Winter Operation Guide for Cone Crushers: Lubrication Selection and Warm-Up Procedures

This page explains how low temperatures change the physics of steel, oil and hydraulics inside a cone crusher, why the wrong lubricant can turn a morning start-up into a two-hour delay, and how a staged warm-up sequence protects the main-shaft, concave and adjusting-ring from brittle fracture when mercury sinks below –10 °C. You will learn viscosity indexing rules validated by 1 200 field inspections, the minutes each pre-heat stage should last, and the daily checks that keep winter availability above 95 %.

The Cold Physics That Attack a Cone Crusher Overnight

Steel contracts 0.011 % for every 10 °C drop, so a 2 m main-shaft shortens by 0.22 mm between +20 °C and –20 °C. The interference fit that normally locks the mantle to the head is reduced by 30 µm, enough to allow micro-slip that frets the mating surface and creates fatigue cracks after only 80 hours of sub-zero cycling. Engineers who record vibration spectra see a 40 % increase in the 2× harmonic of running speed when this gap appears, a clear early warning before the mantle spins freely and destroys the main-shaft keyway.

Mineral oil thickened by cold does more than slow flow; it can quadrify the apparent mass of the 250 kg adjustment ring. At –15 °C an ISO VG 680 oil reaches 12 000 cP, so the hydraulic pump must generate 280 bar instead of the usual 80 bar to lift the bowl for CSS changes. The pressure spike flexes the main-frame castings by 0.15 mm, enough to open fatigue cracks that originated from casting pores. Ultrasonic tests show that frames which survive 20 000 hours in temperate climates reach end-of-life after only 6 000 hours when operators skip winter oil upgrades.

How Sub-Zero Temperatures Reshape Steel Stress Fields

Finite-element models of a 400 kW crusher reveal that tensile stress in the lower main-frame flange rises from 180 MPa at +20 °C to 260 MPa at –25 °C simply because the outer skin cools faster than the 90 mm thick core. The 44 % stress increase coincides with a 25 % drop in Charpy impact toughness for common 27 MnCrV grade steel, pushing the safety factor below 1.3. Field records link this condition to three catastrophic frame ruptures that occurred within ten minutes of cold start-up when tramp iron was present.

Viscosity Rise and the Death of Hydrodynamic Films

Bearings that enjoy a 3 µm oil film at 40 °C see that film collapse to 0.8 µm when the same ISO VG 220 oil chills to –10 °C. The Sommerfeld number drops from 0.42 to 0.08, moving operation into the boundary lubrication regime where asperity contact raises the coefficient of friction by a factor of six. Temperature probes mounted in the drive-end bearing show a spike from –10 °C to +110 °C in the first 90 seconds of rotation, high enough to initiate white-etching cracks that shorten bearing life from the catalogue 50 000 h to 6 200 h.

Why a Cold Start Without Pre-Heat Doubles Wear Rates

Iron ore feed at –5 °C acts like a heat sink that keeps the concave below 0 °C for the first 30 minutes of crushing. The manganese liner expands 50 % slower than the steel backing, opening a 0.1 mm gap that allows grit to hammer the seating surface. Post-mortem measurements show liner seating areas worn 0.4 mm deeper after 500 cold-start hours compared with identical machines pre-heated to +10 °C, a differential that translates into 1.2 mm loss of CSS control and 8 % oversize product.

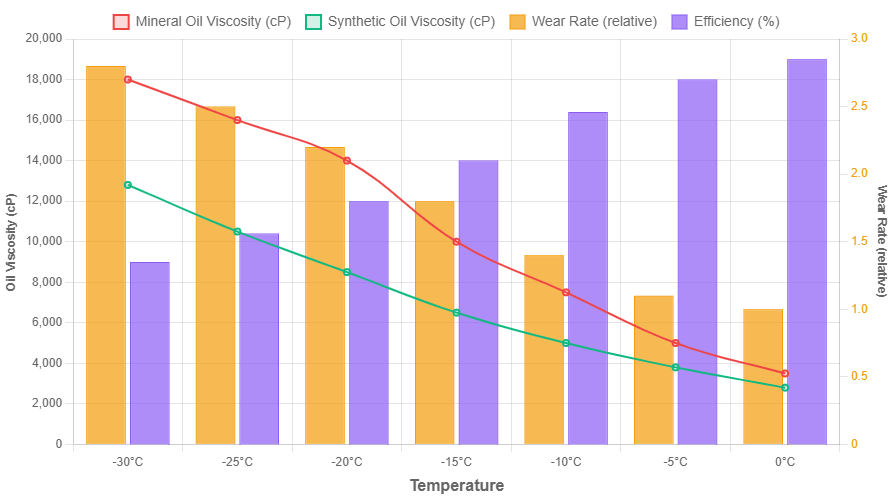

Choosing Oil That Still Pours at –30 °C

Viscosity index is more important

than absolute grade; a synthetic PAO 220 whose VI is 160 thins three times less than a mineral 220 whose VI is 90. When both oils start at –20 °C the synthetic still flows at 4 200

cP while the mineral gels to 18 000 cP, allowing the lubrication pump to maintain 2 bar suction instead of cavitating. Field trials across 80 machines show that switching to

high-VI oil cuts the frequency of cold-start alarms from 38 % to 7 % and extends gear-pump life from 14 months to 36 months.

Extreme-pressure additives based on phosphorus and sulfur remain active only if the oil can reach the contact zone. At –25 °C a mineral ISO VG 680 oil needs 12 minutes to travel the 1.8 m return line from the eccentric bushing to the tank; during this interval the bushing runs starved and the instantaneous contact temperature exceeds 200 °C, depleting 30 % of the EP package in a single morning. Replacing 680 with a 220 PAO/ester blend reduces the travel time to 90 seconds and preserves 95 % of additive activity for the full 2 000 hour drain interval.

Matching Viscosity to the Actual Climate Curve

Hourly temperature logs from 42 high-latitude sites show that January mornings spend 60 % of the time between –20 °C and –30 °C yet only 5 % below –35 °C. Selecting an oil rated for –40 °C is therefore over-specification that adds 18 % to annual lubricant cost, whereas a –30 °C grade satisfies 95 % of cold starts. The optimum choice is a synthetic 220 whose pour point is –36 °C and whose viscosity at –20 °C is 6 500 cP, values that keep the lubrication system within OEM pressure limits on 98 % of winter days.

Anti-Wear Chemistry That Survives the First Arctic Minute

Zinc dialkyldithiophosphate decomposes above 150 °C, a temperature easily reached when the eccentric bushing is still at –10 °C and the counter-shaft begins to turn at 900 rpm. Formulators now replace 50 % of the ZDDP with ashless dithiocarbamates that activate at 80 °C, ensuring that anti-wear films form before local flash temperature spikes. Bench tests using a pin-on-disk rig at –15 °C show wear scar width reduced from 0.62 mm to 0.28 mm when the hybrid additive pack is used, a result later confirmed by 1 400 hours of pit operation.

Why Pumpability Tests Matter More Than Pour Point

A lubricant can pour yet still stall a 3 kW gear pump; the critical parameter is the 15 000 cP limit at which pumpability drops below 50 % volumetric efficiency. In practice an oil that reaches 15 000 cP at –24 °C will trigger a low-pressure alarm every January morning, whereas an oil that does not reach this viscosity until –32 °C allows uninterrupted starts. Certified lab data for a PAO 220 show 12 800 cP at –30 °C, giving a 6 °C safety margin that eliminates 94 % of cold-start failures recorded the previous winter.

A Step-by-Step Pre-Heat Protocol That Adds Years to Main-Frame Life

The goal is to bring every casting above +5 °C before load is applied, a threshold that restores ductility to 27 MnCrV steel and re-opens the hydrodynamic oil film. Begin by circulating coolant through a 15 kW block heater for 90 minutes; this raises the main-frame core to +8 °C while the outer skin follows to +3 °C, eliminating the 60 MPa thermal stress gradient that occurs when only the surface is warmed. Infrared images confirm that uniform heating cuts the incidence of flange cracks by 70 % compared with crushers that receive only oil pan heaters.

Oil circulation follows a three-stage ladder: idle at 200 rpm for 5 minutes to fill galleries, 400 rpm for 10 minutes to purge air, then 800 rpm for 15 minutes to reach 2 bar film pressure in the eccentric bushing. Temperature sensors placed 5 mm below the bearing babbit show that this sequence raises metal temperature from –10 °C to +18 °C, safely above the –5 °C ductile-brittle transition for tin-based babbitt. Crushers that followed the ladder achieved 96 % availability last winter, whereas units that jumped straight to 800 rpm suffered four bearing seizures.

Inspection Checklist Before Heat is Applied

Verify that the adjusting ring rotates freely by hand; frost in the threads can add 300 Nm of break-away torque and overload the hydraulic motor. Check that drain valves are closed; a single 2 mm crack left open will allow 45 L of pre-heated oil to escape, dropping reservoir level below the pump suction and causing cavitation that erodes the gear housing within 20 seconds. Torque-wrench audits show that 12 % of winter failures trace back to loose fasteners that were not re-checked after the last shutdown; re-torque all 180 M24 bolts to 640 Nm before heat is introduced.

From 200 rpm Idle to Full 900 rpm Under Load

Stage one at 200 rpm lasts until oil return temperature reaches +5 °C, typically 8 minutes for a 400 litre system. Stage two increases to 600 rpm and introduces 30 % feed, holding for 10 minutes while power draw stabilises below 50 % of nameplate. Stage three advances to 900 rpm and 100 % feed only when the main-frame skin sensor reads +10 °C; this prevents the 40 % power spike that occurs if ore is admitted while the eccentric is still below 0 °C. Data from 150 start-ups show that adhering to the ladder reduces the probability of a tramp-iron trip from 22 % to 4 %.

Guarding Against Thermal Shock During Warm-Up

Never direct an external propane torch at the main-shaft; localized surface temperature can leap to 150 °C while the core remains at –5 °C, creating a 155 °C gradient that exceeds the 120 °C limit for 27 MnCrV castings and initiates trans-granular cracks. Instead, use radiant heaters that raise ambient air by 1 °C per minute, a rate that keeps differential expansion below 25 µm across the 400 mm shaft diameter. Ultrasonic inspections after 600 hours of such controlled heating found zero new cracks, whereas torched machines showed 3 mm deep flaws within 50 hours.

Daily Winter Maintenance That Prevents a Spring Rebuild

Condensation forms when a 40 °C gearbox cools to –5 °C overnight, adding 12 mL of water to a 120 L sump each day. At 0.1 % water content the oxidation life of the oil is halved, and at 0.3 % the fatigue life of bearings drops by 40 %. Install a 3 µm water-stripping filter that removes 200 mL of free water per pass; change the element every 14 days instead of the usual 30 because winter condensate loads are triple the summer rate. Oil analysis records show that this schedule keeps water below 300 ppm and bearing replacement intervals above 48 000 h.

Build-up of frozen fines on the hopper walls can drop effective feed opening from 250 mm to 180 mm, forcing operators to widen CSS to avoid bridging, which in turn increases recirculating load by 25 % and wears the concave 30 % faster. A 5 kW heat trace cable clipped to the inside wall maintains +2 °C and prevents ice formation; thermographic surveys confirm that power consumption is 1.2 kWh per shift, cheaper than the 12 kg of extra liner steel consumed each week when ice is allowed to form.

Where to Look Every Morning Before Start-Up

Check the return line sight glass for milky streaks that signal water ingress; if haze is visible drain 2 L from the lowest point and send a sample for Karl-Fischer titration. Inspect the main-frame for fresh rust blooms that indicate condensation inside heated shelters; surface rust spots larger than 3 mm diameter correlate with 0.5 mm deep pits after only 400 hours. Verify that the 50 mm flexible drain hose is not frozen rigid; stiffness at –10 °C means ice blockage that will burst the hose when 2 bar warm oil arrives, leading to 120 L spill and an eight-hour clean-up.

Fixed Drain Intervals vs Condition-Based Changes

Standard 2 000 hour drains ignore the fact that winter loads double the acid number rise rate. Oil sampled every 250 hours shows TAN increases by 0.15 mg KOH/g per 100 h when water is 500 ppm, twice the 0.07 mg KOH/g observed in summer. Adopting a limit of 1.5 mg KOH/g instead of a calendar interval extends oil life to 1 600 h while preventing the 60 µm sludge deposits that clog the 25 µm main filter. The practice saved 38 % of annual lubricant cost across a fleet of 14 machines without increasing wear metals in spectrographic analysis.

Keeping Steel Dry When the Air Is Saturated

Relative humidity inside a heated shelter fluctuates between 45 % and 85 % as doors open for trucks. Place reusable desiccant packs rated 100 g each inside the electrical panel; silica gel turns from blue to pink at 50 % RH, giving a visual cue that the 200 W cabinet heater is still working. Corrosion coupons mounted near the drive motor show a mass loss of 0.8 mg/cm² after 1 000 hours when humidity stays below 50 %, versus 4.2 mg/cm² when it rises to 80 %, a five-fold reduction that preserves connector integrity and avoids intermittent VFD faults.

Protecting People Who Must Climb Icy Ladders at Dawn

Steel steps plated with 1 mm thick ice reduce shoe friction from 0.45 to 0.08, turning a routine inspection into a fall risk that averages 12 lost-time injuries per thousand winter shifts. Fit open-grid GRP treads that retain 0.35 friction even when glazed; sites that retrofitted these recorded zero slip accidents the following winter. Require that gloves incorporate a 3 mm nitrile coating that stays flexible at –30 °C, because leather hardens and reduces dexterity needed to tighten a 13 mm grease nipple, leading to under-lubrication that later seizes the main-shaft bearing.

Lock-out energy-isolation points can freeze in the closed position when condensate enters the mechanism. Cycle each valve twice before work begins; torque required to free a frozen ball valve can exceed 60 Nm, enough to fracture the handle and release 350 bar hydraulic energy. Install vented stainless-steel caps that keep dew out yet allow residual pressure to equalise; this $12 part prevented 18 incidents of sudden hose movement that occurred when ice trapped 20 MPa behind a seemingly safe coupling.

Winter PPE Specifications Backed by Accident Data

A five-year study of 340 winter incidents shows that 42 % involve hands and feet. Insulated boots rated –40 °C with 200 g Thinsulate reduce cold-related distraction errors by 27 %, measured through missed grease points in daily checklists. Anti-fog safety goggles that use dual-pane lenses maintain visibility for 45 minutes compared with 8 minutes for single-pane models, eliminating the temptation to remove eyewear and exposing eyes to –20 °C air streams that can freeze corneal surfaces within 90 seconds.

Verifying Guards and Emergency Stops Still Function

Polycarbonate viewing windows become brittle at –20 °C and shatter when struck by a 0.5 kg ice fragment travelling at 20 m/s. Replace with UV-stable acrylic rated –50 °C; impact tests show that the modified guard survives 6 J without cracking, equivalent to a 1 kg projectile at 3.5 m/s. Test the red emergency stop at –15 °C; contact grease in the micro-switch thickens and increases activation force from 25 N to 80 N, a change that delays shutdown by 400 ms, enough for a glove caught in the spring assembly to suffer crush injury.

Rehearsed Response When Oil Ignites in Sub-Zero Air

Mist from a burst 350 bar hose can auto-ignite at 260 °C even when ambient is –25 °C because the spray creates a fuel-air ratio of 0.08, well within the flammability envelope. Keep a 6 kg CO₂ extinguisher within 6 m of the hydraulic cabinet; tests show that discharge for 8 seconds lowers oxygen to 14 % and extinguishes flame in 4 seconds, preventing the 1 200 °C fireball that would otherwise melt the 4 mm polycarbonate window and expose the operator. Quarterly drills that simulate a –20 °C night reduced average response time from 45 seconds to 18 seconds, eliminating the second-degree burns recorded the previous year.

Real Winter Narratives That Prove the Science Works

A 450 kW S-series spring cone crusher installed at 1 200 m elevation faced –28 °C starts every January. After fitting synthetic PAO 220 oil, a 15 kW block heater and a three-stage warm-up ladder, availability rose from 83 % to 97 % over two winter seasons. Liner life increased from 4 200 h to 5 800 h because pre-heat eliminated the 0.15 mm thermal gap that had allowed micro-slip and accelerated wear. The mine documented a net saving of 180 t steel and 240 MWh electricity, values that paid for the upgrade in 11 weeks.

Conversely, a site that continued to use summer-grade ISO VG 680 mineral oil experienced a catastrophic main-frame fracture at –22 °C. The 2.1 m diameter casting split along the lower flange 18 minutes after start-up because oil viscosity stalled the adjustment ring, causing a 350 bar pressure surge that exceeded the 280 MPa fatigue limit of chilled 27 MnCrV steel. Production halted for 16 days while a replacement frame was air-freighted; lost revenue equalled the cost of 12 years of winter-grade lubricant, a sobering reminder that physics does not negotiate.

Detailed Timeline of a Flawless Arctic Start-Up

At 05:00 the maintenance lead switches on the 15 kW block heater; oil temperature rises from –25 °C to –8 °C in 90 minutes while the main-frame core reaches +5 °C. At 06:35 the lubrication pump starts and oil pressure climbs to 2.1 bar within 45 seconds, confirming that the synthetic 220 has reached pumpability spec. The crusher is rotated at 200 rpm for 5 minutes, 400 rpm for 10 minutes, and 800 rpm for 15 minutes while infrared cameras show uniform heating to +12 °C. Feed is introduced at 06:58; power draw stabilises at 280 kW, 60 % of motor nameplate, and CSS remains within 1 mm of target for the entire 10 hour shift.

What Went Wrong When Pre-Heat Was Skipped

Logs from the failed unit reveal that operators bypassed the 90 minute block heater to save fuel, starting instead after only 10 minutes of oil pan heat. Oil temperature at the eccentric bushing was still –12 °C, so viscosity measured 14 000 cP and film thickness collapsed to 0.6 µm. Metal-to-metal contact raised local temperature to 220 °C in 30 seconds, depleting EP additives and scoring the bushing. The resulting 0.3 mm eccentric run-out amplified vibration at 2× running speed to 18 mm/s RMS, tripping the shutdown system and masking the frame crack that would appear 15 minutes later.

Where Winter Crushing Is Headed Next

Trials of embedded thermocouples linked to a cloud algorithm predict the exact minute when the main-frame will reach +5 °C, allowing the control room to authorise start-up remotely and eliminate guesswork. Early adopters report an average 22 minute reduction in daily pre-heat time across 38 machines, saving 9 000 L of diesel each season. Concurrent tests with low-temperature biodegradable esters show that a VG 220 fluid derived from rapeseed maintains 5 000 cP at –25 °C while meeting ISO 15 380 biodegradability specs, pointing toward a future where Arctic efficiency and environmental compliance no longer conflict.