What flammable and explosive materials are suitable for the explosion-proof design of European-style mills?

European-style grinding mills are essential in processing various industrial materials, but their high-speed rotation, mechanical impact, and friction can generate heat and sparks,

potentially forming explosive dust clouds. When conditions align, this can lead to catastrophic dust explosions. Therefore, explosion-proof design is not an optional feature but a

mandatory safety requirement for handling flammable and explosive materials. This article systematically outlines common categories of materials with combustion and explosion

risks, delves into the active and passive explosion-proof technologies integrated into European mills, and clarifies their application limits and operational protocols for safe

processing, providing critical technical assurance for industrial safety.

Understanding the Five Elements of Dust Explosion and Their Formation Conditions in Mills

The foundation of explosion-proof design lies in disrupting at least one element of the "explosion pentagon," a model that describes the necessary conditions for a dust explosion to occur. Within a grinding mill, these elements can converge due to the nature of the operation, where materials are pulverized and suspended in air. The mechanical actions involved, such as crushing and grinding, inherently create environments where these factors can interact, making it crucial to address each one through design and operational controls.

Combustible Dust Material Properties

The material itself must be capable of being ground into fine, combustible particles that can ignite under certain conditions. Many substances that seem harmless in larger chunks become highly reactive when reduced to powders with high surface area-to-volume ratios. The particle size distribution significantly influences explosibility, with finer powders often having lower ignition energies and higher combustion rates.

Oxidant Typically Atmospheric Oxygen

Oxygen present in the air serves as the oxidant that supports combustion within the mill system. In normal atmospheric conditions, oxygen concentration is sufficient to sustain a fire or explosion if other elements are present. Controlling this factor often involves altering the atmosphere inside the equipment to reduce oxygen levels below the threshold required for combustion.

Ignition Source Potential Ignition Points Inside the Mill

Grinding mills contain several potential ignition sources, including mechanical friction sparks from grinding components, hot surfaces from bearings or motors, electrostatic discharges from powder movement, and impact sparks from foreign objects. Each of these requires specific mitigation strategies, such as using special materials and monitoring systems to prevent temperatures from reaching critical points. The design of rotating parts like the rotor is critical to minimize friction and spark generation.

Dispersion of Dust Cloud

The process of conveying and suspending materials inside the mill through air flow naturally creates the dispersed dust cloud necessary for an explosion. This state allows the fine particles to mix uniformly with oxygen, enabling rapid combustion if ignited. Operational parameters such as airflow velocity and feed rate must be carefully controlled to avoid creating ideal conditions for dispersion without adequate safety measures.

Confinement Equipment Providing enclosed Space

The mill and its connected piping systems form a confined space that can contain and intensify an explosion, leading to a rapid pressure rise that can cause catastrophic equipment failure. This confinement effect increases the severity of any incident, making structural integrity and pressure relief mechanisms vital components of the overall safety design. The crushing chamber must be designed to withstand or safely vent excessive pressures.

Typical Flammable and Explosive Materials Suitable for Explosion Proof European Mills

Various materials processed in industrial settings pose significant explosion risks due to their physical and chemical properties when finely ground. Understanding these categories helps in selecting appropriate mill designs and safety protocols tailored to specific material hazards. Each group has unique characteristics that influence the choice of explosion-proof measures, from material handling to system integration.

Metal and Alloy Powders Aluminum Powder Magnesium Powder Titanium Powder Zinc Powder

These materials are highly reactive and can produce extremely powerful explosions, making them a focal point for explosion-proof design challenges. Their low ignition energies and high combustion temperatures require robust safety systems, including inert gas blanketing and advanced ignition source control. Processing such powders often demands mills with enhanced sealing and monitoring capabilities.

Chemicals and Polymers Certain Dyes Pesticides Plastics PE PP PVC Resins

Many chemicals and polymeric materials have low ignition temperatures and minimal ignition energies, increasing their susceptibility to combustion during grinding operations. Their organic nature often leads to the generation of static electricity, which can serve as an ignition source if not properly managed. Mills handling these materials must incorporate comprehensive electrostatic protection and temperature control.

Agricultural and Organic Materials Flour Starch Sugar Milk Powder Wood Dust

These materials are classic sources of dust explosions, with numerous historical incidents highlighting their risks, which are often underestimated due to their commonplace use. Their organic composition allows for easy combustion, and their widespread application in food and feed industries necessitates strict safety measures. Equipment like the hammer crusher may be adapted with explosion-proof features for such applications.

Energy Materials Coal Petroleum Coke

The volatile content in these materials is a key risk indicator, as it can be released during grinding and contribute to explosibility. Special attention is required during processing to monitor temperature and control dust concentrations, ensuring that operational parameters do not approach hazardous levels. Their use in energy production links them to applications discussed in mining and quarrying operations.

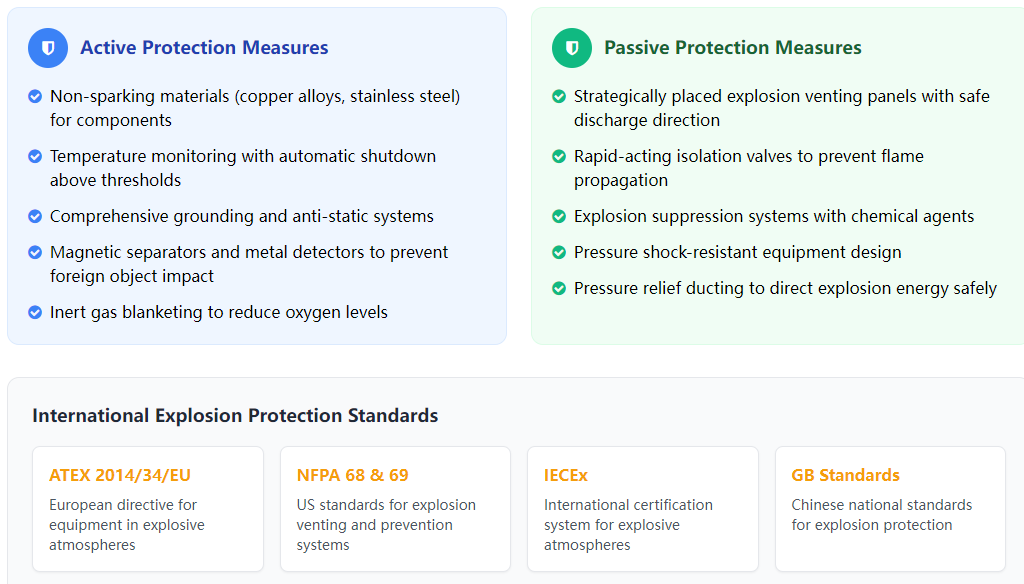

Cornerstone of Explosion Proof Design Active Measures to Avoid Ignition Sources

The first line of defense against explosions is to prevent ignition sources from occurring within the mill system through proactive design and operational practices. Active measures focus on eliminating or reducing the likelihood of sparks, hot surfaces, and other triggers that could initiate combustion. These strategies are integrated into the mill's components and control systems to ensure continuous safety during operation.

Avoiding Mechanical Friction Sparks Special Materials and Non Sparking Design

Using materials such as copper alloys and stainless steel for tools and internal components reduces the risk of spark generation during contact or impact. Design optimizations ensure that moving parts do not inadvertently rub against each other, minimizing frictional heat and spark potential. This approach is critical in areas with high mechanical stress, such as grinding zones.

Controlling Surface Temperature Monitoring and Cooling Measures

Temperature sensors are installed on bearings, grinding rollers, and other heat-prone areas to monitor conditions and trigger shutdowns if thresholds are exceeded. Supplemental cooling systems, such as water cooling, may be employed to maintain surfaces below critical temperatures, preventing them from becoming ignition sources. The motor and drive systems are often included in such monitoring schemes.

Comprehensive Electrostatic Protection System

Ensuring the entire equipment is properly grounded prevents the buildup of static electricity, which could discharge and ignite dust clouds. Anti-static filter bags and ionizing air systems are used in key locations to neutralize electrostatic charges, providing an additional layer of safety against this common ignition risk.

Preventing Metal Intrusion Strong Magnetic Separators Metal Detectors and Pneumatic Ejection

Multi-stage iron removal and metal detection systems are installed at feed inlets to identify and remove metallic contaminants before they enter the mill. Upon detection, automated systems eject the metal or halt operation to prevent impact sparks. This is similar to protection mechanisms in other equipment like the cone crusher, where foreign object damage is a concern.

Passive Protection Measures to Control Explosion Consequences Venting and Isolation

Acknowledging that explosions might still occur despite preventive measures, passive protection

systems are designed to mitigate their effects and minimize damage. These measures focus on containing or safely directing the force of an explosion, protecting both equipment and

personnel. They are typically integrated into the mill structure and ancillary systems to provide a reliable safety net.

Explosion Venting Panel Design and Installation

Venting panels are strategically placed on equipment or ducts to rupture at predetermined pressures, releasing explosion flames and pressure to a safe area outdoors. This rapid pressure relief prevents structural failure of the mill, reducing the risk of projectile damage and containing the incident within designated boundaries.

Explosion Isolation System Chemical and Mechanical Isolation Valves

Fast-acting isolation valves are installed in connecting ducts to prevent flame propagation between equipment pieces, avoiding secondary explosions. These valves close within milliseconds of detecting an explosion, isolating sections of the system and limiting the spread of damage. The concept parallels safety systems in feed size control equipment, where flow must be managed precisely.

Explosion Suppression System

This system detects the initial pressure rise of an explosion and injects fire-suppressing chemicals into the equipment within milliseconds, quenching the reaction before it can develop into a full-scale event. It is an active-passive hybrid that provides rapid response to incipient explosions, often used in high-risk applications.

Explosion Proof Integrated Design in Process Systems and Operational Procedures

Explosion safety is not solely dependent on the mill itself but requires a holistic approach that encompasses the entire processing system and operational practices. Integration involves coordinating equipment design, process parameters, and human factors to create a seamless safety environment. This ensures that all elements work together to prevent incidents and respond effectively if they occur.

Inerting Treatment Using Inert Gases Like Nitrogen for System Protection

Inert gases such as nitrogen are introduced into the system to reduce oxygen concentrations below the limiting oxygen concentration, effectively eliminating the oxidant element of the explosion pentagon. This method provides a fundamental prevention strategy, especially for high-risk materials, by creating an atmosphere that cannot support combustion.

Pressure Shock Resistance Design

Equipment is constructed to withstand specified explosion pressures without rupturing, complying with standards such as ATEX or NFPA. This design ensures that even if an explosion occurs, the mill remains intact, preventing secondary hazards and allowing for safer operation. The structural resilience is akin to that required in the main frame of heavy-duty crushers.

Safety Operating Procedures and Personnel Training

Strict protocols are established for startup, shutdown, cleaning, and maintenance, including hot work permits for any activities that could generate ignition sources. Comprehensive training programs educate operators and maintenance staff on explosion risks and proper response strategies, fostering a culture of safety. Training often covers aspects like discharge size monitoring to ensure product quality and safety are maintained.

Compliance and Certification Adhering to Global Explosion Proof Standards

Adherence to international safety standards is crucial for ensuring that explosion-proof mills meet legal and regulatory requirements across different markets. Certification provides assurance that the equipment has been tested and validated for safe operation under specific conditions. It also facilitates global trade and compliance with local regulations, reducing liability risks.

European ATEX Directive 2014 34 EU and Equipment Certification

This directive sets essential health and safety requirements for equipment intended for use in potentially explosive atmospheres, ensuring a high level of protection across the European Union. Certification under ATEX involves rigorous testing and assessment of the equipment's design and manufacturing processes.

US NFPA 68 Venting and NFPA 69 Explosion Prevention Systems Standards

These standards provide guidelines for the design and installation of explosion venting and prevention systems, focusing on practical measures to mitigate risks in industrial settings. Compliance with NFPA standards is often required for insurance and regulatory approval in the United States.

International Electrotechnical Commission IECEx System Certification

The IECEx scheme offers international certification for equipment used in explosive atmospheres, promoting global harmonization of standards and facilitating cross-border acceptance of certified products. It simplifies the process for manufacturers operating in multiple countries.

Chinese GB Standards and Explosion Proof Certification Requirements

China's GB standards outline specific technical requirements for explosion-proof equipment, and obtaining the requisite certification is mandatory for market access. This ensures that equipment meets national safety benchmarks, similar to other regional regulations. The European-type grinding mill must often comply with these standards when used in relevant markets.