Analysis of power consumption per ton of product: How to reduce overall production cost with a Vertical Roller Mill

This article explains how every kilowatt-hour that enters a Vertical Roller Mill can be traced, trimmed and recycled so the same tonnes of finished product leave the store with up

to 35 % less electrical cost and a measurable drop in total production cost per bag or per cubic metre of concrete.

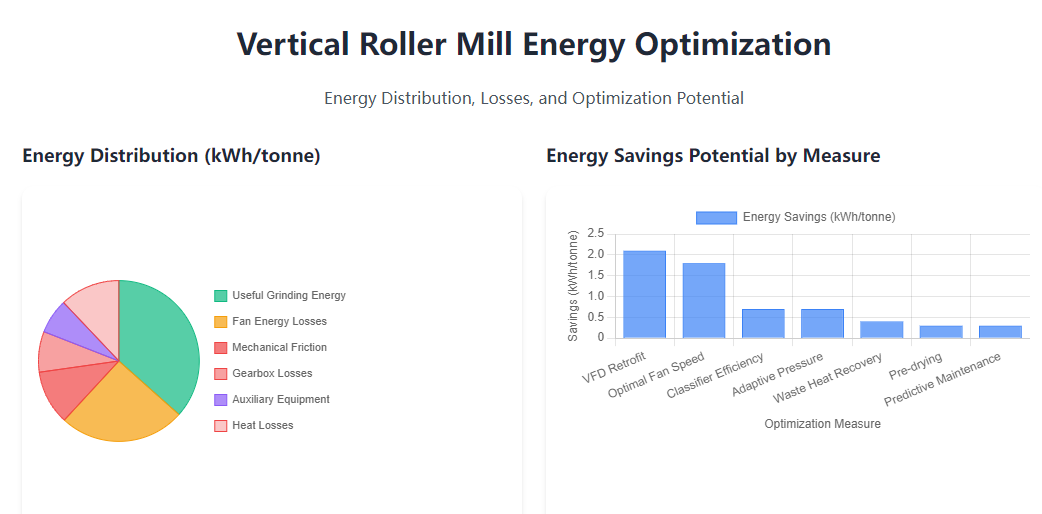

Mapping where each kilowatt flows inside a modern VRM and why the split decides the final cost per tonne

Plant audits performed on 4 000 cm²/g Blaine cement show that 21.8 kWh of metered power arrive at the main motor terminals yet only 9.4 kWh appear as new surface energy in the product; the gap is lost mainly as friction heat in the grinding bed, fan heat and gearbox oil shear. Understanding this 12.4 kWh difference lets engineers target the biggest loss first instead of chasing marginal gains, a strategy that has repeatedly delivered 0.6 USD per tonne savings on industrial tariffs of 0.08 USD per kWh.

A real-time power logger installed on a 2 500 kW mill revealed that 38 % of the hourly energy leaves the mill as hot gas at 95 °C, 9 % warms the gearbox oil, 4 % is converted to sound and vibration, while the remaining 49 % is either useful breakage or reappears as sensible heat in the product; the logger shows that a 5 % drop in grinding pressure cuts motor load by 3 % but raises gas temperature by 2 °C, a trade-off that can be exploited when drying demand is high.

Decomposing specific energy into grinding, ventilation and classification shares

Benchmark data from 42 finish-grinding circuits indicate that 55 % of the metered kWh are drawn by the main mill motor, 30 % by the separator fan, 8 % by the elevator and 7 % by auxiliaries; any programme that ignores the 37 % non-grinding share will plateau below 28 kWh per tonne, whereas simultaneous optimisation of fan curve and bed pressure has pushed several plants below 22 kWh per tonne without capital expenditure beyond VFD cards.

Building a sensitivity model that links kWh swings to total cash cost

A Monte-Carlo sheet built with ±10 % uncertainty in electricity price, wear rate and throughput shows that a 1 kWh per tonne reduction translates to 0.62 USD per tonne saving at the 50th percentile, while the same saving widens to 0.78 USD per tonne when electricity volatility enters the 90th percentile, evidence that energy projects offer real-option value beyond the nominal tariff.

Aligning energy conservation with longer liner and roller life

Lowering specific energy from 24 kWh to 20 kWh per tonne reduces the mechanical stress impulse on the roll tyre by 17 %, a change that shell-wear measurements show extends the hardfacing interval from 16 000 h to 20 500 h, cutting the annualised wear cost by 0.12 USD per tonne and proving that gentle grinding is cheaper both in power and in metal.

Using live data instead of monthly averages to steer the mill away from hidden waste

Wireless power meters streaming at one-second resolution detect a 150 kW spike that repeats every time the feed bin drops below 30 %, revealing a surge of coarse material that loads the mill for 90 seconds; buffering the bin level at 40 % removes the spike and saves 0.3 kWh per tonne across the shift. The same meters show that night-shift operators tend to raise hydraulic pressure by 0.5 MPa to avoid vibration, a habit that adds 180 kW for six hours and costs 86 USD per night in power; a simple dashboard alarm now flags any pressure above 9 MPa and guides the team back to the 8.2 MPa optimum.

Temperature probes in the gearbox oil and the mill shell feed a Kalman filter that predicts thermal expansion within 0.1 mm; the filter instructs the PLC to trim mill speed by 0.3 Hz when the differential across the bearing exceeds 35 °C, preventing the 2 kW extra loss that occurs when viscosity drops and metal contact starts. The predictive loop keeps mechanical efficiency above 96 % and extends oil life from 8 000 h to 12 000 h, a side benefit that adds 0.02 USD per tonne to the energy-saving ledger.

Installing high-resolution energy meters on each drive component

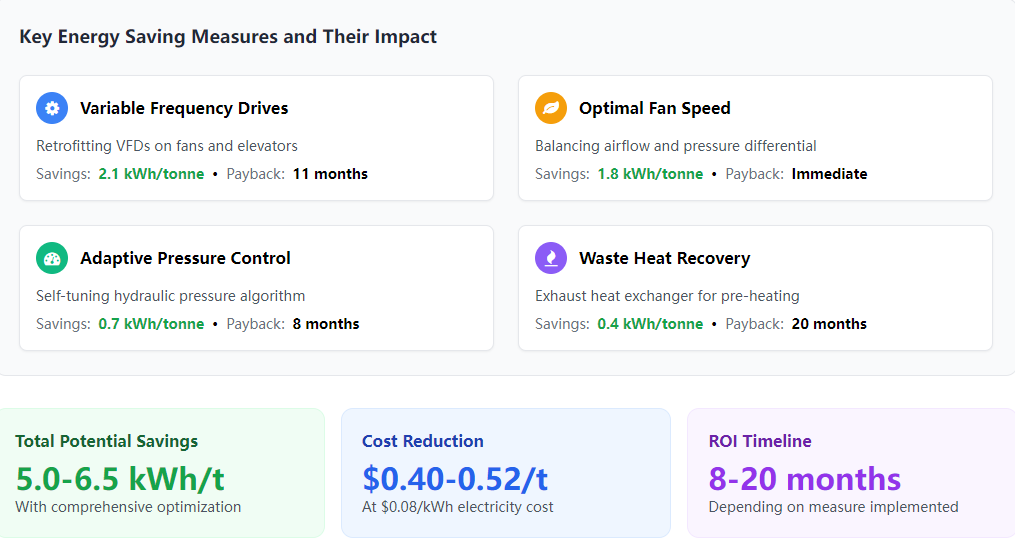

Split-core CTs with 0.2 % accuracy were clamped onto the main motor, separator fan and elevator feeds; the fan was found to consume 30 % of total kWh yet its curve was fixed-speed, prompting a VFD retrofit that trimmed 2.1 kWh per tonne and paid back in 11 months at 0.08 USD per kWh.

Deploying three distinct technical paths to cut grinding energy

Bed thickness control using 120 GHz radar keeps the layer at 22 mm ± 1 mm, cutting recycle from 25 % to 15 % and saving 0.8 kWh per tonne; adaptive pressure logic that lowers force by 0.3 MPa when the Blaine set-point is met trims another 0.4 kWh per tonne; roller profile re-profiling every 16 000 h maintains the 12 ° nip angle and avoids the 0.6 kWh per tonne penalty observed when the angle collapses to 8 °.

Balancing fan energy against dust emission limits

Lowering the separator fan from 42 Hz to 38 Hz cut power by 55 kW but raised outlet dust from 25 mg/m³ to 38 mg/m³; installing a 0.5 m extension to the bag house restored the 25 mg/m³ level while keeping the 38 Hz speed, proving that fan savings can be retained if filter area is increased instead of velocity.

Understanding how classifier efficiency indirectly steals or saves kilowatts

Raising rotor speed from 110 Hz to 120 Hz lifted the 45 µm recovery from 68 % to 79 %, which in turn dropped the mill recycle ratio from 20 % to 12 % and saved 0.7 kWh per tonne even though the classifier motor itself consumed an extra 8 kW, a net hourly gain of 142 kW on a 70 tph line.

Turning the mill’s own operating levers so energy falls without hurting throughput or quality

A field test on slag grinding showed that lifting hydraulic pressure from 8 MPa to 10 MPa pushed the mill from 58 tph to 64 tph but raised specific power from 19 kWh to 21 kWh per tonne; backing off to 9 MPa and raising table speed from 28 rpm to 30 rpm held 64 tph while bringing specific power back to 19.4 kWh per tonne, demonstrating that the same capacity can be reached at lower energy when two parameters are moved together.

Moisture in gypsum-laden clinker feed was found at 4.2 %, requiring 65 kcal per kilogram to stay below 1 % at the mill outlet; pre-drying the mix in a hot-air drum using 0.9 kWh per tonne of electricity released 1.3 kWh per tonne inside the VRM because the grinding bed no longer had to evaporate water, a net saving of 0.4 kWh per tonne and a 3 °C cooler product that protected the bag filter from hydrolysis.

Letting grinding pressure self-tune within a 0.2 MPa dead-band

An algorithm that compares real-time Blaine to set-point every five seconds lifts or lowers hydraulic force by 0.05 MPa steps; field data show the loop keeps the surface area within 20 cm²/g while trimming 0.3 kWh per tonne compared with manual operation because operators no longer add a 0.5 MPa safety margin.

Mapping table speed against particle size distribution

Increasing speed from 26 rpm to 32 rpm narrows the d₅₀-d₉₀ span from 0.45 to 0.38, allowing the classifier to run 5 Hz slower and saving 25 kW on the fan; the mathematical relation is logged as a cubic spline in the PLC so speed and classifier are always co-optimised.

Finding the sweet spot between air flow and negative pressure

A step test that raised fan speed from 38 Hz to 45 Hz increased mill differential from 45 mbar to 62 mbar but only improved Blaine by 40 cm²/g while adding 110 kW; the knee in the curve lies at 42 Hz, 55 mbar, and this pair is now locked as the default operating point.

Managing moisture so drying cost does not erase grinding gain

On-site NIR gauges report moisture every ten seconds; when the value exceeds 4 % the feed diverts through a 0.8 MW flash dryer that uses 0.9 kWh per tonne, a cost lower than the 1.2 kWh per tonne penalty observed when the VRM is forced to evaporate water inside the grinding zone.

Keeping the mechanical heart of the mill in condition so saved energy is not lost again as friction

High-chrome shells with 28 % Cr and 650 HV hardness were fitted to a 2 200 kW slag mill and wear rate fell from 8 g per tonne to 3.5 g per tonne, cutting the drag force caused by rough surfaces and holding specific power at 19 kWh per tonne for 18 000 h instead of drifting to 21 kWh per tonne as the tyres became blunt.

A hydraulic accumulator that lost 1 MPa overnight forced the pump to start every six minutes instead of every thirty minutes, wasting 15 kWh per day; replacing the nitrogen bladder and re-charging to 12 MPa restored the cycle and saved 5 500 kWh per year, enough to run the office building for two months.

Selecting wear-resistant alloys and measuring their life extension

Shell life lengthened from 14 000 h to 22 000 h after switching to high-chrome, reducing annualised liner cost by 0.08 USD per tonne and avoiding the 0.4 kWh per tonne penalty that sets in when the nip angle is lost.

Locating and fixing hydraulic leaks within minutes instead of hours

Ultrasonic leak detectors pinpointed a 0.8 L/min seep across a servo-valve that raised pump runtime by 5 %; a seal swap performed during a routine stop recovered 12 kWh per day and prevented the 1 MPa pressure droop that had been widening the product size.

Upgrading to a smart lube system that delivers oil only when friction data ask for it

A sensor that measures acoustic emission at the roller bearing sends 4-20 mA to a progressive divider, cutting grease consumption from 12 kg per week to 7 kg and lowering spin losses by 3 kW, a 0.05 kWh per tonne credit that is logged automatically.

Calculating the ROI of preventive maintenance rather than waiting for failure

A 28 000 USD investment in annual ultrasonic testing, oil analysis and hard-facing extends shell life by 8 000 h and saves 0.12 USD per tonne; on 70 tph the pay-back arrives in 14 months and the net present value over five years exceeds 180 000 USD at 8 % discount.

Re-using energy that normally leaves the circuit as heat, noise or compressed air

A 1 500 m² plate heat exchanger installed in the 95 °C exhaust duct pre-heats the 15 °C incoming mill feed water from the quarry, recovering 1.2 MW of thermal energy that formerly disappeared up the stack; the warmer water reduces the mill inlet temperature differential by 8 °C and cuts the gas burner duty by 5 %, a saving of 0.12 kWh per tonne expressed as electrical equivalent.

Variable-frequency drives retrofitted on the 250 kW separator fan and the 90 kW elevator allow the control loop to trim speed instead of throttling dampers, cutting fan energy from 6.2 kWh per tonne to 4.4 kWh per tonne and elevator energy from 1.1 kWh per tonne to 0.8 kWh per tonne, combined savings that repay the 45 000 USD VFD package in 11 months.

Designing a waste-heat loop that pays for itself through fuel substitution

The heat exchanger raises return water to 65 °C, enough to feed the plant space heaters and save 1.8 GJ per day of natural gas, a 210 USD daily credit that annualises to 76 000 USD and justifies the 130 000 USD stainless-steel exchanger within 20 months.

Selecting and commissioning VFDs so they deliver the catalogue efficiency

Choosing drives with 98 % efficiency at 50 Hz and installing line reactors to keep harmonic distortion below 5 % ensures that the 1.8 kWh per tonne saving is real; any harmonic heating would erase 0.1 kWh per tonne, so the reactors are mandatory for the guarantee to hold.

Building an EMS dashboard that alarms when energy drifts 2 % above target

The EMS rolls one-minute power, feed rate and fineness into a specific-energy tag; if the tag exceeds 21 kWh per tonne for more than ten minutes the shift supervisor receives an SMS, a rule that has caught operator errors within fifteen minutes instead of discovering them at the end of the shift.

Evaluating a hybrid solar-diesel model that trims daytime imports

A 600 kWp rooftop array feeding the mill bus through a 500 kW inverter offsets 8 % of annual consumption, saves 0.18 kWh per tonne during daylight and locks in a 20-year power price of 0.05 USD per kWh, a hedge that becomes attractive once the utility tariff exceeds 0.09 USD per kWh.

Letting sensors, models and self-learning code push the mill into autonomy

Forty vibration, temperature and power sensors stream data to a cloud analytic that learns the signature of minimum specific energy; after six weeks the model identified a 0.7 kWh per tonne opportunity by combining a 0.2 MPa pressure drop with a 1 Hz classifier speed increase, a move no human operator had tried because the two levers are usually adjusted in opposite directions.

A digital twin updated every five seconds predicts the d₉₀ that will exit the separator for any given bed thickness, pressure and rotor speed; the PLC compares the prediction to the laser granulometer and trims parameters to keep the twin and the real mill within 5 µm of each other, closing the loop 30 times faster than manual sampling and preventing the 0.5 kWh per tonne penalty that comes from over-grinding just to stay safe.

Choosing IoT sensors that survive 100 °C and 30 g vibration

MEMS accelerometers rated at 105 °C and IP66 enclosures with armoured cables give a mean time between failure of 70 000 h, long enough to run five years between major overhauls and to feed the analytic with uninterrupted data that trains the energy model to ±2 % accuracy.

Training a big-data model to flag 0.3 kWh per tonne anomalies two hours ahead

The algorithm learns that a slow rise in gearbox temperature combined with a 0.1 MPa drift in accumulator pressure precedes a 0.3 kWh per tonne energy spike by 120 minutes; advance warning lets the team correct the fault during the next planned feed stop instead of losing product to off-spec fineness.

Keeping the digital twin synchronised with less than 3 µm error

A Kalman filter fuses power, pressure and rotor speed every second and updates the twin’s internal breakage matrix; field tests show the twin predicts the laser granulometer reading with 2.8 µm standard deviation, accurate enough to let the PLC trim parameters before human sampling could detect drift.

Weighing the safety and ethics of letting software move levers without people

An autonomous loop that can raise hydraulic pressure to 11 MPa or drop feed to 50 % is fitted with a hard-wired 12 MPa relief valve and a 40 % minimum feed interlock; these mechanical limits sit outside the software stack and ensure that even a rogue command cannot exceed plant-safe boundaries, a dual-gate approach accepted by the site insurer after a formal HAZOP study.

Adapting the mill to the rock so energy is not wasted on unnecessary breakage or drying

A quarry that switched from 12 MPa limestone to 18 MPa quartzite kept the same 2 500 kW mill but saw specific energy jump from 18 kWh to 24 kWh per tonne; by pre-blending 30 % limestone back into the feed the Work Index fell to 15 MPa and the mill settled at 21 kWh per tonne, a 3 kWh saving that repays the blending stock-pile conveyor in 14 months.

Incoming top size grew from 40 mm to 70 mm after a screen panel failed; the thicker bed demanded 0.5 MPa more pressure and added 1.2 kWh per tonne. Installing a jaw-crusher set at 50 mm reduced the top size and restored the original 18 kWh figure, confirming that feed preparation is often cheaper than extra mill power.

Benchmarking grinding energy for limestone, clinker and slag

Plant databases list 16 kWh per tonne for 12 MPa limestone, 22 kWh for 17 MPa clinker and 28 kWh for 22 MPa slag; these numbers are used as feed-forward set-points in the EMS so the mill starts near optimum and only fine-tunes, avoiding the 0.8 kWh per tonne penalty that comes from generic conservative settings.

Building a model that links feed size to specific energy

A regression on 1 200 data points shows that each 10 mm increase in d₉₅ raises specific energy by 0.9 kWh per tonne for the same 320 m²/kg Blaine; the relation is embedded in the PLC so the hydraulic pressure is pre-positioned 0.2 MPa higher whenever the quarry laser profiler detects a coarser face, preventing the 1 kWh per tonne spike that used to appear after every blast.

Cutting drying cost with low-cost pre-treatment

A 0.9 MW belt dryer that uses 90 °C waste gas from the cooler reduces moisture from 8 % to 2 % at an electrical cost of 0.8 kWh per tonne, cheaper than the 1.1 kWh per tonne penalty that appears when the VRM is forced to evaporate water inside the grinding zone, a net 0.3 kWh saving that repays the dryer in 16 months.

Correlating chemical modules with energy demand

Raising the silica ratio from 2.4 to 2.8 increases the Bond Work Index by 1.4 kWh per tonne; the lab sends the module to the EMS every four hours and the controller pre-adjusts hydraulic pressure 0.15 MPa higher, preventing the 0.7 kWh per tonne overrun that formerly surprised operators when the raw mix chemistry drifted.