Applications of Fine Crushers in Water Conservancy Project Construction: A High-quality Choice for Crushing River Pebbles

This analysis examines the application of fine crushers in water conservancy projects, particularly focusing on river pebble processing requirements. Water resource management infrastructure projects present unique material processing challenges, with specific quality and performance requirements for construction materials. Fine crushers offer particular advantages in meeting these demands while addressing the practical constraints of project execution. The discussion covers project requirements, equipment selection considerations, operational approaches, and performance expectations in this specialized application area.

Water Conservancy Project Material Requirements

Water conservancy infrastructure including dams, levees, and channel improvements demands particular material specifications ensuring long-term structural integrity and performance. Processed aggregates must demonstrate consistent grading, physical properties, and chemical stability under water immersion conditions. These requirements influence crushing approach selection and equipment configuration to ensure produced materials meet project specifications.

Project scale typically involves substantial material quantities, necessitating equipment with sufficient capacity while maintaining product quality consistency. Environmental considerations often influence equipment selection, with noise, dust, and vibration control becoming important factors in project approval processes. Modern water conservancy projects increasingly emphasize sustainable construction approaches, influencing material sourcing and processing decisions.

River Pebble Characteristics and Processing Considerations

River pebbles present specific characteristics influencing their processing requirements and equipment selection. These naturally rounded stones typically exhibit high hardness and abrasion resistance, challenging conventional crushing approaches. The smooth surface characteristics affect how materials behave during processing, influencing equipment wear and energy consumption patterns.

Size distribution variations in natural deposits require processing equipment capable of handling feed variations while maintaining consistent product quality. Modern fine crusher designs address these challenges through specific features enhancing performance with difficult materials like river pebbles. These include enhanced wear protection, optimized crushing chamber designs, and control systems maintaining performance despite feed variations.

Equipment Selection for River Pebble Processing

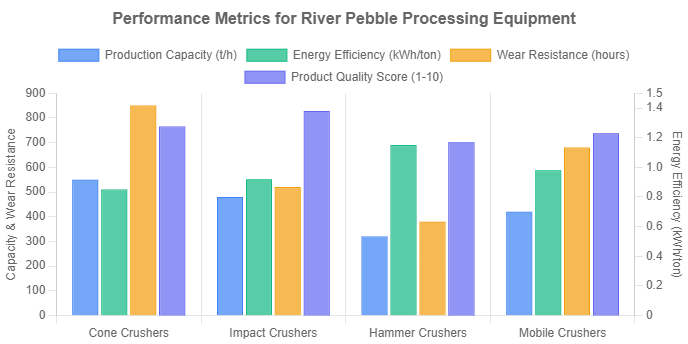

Selecting appropriate fine crushers for river pebble processing begins with thorough material testing and characterization. Hardness measurements, abrasiveness testing, and size distribution analysis provide fundamental data informing equipment selection decisions. Production capacity requirements influence machine size selection, while product specifications determine specific crusher type suitability.

Project duration and mobility requirements influence choices between stationary and mobile crushing solutions. Modern mobile crushers offer particular advantages for water conservancy projects, enabling on-site processing that reduces transportation requirements and associated environmental impact. These systems typically incorporate comprehensive dust and noise control features addressing project environmental requirements.

Operational Practices for River Pebble Crushing

Effective river pebble processing begins with appropriate feed preparation, including removal of oversize materials and potential washing to remove fine particles. Crusher operation optimization involves careful parameter adjustment balancing production rate against product quality requirements. Modern control systems continuously monitor operation, automatically adjusting parameters to maintain optimal performance despite material variations.

Maintenance approaches must address the particularly abrasive nature of river pebble processing. Regular inspection and component replacement according to established schedules prevent unexpected failures and maintain performance consistency. Operational data collection supports continuous improvement efforts, identifying opportunities for enhanced efficiency or reduced maintenance requirements.

Performance Expectations and Benefits

Properly selected and operated fine crushers typically demonstrate excellent performance in river pebble processing applications. Modern equipment consistently achieves production rates exceeding 500 tons per hour while maintaining precise product quality control. Energy consumption typically ranges between 0.5-1.0 kWh per ton of processed material, representing significant efficiency improvements over previous technologies.

Environmental performance metrics including dust emissions and noise levels consistently meet stringent project requirements through integrated control systems. The economic benefits include reduced operational costs through lower energy consumption and maintenance requirements, alongside improved product value through consistent quality meeting project specifications.

Future Development Directions

River pebble crushing technology continues evolving toward greater efficiency and environmental performance. Research focuses on enhanced wear materials better resisting abrasive wear while maintaining mechanical properties. Control system advancements enable more precise operation adaptation to changing material characteristics, optimizing performance throughout project duration.

Integration with project management systems represents another development direction, with crushers providing real-time production data supporting project scheduling and material management. Sustainability considerations drive development of equipment with reduced environmental impact through lower energy consumption and enhanced emission control capabilities.