Essential Stone Crusher Maintenance Strategies for Reliable Operation

This comprehensive guide explores the critical maintenance practices necessary for ensuring the reliable and stable operation of stone crushers. These powerful industrial machines reduce large rocks and minerals into smaller aggregates through mechanical force and require consistent care to maintain optimal performance. We will examine systematic approaches to daily inspections, scheduled maintenance tasks, and effective troubleshooting procedures. The strategies outlined here provide equipment managers with practical knowledge to extend machinery lifespan, prevent unexpected breakdowns, and maintain consistent production quality across various industrial applications.

Daily Inspection Protocols for Stone Crushers

Implementing thorough daily inspections forms the foundation of effective stone crusher maintenance. These routine checks serve as an early warning system, identifying potential issues before they develop into major problems. A comprehensive visual examination of the equipment's exterior and all connection points can reveal signs of wear, misalignment, or loose components that might otherwise go unnoticed during operation.

Regular monitoring of lubrication systems ensures proper protection for all moving parts. Checking oil levels and assessing lubricant quality for contamination prevents excessive friction and wear. Simultaneous observation of electrical system performance indicators and measurement of transmission component temperatures and vibration levels provide valuable data about the machine's operational health and help prevent catastrophic failures.

Scheduled Maintenance Tasks and Intervals

Periodic maintenance involves planned tasks performed at specific intervals to address predictable wear patterns. This proactive approach is particularly important for components within the crushing chamber that experience constant abrasion and impact. Establishing precise replacement cycles for these parts based on operational hours and material processed prevents unexpected failures and maintains consistent product quality.

Routine maintenance must include comprehensive servicing of hydraulic systems, including filter replacement and fluid analysis to ensure optimal performance. Regular adjustment and testing of spring mechanisms and overload protection systems guarantee the crusher can safely handle unexpected hard materials. Complete equipment cleaning and application of anti-corrosion treatments protect against environmental damage and preserve structural integrity.

Common Failure Types and Root Cause Analysis

Stone crusher failures typically fall into mechanical, electrical, and hydraulic categories. Mechanical issues often manifest through unusual noises, reduced throughput, or visible damage to crushing components. These problems frequently originate from abrasive wear, improper material feed, or incorrect operational parameters that stress the equipment beyond its design limitations.

Electrical system failures may involve motor malfunctions or control circuit disruptions that halt operations completely. Hydraulic complications such as leaks or pressure irregularities often stem from seal degradation or pump inefficiencies. Understanding the relationship between operating conditions, material characteristics, and failure modes is essential for effective problem resolution and prevention.

Systematic Troubleshooting Procedures

Effective troubleshooting begins with meticulous documentation of all observed symptoms and the conditions present during failure. This detailed record-keeping establishes a factual foundation for analysis and prevents reliance on memory or assumptions. A methodical approach progresses from examining the simplest potential causes to investigating more complex system interactions, ensuring no aspect is overlooked during the diagnostic process.

Proficient use of diagnostic tools, ranging from basic measurement instruments to advanced vibration analyzers, enables accurate identification of underlying issues. Following any repair intervention, comprehensive testing under controlled conditions verifies the effectiveness of the solution and confirms the equipment has returned to its specified operational parameters and production capacity.

Maintenance Data Management and Analysis

Maintaining detailed and standardized maintenance records transforms reactive repair approaches into predictive management strategies. These historical records provide invaluable insights into component life cycles, failure patterns, and maintenance effectiveness. Well-structured documentation should include comprehensive details of all inspections, parts replacements, operational parameters, and environmental conditions.

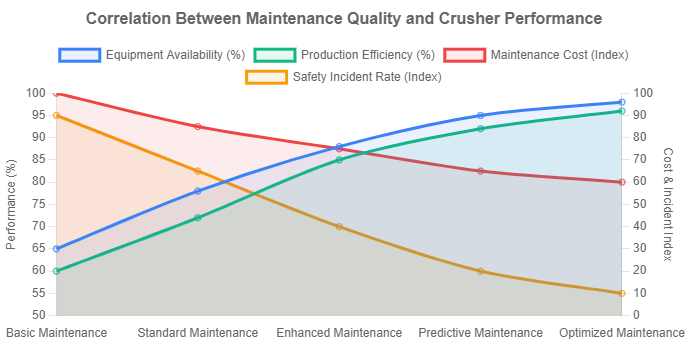

Analyzing maintenance data over time reveals trends and patterns that enable accurate prediction of potential failures. This data-driven approach allows for optimization of maintenance schedules, reduction of spare parts inventory costs, and significant improvement in overall equipment efficiency. Implementing a digital database system facilitates efficient data access, analysis, and reporting, supporting continuous improvement in maintenance practices.

Developing Professional Maintenance Teams

The competence and expertise of maintenance personnel directly influence stone crusher reliability and performance. Investing in comprehensive training programs ensures team members develop proficiency in modern diagnostic techniques and repair methodologies. This training should encompass specific equipment types used in the operation, including various jaw crusher configurations and their maintenance requirements.

Creating an organizational culture that values knowledge sharing and practical experience exchange significantly enhances collective problem-solving capabilities. Establishing clear performance incentives and recognition systems fosters increased motivation and responsibility among maintenance staff. Regular engagement with equipment manufacturers and participation in industry forums provides access to valuable technical insights and emerging best practices, further elevating team competencies and ensuring long-term operational excellence in mining operations and other applications.