Selecting Fine Crushers According to Processed Materials: A Guide to Suitable Models for Crushing Various Ores

This guide provides a systematic approach to selecting fine crushers based on the specific characteristics of processed materials, particularly focusing on various ore types. Material properties significantly influence crushing efficiency, equipment wear, and final product quality, making proper equipment selection essential for operational success. The examination covers fundamental material characteristics, equipment compatibility considerations, and practical selection methodologies for optimizing crushing operations across different mining and processing applications.

Ore Classification and Crushing Characteristics Overview

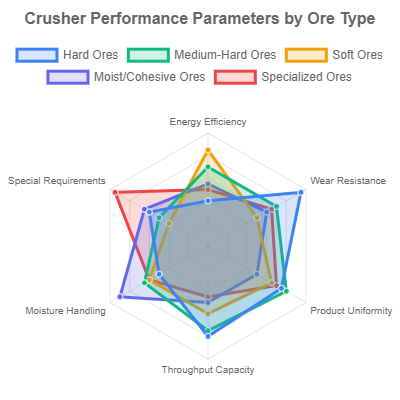

Ores demonstrate considerable variation in their response to crushing forces, influenced by mineral composition, geological history, and physical properties. Hardness represents perhaps the most significant characteristic, typically measured using Mohs scale or more precise Bond work index determinations. Brittle materials tend to fracture cleanly under impact forces, while ductile materials may deform rather than break, requiring different crushing approaches. Material structure, including the presence of natural cleavage planes or grain boundaries, significantly influences size reduction behavior.

Moisture content introduces additional complexity to crushing operations, particularly with clay-containing ores that may become cohesive when wet. Surface chemistry affects how particles behave during and after crushing, influencing dust generation and particle adhesion. Understanding these material characteristics enables prediction of crushing energy requirements, equipment wear rates, and expected product size distributions, forming the foundation for appropriate equipment selection.

Hard Ore Crushing Equipment Selection

Hard ores including many metallic deposits and some industrial minerals present particular challenges for fine crushing operations. These materials require substantial energy input for size reduction and cause accelerated wear on crushing components. Cone crushers typically serve as the preferred solution for hard ore applications, utilizing interparticle compression between mantle and concave surfaces to achieve efficient size reduction. Their robust construction and ability to apply high forces make them suitable for the most demanding applications.

High-pressure grinding rolls offer an alternative approach for hard ore processing, utilizing compression between counter-rotating rolls to achieve size reduction. This technology typically provides energy savings compared to conventional crushers while producing less fine material. Wear protection strategies become particularly important for hard ore processing, often incorporating advanced materials like tungsten carbide or specialized alloys in critical wear areas. Operational parameters must be carefully controlled to prevent equipment damage while maintaining production targets.

Medium-Hard and Soft Ore Processing Solutions

Medium-hard ores including many industrial minerals and some metallic deposits allow for greater flexibility in equipment selection. Impact crushers effectively process these materials, utilizing high-speed rotors to accelerate ore particles against impact surfaces or other particles. This mechanism typically produces well-shaped particles with good cubic characteristics, desirable for many applications. The relatively lower crushing forces required reduce energy consumption and component wear compared to hard ore processing.

Hammer mills provide another option for medium-hard materials, particularly when further reduction beyond typical crusher capabilities is required. These systems offer high reduction ratios and the ability to handle moderately abrasive materials. Operational flexibility becomes an important consideration, as many operations process ores with varying characteristics. Equipment that can accommodate these variations without significant adjustment or performance degradation provides particular value in such applications.

Moist and Cohesive Ore Processing Challenges

Ores with significant moisture content or cohesive characteristics present unique challenges for crushing operations. These materials tend to adhere to equipment surfaces, reducing processing efficiency and potentially causing blockages. Specialized equipment designs address these issues through various mechanisms, including impact elements that prevent material buildup and configurations that promote material flow through the crushing chamber.

Pre-processing approaches sometimes prove necessary for particularly challenging materials, including preliminary drying or blending with drier ores to achieve processable conditions. Equipment selection must consider not only the crushing mechanism itself but also ancillary systems for material handling and feeding. These integrated approaches ensure consistent operation despite variations in material characteristics that might otherwise disrupt processing.

Specialized Ore Processing Requirements

Certain ore types present unique characteristics requiring specialized crushing approaches. Radioactive ores necessitate particular safety considerations, often requiring fully enclosed systems with appropriate shielding and monitoring. Some precious metal ores benefit from selective liberation through careful size reduction, preserving valuable mineral structures while achieving necessary liberation.

Complex ores containing multiple valuable minerals may require tailored crushing strategies to optimize subsequent separation processes. The relationship between particle size, mineral liberation, and processing recovery becomes particularly important in these applications. Equipment selection must balance these specialized requirements with practical operational considerations to achieve overall process optimization.

Material Compatibility in Crusher Selection

The chemical composition of processed ores influences equipment material selection beyond mere wear considerations. Some ore components may interact with certain alloy elements,

necessitating careful material compatibility assessments. Corrosion resistance requirements vary significantly based on ore chemistry and processing conditions, influencing

material selections for crusher components.

Modern crusher designs increasingly incorporate advanced materials specifically developed for challenging processing conditions. These include specialized alloys, composite materials, and surface treatments that enhance performance while reducing maintenance requirements. The selection process must consider not only initial performance but also how material characteristics will evolve over the equipment's operational lifespan.