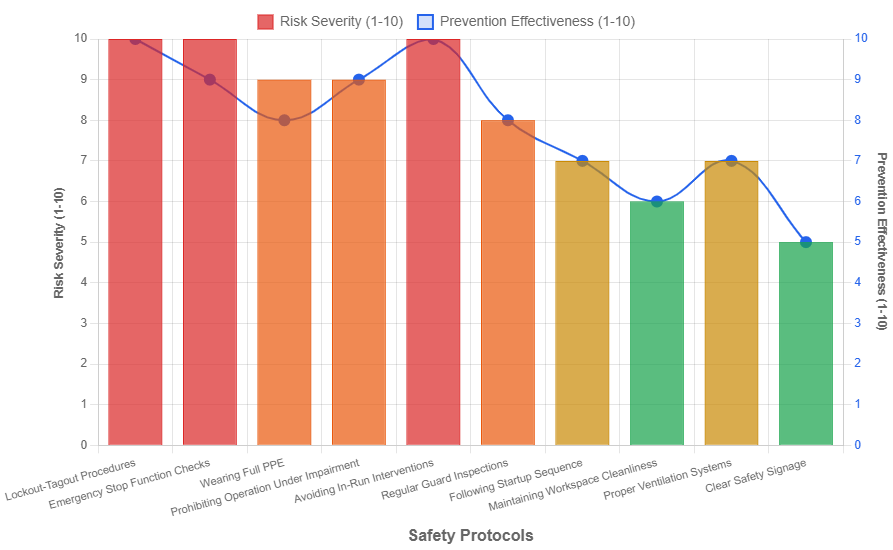

Top 10 Safety Operation Rules for Cone Crushers: Must-Know Dos and Don'ts

This guide outlines the fundamental safety protocols for operating cone crushers, which are powerful machines essential in material processing. Adherence to these rules is paramount for preventing accidents, ensuring the longevity of the equipment, and maintaining a productive workflow. The following sections detail critical procedures from initial preparation to emergency response, providing a comprehensive framework for safe and responsible operation.

Safety Protocols During the Pre-Operation Phase

Thorough preparation forms the foundation of safe cone crusher operation. Before approaching the machine, personnel must equip themselves with industry-standard personal protective equipment. This gear acts as a vital defense against the myriad hazards present in a crushing environment, from flying rock fragments to excessive noise and dust.

A comprehensive visual inspection of the crusher and its immediate surroundings is the next critical step. This involves verifying that all safety guards and emergency stop buttons are in place and functional. Operators must also be intimately familiar with the machine's manual, understanding its specific operational parameters and the outlined emergency procedures for various scenarios.

Utilizing Personal Protective Equipment

A hard hat is non-negotiable for protection against falling objects from the feed hopper. Safety glasses with side shields are essential to guard eyes from airborne dust and potential debris, while hearing protection mitigates the risk of long-term auditory damage from the crusher's high noise levels.

Sturdy steel-toed boots protect feet from heavy rolling objects, and durable gloves safeguard hands during routine checks and when handling rough materials. This combination of equipment creates a essential barrier against common physical hazards encountered during a shift.

Inspecting Machine Safety Guards and Devices

All rotating components, such as driveshafts and belts, must be fully enclosed by fixed guards to prevent contact. Emergency stop pull cords, designed to run the length of the conveyor system, and prominently located stop buttons must be tested regularly to ensure they function correctly and can halt the entire system instantly.

Physical inspections confirm that these safety devices are not only present but are also unobstructed and in good working order. Any missing, damaged, or bypassed guard constitutes a severe violation of safety protocols and requires immediate rectification before operation can commence.

Reviewing Operational Manuals and Emergency Plans

The manufacturer's operation manual provides machine-specific information regarding its crushing capacity, proper startup sequences, and critical maintenance schedules. Understanding this document is mandatory for any authorized operator.

Furthermore, every operator must be drilled on the site-specific emergency response plan. This includes knowing the exact location of first-aid stations, fire extinguishers, and the procedures for reporting an incident, ensuring a swift and coordinated response to any unforeseen event.

Safe Procedures for Startup and Normal Operation

Initiating crusher operation requires a methodical and deliberate approach. The startup sequence must follow the manufacturer's specified procedure, which typically involves activating support systems like lubrication and cooling before engaging the main drive motor. This gradual process allows each system to stabilize and confirms everything is functioning before applying full load.

During operation, continuous monitoring is essential. Operators must vigilantly observe instrument readings and listen to the machine's rhythm, ready to identify any deviation from normal operating conditions that could indicate a developing problem.

Following the Prescribed Startup Sequence

The correct sequence often begins by initiating the lubrication system to ensure all bearings are receiving oil before any movement occurs. Only after lubrication pressure is confirmed stable should the crusher drive motor be energized, typically in an unloaded state.

The final step is engaging the feed system to begin introducing material into the crushing chamber. This staggered startup prevents the motor from being subjected to a high starting torque under load, which can cause electrical and mechanical stress.

Monitoring Operational Parameters and Machine Behavior

Key parameters such as hydraulic pressure, oil temperature, and main shaft amperage must be constantly monitored via the control panel. Normal operating ranges are defined in the manual; significant deviations often serve as the first warning of an issue like an impending jam or a lubrication failure.

Beyond gauges, sensory awareness is crucial. The sound of consistent crushing versus the sound of metal-on-metal grinding, or the feel of normal vibration versus a violent shake, are critical indicators that operators learn to distinguish through experience and attention.

Avoiding Overloading and Improper Practices

Respecting the machine's design limits is a cornerstone of safety. Consistently exceeding the crusher's rated crushing capacity or feeding oversize material can lead to catastrophic failures. The hydraulic relief system is a safeguard, not a routine operating feature.

Improper practices, such as attempting to clear a jam while the machine is running or making unauthorized adjustments to the adjusting ring under power, are strictly prohibited. These actions bypass built-in safety systems and expose personnel to extreme risk.

Guidelines for Maintenance and Servicing Activities

Maintenance is vital for reliability, but it introduces unique hazards if not performed correctly. The absolute first step for any maintenance task is to isolate the crusher from all energy sources and secure it against accidental re-energization. This process creates a safe work environment for personnel.

Using the correct tools for each job is equally important. Specialized tools are designed for specific tasks on the crusher, ensuring that repairs are performed effectively without causing damage to components or putting the technician at risk of injury from tool failure.

Implementing Energy Isolation and Lockout Procedures

Lockout-Tagout is a formalized safety procedure. It involves physically disconnecting the crusher from its electrical power source at the main breaker and then placing a personal lock on the disconnect handle. Each involved worker places their own lock, and the keys are kept in their possession.

Tags are attached to each lock to provide information such as the name of the person who applied it, the time, and the reason for the lockout. This system ensures that the equipment cannot be started until the last lock is removed by the person who placed it, guaranteeing everyone's safety.

Applying Designated Tools for Specific Tasks

Using a drift and hammer designed for the specific thread size is the correct method for removing a mantle, preventing damage to the head threads. Similarly, using calibrated torque wrenches for reassembly ensures fasteners are tightened to the manufacturer's exact specifications, preventing future loosening or failure.

Improvisation with incorrect tools, such as using a standard wrench instead of a certified high-torque tool, can lead to rounded fittings, damaged components, and personal injury from tool slippage or breakage under extreme pressure.

Inspecting and Replacing Worn Components Regularly

A proactive maintenance schedule involves periodic inspections of wear parts like concaves, mantles, and eccentric bushings. Measuring wear and replacing components before they fail prevents unplanned downtime and more extensive damage to the crusher's core structure.

Keeping a detailed log of component life cycles helps predict replacement intervals accurately. This data-driven approach moves maintenance from a reactive process to a predictive one, enhancing overall safety and operational efficiency.

Emergency Response and Fault Management

Despite all precautions, malfunctions can occur. The immediate response to any unusual noise, sight, or smell from the crusher must be to stop the equipment. Quick and decisive action can prevent a minor issue from escalating into a major failure or a safety incident.

Once the machine is safely stopped and isolated, a careful assessment must be conducted to understand the fault's nature and severity. This assessment dictates the subsequent steps, which must always align with the pre-established emergency protocols.

Immediate Shutdown and Power Disconnection

Activating the nearest emergency stop button is the fastest way to cease all operation. Following this immediate action, the formal process of isolating the crusher at the main electrical disconnect must be completed to secure the area for further investigation and repair.

This swift disconnection of power eliminates risks from unexpected startup, electrical arcing, or moving parts, creating a stable and safe environment for personnel to begin diagnosing the problem without time pressure.

Evaluating the Severity and Potential Risks

From a safe distance, operators should perform a visual and auditory assessment. Signs like visible smoke, leaking hydraulic fluid, or a noticeable misalignment of components help gauge the severity of the fault and the potential hazards involved in the repair.

This evaluation determines the level of response required. A simple jam might be cleared by the operations team, while a suspected major mechanical failure, like a broken main shaft, would necessitate shutting down the entire circuit and involving specialized maintenance engineers.

Adhering to Established Emergency Protocols

Every site should have clear, written procedures for common emergency scenarios. These protocols provide a step-by-step guide for responders, covering aspects like communication, evacuation if necessary, and containment of spills, ensuring a calm and organized reaction under stress.

Following these protocols ensures that all actions are coordinated and effective. It prevents well-intentioned but potentially dangerous ad-hoc responses and ensures that management and emergency services are informed appropriately and in a timely manner.

Operator Conduct and Prohibited Actions

Safe operation is as much about what an operator does as what they avoid doing. Maintaining a high standard of personal conduct and vigilance is critical. Operators must remain focused on the task, avoiding any distractions that could lead to a lapse in attention while controlling powerful machinery.

There are clear and non-negotiable prohibitions designed to eliminate the most common and severe risks. These rules are often written from historical incident analyses and are strictly enforced to protect everyone involved.

Prohibition on Interventions During Machine Operation

Under no circumstances should any part of the body or a tool be inserted into the hopper or the discharge area while the crusher is running. The immense and unpredictable forces within the chamber can eject material with tremendous force or draw objects inward.

Adjustments to the crusher's setting or clearance must only be performed when the machine is completely stopped, isolated from power, and all moving parts have come to a full rest. Any attempt to adjust a running crusher risks severe crushing injuries.

Ban on Unauthorized Modifications to Safety Settings

The factory-set parameters for hydraulic relief pressures, motor overload protections, and control system interlocks are calibrated to protect both the machine and the operator. Tampering with these settings to increase production or bypass an alarm disables critical safeguards.

Only qualified maintenance personnel with explicit authorization may adjust these settings, and any changes must be documented. Unauthorized modifications are a direct violation of safety policy and can lead to equipment destruction and serious personal injury.

Restriction on Operating Under Impaired Conditions

Operating heavy machinery like a cone crusher requires full cognitive and physical capabilities. Fatigue, illness, or the influence of medications that cause drowsiness significantly impair reaction time, judgment, and situational awareness.

The presence of alcohol or non-prescription drugs in an operator's system is strictly forbidden and grounds for immediate removal from duty. Sites must foster a culture where operators feel empowered to report fatigue without penalty, ensuring they are fit to perform their duties safely.

Maintaining a Safe Worksite Environment

The area surrounding the cone crusher significantly influences overall safety. A clean, well-organized, and clearly marked workspace prevents accidents that are not directly related to the machine's operation but are equally dangerous. Good housekeeping is a continuous responsibility of all personnel.

Proper environmental controls, such as ventilation and lighting, are not merely comforts but essential safety features. They ensure that operators can see clearly and are not exposed to hazardous atmospheres, thereby reducing the likelihood of errors and health risks.

Ensuring Worksite Cleanliness and Organization

Spilled material, especially fine dust and slurry, creates slip and trip hazards around the crusher's base. These should be regularly removed. Tools and unused parts should be stored in designated areas, not left on walkways or equipment surfaces where they could fall or cause someone to stumble.

Oil and grease leaks must be cleaned up promptly, and their source identified and repaired. A clean workspace reflects a disciplined safety culture and allows for easier inspection of the equipment for its own leaks or cracks.

Providing Adequate Ventilation and Lighting

Crushers generate dust, and in enclosed spaces, this can reduce visibility and create respiratory hazards. Effective ventilation systems, sometimes supplemented with water spray dust suppression, are necessary to maintain air quality and keep the dust below exposure limits.

Proper illumination is crucial for operators to accurately read gauges, identify potential issues like smoldering belts, and move around the site safely. All work areas, especially those requiring equipment inspection, must be equipped with sufficient lighting to eliminate shadows and dark spots.

Posting Clear Safety Signs and Barriers

Hazard areas must be clearly marked with standardized signs indicating dangers such as high noise, falling material, and crushing hazards. Physical barriers or guardrails should be installed around permanent hazards like open pits or conveyor drives to prevent accidental access.

The crusher itself should be demarcated to define a safe operating perimeter. This helps keep unauthorized personnel at a safe distance and reminds those working nearby to remain aware of the active machinery and its potential ejection zones.