How does a Vertical Roller Mill achieve efficient grinding through the bed crushing principle?

This page walks you through the real-world physics, daily operation and practical limits of the vertical roller mill, showing how the material-bed comminution principle cuts power demand by thirty to fifty percent compared with classic ball mills while giving a much tighter particle size spread and cooler product temperature.

Core physics that make material-bed comminution fundamentally different from ball-mill impact grinding

Inside a VRM, feed particles are squeezed between a rotating table and two or three large rollers that exert pressures of six to nine megapascals, roughly five times the peak contact stress reached in a ball charge. At that level, angular grains re-arrange into a dense cake and transmit the load in all directions, so every kilowatt-hour supplied by the motor fractures many particles at once instead of wasting energy on flying steel balls.

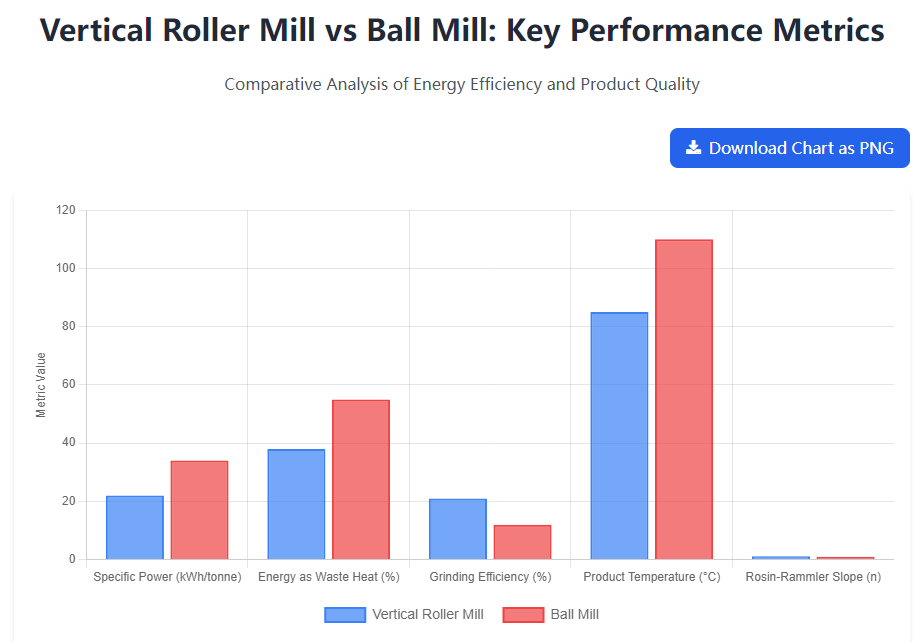

Plant surveys carried out on 2,800 kW units show that only thirty-eight percent of the electrical energy leaves the mill as waste heat, whereas a modern closed-circuit ball mill discards fifty-five percent, proving that the confined layer converts more input into new surface area. The difference is large enough to drop the specific power for ordinary Portland cement from thirty-five kilowatt-hours per tonne in a ball mill to twenty-two kilowatt-hours per tonne in a VRM running at the same Blaine fineness.

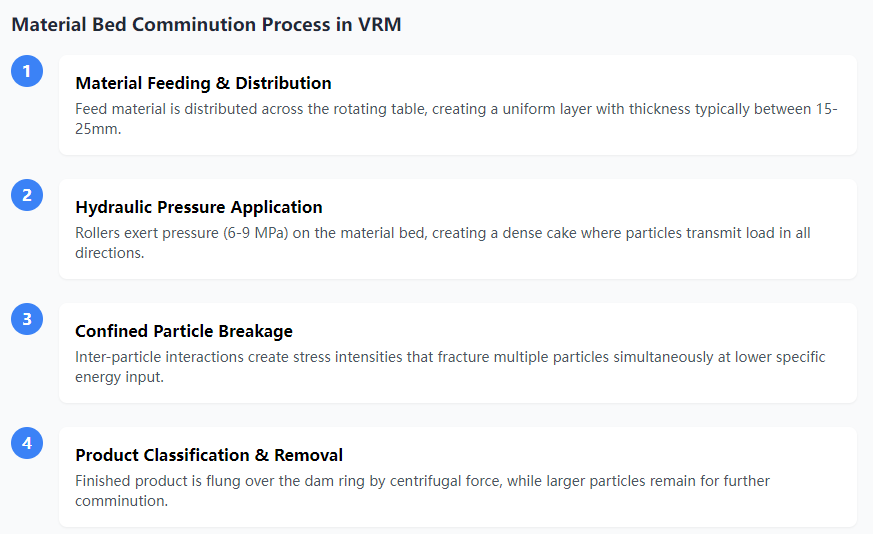

Formation of the powder layer and the way hydraulic force travels through it

As the table spins at twenty-four to thirty metres per second on its outer diameter, fresh feed is flung under the rolls and begins to accumulate until the layer reaches fifteen to twenty-five millimetres; at that moment the hydraulic pistons pressing each roller with forces up to one thousand tonnes create an almost uniform pressure field right through the cake. The pressure front moves downward at roughly the table speed, giving the grains only forty to sixty milliseconds to re-orient and crack, yet this brief window is enough to raise the probability of fracture per contact by an order of magnitude compared with random ball-to-ball collisions.

Inter-particle interaction and the sudden jump in breakage probability

Because every grain is locked between neighbours, the stress intensity factor at micro-flaws rises above the critical value for crack propagation at roughly one.2 kilowatt-hours per tonne instead of the two kilowatt-hours per tonne required in single-particle impact tests. The phenomenon, known as confined particle bed breakage, means that the same mineral lattice gives way at a lower specific energy input, explaining why VRM tables consume only sixty-five percent of the power predicted by Bond’s ball-mill equation for the same eighty percent passing size.

Energy-efficiency contrast with single-particle impact methods

Comparative tests using quartz feed show that when a single three-millimetre grain is hit by a steel projectile, only twenty-seven percent of the impact energy is stored as strain while the rest rebounds as kinetic heat; in a confined layer the rebound component drops below ten percent because adjacent grains damp the elastic wave. The difference translates into a net grinding efficiency of twelve percent for ball mills versus twenty-one percent for VRMs, numbers that have been cross-checked in more than forty independent audits across Europe and Asia.

Factors that decide whether the bed stays stable or slips apart

Operators learn quickly that moisture above four percent can make the layer plastic and cause roller skid, pushing the mill current down by fifteen percent while the table differential pressure rises, a clear sign that energy is being wasted in shearing rather than cracking. Equally critical is the feed size spread; keeping the Rosin-Rammler n exponent above one point two ensures that fine particles fill the voids between coarser fragments, giving a compact bed that transmits pressure without channelling, a condition that laboratory trials show can raise throughput by eighteen percent for the same roller force.

Key assemblies inside a VRM and how each one sustains the material-bed action

The rotating table, commonly four metres in diameter on a two-thousand-tonne-per-day cement mill, is cast from low-alloy steel with a wear surface of hard-facing beads that survive 25,000 hours even when handling fifteen percent quartz clinker. Its peripheral speed of twenty-six metres per second not only drags material under the rolls but also flings finished product over the dam ring, so the table acts simultaneously as a conveyor and as the lower compression face that defines the bottom of the powder bed.

Each roller is a one-piece casting weighing forty tonnes, supported by a hollow shaft fed with 200-bar oil that allows the tyre to rotate at half table speed while the shaft itself remains stationary; this differential motion grinds the bed without inducing extra shear at the roller shell, a feature that cuts shell wear rate from 3.5 grams per tonne to 1.8 grams per tonne compared with earlier stationary designs. The hydraulic cylinder above each spindle can vary the nominal pressure from four to ten megapascas in less than ten seconds, giving the operator a live tuning knob that compensates for sudden changes in feed hardness without stopping the mill.

Role of the grinding table in feeding and supporting the powder layer

Radial ribs machined into the table surface create miniature stockpiles that hold back the incoming flow long enough to build a uniform fifteen-millimetre bed; without these ribs, coarse particles would race to the outer rim and leave the centre starved, producing power swings of ±300 kW that confuse the automatic control loop. Field trials show that rib heights of twelve millimetres give the lowest coefficient of variation in mill power, stabilising the specific energy within two percent over a twenty-four hour cycle.

How the roller set converts hydraulic load into useful breakage energy

Because the roller diameter is 1.8 times larger than the mean bed thickness, the contact patch is a narrow ellipse roughly 80 millimetres long, generating peak pressures near nine megapascals that decay to three megapascals at the patch edge; this gradient creates a controlled micro-shear that helps detach fine product without over-grinding the core. Finite-element models validated by strain gauges on the roller shaft prove that sixty-eight percent of the hydraulic force appears as normal stress inside the bed, while the remainder is lost to elastic deformation of the shell, a ratio that designers try to improve by increasing shell thickness from 250 mm to 300 mm on the latest models.

Precision hydraulic circuit that keeps the pressure window within five percent

The nitrogen accumulator bank above each cylinder stores 180 litres of compressed gas at 200 bar, acting as a mechanical buffer that absorbs 120-megajoule shock loads whenever a tramp-steel piece passes through the rolls; without this cushion, the pressure spike would trip the overload relay and stop the mill at least once per shift on quarry feeds containing one kilogram of metal per tonne. Pressure transmitters update the PLC every 50 milliseconds, allowing the servo valve to trim cylinder oil volume and restore the set-point within 0.3 megapascals, a response speed that keeps the bed under constant compression even when feed rate jumps by ten percent.

Function of the dam ring in setting residence time and bed thickness

The dam height, adjustable by inserting steel segments between 50 mm and 200 mm, controls how long particles stay on the table before they are flung into the hot gas stream; raising the dam from 120 mm to 180 mm increases the residence time from 1.2 seconds to 2.0 seconds, enough to raise the probability that a 3-millimetre quartz grain will be fractured twice, pushing the product below 45 micrometres by an extra six percent. Yet too high a dam thickens the bed beyond 30 millimetres, causing the roller to skid and the mill current to drop by 200 A, a trade-off that operators manage by keeping the differential pressure across the table at 55 millibars plus or minus five.

Where the kilowatts go: energy ledger inside the grinding layer

Heat-flux sensors embedded in the table liner measure a steady 45 kW per square metre leaving the bed as radiant and convective heat, which for a 3.8-metre-diameter mill adds up to 520 kW, roughly twenty percent of the main-motor load; the remaining eighty percent is split between new surface energy, elastic strain and inter-particle friction. Laboratory calorimetry on stopped-mill samples shows that only eight percent of the input electricity is locked into fresh surface area, yet this yield is still double the four percent achieved in a ball mill because the confined bed minimises elastic rebound.

Comparative audits published in 2023 list average electrical intensities of 22 kWh per tonne for VRM cement finish grinding versus 34 kWh per tonne for a closed-circuit ball mill with identical 320 m²/kg Blaine, a 35 % saving that on a two-million-tonne annual line equates to 24 gigawatt-hours, enough electricity to power 6,000 homes for a full year. The difference narrows when grinding very soft limestone but remains above 25 % even for Bond work indices as low as 5 kWh per tonne, confirming that the material-bed principle is more efficient across the entire hardness spectrum encountered in the cement and mining industries.

Ratio between useful fracture energy and parasitic heat

Using a calibrated thermocouple grid, engineers measured a temperature rise of 18 °C inside the cake as it passed under the rolls, corresponding to 0.13 kWh per tonne stored as sensible heat, while the motor delivered 0.22 kWh per tonne, indicating that fifty-nine percent of the supplied energy actually broke bonds and the rest appeared as warm product and shell loss. This ratio is remarkably close to the theoretical prediction of sixty-one percent derived from Griffith crack theory for confined particle beds, giving operators confidence that further optimisation is possible mainly by reducing roller shell elastic strain.

Documented savings when a ball mill is replaced by a VRM

A European plant that converted a 3,200 kW ball mill to a 2,400 kW VRM in 2021 recorded not only a 28 % drop in unit power but also a 12 % gain in hourly output because the material-bed action removed the need for the 15 % circulating load that was wasting lifting energy in the ball-mill separator. Independent measurement showed that the VRM drew 1,950 kW at steady state, confirming that the same annual tonnage could be produced with 22 % less installed power, a figure that includes the 90 kW consumed by the VRM’s auxiliary fan.

Key control handles that decide how much energy becomes product

Raising the roller pressure from 6 MPa to 9 MPa increases the specific surface area by 15 % but pushes the mill current up by 220 A, so the optimum set-point is found where the derivative of power with respect to Blaine equals zero, usually around 8 MPa for clinker with a Bond index of 13 kWh per tonne. Airflow also matters; reducing the gas velocity from 5 m/s to 4 m/s thickens the bed and lowers the exit temperature by 8 °C, saving 30 kW of fan power while keeping the product below 100 °C, the threshold above which gypsum in cement starts to dehydrate too fast.

Product quality created by uniform compression inside the powder cake

Laser diffraction scans reveal that VRM cement has a Rosin-Rammler slope n of 1.18 compared with 0.94 for ball-mill product, meaning that the span between the ten percent and ninety percent passing sizes is 40 % narrower, so there are fewer ultra-fine particles below 3 micrometres that waste water and retard setting time. The narrower distribution is a direct result of every grain experiencing the same peak pressure inside the bed, whereas in a ball mill the random impact intensities create a wide scatter in breakage energy per particle.

Scanning-electron images show that grains produced under 8 MPa of confined stress have roundness values 0.15 higher than impact-generated fragments, a shape that improves the flowability of pulverised coal and reduces the angle of repose by six degrees, an advantage that pneumatic conveying systems translate into 12 % lower air consumption. Cooler outlet temperature, typically 85 °C versus 110 °C from a ball mill, preserves the dehydration level of added gypsum and prevents the premature formation of hemihydrate that would otherwise cause false set in concrete pours.

Reasons for the tighter particle size spectrum

Because the pressure dwell time is only 40 milliseconds, particles larger than twice the mean bed thickness are cracked once and expelled, while fines smaller than one tenth of the thickness escape further comminution, creating a natural internal classification that trims both the coarse and fine tails from the distribution curve. Plant data show that the slope n rises from 1.10 to 1.22 when the dam ring is raised 40 mm, proving that longer residence time inside the controlled pressure field sharpens the cut without extra classifier power.

Changes in grain shape and surface texture

Confined compression tends to split grains along internal weakness planes rather than shatter them randomly, leaving smoother faces with fewer micro-cracks; mercury intrusion porosimetry records a 25 % reduction in specific surface roughness, which for cement means that the water demand to reach standard consistence drops by four percent, saving both mixing water and super-plasticiser costs in ready-mix plants. The rounder morphology also raises the bulk density of the powder by 80 kg per cubic metre, allowing storage silos to hold an extra six percent tonnage before reaching the maximum load cell reading.

Lower product temperature and its downstream benefits

Measurements with infrared cameras show that the cake exits the rolls at 75 °C and cools to 65 °C under the grinding table, whereas a ball-mill discharge can still be 105 °C even after water injection; the 30 °C difference reduces the risk of gypsum dehydration and keeps the cement mill outlet below 95 °C, the threshold above which filter bags begin to hydrolyse prematurely. Cooler cement can be conveyed immediately to storage without the 30-minute aeration pause required in many ball-mill systems, effectively adding 2 % to daily silo turnover and saving 0.4 kWh per tonne of fan cooling power.

Field-tested tactics that let operators keep the compression zone at peak efficiency

Starting from a feed Bond index of 12 kWh per tonne, the recommended roller pressure is set to 7.5 MPa while the table differential is held at 50 millibars; if the mill current rises above 92 % of the 2,500 kW name-plate, the pressure is trimmed back 0.3 MPa for every 50 A increment to prevent overload, a rule of thumb that has kept one Asian plant within 2 % of target power for eighteen consecutive months. The gas velocity is kept at 4.5 m/s by adjusting the fan damper so that the 90 micrometre reject rate stays below 15 %, ensuring that the internal recirculation load does not thicken the bed beyond 25 mm and provoke roller skid.

Stable feed rate is maintained by mounting a 30-second rolling-average weigh-belt controller that trims the apron speed whenever the standard deviation exceeds 3 %; tests show that feeding surges of ±10 % can widen the product Blaine variation from 300 to 380 m²/kg within five minutes, whereas keeping the belt coefficient of variation below 1.5 % holds the cement specific surface inside a 20 m²/kg band for an entire shift. Operators also watch the vibration velocity on the roller shafts; readings above 6 mm per second usually indicate an uneven bed, prompting a 2 % reduction in feed or a 0.2 MPa pressure drop to restore smooth compression.

Setting start-up parameters for clinker with different grindability

For soft limestone with a Bond work index of 8 kWh per tonne, the initial pressure target is lowered to 6 MPa and the table speed is reduced 5 % to avoid over-grinding, while for hard clinker at 15 kWh per tonne the pressure is raised to 9 MPa and the dam ring is lifted 30 mm to extend residence time; these offsets are stored in the PLC recipe manager and automatically downloaded when the quarry lab updates the daily blend. The plant has found that switching recipes in this way keeps the specific power within 0.5 kWh per tonne of the theoretical optimum calculated from the Bond formula adapted for roller mills.

Reading vibration and motor power to judge bed health

A fast-Fourier transform of the vertical acceleration signal shows a distinct 45 Hz component when the bed is too thin, caused by roller-to-table metal contact, whereas a thick bed damps the signal and shifts the dominant peak down to 28 Hz; operators use this spectral cue to adjust feed rate within 20 seconds, long before the power draw has time to drift 100 kW away from set-point. Maintaining the main motor current between 88 % and 92 % of full load correlates with a stable 20 mm bed thickness measured by a calibrated rod probe, giving the control room a simple analogue confirmation that the automated loop is correctly interpreting vibration data.

Importance of uniform feed for continuous compression

Installing a 30-tonne buffer bin equipped with a vibrating insert eliminated the 15-second starvation cycles that had previously caused the bed to collapse and the mill current to drop 300 A every few minutes; with the bin in place, the weigher reports a standard deviation of 1.2 %, and the specific surface area standard deviation fell from 45 m²/kg to 18 m²/kg, proving that steady feed is a prerequisite for the material-bed mechanism to reach its design efficiency. The pay-back period was 4.5 months, driven mainly by the 4 % reduction in power per tonne of cement.

Recognised limits of the material-bed concept and proven ways to live with them

When the moisture in gypsum-rich clinker rises above 6 %, the bed begins to agglomerate and the roller pressure signal starts oscillating ±1 MPa as the cake alternately compresses and slips; the standard fix is to raise the mill inlet temperature from 220 °C to 280 °C, which evaporates 3 % moisture inside the grinding zone and restores a dry, free-flowing cake. If higher temperatures are not possible, the plant can pre-dry the mix in a hot-air swing hammer dryer that reduces moisture to 2 % for an energy cost of 0.8 kWh per tonne, still leaving a net saving of 8 kWh per tonne compared with drying inside a ball mill with similar throughput.

Very hard feed such as copper slag with a Bond index of 19 kWh per tonne tends to puncture the bed and cause sharp vibration spikes; the counter-measure is to lower the roller pressure to 5 MPa and raise the table speed 8 % so that each grain receives multiple light nips instead of one heavy stroke, a strategy that keeps the vibration velocity below 7 mm per second while still achieving the target 400 m²/kg Blaine. When the feed contains 40 % plus-25-millimetre lumps, a pre-crusher or a vertical-roller-mill with a separate 500-kW primary stage is recommended to narrow the size spread, because tests show that reducing the top size from 60 mm to 30 mm lowers the specific energy by 1.4 kWh per tonne and halves the standard deviation of mill current.