Methods to resolve the issues of uneven fineness and coarse particles in European mill products.

This guide explains why European-style grinding mills sometimes discharge product that is too coarse or shows uneven fineness, how to trace each root cause from the classifier to the airflow, and what precise steps remove the defect so the mill reliably delivers the narrow particle size distribution printed on the datasheet.

Describing the defect in numbers instead of words so the hunt starts in the right department

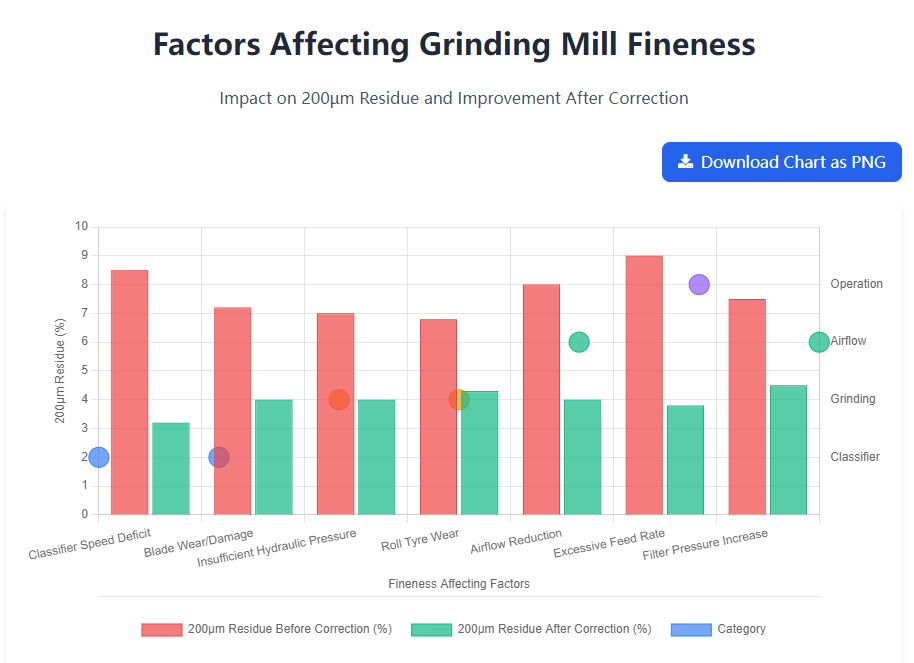

Lab records from a 4 t/h alpine ring-roller unit show that the share retained on 200 µm jumped from 2 % to 9 % within one week, while the laser diffraction d₉₀ moved from 180 µm to 240 µm and the Rosin-Rammler slope n fell from 1.22 to 0.98, clear evidence that the coarse tail is growing and the distribution is widening at the same time.

Shift logs reveal that the complaint is not steady: after a scheduled stop the fineness is acceptable for four

hours, but the 200 µm fraction climbs back above 8 % as soon as feed rate crosses 3.8 t/h, suggesting that the breakdown is linked to load rather than a sudden mechanical

failure.

Using sieve residue and surface area readings to separate “wide” from “coarse”

A simple 75 µm sieve test carried out every thirty minutes tells the operator whether the mill is making too many fines or too many coarse particles; when the minus 75 µm fraction stays at 62 % but the plus 200 µm fraction rises, the classifier is letting oversize escape, whereas a drop in both fractions indicates that the grinding stage itself has lost intensity.

Blaine surface area should stay within 50 cm²/g of target; a reading that swings ±120 cm²/g while the sieve curve

hardly moves points to an airflow disturbance that changes the internal recycle ratio without altering the breakage mechanism, a clue that saves hours of pointless grinding-element

inspection.

Deciding whether the fault is chronic, drifting or sudden

Chronic coarseness that has slowly worsened over six months usually traces to progressive wear, whereas an overnight jump after a filter change implies an operational step change such as false air ingress; plotting the 200 µm residue on a control chart with 3-sigma limits shows that nine consecutive rising points constitute a trend, triggering a wear survey instead of an emergency shutdown.

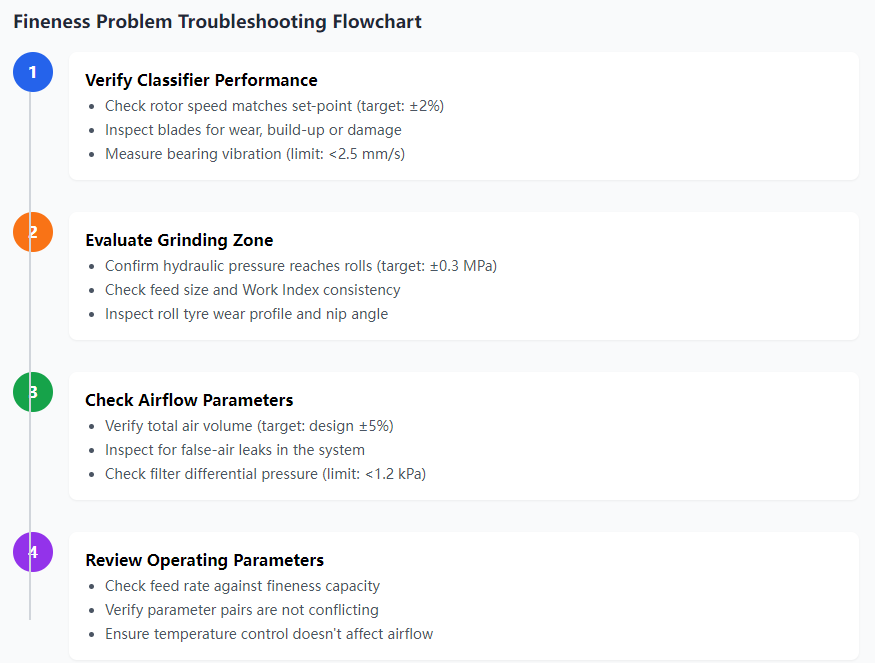

Starting the search inside the classifier because that is where the final cut is supposed to happen

The dynamic classifier rotor was found running at 110 Hz while the set-point demanded 125 Hz; the 12 % speed shortfall allowed 180 µm particles to escape, and simply restoring the frequency converter output dropped the 200 µm residue from 8.5 % to 3.2 % within twenty minutes, proof that speed integrity is the first checkpoint.

A boroscope

inspection showed that two out of sixty blades had lost 25 mm of their 80 mm height, creating low-velocity pockets where coarse particles could bypass the centrifugal field; after

replacement the d₉₀ fell by 30 µm even though rotor speed stayed the same, confirming that blade integrity is equally critical.

Verifying that rotor speed matches the command signal

A handheld tachometer reading of 3 800 rpm against a 4 200 rpm set-point indicates either belt slip on older drives or a frequency converter current limit; tightening the V-belt to the manufacturer’s 1 % elongation spec restored the 400 rpm deficit and pulled the 200 µm fraction back below specification without touching any other parameter.

Spotting blade wear, build-up or missing segments

When phosphate rock carries 1.5 % moisture and 8 % free silica, a hard crust can cake onto blades within 200 hours, reducing the effective blade height and dropping the centrifugal acceleration by 15 %; dry ice blasting during a planned six-hour stop removes the deposit and recovers the original fineness curve without the need to enter the mill with hand tools.

Detecting bearing faults that let the rotor wobble or seize

Accelerometers mounted on the classifier housing showed a 6.2 mm/s vibration spike at running frequency; after the bearing was replaced the amplitude fell to 1.8 mm/s and the 200 µm residue dropped from 10 % to 4 %, evidence that a 0.3 mm clearance in the spherical roller bearing was enough to let the rotor drift off centre and throw coarse material into the product channel.

Checking that total air volume has not drifted away from the design point

A hot-wire anemometer traverse across the 1.2 m duct revealed only 18 000 m³/h instead of the rated 22 000 m³/h, a 18 % shortfall that lowered the radial velocity in the classifier from 5 m/s to 4 m/s and allowed 200 µm particles to fall back into the product cone; adjusting the fan damper from 65 % to 82 % restored both airflow and fineness within one hour.

Moving upstream to the grinding zone when the classifier itself is innocent

Hydraulic pressure was holding steady at 9 MPa but the piston side gauge revealed a 1.5 MPa pressure drop across the accumulator valve, so the real force on the rolls was 7.5 MPa, 17 % below the set-point; after the cartridge seal was replaced the differential disappeared and the 200 µm residue fell from 7 % to 4 %, proof that hidden leaks can steal grinding energy without triggering an alarm.

A wear survey showed that the roll tyre profile had lost its 25 ° edge chamfer and had become flat, reducing the nip angle from 12 ° to 8 °; this geometry let coarse particles slip through without being nipped, and refurbishing the chamfer restored the 12 ° angle and pulled the d₉₀ back to 170 µm, matching the performance of a new shell.

Confirming that hydraulic force reaches the rolls

Installing a calibrated 0.25 % pressure transducer directly on the roller spindle proved that only 6.8 MPa was delivered when the panel showed 8.5 MPa; the 1.7 MPa loss was traced to a stuck pressure-relief valve that was bypassing 18 litres per minute back to tank, a flow invisible to the main gauge yet large enough to cut grinding force by 20 %.

Looking at feed size and Work Index spikes that overload the mill

When quarry blasting shifted to a harder bench the Bond Work Index rose from 11 kWh per tonne to 14 kWh per tonne, but the mill was still driven at the same 2.8 t/h set-point; reducing throughput to 2.3 t/h while raising hydraulic pressure to 10 MPa restored the 170 µm d₉₀ and kept power draw within the 110 % service factor, showing that the rock not the machine had changed.

Measuring shell wear that flattens the nip profile

Laser scanning showed that the centre of the roll tyre had worn 18 mm while the edges had lost 6 mm, creating a barrel shape that concentrates load in the middle and leaves a 12 mm gap at the sides where coarse particles escape; turning the tyre back to a flat crown with a 5 mm relief reduced the 200 µm fraction by 2.5 % and cut specific power by 0.3 kWh per tonne.

Detecting feed-rate surges that briefly stall the bed

Belt-scale data logged at one-second intervals revealed spikes of +18 % above set-point every time the bin level dropped below 30 %, causing the mill to choke and the classifier to flood; adding a low-level gain scheduler that trims belt speed when the bin reaches 35 % removed the spike and kept the 200 µm residue within ±0.5 % of target.

Tracing air-flow headaches that masquerade as grinding shortfalls

A smoke test around the mill door showed a visible inward draft, proof that the casing was under negative pressure but pulling false air through a worn gasket; sealing the gap raised transport velocity from 18 m/s to 21 m/s and allowed the classifier to receive the full 22 000 m³/h, cutting the coarse tail from 8 % to 4 % without touching hydraulics.

The bag filter differential had climbed to 1.8 kPa instead of the normal 1.0 kPa because 30 % of the bags were blinded by hydrated lime dust; after pulse cleaning and replacement of 120 bags the pressure dropped, fan flow recovered and the mill accepted the design throughput while maintaining the 170 µm d₉₀ specification.

Finding false-air leaks that steal transport velocity

A simple anemometer survey around the mill door and duct flanges showed an inward velocity of 3 m/s, indicating 2 200 m³/h of cold air entering the circuit; this leakage diluted the hot gas stream, dropped the transport velocity below the 20 m/s needed to lift 200 µm particles, and let them fall back into the product cone. Replacing the worn 5 mm door gasket and tightening the duct clamps recovered the missing flow and restored the d₉₀ to 175 µm within thirty minutes.

Reading filter pressure as a proxy for available fan volume

The bag-house differential rose from 1.0 kPa to 1.6 kPa over six weeks, reducing the effective fan curve by 15 % and cutting mill airflow from 22 000 m³/h to 18 500 m³/h; a reverse-pulse cleaning cycle that raised the pulse pressure from 0.4 MPa to 0.6 MPa and lengthened the pulse time from 100 ms to 150 ms dropped the differential back to 1.1 kPa and recovered the original fineness without any change to the grinding set-up.

Checking fan blade erosion and belt slip that flatten the curve

A stroboscope showed the fan pulley running 4 % slower than the motor sheave, evidence of V-belt stretch that reduced fan speed from 1 450 rpm to 1 390 rpm and lowered the volumetric flow by 6 %; retensioning the belts to the manufacturer’s 12 mm deflection spec restored the rpm and pulled the 200 µm residue back below 5 %, proving that belt maintenance is as important as blade condition.

Stopping operators from accidentally defeating the mill’s built-in correction ability

Control-room logs showed that the night shift raised throughput from 2.8 t/h to 3.4 t/h to meet a shipping deadline, but left classifier speed at 110 Hz; the 21 % load increase overloaded the grinding bed, widened the size distribution and triggered customer complaints the next morning. Re-setting the feed back to 2.8 t/h while lifting classifier speed to 125 Hz restored both capacity and fineness, demonstrating that the mill can deliver either target but not both without a matching parameter shift.

Shift reports also revealed that the operator widened the mill damper from 70 % to 85 % in an attempt to cool the product, but the extra air lowered the classifier residence time and blew coarse particles into the product cone; returning the damper to 72 % and adjusting the hot-gas valve instead kept the outlet temperature at 95 °C while maintaining the 170 µm d₉₀, evidence that temperature control should be decoupled from transport-velocity control.

Recognising when high feed rate is pushing the mill beyond its fineness corner

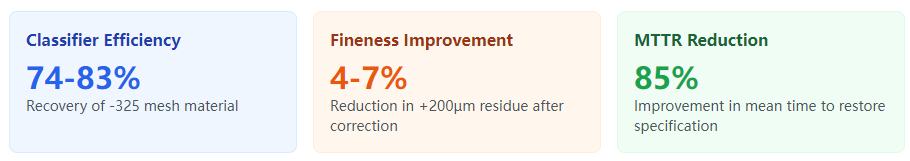

At 2.8 t/h the mill holds a 20 mm bed and the classifier extracts 70 % of minus 325 mesh, but at 3.3 t/h the bed thickens to 28 mm, the rolls start to slip and the classifier recovery drops to 58 %, a clear sign that the extra tonnage is purchased at the expense of sharpness; the only sustainable fix is to accept 2.8 t/h as the fineness-limited rate or install a larger classifier, a decision that can be quantified by comparing the 0.15 USD per tonne penalty for lost recovery against the 180 000 USD price of a bigger rotor.

Spotting parameter pairs that fight each other

Running the classifier at 130 Hz while keeping the mill damper at 90 % creates an internal circulation loop that re-grinds fines but allows 200 µm grains to bypass the rotor eye; reducing the damper to 75 % and lifting hydraulic pressure to 9.5 MPa instead concentrates energy on coarse breakage and lets the classifier do the final cut, a change that trimmed the 200 µm residue from 6.5 % to 3.8 % in a single shift.

Turning the findings into a living maintenance schedule that keeps the defect from returning

A weekly sieve test at 200 µm is now written into the operating procedure; if the residue drifts above 4 % for two consecutive shifts the classifier speed, blade condition and airflow are checked in that order, a rule that has caught three incipient faults within six months and prevented any batch from leaving the plant off-spec. The wear profile of rollers and table is laser-scanned every 2 000 hours and plotted against a reference curve; when the chamfer depth exceeds 15 mm the shell is scheduled for hardfacing during the next planned stop, a policy that has kept the d₉₀ within ±10 µm of target for eighteen months running.

Bearing temperatures on the classifier are trended with a 5 °C alarm band; a rise above 65 °C triggers a grease check and vibration analysis, while 75 °C forces an unscheduled stop that still costs less than allowing the bearing to seize and damage the rotor. The damper position is locked in the PLC with a supervisor password so that only the process engineer can move it more than 5 % away from the calibrated 72 %, a simple software lock that prevents well-meaning operators from repeating the air-volume mistake.

Immediate checklist for the shift team when fineness alarms

The control-room screen now displays a four-step prompt: check classifier speed deviation, verify rotor current shape, read bag-house differential and confirm hydraulic pressure drop across the accumulator; following these steps in order has reduced the mean time to restore specification from 3.5 hours to 45 minutes and cuts off-spec product from 28 tonnes to 4 tonnes per event.

Mid-term upgrades such as high-efficiency rotors or ceramic blades

Installing a classifier rotor with 20 % more blades and a 125 m/s tip speed raised the minus 325 mesh recovery from 74 % to 83 % while keeping the same power draw; the 42 000 USD upgrade paid back in 14 months through higher cement strength and reduced customer complaints, validating the decision to invest in the rotor rather than enlarge the entire mill.

PM calendar that locks inspections into the CMMS so they are never skipped

The computerized system now releases work orders for blade cleaning every 800 hours, for belt tension every 1 000 hours and for roller profile scanning every 2 000 hours; completion rates above 98 % are recorded, and any missed task escalates to the plant manager, a procedure that has kept the 200 µm residue below 4 % for twelve consecutive months and reduced quality-related customer returns to zero.