Dust Control Strategies for Gyratory Crushers in the Era of Environmental Protection Crushing Trends

In the modern industrial landscape, the demand for environmental protection in material crushing processes—such as handling natural rocks (like granite and basalt), metal ores (including iron ore and copper ore), and recycled aggregates (such as construction waste and concrete debris)—has become increasingly stringent. Gyratory crushers, as core equipment in mining and quarrying operations, aggregate processing, and waste recycling, are prone to generating significant dust during operation. This dust not only harms air quality but also poses risks to worker health and equipment lifespan. This page comprehensively explores dust control for gyratory crushers, covering key aspects including the mechanisms of dust generation and inhibition technologies, equipment design and maintenance optimization, eco-friendly material selection and recycling, real-world industry application cases, policy standards and compliance requirements, as well as future development trends and cutting-edge technologies. By integrating practical data and actionable strategies, it aims to provide readers with a holistic understanding of how to achieve efficient dust control while ensuring the crushing process’s productivity and sustainability.

Dust Generation Mechanisms and Inhibition Technologies

Dust formation in gyratory crushers primarily stems from three key processes: the collision and friction between materials during crushing, the free fall of crushed particles from height differences, and the leakage of fine particles from gaps in equipment or conveying systems. Studies show that for every 100 tons of material processed by a gyratory crusher, up to 2-3 tons of dust can be generated, with particles smaller than 10 micrometers accounting for over 40%—these fine particles are particularly difficult to control and pose greater health risks. To address this, a combination of targeted inhibition technologies is essential, focusing on blocking dust generation at the source, capturing airborne dust, and monitoring dust levels in real time. Understanding these mechanisms is the first step toward designing effective control strategies, as it allows for targeted interventions that address the root causes of dust rather than just its symptoms.

Enclosed Conveying and Lightweight Color Steel Enclosure Application

Enclosed conveying systems and lightweight color steel enclosures are fundamental to source dust control, as they prevent fine particles from escaping into the air during material transport and crushing. Traditional open conveying systems can result in 60-70% of dust emissions from gyratory crusher operations, while enclosed conveying—such as using sealed belt conveyors with rubber skirts—reduces these emissions by over 80%. Lightweight color steel enclosures, which wrap around the crusher’s feed port, discharge port, and conveying sections, further enhance this effect: the enclosures are designed with tight-fitting joints and corrosion-resistant materials, ensuring they can withstand the vibration of the crusher while maintaining a sealed environment. Additionally, the lightweight nature of the color steel (typically 2-5 mm thick) makes installation and maintenance easier, without adding excessive load to the crusher’s structure, which is crucial for preserving the integrity of gyratory crusher components over time.

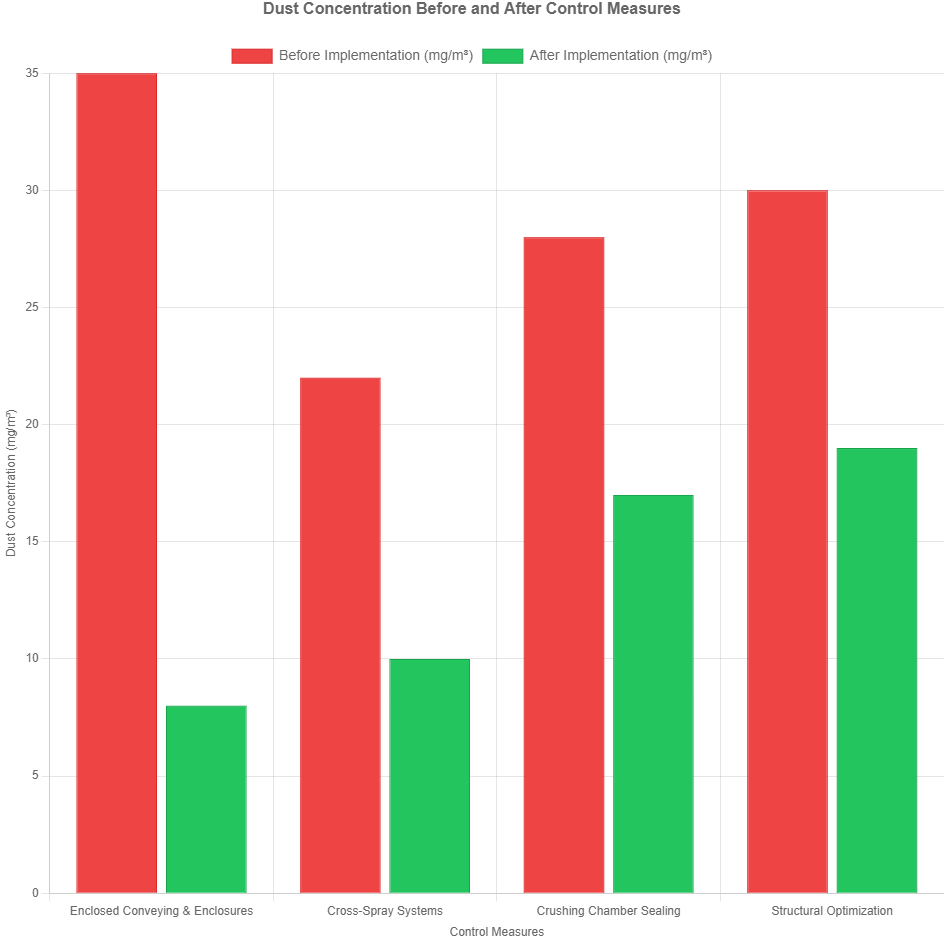

In practical applications, the combination of enclosed conveying and color steel enclosures has proven highly effective. For example, in an aggregate processing plant using a gyratory crusher, after installing enclosed conveyors and a color steel enclosure around the crusher’s discharge area, the ambient dust concentration dropped from 35 mg/m³ to 8 mg/m³—well below the recommended industrial limits. This technology also reduces the need for frequent cleaning of surrounding areas, lowering overall operational costs. When paired with other dust control measures (such as spray systems), the enclosure acts as a barrier that keeps water mist and dust within a confined space, maximizing dust suppression efficiency. Moreover, these enclosures can be customized to fit different sizes of gyratory crushers, making them a versatile solution for both new installations and retrofits of existing equipment.

Spray System Optimization and Cross-Spray Design

Optimized spray systems are critical for capturing airborne dust and wetting materials to prevent dust from becoming airborne in the first place. Traditional single-nozzle spray systems often suffer from uneven water distribution, with some areas receiving too much water (leading to material clumping and reduced crushing efficiency) and others receiving too little (failing to suppress dust). Modern optimized systems address this by adjusting nozzle type, water pressure, and spray angle: using hollow-cone nozzles that produce fine, uniform droplets (with a droplet size of 50-100 micrometers) and operating at a water pressure of 0.3-0.5 MPa, which ensures the droplets can effectively collide with dust particles without disrupting material flow. This precision is especially important for maintaining consistent discharge size of the crushed material, as excess moisture can alter particle properties and affect downstream processes like screening.

Cross-spray design takes this optimization further by arranging nozzles in a crisscross pattern at the crusher’s feed port, crushing chamber, and discharge port. This design creates a “water mist curtain” that covers the entire path of material movement, increasing the contact area between water and dust by 30-40% compared to linear spray systems. Data from a mining operation showed that after upgrading to a cross-spray system, the dust concentration in the crusher’s vicinity decreased by 55%, and the moisture content of the crushed material remained within the ideal range (1-2%)—avoiding issues like clogging in downstream screening equipment. Additionally, the system can be equipped with a flow control valve that adjusts water output based on the feed size and rate of the crusher (monitored via sensors), ensuring optimal dust suppression even as material throughput changes. This adaptability makes cross-spray systems suitable for handling variable material types, from hard rocks like granite to softer recycled aggregates.

Dust Suction Device Layout and Air Volume Control

Dust suction devices complement spray systems by removing residual airborne dust that evades wet suppression, particularly in areas where sealing is difficult (such as the crusher’s inspection hatches or the junction of conveyors). The key to effective suction lies in strategic layout: suction hoods should be placed at “dust hotspots” — including the top of the crusher’s feed hopper, the discharge point of the crushing chamber, and the transfer points between conveyors. Each hood is connected to a central duct system, which funnels dust to a dust collector (such as a baghouse or cyclone separator). Studies indicate that placing suction hoods within 0.5-1 meter of dust sources increases dust capture efficiency by over 75%, a critical factor for meeting strict environmental standards.

Air volume control is equally important, as insufficient air volume will fail to capture dust, while excessive air volume wastes energy and may disrupt material flow. Modern suction systems use variable frequency drives (VFDs) that adjust fan speed based on real-time dust concentration data (from sensors). For example, when the dust concentration exceeds 10 mg/m³, the VFD increases the fan speed to boost air volume (up to 20,000 m³/h for large gyratory crushers), and when concentrations drop below 5 mg/m³, it reduces speed to save energy. In a C&D waste recycling plant, this dynamic air volume control reduced energy consumption of the dust suction system by 25% while maintaining a dust capture rate of 90%. Proper duct design—such as minimizing bends and ensuring uniform airflow—also plays a role: smooth ducts reduce pressure loss by 15-20%, ensuring consistent suction power across all hoods and preventing dust from accumulating in dead zones of the system.

Structural Optimization to Reduce Material Height Differences

Material height differences—such as the drop from the feed hopper to the crushing chamber or from the discharge port to the conveyor—are a major source of dust, as free-falling particles collide with air and each other, releasing fine dust. Structural optimization focuses on minimizing these drops to reduce dust generation at the source. For example, repositioning the feed hopper to be closer to the crushing chamber’s inlet can reduce the drop height from 3-4 meters to 1-1.5 meters; this simple adjustment can decrease dust emissions from material fall by 40-50%, according to data from crusher manufacturers. This optimization not only cuts down on dust but also reduces wear on the crusher’s internal components, as lower drop heights mean less impact force on parts like the movable cone and concave.

Another optimization is the installation of buffer plates or chutes at drop points. Buffer plates—made of wear-resistant materials like manganese steel—absorb the impact of falling material, slowing its descent and reducing particle collision. Chutes, meanwhile, guide material along a gradual slope (with an angle of 30-45 degrees) instead of letting it fall freely. In a metal ore processing plant, adding a curved chute at the gyratory crusher’s discharge port reduced the material drop height by 60% and lowered ambient dust concentration by 35%. Additionally, some modern gyratory crushers integrate a pre-screening module directly below the feed hopper, which separates fine particles (that are more prone to dust) before they enter the crushing chamber; this not only reduces dust from crushing but also minimizes the height difference for fine material transport, as the pre-screened fines can be conveyed directly to downstream equipment via a shorter path. This integration also improves overall crushing capacity by reducing the load on the main crushing chamber.

Real-Time Dust Concentration Monitoring and Alarm System

Real-time monitoring and alarm systems are the “eyes” of dust control, providing continuous data on dust levels to ensure timely adjustments of control measures. These systems consist of dust sensors (installed at key locations like the crusher’s vicinity, worker operation areas, and exhaust outlets), a data processing unit, and an alarm module. The sensors use laser scattering technology to measure dust concentration with high accuracy (±5% of the measured value) and can detect particles as small as 0.3 micrometers. Data is transmitted to a central control panel every 1-2 seconds, allowing operators to track dust levels in real time and identify trends—such as increased dust during peak crushing capacity periods—that may require adjustments to spray or suction systems.

The alarm system is set to trigger at two thresholds: a “warning” threshold (typically 10 mg/m³) that alerts operators to potential dust increases, and an “action” threshold (typically 20 mg/m³) that automatically activates backup control measures, such as increasing spray water flow or boosting suction fan speed. In one mining site, this dual-threshold system prevented 12 potential dust exceedances in a single month by enabling proactive interventions. Additionally, the data collected by the monitoring system can be used for long-term analysis, such as identifying which operating conditions (e.g., specific feed size or material type) lead to higher dust emissions. This insight allows for ongoing optimization of dust control strategies, such as adjusting spray nozzle positions or modifying conveyor speeds to minimize dust generation during high-risk operations. The integration of these systems with overall plant control platforms also ensures that dust control is aligned with other operational goals, like maintaining product quality and maximizing equipment uptime.

Equipment Design and Maintenance Optimization

Effective dust control for gyratory crushers is not only dependent on external inhibition technologies but also on the inherent design of the equipment and consistent maintenance practices. A well-designed gyratory crusher minimizes dust generation by reducing material leakage and optimizing internal airflow, while regular maintenance ensures that dust control components—such as seals and filters—remain functional over time. Studies show that crushers with optimized dust-resistant designs can reduce dust emissions by 30-40% compared to standard models, even without additional external control systems. Maintenance, meanwhile, plays a critical role in sustaining these gains: neglected equipment, such as worn seals or clogged filters, can lead to a 50% increase in dust emissions within just a few months of operation. This section explores key design improvements and maintenance strategies that enhance dust control, from sealing structures in the crushing chamber to the use of smart diagnostic tools for proactive upkeep.

Crushing Chamber Dust-Proof Sealing Structure Improvement

The crushing chamber is the primary site of dust generation in a gyratory crusher, as it is where materials are compressed, fractured, and ground into smaller particles. Traditional crushing chambers often suffer from dust leakage through gaps between moving parts—such as the interface between the movable cone and the adjusting ring—due to wear or poor sealing design. Modern improvements to dust-proof sealing structures address this issue by using multi-layer sealing systems, such as combining rubber lip seals with labyrinth seals. The rubber lip seal creates a tight physical barrier against dust, while the labyrinth seal uses a series of interlocking grooves to trap any remaining particles, preventing them from escaping into the surrounding environment. Tests conducted by crusher manufacturers show that this multi-layer sealing system reduces dust leakage from the crushing chamber by 65-75% compared to single-layer seals.

Another key improvement is the integration of dust scrapers within the sealing structure. These scrapers—mounted on the adjusting ring—continuously remove dust and debris that accumulate on the surface of the movable cone, preventing the buildup from damaging the seals or creating gaps. For example, in a limestone processing plant, retrofitting a gyratory crusher’s crushing chamber with multi-layer seals and dust scrapers reduced ambient dust concentration around the equipment by 40%, from 28 mg/m³ to 17 mg/m³. Additionally, the use of wear-resistant materials for the seals, such as nitrile rubber reinforced with carbon fiber, extends their lifespan by 2-3 times compared to standard rubber seals. This not only reduces maintenance frequency but also ensures consistent sealing performance over the crusher’s operational cycle. The design of the crushing chamber’s feed and discharge ports is also optimized, with tapered edges that guide material into the chamber without creating dead zones where dust can accumulate and leak out.

Wear-Resistant Material Anti-Adhesion Feature improvement

Wear-resistant materials used in gyratory crusher components—such as the concave (fixed liner) and movable cone liner—play a dual role: they protect the crusher’s main structure from abrasion and can also reduce dust generation by minimizing material adhesion. When materials adhere to the inner surfaces of the crushing chamber, they can form hard crusts that break off into fine dust during subsequent crushing cycles. Additionally, adhered material can create uneven crushing conditions, leading to more particle fragmentation and increased dust. Modern wear-resistant materials are engineered with anti-adhesion properties, typically by adding additives like molybdenum disulfide or polytetrafluoroethylene (PTFE) to the base material (such as high-chromium cast iron). These additives create a smooth, low-friction surface that prevents material from sticking, even when processing moist or sticky materials like clay-rich ores.

Testing of these anti-adhesion wear-resistant materials in a copper ore processing plant showed significant benefits: material adhesion on the concave liner was reduced by 50%, and the frequency of dust-generating crust breakage decreased by 45%. This not only lowered dust emissions but also improved crushing efficiency, as the smooth liner surfaces allowed for more uniform material flow and reduced energy consumption by 8-10%. The lifespan of the liners also increased by 30%, as adhesion-related wear—such as uneven abrasion from crust buildup—was minimized. Another innovation is the use of textured surfaces on some liners, which feature small, evenly spaced grooves that break up potential adhesion points while still maintaining the material’s wear resistance. These textured liners are particularly effective for processing materials with high clay content, such as some types of iron ore, and have been shown to reduce dust generation by an additional 15-20% compared to smooth anti-adhesion liners.

Regular Cleaning and Filter Replacement Cycle Management

Even with advanced dust control technologies, dust will inevitably accumulate on equipment surfaces, in ducts, and in dust collection systems over time. Regular cleaning is essential to prevent this buildup from reducing the effectiveness of dust control measures or causing equipment damage. For example, dust that accumulates on the surface of spray nozzles can clog the orifices, leading to uneven water distribution and reduced dust suppression. Similarly, dust buildup in suction ducts can restrict airflow, lowering the efficiency of dust capture. A structured cleaning schedule—tailored to the operating environment and material type—ensures that these components remain clean and functional. In aggregate processing plants, where dust generation is moderate, weekly cleaning of spray nozzles and monthly cleaning of suction ducts is typically sufficient, while in mining operations processing dry, fine ores, bi-weekly duct cleaning and daily nozzle checks may be necessary.

Filter replacement is another critical aspect of maintenance, as dust collection systems (such as baghouses) rely on filters to trap and contain dust. Over time, filters become clogged with dust, reducing their airflow capacity and dust capture efficiency. The key to effective filter management is establishing a replacement cycle based on filter type, dust load, and operating conditions. For example, polyester felt filters used in baghouses for gyratory crushers typically have a replacement cycle of 6-12 months in aggregate plants, but this can be shortened to 3-6 months in mining operations with high dust loads. To optimize this cycle, many plants use differential pressure sensors that measure the pressure drop across the filters: when the pressure drop exceeds a set threshold (usually 1.5-2 kPa), it indicates that the filters are clogged and need replacement. This data-driven approach prevents premature replacement (reducing costs) and avoids overdue replacement (which would lead to increased dust emissions). A case study in a granite crushing plant showed that using differential pressure sensors to manage filter replacement cycles reduced filter costs by 20% while maintaining a dust capture rate of over 99%.

Intelligent Diagnostic System in Dust Control Application

Intelligent diagnostic systems leverage sensors, data analytics, and machine learning to monitor the performance of dust control components and identify potential issues before they lead to increased dust emissions or equipment failure. These systems collect real-time data from various parts of the crusher and its dust control systems, such as the pressure of the spray system, the airflow of the suction device, the condition of sealing structures, and the status of filters. By analyzing this data, the system can detect anomalies that indicate problems—for example, a sudden drop in spray pressure may signal a clogged nozzle.