Cone Crusher Troubleshooting and Maintenance: A Practical Guide

This comprehensive manual provides detailed guidance on identifying and resolving common operational issues in cone crushers. It systematically addresses mechanical failures, electrical system malfunctions, hydraulic complications, and lubrication problems that may occur during equipment operation. The guide offers practical solutions based on engineering principles and field experience, enabling operators to maintain optimal crusher performance and minimize downtime. By understanding these troubleshooting techniques, maintenance personnel can effectively extend equipment lifespan and ensure consistent production quality in various crushing applications.

Common Mechanical Fault Diagnosis and Resolution

Mechanical issues represent some of the most frequent challenges in cone crusher operation, often manifesting through abnormal vibrations, reduced crushing force, or irregular product sizing. These problems typically originate from component wear, improper adjustments, or structural imbalances that develop over time. Early detection and proper diagnosis are crucial for preventing minor issues from escalating into major equipment failures that require extensive repairs and prolonged downtime.

Regular inspection protocols form the foundation of effective mechanical maintenance, allowing operators to identify potential problems before they impact production. Through systematic monitoring of vibration patterns, crushing force measurements, and product quality indicators, maintenance teams can develop predictive maintenance schedules that address issues during planned shutdowns. This proactive approach significantly reduces unplanned downtime and maintains consistent operational efficiency throughout the equipment's service life.

Excessive Equipment Vibration Analysis

Unbalanced rotating components represent a primary cause of excessive vibration in cone crushers. These imbalances often develop gradually as wear occurs unevenly on crusher components, particularly the mantle and concave surfaces. When the rotational mass becomes unevenly distributed, it generates centrifugal forces that translate into measurable vibration patterns. Modern monitoring systems can detect these imbalances early, typically when vibration velocities exceed 4.5 millimeters per second, allowing for corrective action before damage occurs.

Bearing wear contributes significantly to vibration issues, as deteriorated bearing surfaces create excessive clearance between rolling elements and raceways. This wear pattern allows for component movement beyond design parameters, generating impact forces that manifest as high-frequency vibrations. Advanced condition monitoring systems track bearing health through vibration frequency analysis, often detecting degradation months before complete failure occurs. Regular lubrication maintenance and proper installation techniques can extend bearing life by up to thirty percent in typical operating conditions.

Insufficient Crushing Force Solutions

Hydraulic system pressure deficiencies frequently cause inadequate crushing force in modern cone crushers. The hydraulic system must maintain specific pressure levels, typically between 25-35 megapascals, to generate sufficient crushing force for various materials. Pressure drops below this range indicate potential issues with hydraulic pumps, pressure relief valves, or accumulator systems that require immediate attention. Regular pressure testing and system calibration ensure consistent crushing performance across different material types and operating conditions.

The crushing chamber configuration significantly influences force transmission and crushing efficiency. Worn chamber components, particularly mantles and concaves, reduce the effective compression ratio and diminish crushing force application. Modern crushers incorporate chamber design optimization through computer modeling, ensuring optimal force distribution throughout the crushing process. Regular inspection and timely replacement of wear parts maintain crushing efficiency and prevent gradual performance degradation that might otherwise go unnoticed until production quality suffers.

Irregular Discharge Size Adjustment Strategies

The discharge opening setting directly determines maximum product size but requires precise adjustment to maintain consistency. Mechanical wear on adjustment components can cause setting drift during operation, leading to gradual product size variation. Modern crushers incorporate hydraulic setting adjustment systems that maintain precise control over the discharge opening, typically within ±2 millimeter accuracy throughout operation. These systems automatically compensate for wear, ensuring consistent product size despite changing conditions.

Crushing chamber wear patterns significantly influence product gradation by altering the effective compression ratio and material flow path. As wear progresses, the chamber geometry changes, affecting the inter-particle compression action that produces cubical product shapes. Regular chamber inspections and proactive wear part replacement maintain optimal crushing action and product quality. Advanced monitoring systems track chamber wear rates, predicting replacement intervals with over ninety percent accuracy based on actual production data rather than simple operating hours.

Equipment Overheating Causes and Treatment

Lubrication system failures represent a primary cause of operational overheating in cone crushers. Inadequate oil flow, typically below 40 liters per minute for medium-sized crushers, prevents proper heat dissipation from bearings and other critical components. Oil contamination accelerates temperature rise by reducing lubricity and increasing friction between moving parts. Regular oil analysis programs detect contamination early, allowing for corrective action before temperature issues develop into component failures.

Cooling system design directly impacts operational temperature control through heat exchange efficiency. Air-cooled systems require clean fin surfaces and adequate airflow, while water-cooled systems depend on proper coolant flow and heat exchanger integrity. Modern crushers incorporate temperature monitoring at multiple points, triggering alarms when temperatures exceed safe operating limits, typically above 85 degrees Celsius for bearing locations. Proper maintenance of cooling systems maintains operational temperatures within optimal ranges, extending component life and preventing thermal degradation of lubricants.

Electrical System Fault Diagnosis and Resolution

Electrical system malfunctions can paralyze cone crusher operations despite mechanical soundness, requiring systematic troubleshooting approaches. These issues range from simple power supply interruptions to complex control system failures that demand specialized diagnostic equipment. Understanding electrical system fundamentals enables maintenance personnel to quickly identify problems and implement appropriate solutions, minimizing production interruptions and preventing secondary damage to electrical components.

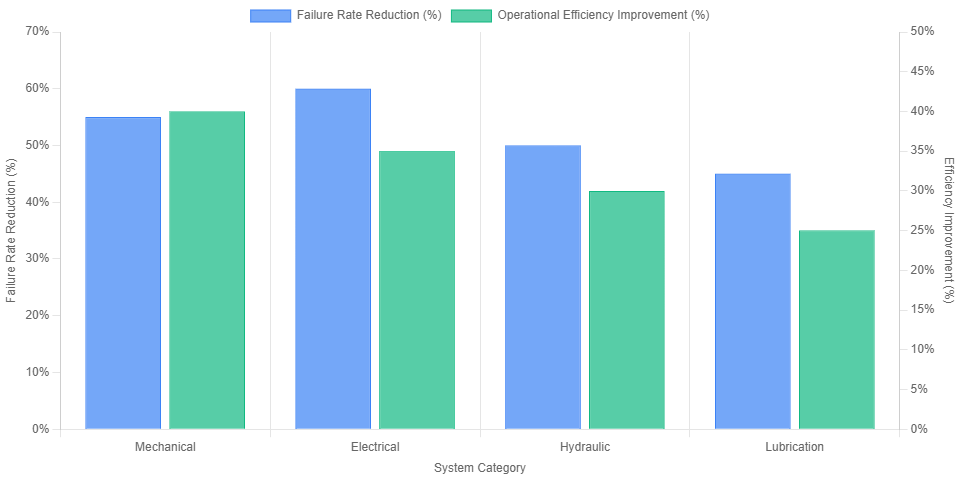

Modern crushers incorporate sophisticated electrical control systems that monitor and regulate all operational aspects, from motor performance to lubrication flow. These systems generate valuable diagnostic data that technicians can use to pinpoint developing issues before they cause operational disruptions. Regular electrical system inspections, including connection integrity checks and insulation resistance testing, form the foundation of reliable operation. Proper maintenance procedures reduce electrical failures by up to sixty percent compared to reactive repair approaches.

Motor Starting Failure Troubleshooting Steps

Power supply quality significantly influences motor starting reliability, with voltage drops during startup often preventing successful engagement. Three-phase systems must maintain voltage balance within two percent and proper phase rotation to ensure smooth motor operation. Starting current requirements, typically 600-700% of full load current, demand adequate power supply capacity to prevent voltage sag that could trigger protection devices. Regular power quality monitoring identifies developing issues before they cause operational problems.

Internal motor faults develop gradually through insulation degradation, bearing wear, or winding contamination that eventually prevents normal operation. Insulation resistance testing, typically showing values above 100 megohms for healthy motors, provides early warning of developing problems. Bearing vibration analysis detects mechanical issues before they cause rotor-stator contact or complete seizure. Scheduled motor maintenance including cleaning, lubrication, and electrical testing prevents unexpected failures and extends operational life beyond typical design expectations.

Control Cabinet Fault Identification and Repair

Control component failures disrupt crusher operation by interrupting signal processing or power distribution within the control system. Modern cabinets contain numerous relays, contactors, and programmable controllers that require periodic inspection and testing. Thermal imaging surveys identify overheating components before complete failure occurs, while contact resistance measurements ensure proper current carrying capacity. Preventive replacement of aging components based on service hours rather than failure occurrence significantly improves system reliability.

Repair methodology selection depends on fault nature, with component-level repairs appropriate for simple issues and module replacement recommended for complex integrated circuits. Proper tool selection including multimeters, insulation testers, and communication interface devices enables efficient diagnosis and repair. Static protection measures prevent damage to sensitive electronic components during maintenance activities. Documentation of repairs and component replacements creates valuable historical data for predicting future maintenance requirements and optimizing spare parts inventory.

Cable and Connector Fault Detection Methods

Insulation integrity directly impacts electrical safety and system reliability by preventing ground faults and short circuits. Megohmmeter testing measures insulation resistance, with values below 5 megohms indicating potential moisture intrusion or thermal degradation. Regular infrared inspections identify overheating connections before they cause complete failure, particularly at termination points where resistance increases develop over time. Proper installation techniques including strain relief and environmental protection maintain connection integrity throughout equipment vibration and environmental challenges.

Detection equipment selection ranges from basic continuity testers to sophisticated time-domain reflectometers that pinpoint exact fault locations along cable runs. Connection resistance measurements identify developing problems at termination points, with values exceeding 10 microhms per connection indicating need for cleaning or retightening. Environmental sealing integrity prevents moisture intrusion that accelerates insulation degradation, particularly in outdoor installations or high-humidity environments. Scheduled connection maintenance including cleaning and retorquing prevents most connection-related failures.

Electrical System Overload Protection Measures

Overload protection devices prevent equipment damage by interrupting power during excessive current conditions that could overheat conductors and insulation. Thermal-magnetic circuit breakers provide both instantaneous short circuit protection and time-delayed overload protection based on current-time characteristics. Proper coordination between protection devices ensures selective operation where only the device closest to the fault interrupts, maintaining power to unaffected systems. Regular testing verifies protection device operation within specified time-current characteristics.

Protection system implementation requires careful calculation of operating parameters based on actual equipment characteristics rather than nameplate ratings alone. Motor starting characteristics particularly influence protection settings, requiring allowances for high starting currents without nuisance tripping. Verification testing confirms proper operation under simulated fault conditions, ensuring protection when needed while avoiding unnecessary interruptions. Coordination studies analyze protection device operation sequences, optimizing response times to minimize damage while maintaining maximum system availability.

Hydraulic System Fault Diagnosis and Resolution

Hydraulic system performance directly influences crushing efficiency through pressure regulation, setting adjustment, and overload protection capabilities. These complex systems combine mechanical, electrical, and fluid power components that require integrated troubleshooting approaches. Understanding hydraulic principles enables technicians to diagnose issues systematically rather than through component replacement trials, reducing downtime and maintenance costs while improving repair quality.

Modern crusher hydraulic systems operate at high pressures, typically between 20-35 megapascals, demanding precision components and clean hydraulic fluid for reliable operation. Contamination control represents the most critical maintenance aspect, with particle ingress causing rapid component wear and performance degradation. Regular fluid analysis programs monitor contamination levels, additive depletion, and water content, allowing proactive maintenance before system performance suffers. Proper filtration maintenance maintains fluid cleanliness at ISO 18/16/13 or better, extending component life and maintaining system reliability.

Hydraulic System Pressure Deficiency Solutions

Hydraulic pump performance degradation gradually reduces system pressure through internal wear that diminishes volumetric efficiency. Flow testing at specified pressures identifies pump condition, with output reductions exceeding ten percent indicating need for repair or replacement. Pressure compensation mechanisms maintain output stability despite viscosity changes from temperature variations, but cannot compensate for mechanical wear internal to the pump. Regular hydraulic oil analysis detects wear metals from pump components, providing early warning of developing issues.

Pressure regulation valves require periodic adjustment and testing to maintain proper system pressure settings. Sticking valves or contaminated pilot passages cause erratic pressure control that impacts crushing force consistency. Pressure transducer calibration verifies measurement accuracy, ensuring control systems respond appropriately to actual system conditions. Flow control valves regulate operation speed while pressure sequence valves ensure proper actuation timing between different hydraulic functions. Comprehensive testing during scheduled maintenance identifies developing issues before they affect production quality.

Hydraulic Fluid Leak Detection and Repair

Leakage points impact system performance by reducing operating pressure and potentially introducing contamination into the hydraulic circuit. External leaks manifest as fluid accumulation while internal leaks require pressure testing and flow measurement for detection. Pressure decay tests identify internal leakage paths, with acceptable rates typically below 5% of system volume per minute. Ultrasonic detection equipment pinpoints external leakage sources even when visual observation proves difficult due to component arrangement or environmental conditions.

Repair methodology depends on leakage type and location, with seal replacement addressing most external leaks and component refurbishment required for internal leakage issues. Proper seal selection considers fluid compatibility, pressure ratings, and temperature ranges while installation techniques prevent damage during assembly. Connection retorquing after initial operation addresses relaxation effects that can develop leaks at flange connections. Systematic approach to leak repair prevents recurrent problems and maintains system integrity throughout operational cycles.

Hydraulic Pump Fault Identification and Replacement

Pump performance deterioration affects overall system operation through reduced flow rates and diminished pressure capabilities. Flow measurements at various pressures identify pump condition, with performance drops exceeding fifteen percent indicating need for attention. unusual noise patterns including cavitation sounds or bearing rumble provide audible indications of developing problems. Vibration analysis detects bearing wear or shaft misalignment before catastrophic failure occurs, allowing planned rather than emergency repairs.

Replacement procedures require careful attention to alignment, coupling condition, and drive system integrity to prevent premature failure. Proper reservoir cleaning before component installation prevents immediate contamination of new components. System flushing removes debris generated during failure, protecting new components from damage. Priming procedures ensure proper lubrication during initial operation while run-in periods allow new components to settle before full operational loading. Documentation of replacement activities including serial numbers and installation dates facilitates future maintenance planning.

Hydraulic System Overheating Treatment Strategies

Cooling system capacity directly influences hydraulic fluid temperature through heat exchange efficiency. Air-cooled radiators require clean fins and adequate airflow while water-cooled heat exchangers need proper coolant flow and cleanliness. Temperature differential measurements across heat exchangers identify performance degradation, with reduced differences indicating fouling or flow problems. Bypass conditions allow fluid to circumvent cooling elements when thermostatic controls malfunction, causing rapid temperature rise during operation.

Overheating consequences include accelerated fluid degradation, reduced viscosity, and diminished lubrication properties that accelerate component wear. Temperature monitoring at multiple system points identifies heat generation sources, allowing targeted corrective actions. Flow restrictions in return lines or clogged filters cause excessive backpressure that generates heat through fluid compression. Proper system design maintains operating temperatures below 65 degrees Celsius, preventing thermal damage to seals and fluid degradation that would otherwise occur at higher temperatures.

Lubrication System Fault Diagnosis and Resolution

Lubrication system integrity ensures proper equipment operation by reducing friction, dissipating heat, and preventing corrosion in moving components. These systems range from simple splash lubrication to complex forced-feed systems with filtration and cooling capabilities. Understanding lubrication principles enables maintenance personnel to identify developing issues through oil analysis, temperature monitoring, and performance observation before equipment damage occurs.

Modern crusher lubrication systems incorporate multiple protection features including flow indicators, temperature sensors, and pressure switches that monitor system performance continuously. Automatic protection systems can shutdown equipment before damage occurs when lubrication problems develop. Regular oil analysis programs provide the most effective monitoring method, detecting wear metals, contamination, and additive depletion months before symptoms become apparent through equipment performance or inspection. Proper maintenance extends component life significantly while reducing unexpected failures.

Insufficient Lubricant Level Replenishment Methods

Oil level deficiency accelerates equipment wear by reducing heat dissipation capacity and compromising lubrication film integrity between moving surfaces. Level monitoring systems provide continuous indication, with automatic alarms activating when levels drop more than ten percent below optimum. Visual inspection methods complement automated systems, particularly for detecting foam formation or emulsion conditions that might not trigger level alarms. Scheduled lubrication checks during shift changes provide early detection of developing leakage or consumption issues.

Replenishment procedures require careful attention to oil type compatibility, cleanliness during transfer, and proper filling rates to prevent aeration. Volume-based replenishment records help identify abnormal consumption rates that indicate developing leakage or internal ingestion problems. Filter inspection after replenishment detects contamination introduced during the filling process, allowing corrective action before system circulation distributes contaminants throughout the lubrication system. Documentation of replenishment activities including dates, quantities, and oil types facilitates consumption trend analysis.

Lubricant Degradation Identification and Replacement

Oil quality deterioration diminishes lubricating properties through additive depletion, viscosity change, or contamination accumulation that reduces protective capabilities. Regular oil analysis programs monitor key parameters including viscosity, acid number, and water content, providing objective data for replacement decisions. Visual inspection identifies obvious problems including discoloration, sludge formation, or emulsion conditions that require immediate attention regardless of scheduled maintenance intervals.

Replacement interval determination considers operational hours, environmental conditions, and crusher loading characteristics rather than following fixed time periods. Used oil analysis provides the most accurate replacement timing, with key indicators including additive depletion below fifty percent of original levels or contamination exceeding ISO cleanliness code limits. Complete system flushing removes old oil and contaminants before refilling, particularly important when changing oil types or addressing severe contamination issues. Proper disposal of used oil follows environmental regulations while maintaining facility cleanliness and safety standards.

Lubrication Passage Blockage Clearing Strategies

Flow restrictions diminish lubrication effectiveness by reducing oil delivery to critical components, particularly bearing surfaces that depend on continuous flow for heat dissipation and wear prevention. Pressure differential measurements across filters indicate restriction levels, with increases above 1.5 bar typically triggering maintenance indicators. Flow verification tests at distribution points confirm adequate lubrication reaching all components, identifying blockages before damage occurs.

Cleaning methodology selection depends on blockage nature and location, with mechanical cleaning required for hardened deposits and chemical cleaning effective for varnish or sludge accumulation. Ultrasonic cleaning techniques remove stubborn deposits from complex passageways where physical access proves difficult. Flushing procedures with specialized cleaning fluids remove contamination from entire systems following component replacement or major repairs. Verification testing after cleaning confirms passage integrity and flow restoration before returning equipment to service.

Lubrication Pump Malfunction Repair Methods

Pump failures disrupt entire lubrication systems, potentially causing rapid equipment damage if not detected immediately. Flow monitoring provides the primary failure indication, with reductions below design requirements triggering alarms before temperature rises indicate damage. Pressure measurements complement flow data, particularly for positive displacement pumps where flow reductions accompany pressure capability diminishment. Vibration analysis identifies mechanical issues including bearing wear or shaft misalignment before complete failure occurs.

Repair procedures range from seal replacement for external leaks to complete overhaul for internal wear issues. Component inspection during repair identifies root causes including contamination ingestion, cavitation damage, or improper assembly from previous maintenance. Alignment verification following repair ensures proper coupling operation and prevents premature failure recurrence. Performance testing after repair confirms flow and pressure capabilities meet design specifications before returning the system to operational service. Documentation of repair activities and replacement components facilitates future maintenance planning and inventory management.