How Fine Crushers Enable Efficient Crushing of Materials Like Cement Clinker

This comprehensive guide explores the specialized role of fine crushers in processing cement clinker and similar industrial materials. The content examines the technical challenges of clinker crushing, equipment selection criteria, operational methodologies, and the significant advantages modern crushing technology brings to industrial processes. Readers will gain understanding of how these machines transform hard, abrasive materials into precisely sized particles ready for final processing, contributing to more efficient and sustainable industrial operations.

The Importance and Challenges of Cement Clinker Crushing

Cement clinker represents the intermediate product created when limestone and clay are heated in a kiln during cement production. This nodular material possesses exceptional hardness and abrasive qualities that present substantial challenges for conventional crushing equipment. The crushing process must reduce these hard nodules to specific size ranges that optimize the subsequent grinding operation, which ultimately determines the quality and performance characteristics of the final cement product.

Industrial operations face multiple difficulties when processing cement clinker, including extreme equipment wear, energy consumption concerns, and environmental considerations. The material's high temperature immediately after kiln processing introduces additional complexity, as equipment must withstand thermal stress while maintaining operational efficiency. Modern fine crusher technology addresses these challenges through specialized designs that maximize efficiency while minimizing operational costs and environmental impact.

Advantages of Fine Crushers in Cement Clinker Processing

Fine crushers offer distinct advantages for cement clinker processing compared to traditional crushing methods. These machines achieve higher reduction ratios in single processing stages, significantly reducing the number of equipment required in the production circuit. The precise control over final product size distribution enables downstream grinding operations to perform more efficiently, ultimately reducing overall energy consumption by approximately 20-30% compared to conventional approaches.

Modern crushing systems incorporate advanced dust suppression and noise reduction technologies that address environmental and workplace safety concerns. The enclosed designs prevent particulate matter from escaping into the atmosphere, while specialized damping systems reduce operational noise levels below 85 decibels. These features create safer working environments while ensuring compliance with increasingly stringent industrial emission standards.

Selection Principles for Cement Clinker Fine Crushers

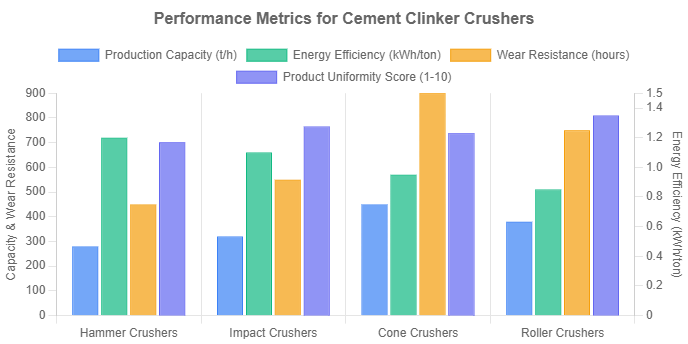

Selecting appropriate crushing equipment for cement clinker requires careful consideration of multiple technical factors. The material's exceptional hardness, typically measuring between 6-7 on the Mohs scale, necessitates equipment constructed from specialized wear-resistant materials. Production capacity requirements must align with overall plant output, with modern installations typically processing between 100-500 tons per hour depending on specific operational requirements.

Equipment configuration must account for the specific characteristics of cement clinker, including its abrasive nature and occasional temperature variations. Crusher designs incorporating hydraulic adjustment systems enable operators to maintain optimal performance despite changing material conditions. The integration of automated control systems allows real-time monitoring and adjustment of operational parameters, ensuring consistent product quality while maximizing equipment lifespan.

Operational Techniques for Cement Clinker Fine Crushers

Effective operation of fine crushers in cement clinker applications begins with comprehensive material preparation. Pre-screening removes oversize materials that could cause equipment damage or processing inefficiencies. Modern control systems continuously monitor feed rates and material characteristics, automatically adjusting crusher parameters to maintain optimal performance under varying conditions.

Regular maintenance protocols significantly enhance equipment reliability and operational lifespan. Scheduled inspections of wear components, lubrication systems, and structural elements prevent unexpected downtime and maintain processing efficiency. Advanced monitoring systems track performance metrics including energy consumption, throughput rates, and product quality, enabling predictive maintenance approaches that further enhance operational reliability.

Case Studies of Fine Crusher Applications in Cement Clinker Processing

Industrial applications demonstrate the tangible benefits of modern fine crusher technology in cement production. One installation achieved a 28% reduction in energy consumption while increasing overall processing capacity by 15% through the implementation of advanced crushing technology. The improved product consistency enabled downstream processes to operate more efficiently, contributing to additional energy savings and quality improvements throughout the production chain.

Another application focused on environmental performance, reducing dust emissions by 75% while decreasing noise levels significantly. The installation incorporated comprehensive material handling and dust collection systems that transformed the working environment while maintaining processing efficiency. These improvements demonstrated how technological advancements can simultaneously enhance operational performance, environmental compliance, and workplace safety.

Future Development Trends in Cement Clinker Crushing Technology

Cement clinker crushing technology continues evolving toward greater efficiency, reliability, and environmental sustainability. Research focuses on developing advanced wear materials that extend component lifespan while maintaining crushing efficiency. These developments aim to reduce maintenance requirements and operational costs while enhancing overall equipment performance in demanding industrial environments.

Intelligent control systems represent another significant development direction, incorporating artificial intelligence and machine learning algorithms to optimize crushing parameters in real-time. These systems analyze operational data to predict maintenance needs, adjust performance parameters, and identify optimization opportunities. The integration of these advanced technologies promises further improvements in energy efficiency, operational reliability, and environmental performance for cement production operations.