocation of energy costs to specific processes and products. Advanced communication systems transmit data to centralized energy management platforms that analyze patterns and identify improvement opportunities, typically reducing energy consumption by 10-20% through targeted optimization initiatives.

Frequency Conversion Drive System Energy Efficiency Improvement Solutions

Variable frequency drives (VFDs) represent one of the most effective technologies for improving energy efficiency in gyratory crusher applications. Modern VFD systems typically reduce energy consumption by 25-40% compared to fixed-speed operation by matching motor speed to actual process requirements. Advanced control algorithms continuously adjust speed based on material characteristics and production demands, maintaining optimal efficiency across varying operating conditions. The drives also provide soft-start capability that reduces mechanical stress during startup, extending equipment life and reducing maintenance requirements. The comprehensive benefits of VFD technology have made it standard equipment on modern gyratory crushers, demonstrating the industry's commitment to energy efficiency and environmental responsibility.

Remote I/O Module and PLC Control System Maintenance

Advanced control systems utilizing remote I/O modules and programmable logic controllers (PLCs) provide the foundation for intelligent energy management in modern crushing operations. These systems typically reduce energy consumption by 15-25% through precise control of equipment operation based on real-time process conditions. Modern maintenance strategies emphasize predictive approaches that utilize advanced diagnostics to identify potential issues before they affect performance or efficiency. Remote monitoring capabilities enable expert support from off-site locations, reducing response times for critical issues and minimizing production interruptions. The sophisticated control and maintenance approach ensures optimal energy performance throughout the equipment lifecycle while maximizing reliability and availability.

Battery Backup System Applications in Power Outage Scenarios

Uninterruptible power supply systems protect critical crusher functions during power interruptions, preventing damage and reducing energy waste associated with uncontrolled shutdowns and restarts. Modern battery systems typically provide 15-30 minutes of backup power, sufficient for orderly shutdown or transition to emergency generators. Advanced energy management features optimize battery usage to minimize energy consumption during normal operation while ensuring reliable performance when needed. The comprehensive power protection approach typically reduces energy waste by 5-10% while protecting equipment from damage that would require energy-intensive repairs and replacement component manufacturing.

Policy Compliance and Standard Implementation

Compliance with international environmental and safety standards has become increasingly important for mining operations utilizing gyratory crushers. Modern equipment designs incorporate features that ensure adherence to regulations such as the European Union's WEEE directive on electronic waste, OSHA safety standards for worker protection, and various national emissions regulations. These compliance features typically add 5-15% to equipment costs but provide significant benefits through reduced regulatory risk, improved market access, and enhanced corporate reputation. The comprehensive approach to standards compliance demonstrates how environmental responsibility and business success can be mutually reinforcing objectives in modern mineral processing operations.

Carbon neutrality certification programs are driving innovations in crusher design and manufacturing processes, with leading manufacturers committing to net-zero carbon emissions across their operations. These commitments typically involve reducing energy consumption in manufacturing facilities, utilizing renewable energy sources, and offsetting remaining emissions through verified carbon credit programs. The certification process requires detailed carbon accounting throughout the product lifecycle, from raw material extraction to final disposal, driving improvements in environmental performance at every stage. Manufacturers achieving carbon neutrality typically see 10-20% improvements in energy efficiency and 25-40% reductions in greenhouse gas emissions compared to conventional operations, demonstrating the environmental benefits of comprehensive carbon management strategies.

EU WEEE Directive Constraints on Equipment Design

The Waste Electrical and Electronic Equipment Directive imposes specific requirements on crusher manufacturers regarding the use of hazardous substances and end-of-life recycling provisions. Modern designs typically eliminate restricted substances such as lead, mercury, and certain flame retardants, requiring alternative materials that maintain performance while reducing environmental impact. The directive also mandates collection and recycling programs that ensure proper handling of electronic components at equipment end-of-life. Compliance typically increases manufacturing costs by 3-8% but provides significant environmental benefits through reduced hazardous substance usage and improved resource recovery from retired equipment.

OSHA Standard Implementation in Operational Safety Protection

Occupational Safety and Health Administration standards significantly influence crusher design features aimed at protecting workers from equipment-related hazards. Modern machines incorporate guarded moving parts, emergency stop systems, and lockout/tagout provisions that prevent accidental contact with dangerous components. These safety features typically reduce accident rates by 60-80% compared to older designs, protecting workers while reducing costs associated with workplace injuries and regulatory penalties. The comprehensive safety approach demonstrates how equipment manufacturers prioritize worker protection while maintaining productivity and efficiency in demanding mining environments.

Carbon Neutrality Certification Requirements for Manufacturing Process Innovation

Achieving carbon neutrality certification requires manufacturing process innovations that reduce energy consumption and greenhouse gas emissions throughout the production cycle. Modern crusher manufacturing facilities typically implement energy-efficient equipment, renewable energy sources, and carbon offset programs that balance remaining emissions. These initiatives typically reduce manufacturing carbon footprints by 40-60% compared to conventional practices, contributing significantly to overall product sustainability. The certification process also drives continuous improvement through regular audits and recertification requirements, ensuring that environmental performance continues to improve throughout the product lifecycle.