Drive-belt tension inspection and replacement maintenance for S Series Spring Cone Crusher Slug: s-spring-cone-crusher-drive-belt-maintenance

roper drive belt maintenance represents a critical aspect of cone crusher operation that directly influences equipment performance, energy efficiency, and operational safety. This comprehensive guide provides detailed procedures for tension inspection, adjustment techniques, and replacement protocols specifically designed for S Series spring cone crushers. The systematic approach outlined in this document enables operators to maintain optimal belt condition through regular monitoring and preventive maintenance strategies. By implementing these practices, operations can significantly reduce unplanned downtime, extend component lifespan, and maintain consistent crushing performance. The guide incorporates safety considerations, technical specifications, and practical recommendations based on industry standards and manufacturer guidelines to ensure reliable operation in various working conditions.

Function and Importance of Drive Belts in S Series Crushers

Drive belts in S Series spring cone crushers serve as the critical power transmission component between the electric motor and the crusher's main shaft, converting rotational energy into crushing action through friction-based power transfer. These belts must maintain precise tension to ensure efficient operation without excessive slippage or strain on bearing systems. The spring cone crusher design relies on consistent power delivery to maintain proper compression and release cycles during the crushing process. When belt tension deviates from optimal parameters, the crusher experiences reduced efficiency, increased energy consumption, and potential damage to mechanical components. Understanding the fundamental role of drive belts helps operators appreciate the importance of regular maintenance and proper tension management.

Incorrect belt tension manifests in multiple operational issues that affect overall crusher performance and productivity. Over-tensioned belts create excessive bearing loads that accelerate wear in the motor and crusher bearings, potentially reducing bearing life by up to 50% according to industry studies. Under-tensioned belts slip during operation, generating heat through friction that deteriorates belt integrity and reduces power transmission efficiency. This slippage can decrease crusher throughput by 10-20% while increasing energy consumption due to inefficient power transfer. The spring mechanism in these crushers requires consistent power input to maintain proper crushing forces, making belt tension a crucial factor in product quality and production consistency. Regular attention to belt condition and tension represents one of the most cost-effective maintenance practices for ensuring reliable crusher operation.

Working Principle of Drive Belts

Drive belts operate on the principle of friction transmission, where the belt material grips the pulley surfaces to transfer rotational motion from the motor to the crusher's drive shaft. The V-shaped design of typical crusher belts creates wedging action in the pulley grooves, increasing the surface contact area and enhancing grip capability. This mechanical arrangement allows for some flexibility in alignment while maintaining positive power transfer under varying load conditions. The elastic properties of the belt material accommodate minor shock loads during crusher operation, providing a cushioning effect that protects both the motor and crusher components from sudden impact forces. This working principle makes belt drives particularly suitable for crushing applications where load fluctuations frequently occur.

The power transmission efficiency of drive belts typically ranges between 95-98% when properly tensioned and aligned, making them highly effective for crusher applications. The belt material composition, typically reinforced rubber with polyester or aramid cord reinforcement, provides the necessary strength to handle the substantial torque requirements of cone crusher operation. During the crushing cycle, the spring cone crusher generates variable resistance as material compresses and releases, creating fluctuating power demands that the belt must accommodate without slipping or stretching beyond design limits. The flexibility of belt drives also helps dampen vibration transmitted between the motor and crusher, contributing to smoother operation and reduced mechanical stress. Understanding these fundamental principles enables operators to better diagnose issues and maintain optimal belt performance.

Impact of Tension on Crusher Performance

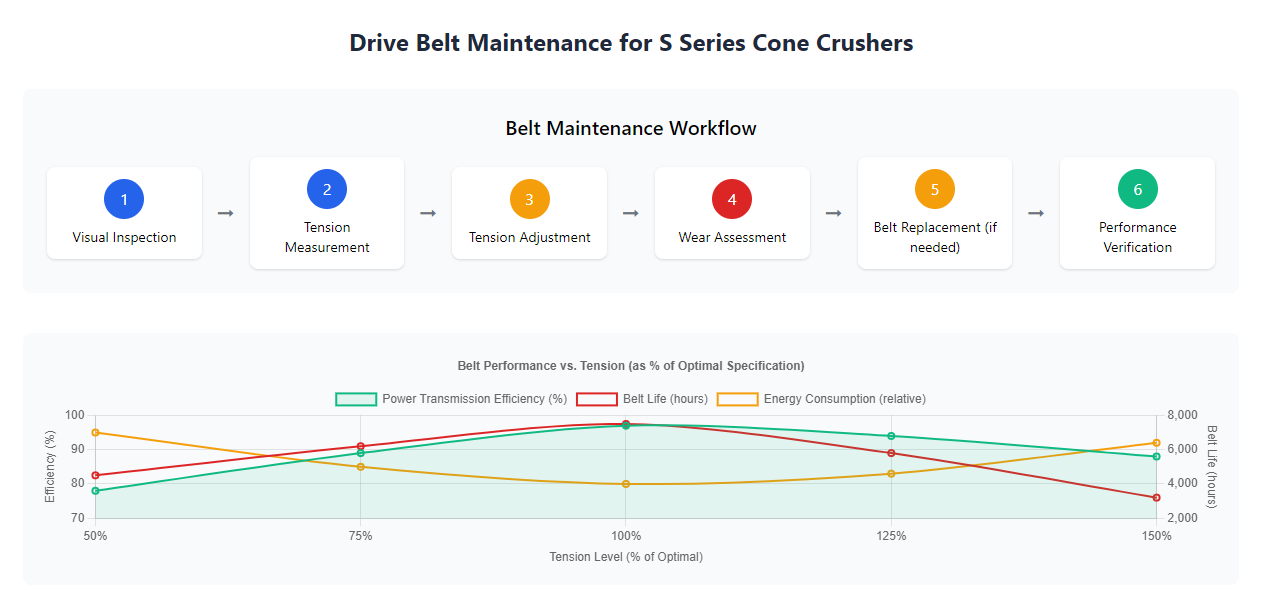

Proper belt tension directly influences multiple aspects of crusher performance, including power transmission efficiency, component lifespan, and operational reliability. Correctly tensioned belts ensure maximum contact with pulley grooves, optimizing the friction interface that transfers power from the motor to the crusher. Industry studies demonstrate that optimal tension can improve power transmission efficiency by 8-12% compared to improperly tensioned belts, directly reducing energy consumption per ton of processed material. The tension also affects the crusher's ability to maintain consistent operating speed under variable load conditions, which is particularly important for spring cone crushers where proper compression cycle timing affects product gradation and throughput rates.

Beyond efficiency considerations, belt tension significantly impacts the service life of crusher components and the belts themselves. Over-tensioning increases radial loads on motor and crusher bearings by 20-30%, potentially cutting bearing life in half according to manufacturer data. This excessive force also accelerates wear on the belt cords and cover material, leading to premature failure. Under-tensioning allows belts to slip, generating heat that can reach temperatures sufficient to degrade rubber compounds and weaken adhesive bonds within the belt structure. This thermal degradation reduces belt life by 40-60% in severe cases while also causing glazing on belt surfaces that further reduces grip capability. Maintaining tension within manufacturer specifications represents the single most important factor in maximizing belt service life and protecting associated crusher components.

Common Drive Belt Problems and Consequences

Drive belts in spring cone crusher applications commonly experience several specific issues that can lead to operational problems and unexpected downtime. Visible cracking on the belt surface typically indicates material aging from heat exposure, ozone attack, or flex fatigue, compromising the belt's structural integrity and increasing the risk of sudden failure. Glazing appears as a shiny, hardened surface on the belt sides, resulting from slippage that generates sufficient heat to melt and re-harden the rubber compound. This condition reduces friction coefficients and accelerates further slippage in a self-perpetuating cycle. Misalignment issues cause uneven wear patterns where one side of the belt shows more significant wear than the other, indicating pulley misalignment that creates sideways forces during operation.

The consequences of these common problems extend beyond simple belt replacement needs to affect overall crusher operation and safety. Cracked belts may fail suddenly during operation, causing immediate production stoppage and potential damage to other components from the whipping action of a broken belt. Glazed belts require higher tension to maintain grip, increasing bearing loads and power consumption while still suffering from reduced power transmission capability. Misaligned belts experience accelerated wear that shortens service life while also generating vibration that transfers to bearings and other mechanical components. In severe cases, these issues can lead to secondary damage including overheated motors, damaged pulley grooves, and even bearing failures that require extensive repairs. Early identification of these common problems through regular inspection allows for corrective action before they develop into more serious issues.

Maintenance Necessity and Benefits

Regular drive belt maintenance provides multiple operational benefits that justify the relatively modest time investment required for proper care. Scheduled inspections and tension checks help identify developing issues before they cause unplanned downtime, allowing repairs to be scheduled during planned maintenance periods. Industry data indicates that operations implementing regular belt maintenance programs experience 30-40% fewer belt-related breakdowns compared to those using reactive maintenance approaches. The economic impact extends beyond direct replacement cost savings to include maintained production capacity, reduced emergency repair expenses, and extended service life for associated components. These benefits make belt maintenance one of the highest-return activities in crusher preventive maintenance programs.

The systematic approach to belt maintenance begins with establishing regular inspection intervals based on operating hours and environmental conditions. Most manufacturers recommend initial tension checks after the first 24-48 hours of operation with new belts, followed by weekly inspections during the first month, and monthly inspections thereafter under normal operating conditions. Operations in harsh environments with extreme temperatures, high dust levels, or corrosive atmospheres may require more frequent inspections to detect degradation before it affects performance. Documentation of inspection findings creates a valuable historical record that helps identify patterns and optimize maintenance schedules. This proactive approach to belt maintenance not only prevents unexpected failures but also contributes to more consistent crusher performance through maintained optimal operating conditions.

Drive Belt Tension Inspection Methods and Tools

Accurate tension inspection requires systematic procedures using appropriate tools to obtain reliable measurements that reflect true operating conditions. The inspection process begins with visual examination to identify obvious issues followed by quantitative measurement using specialized tension gauges or manual methods. Visual inspection focuses on identifying visible signs of wear, misalignment, or contamination that might affect belt performance even if tension measurements appear correct. Quantitative measurement provides objective data for comparison against manufacturer specifications, enabling precise adjustments when necessary. Consistent inspection methodology ensures comparable results across different inspection intervals, helping identify gradual changes that might indicate developing issues. Proper documentation of inspection results creates a valuable historical record for trend analysis and maintenance planning.

The timing of tension inspections should account for both operating hours and specific operating conditions that might accelerate tension changes. New belts typically experience an initial stretch period during the first 24-48 hours of operation, requiring more frequent tension checks until stabilization occurs. Operations experiencing significant temperature variations should conduct inspections at consistent temperatures since belt materials expand and contract with temperature changes, affecting tension readings. Crushers operating under heavy loads or in dirty environments may require more frequent inspections to detect issues before they affect performance. Establishing a regular inspection schedule based on these factors ensures that tension remains within optimal ranges while minimizing the inspection burden on maintenance personnel. This balanced approach maximizes the benefits of tension monitoring without excessive time commitment.

Visual Inspection Guidelines

Visual inspection represents the first line of defense in identifying belt issues before they develop into serious problems requiring immediate attention. The inspection should begin with examination of the belt surface for cracks, glazing, or unusual wear patterns that indicate underlying issues. Crack inspection should focus on both the belt's top surface and sidewalls, looking for patterns that might indicate specific problems such as heat degradation, ozone attack, or mechanical damage. Glazing appears as a shiny, hardened surface on the belt sides where it contacts the pulley grooves, indicating slippage that has generated sufficient heat to alter the rubber composition. Wear patterns should be examined for consistency across the belt width, with uneven wear suggesting alignment issues that require correction.

Beyond the belt itself, visual inspection should include examination of pulley condition, alignment verification, and assessment of the general belt environment. Pulley inspection focuses on groove wear that might reduce grip capability, buildup of material in grooves that prevents proper belt seating, and signs of corrosion or damage that could accelerate belt wear. Alignment checks can be performed using straightedges or laser alignment tools to ensure pulleys are properly positioned relative to each other. Environmental assessment includes checking for sources of contamination such as oil leaks, excessive dust accumulation, or exposure to chemicals that might degrade belt materials. Documenting findings with photographs creates a valuable reference for comparison during future inspections, helping identify gradual changes that might not be immediately obvious. This comprehensive visual inspection typically requires only 10-15 minutes but provides essential information for maintaining optimal belt performance.

Tension Measurement Techniques

Accurate tension measurement requires appropriate techniques that account for belt type, length, and operating conditions to obtain reliable results. The deflection method represents the most common manual technique, involving applying a specific force at the belt's midpoint and measuring the resulting deflection distance. This method requires knowledge of the belt span length and specific force values recommended by the manufacturer for accurate interpretation. For V-belts used in cone crushers, typical deflection ranges between 1/64 and 1/32 of the span length per inch of span, translating to approximately 5-10mm for most crusher applications. The force application must be perpendicular to the belt span at the exact midpoint between pulleys to ensure accurate measurements. Consistency in measurement technique ensures comparable results across different inspection intervals.

Electronic tension gauges provide more precise measurements by directly reading belt tension through various operating principles including frequency measurement, ultrasound, or direct force application. Frequency-based gauges measure the natural vibration frequency of the belt when plucked, calculating tension based on belt mass and length parameters. These devices typically offer accuracy within ±5% when properly calibrated and used according to manufacturer instructions. Ultrasound gauges measure the speed of sound through the belt material, which correlates with tension levels when combined with belt dimension data. Direct tension measurement devices physically separate the belt from one pulley and measure the force required to maintain position. Each method has specific advantages and limitations, with selection depending on accuracy requirements, budget constraints, and operator preference. Regardless of the method chosen, consistent application and proper documentation ensure reliable tension management.

Standard Tension Values and Specifications

Manufacturers provide specific tension recommendations for each crusher model and belt configuration based on engineering calculations and testing under various operating conditions. These specifications typically include both initial installation tension values and operational tension ranges that account for normal stretch during the belt's service life. For S Series spring cone crushers, typical tension values range between 150-250 Newtons per belt for standard V-belt configurations, though exact specifications vary by crusher size and drive configuration. The deflection method typically specifies a force application of 5-15 Newtons at the belt midpoint with corresponding deflection distances of 8-15mm depending on belt span length. These values ensure optimal power transmission while minimizing bearing loads and maximizing belt service life.

Proper interpretation of manufacturer specifications requires understanding the relationship between belt tension, operational load, and environmental conditions. Crushers operating under heavy loads or frequent start-stop cycles may require tension at the higher end of recommended ranges to prevent slippage during peak demand periods. Operations in high-temperature environments should consider the thermal expansion characteristics of belt materials, which may require slightly lower initial tension to accommodate expansion during operation. Belt age also influences tension requirements, with newer belts typically requiring more frequent adjustment during the initial run-in period as they undergo permanent stretch. Documentation of specific tension values used during adjustments helps establish patterns that optimize future maintenance activities. Adherence to manufacturer specifications represents the most reliable approach to ensuring proper tension while protecting crusher components from excessive loads.

Inspection Frequency and Documentation

Establishing appropriate inspection intervals represents a balance between maintenance resource allocation and risk management for potential belt failures. Most manufacturers recommend initial tension checks after the first 8-24 hours of operation with new belts, followed by weekly inspections during the first month to monitor the initial stretch period. After this run-in phase, monthly inspections typically suffice for most operating conditions, with additional checks following any significant operating changes or maintenance activities. Operations experiencing extreme conditions such as high dust levels, temperature extremes, or heavy cyclical loading may benefit from more frequent inspections to detect issues before they affect performance. Documentation of each inspection creates a valuable historical record that supports maintenance decision-making and identifies developing trends.

Effective documentation should include quantitative tension measurements, visual observations, and contextual information about operating conditions at the time of inspection. Tension values should be recorded using consistent measurement methods to ensure comparability across different inspection dates. Visual observations should note any signs of wear, misalignment, or contamination that might not yet affect tension measurements but could indicate developing issues. Contextual information including operating hours since last inspection, environmental conditions, and any recent maintenance activities helps interpret measurement results and identify patterns. This documentation becomes particularly valuable when troubleshooting recurring issues or optimizing maintenance schedules based on actual operating experience. Digital maintenance management systems facilitate this documentation process while providing analysis tools that help identify correlations between operating conditions and belt performance.

Tension Adjustment Procedures and Techniques

Proper tension adjustment requires systematic procedures that ensure accurate results while maintaining safety throughout the process. The adjustment process begins with comprehensive safety preparations including equipment isolation, lockout-tagout implementation, and verification of zero energy state before any physical intervention. Once safety measures are confirmed, the existing tension should be measured and recorded to establish a baseline for adjustment calculations. The specific adjustment mechanism varies by crusher design but typically involves loosening motor base bolts, adjusting motor position to increase or decrease belt tension, and securely retightening all fasteners to specified torque values. Final verification includes tension measurement confirmation and operational testing to ensure proper performance under load conditions.

The adjustment technique must account for the relationship between motor movement and resulting tension change, which varies based on drive configuration and belt arrangement. For crushers with multiple belt drives, tension must be balanced across all belts to ensure equal load sharing and prevent individual belt overload. Simultaneous adjustment of all belts requires careful measurement and incremental changes to maintain balance throughout the process. The use of proper tools including torque wrenches, alignment instruments, and tension gauges ensures accurate adjustments that meet manufacturer specifications. Following adjustment, a run-in period of 24-48 hours typically requires rechecking tension as belts seat properly in pulley grooves and undergo initial stretch. This systematic approach to tension adjustment maximizes belt life while ensuring optimal power transmission efficiency.

Safety Preparation Protocols

Comprehensive safety preparations represent the essential first step in any belt tension adjustment procedure to protect personnel from potential hazards. The process begins with complete equipment shutdown following established procedures that ensure all energy sources are isolated and dissipated. Electrical isolation requires disconnecting power at the main breaker or switchgear and applying lockout-tagout devices to prevent accidental re-energization during maintenance activities. Mechanical energy isolation involves ensuring the crusher bowl and mantle are in a stable position with no residual compression in the spring system. Verification of zero energy state includes physically checking that all moving components have come to complete rest and cannot move unexpectedly during the adjustment process.

Additional safety measures include personal protective equipment requirements specific to belt maintenance activities. Safety glasses with side shields protect eyes from debris during bolt loosening and adjustment procedures. Heavy-duty gloves prevent hand injuries from sharp edges on crusher components and provide protection against accidental contact with hot surfaces. Steel-toed footwear offers protection against dropped tools or components during the adjustment process. The work area should be clearly marked with warning signs indicating maintenance in progress to prevent unauthorized operation attempts. These comprehensive safety protocols, while adding time to the adjustment process, represent essential protection against the significant hazards present in crusher maintenance activities. Documentation of safety procedures completion provides accountability and ensures consistent application across all maintenance activities.

Adjustment Mechanism Operation

The tension adjustment mechanism in S Series spring cone crushers typically utilizes motor base positioning to control belt tension through precise movement of the drive motor. The process begins with loosening the motor mounting bolts that secure the motor to its base or slide rails, allowing controlled movement to increase or decrease tension. Most designs incorporate adjustment bolts specifically intended for fine positioning of the motor once the main mounting bolts are loosened. These adjustment bolts enable precise control of motor position with typical movement increments of 0.5-1.0mm per revolution, allowing operators to make small tension changes without guesswork. The direction of movement depends on the specific drive configuration, with movement away from the crusher typically increasing tension and movement toward the crusher decreasing tension.

For crushers with multiple belt arrangements, simultaneous adjustment of all belts requires careful attention to maintain equal tension across the entire drive set. Specialized tools including laser alignment systems help ensure the motor moves parallel to the crusher shaft during adjustment, preventing misalignment that would cause uneven belt wear. Incremental adjustments followed by tension measurements prevent overshooting the target tension value, which would require repeating the process in the opposite direction. Once the desired tension is achieved, the motor mounting bolts should be tightened gradually and evenly following a crisscross pattern to prevent distortion of the motor base. Final torque values should comply with manufacturer specifications, typically ranging from 150-400 Nm depending on bolt size and crusher model. This systematic approach to adjustment mechanism operation ensures accurate tension setting while maintaining proper alignment between drive components.

Precision Adjustment and Locking Procedures

Precision adjustment requires incremental changes with verification measurements between adjustments to approach the target tension methodically without overshooting. The process begins with an initial tension measurement to establish the baseline condition and calculate the required adjustment magnitude. Based on the drive configuration and belt span length, operators can estimate the approximate motor movement needed to achieve the desired tension change. Typical adjustment increments of 1-2mm of motor movement followed by tension measurement prevent large overshoots that would require corrective actions. For critical applications, tension should be measured at multiple points along the belt span to ensure consistency, with variations of more than 10% indicating potential alignment issues that require correction before proceeding.

Once the target tension is achieved, the locking procedure secures the adjustment mechanism to maintain tension during operation. Motor mounting bolts should be tightened following a specific sequence that ensures even clamping force across the entire base. Torque values must comply with manufacturer specifications, typically provided in technical documentation for each specific crusher model. The use of calibrated torque wrenches ensures accurate bolt tension that prevents loosening during operation while avoiding damage from over-tightening. After tightening, a final tension measurement verifies that the locking process hasn't altered the achieved tension setting. Some designs incorporate locking nuts on adjustment bolts that require securing after the main mounting bolts are tightened to prevent gradual movement during operation. This meticulous approach to precision adjustment and locking ensures long-term tension stability between maintenance intervals.

Post-Adjustment Testing and Verification

Comprehensive testing following tension adjustment verifies proper operation and identifies any issues that might require additional attention before returning the crusher to full production. The testing process begins with visual inspection to confirm proper belt seating in pulley grooves and absence of obvious misalignment. Manual rotation of the crusher drive system through several complete revolutions checks for binding or interference that might indicate installation issues. Initial startup should occur without material in the crushing chamber to establish baseline operation before applying load. During this no-load operation, visual observation should confirm smooth belt operation without visible flutter or abnormal movement patterns that might indicate residual issues.

Operational testing under load provides the final verification of proper tension adjustment and overall drive system performance. The crusher should be operated with minimal feed material initially, gradually increasing to full capacity while monitoring for signs of slippage or abnormal noise. Power consumption monitoring during this ramp-up period helps identify efficiency improvements resulting from proper tension adjustment. Infrared temperature guns can measure belt and bearing temperatures during operation, with significant differences between belts potentially indicating unequal tension distribution. Vibration analysis using portable meters provides quantitative data on drive system smoothness, with significant increases potentially indicating alignment issues or other problems. Documentation of test results including operational parameters, measurements, and observations creates a baseline for future comparison and helps identify developing issues during subsequent maintenance intervals. This thorough testing approach ensures that tension adjustments achieve their intended benefits while identifying any secondary issues requiring attention.

Drive Belt Replacement Timing and Decision Criteria

Determining the optimal timing for belt replacement requires consideration of multiple factors including visible wear indicators, performance degradation, and preventive maintenance schedules. Visible inspection criteria include cracking depth and pattern, glazing severity, wear groove formation, and edge damage that compromise belt integrity. Performance-based indicators include recurring tension problems, slippage under load, and vibration issues that persist despite proper tension and alignment. Preventive replacement based on operating hours or calendar time provides a proactive approach that prevents unexpected failures during production periods. The decision matrix should balance replacement cost against the risk and consequences of unexpected failure, with more critical applications typically favoring earlier replacement to ensure reliability.

Documenting belt service life under specific operating conditions creates valuable reference data for optimizing future replacement intervals. Factors influencing belt life include operating hours, load characteristics, environmental conditions, and maintenance practices that collectively determine replacement timing. Belts operating in high-temperature environments typically experience accelerated aging of rubber compounds, reducing service life by 30-40% compared to moderate temperature operations. Heavy dust conditions abrasive particles accelerate surface wear while potentially causing groove clogging that affects belt seating. Operations with frequent start-stop cycles or heavy shock loads experience more significant flex fatigue that shortens belt life. Analyzing these factors in relation to actual service life helps establish appropriate replacement intervals that maximize value while maintaining reliability.

Wear Limit Indicators and Assessment

Visible wear indicators provide objective criteria for determining when belts require replacement regardless of operating hours or time in service. Crack formation represents one of the most common wear indicators, with depth and density determining replacement necessity. Surface cracks extending more than 25% through belt thickness typically indicate replacement requirement, while widespread micro-cracking across the belt surface suggests material degradation from environmental exposure. Groove wear in V-belts reduces the wedging action in pulley grooves, with wear beyond the belt's wear lines or significant shape distortion indicating replacement need. Glazing severity assessment considers the extent of shiny, hardened surface areas, with complete sidewall glazing typically requiring replacement even if cracking hasn't yet developed.

Additional wear indicators include cover separation, cord exposure, and edge damage that compromise belt integrity and safety. Cover separation appears as bubbling or lifting of the outer rubber layer from the internal cord structure, indicating adhesive failure that can lead to rapid deterioration. Cord exposure occurs when wear reaches the reinforcement layer, creating weakness points that significantly reduce belt strength and increase failure risk. Edge damage including chunks missing from belt sides creates stress concentration points that can initiate tearing under operational loads. Measurement tools including depth gauges for crack assessment and profile gauges for groove wear evaluation provide quantitative data for replacement decisions. Documentation of these wear indicators with photographs creates reference standards that improve consistency in replacement timing decisions across different maintenance personnel.

Performance Degradation Symptoms

Operational symptoms provide additional indicators for belt replacement needs based on performance changes that affect crusher operation and efficiency. Slippage during operation represents the most obvious performance issue, typically manifesting as audible squealing during load application or startup. This slippage generates heat that further degrades belt condition in a self-perpetuating cycle that accelerates replacement necessity. Vibration increases often indicate belt issues including uneven wear, stiffness variations, or internal damage that creates imbalance during operation. Power transmission efficiency reduction manifests as increased energy consumption for the same production output, though this requires baseline data for accurate assessment. These performance symptoms often develop gradually, making regular comparison to established baselines essential for early detection.

Additional performance indicators include unusual noise patterns, visible movement abnormalities, and temperature increases that suggest belt issues requiring attention. Noise assessment should distinguish between normal operational sounds and abnormal frequencies that might indicate specific problems such as misalignment, bearing issues, or belt defects. Visual observation during operation can identify belt whip or flutter that indicates tension problems or wear issues affecting operational stability. Temperature measurements using infrared thermometers can identify overheating in specific belt sections that might indicate localized issues requiring replacement. Tracking these performance indicators alongside maintenance activities helps establish correlations between specific symptoms and underlying belt conditions. This performance-based approach to replacement timing complements visual inspection criteria to provide comprehensive assessment of belt condition and replacement necessity.

Replacement Interval Guidelines

Establishing appropriate belt replacement intervals requires balancing preventive maintenance principles with operational experience under specific working conditions. Manufacturer recommendations typically provide baseline intervals ranging from 12-24 months or 4,000-8,000 operating hours for standard applications, though actual intervals vary significantly based on operational factors. Operations with favorable conditions including stable temperatures, clean environments, and consistent loads often achieve service life at the upper end of these ranges. Applications with challenging conditions such as extreme temperatures, abrasive dust, heavy shock loads, or frequent start-stop cycles typically require more frequent replacement, often at 50-70% of standard intervals. Documenting actual service life under specific conditions provides the most reliable basis for establishing appropriate replacement schedules.

The replacement interval decision should also consider the criticality of the application and consequences of unexpected failure. Crushers supporting continuous production processes with limited redundancy typically justify more conservative replacement intervals to prevent unexpected downtime. Operations with easy access to replacement parts and quick changeout capabilities might extend intervals slightly while accepting slightly higher failure risk. Economic analysis should compare the cost of preventive replacement against the potential costs of unexpected failure including production losses, emergency repair expenses, and possible secondary damage. This analysis typically favors preventive replacement when failure costs significantly exceed replacement costs, which applies to most crusher applications. Establishing clear replacement criteria based on this multidimensional analysis optimizes maintenance spending while ensuring operational reliability.

Pre-Replacement Checklist and Preparation

Comprehensive preparation before belt replacement ensures efficient execution while preventing issues that might compromise the quality of the replacement activity. The preparation process begins with verifying the correct replacement belt specification including type, size, and quantity requirements. Belt identification should cross-reference manufacturer part numbers, dimensional specifications, and performance characteristics to ensure compatibility with the specific crusher model and application requirements. Tool preparation includes assembling all necessary equipment for safe removal and installation including appropriate lifting devices, tension measurement tools, and fastening equipment. Workspace preparation ensures adequate clearance for replacement activities with proper lighting and access to facilitate efficient work execution.

Additional preparation activities include reviewing replacement procedures, coordinating necessary support resources, and establishing communication protocols for the replacement activity. Procedure review ensures all personnel understand their roles and responsibilities while identifying any special requirements for the specific replacement situation. Resource coordination might include arranging for additional personnel, specialized equipment, or technical support if complex issues are anticipated. Communication protocols establish clear lines of responsibility and reporting during the replacement process, particularly for activities involving multiple personnel or coordination with production scheduling. Safety preparation includes reviewing hazard analyses, confirming personal protective equipment availability, and establishing emergency response procedures. This comprehensive preparation approach typically requires modest time investment but significantly improves replacement efficiency while reducing the potential for errors or safety incidents during execution.

Detailed Drive Belt Replacement Procedures

Systematic belt replacement procedures ensure efficient execution while maintaining safety and quality standards throughout the process. The replacement process begins with comprehensive safety preparations including equipment isolation, lockout-tagout implementation, and workspace securing to prevent accidental operation during replacement activities. Existing belt removal requires careful sequencing to avoid damage to surrounding components while dealing with tensioned systems that store significant energy. New belt installation focuses on proper positioning without twisting or stretching that could compromise belt integrity or performance. Initial tension setting establishes the baseline for operational run-in, with follow-up adjustments required after the initial operational period to compensate for normal stretch and seating.

The replacement procedure must account for specific crusher design features that affect belt access and replacement methodology. Crushers with limited access might require temporary removal of guards or other components to create sufficient workspace for safe replacement activities. Multiple belt drives require careful sequencing to maintain system stability during the replacement process, with temporary supports sometimes necessary to position components correctly. The use of proper tools specifically designed for belt replacement improves efficiency while reducing the risk of damage to belts or other components. Documentation throughout the replacement process including photographs, measurements, and observations creates valuable reference material for future maintenance activities and troubleshooting needs. This systematic approach to belt replacement maximizes the service life of new belts while ensuring proper operation from initial installation.

Existing Belt Removal Process

Safe removal of existing belts begins with tension release to eliminate stored energy that could cause unexpected movement during disassembly. The specific tension release method varies by crusher design but typically involves loosening motor mounting bolts and adjusting motor position to create sufficient slack for belt removal. Complete removal of tension allows belts to be lifted from pulley grooves without forcing or prying that might damage pulley surfaces or other components. For multiple belt arrangements, removal typically proceeds one belt at a time to maintain some stability in the drive system until replacement belts are positioned. Careful inspection during removal can identify wear patterns that provide valuable information about alignment issues or other problems requiring correction before new belt installation.

Challenging removal situations might require specialized techniques or tools to overcome issues such as seized components, limited access, or belts stuck in pulley grooves. Penetrating lubricants applied to adjustment mechanisms can loosen corrosion that prevents proper movement for tension release. Specialty tools including belt removal hooks or pulley rotation devices can facilitate removal without damaging belt surfaces or applying excessive force to components. Documentation of removal challenges helps improve future replacement activities through procedural modifications or additional tool acquisition. The removed belts should be retained for detailed inspection that might reveal underlying issues affecting belt life, with particularly informative specimens preserved for training purposes or further analysis. This thorough approach to belt removal not only facilitates efficient replacement but also provides valuable diagnostic information for improving overall drive system maintenance.

New Belt Selection and Verification

Proper new belt selection requires verification of multiple parameters to ensure compatibility with the specific crusher application and operating conditions. Dimensional verification includes precise length measurement, cross-section dimensions, and angle specifications that match pulley groove requirements. Material composition should align with operational environment considerations including temperature resistance, oil resistance, and static conductivity requirements for specific applications. Performance characteristics including strength ratings, flexibility, and stretch characteristics should match or exceed the original equipment specifications. Manufacturer recommendations typically provide specific part numbers and alternative options that have been validated for the application, representing the most reliable selection guidance.

Physical inspection of new belts before installation identifies potential issues that might affect performance or service life. Visual examination should confirm absence of manufacturing defects including uneven curing, molding flaws, or surface imperfections that might indicate quality issues. Dimensional verification using calibrated measuring devices ensures the belt meets published specifications, with particular attention to length consistency for multiple belt drives. Flexibility assessment through manual manipulation identifies unusual stiffness that might indicate storage issues or manufacturing variations. Documentation of belt identification information including manufacturer, date codes, and batch numbers facilitates tracking and potential warranty claims if issues develop during service. This thorough selection and verification process represents a critical investment in ensuring replacement success and maximizing new belt service life.

New Belt Installation Techniques

Proper installation techniques prevent damage to new belts while ensuring correct positioning for optimal performance and service life. The installation process begins with verification of pulley condition and alignment to eliminate external factors that might compromise new belt performance. Pulley cleaning removes accumulated debris, rust, or residual rubber from previous belts that might affect proper seating of the new belt. Installation should avoid using tools that pry or stretch the belt excessively, instead relying on proper tension release to create sufficient slack for positioning. For multiple belt drives, all belts should be installed before applying tension to ensure equal initial positioning. The use of installation tools specifically designed for belt handling improves efficiency while reducing the risk of damage during the installation process.

Specific techniques vary based on belt type and drive configuration, with different approaches required for standard V-belts, joined V-belts, and synchronous belt designs. Standard V-belts typically require sufficient motor movement to create clearance for slipping the belt over pulley flanges without excessive force. Joined V-belts offer installation advantages in limited access situations but require verification of connecting link integrity and proper seating in pulley grooves. Synchronous belts demand particular care during installation to prevent damage to teeth while ensuring proper engagement with pulley grooves. The installation process should include visual verification of proper seating in all pulley grooves before tension application, with particular attention to drives incorporating multiple pulleys or idlers. This meticulous approach to installation establishes the foundation for optimal performance and maximum service life from the new belts.

Initial Tension Setting and Run-In Procedures

Initial tension setting for new belts requires specific consideration of the run-in period during which belts undergo permanent stretch and seating in pulley grooves. Manufacturer recommendations typically specify higher initial tension values for new belts compared to used belts, compensating for the expected stretch during the initial operational period. The specific initial tension value depends on belt type, drive design, and operational requirements, with typical values ranging from 20-30% higher than normal operating tension. This initial setting ensures adequate power transmission capability while the belt undergoes initial seating and stretch during the first operational hours. Documentation of the initial tension setting provides reference for comparison during subsequent adjustments and establishes a baseline for future maintenance activities.

The run-in period typically spans 24-48 hours of operation, during which tension should be monitored more frequently to track stretch progression and make necessary adjustments. Initial operational checks after the first 2-4 hours identify any significant issues requiring immediate attention before continuing operation. Tension measurements at 8-hour intervals during the first 24-48 hours track the stretch pattern and determine when stability occurs. Following the run-in period, tension should be adjusted to normal operating values and monitored according to standard maintenance schedules. Operational parameters during the run-in period should approximate normal operating conditions to ensure proper seating under representative loads. This systematic approach to initial tension setting and run-in management maximizes new belt performance while establishing proper conditions for long service life.

Common Problems and Troubleshooting Approaches

Belt drive systems experience various common problems that require specific troubleshooting approaches to identify root causes and implement effective solutions. Rapid or unusual wear patterns often indicate alignment issues, improper tension, or environmental factors that accelerate degradation. Slippage problems typically result from insufficient tension, contamination, or worn pulley grooves that reduce friction capability. Vibration issues might indicate imbalance, misalignment, or belt defects that create operational instability. Noise abnormalities can signal specific problems including misalignment, bearing issues, or belt defects that require identification and correction. Systematic troubleshooting approaches for these common problems follow logical progression from symptom observation through root cause identification to corrective action implementation.

Effective troubleshooting requires comprehensive information gathering including operational history, maintenance records, and specific symptom documentation. Symptom patterns including timing, frequency, and relationship to operational parameters provide valuable clues for identifying underlying causes. Historical maintenance information helps identify recent changes that might correlate with problem development. Environmental factors including temperature variations, contamination sources, or unusual operating conditions might contribute to specific issues. The troubleshooting process should progress from simple, easily addressed potential causes to more complex possibilities, minimizing unnecessary disassembly or component replacement. Documentation of troubleshooting activities and outcomes creates valuable reference material for future problem resolution and helps identify recurring issues that might indicate systemic problems requiring more comprehensive solutions.

Tension Adjustment Difficulties

Difficulties in achieving or maintaining proper tension typically indicate underlying issues with adjustment mechanisms, component condition, or installation problems. Frozen adjustment bolts often result from corrosion accumulation in threads or between sliding surfaces, preventing smooth movement for tension control. Distorted motor bases or mounting rails can create binding that restricts movement or prevents proper positioning once adjusted. Worn or damaged components including elongated bolt holes, damaged threads, or deformed sliding surfaces compromise adjustment capability and precision. Identification of the specific constraint preventing proper adjustment determines the appropriate corrective approach, ranging from simple cleaning and lubrication to component replacement or repair.

Systematic approaches to resolving adjustment difficulties begin with thorough cleaning and inspection of all adjustment mechanism components. Penetrating lubricants applied to threaded components and sliding surfaces can loosen corrosion bonds that restrict movement. Careful application of force using proper tools can overcome initial resistance, though excessive force risks component damage that exacerbates the problem. For severely corroded or damaged components, disassembly might be necessary for proper cleaning, repair, or replacement. Verification of component condition during disassembly identifies wear or damage requiring correction to restore proper adjustment capability. Following resolution of adjustment difficulties, preventive measures including regular lubrication, protective coatings, or environmental improvements can prevent recurrence. This systematic approach to addressing adjustment difficulties restores proper functionality while implementing measures to maintain long-term performance.

Rapid Wear Causes and Solutions

Rapid belt wear indicates specific issues with drive system configuration, operating conditions, or environmental factors that accelerate degradation. Misalignment represents the most common cause of rapid wear, creating uneven contact patterns that concentrate wear on specific belt areas. Pulley groove wear changes the contact geometry, reducing the wedging action that provides proper grip while creating sharp edges that accelerate belt surface damage. Environmental contamination including abrasive dust, chemical exposure, or temperature extremes accelerates material degradation through specific mechanisms. Improper tension either excessively tight or loose creates wear patterns characteristic of the specific tension problem. Identification of the specific wear pattern provides the primary clue for determining the underlying cause and appropriate corrective action.

Systematic investigation of rapid wear begins with detailed documentation of the specific wear pattern including photographs, measurements, and operational context. Alignment verification using precision tools identifies angular or parallel misalignment that might not be visible during casual inspection. Pulley condition assessment includes groove profile measurement, surface finish evaluation, and dimensional verification to identify wear beyond acceptable limits. Environmental analysis identifies contamination sources, temperature extremes, or other factors that might accelerate wear beyond normal expectations. Tension history review determines whether improper tension settings or inadequate maintenance intervals contribute to the rapid wear problem. Corrective actions address the identified root causes while considering potential interactions between multiple contributing factors. Implementation of corrective measures should include follow-up monitoring to verify effectiveness and identify any additional issues requiring attention.

Noise and Vibration Troubleshooting

Unusual noise and vibration in belt drive systems indicate specific issues requiring identification and correction to prevent component damage and maintain operational efficiency. Noise characteristics including frequency, timing, and relationship to operational parameters provide valuable diagnostic information for identifying potential causes. High-frequency squealing typically indicates slippage under load, while lower-frequency rumbling often suggests bearing issues or misalignment. Vibration patterns including direction, frequency, and amplitude help distinguish between imbalance, misalignment, and other potential causes. Systematic investigation progresses from simple external factors to more complex internal issues, minimizing unnecessary disassembly while ensuring comprehensive problem resolution.

Initial troubleshooting steps focus on easily addressed potential causes including tension verification, visual alignment checks, and basic component inspection. Tension measurement confirms whether values fall within recommended ranges, with adjustment resolving slippage-related noise issues. Visual alignment checks using straightedges or laser tools identify obvious misalignment that might cause vibration or unusual wear patterns. Component inspection includes examination of pulley condition, belt surfaces, and guard clearance that might contribute to noise or vibration. Advanced troubleshooting techniques might include vibration analysis, thermal imaging, or stroboscopic examination to identify less obvious issues. Vibration analysis particularly helps distinguish between various potential causes based on frequency signatures and operational patterns. This systematic approach to noise and vibration troubleshooting efficiently identifies root causes while minimizing unnecessary component replacement or disassembly.

Safety Incident Prevention Measures

Comprehensive safety measures prevent incidents during belt maintenance activities, protecting personnel from the significant hazards present in crusher drive systems. Mechanical hazards include unexpected movement from stored energy in tensioned systems, rotating components during testing, and sharp edges on crusher components. Electrical hazards stem from improper isolation during maintenance activities or accidental contact with live components. Environmental hazards include falling objects, confined spaces, and atmospheric contaminants that might affect personnel during maintenance activities. Systematic risk assessment before maintenance activities identifies specific hazards and appropriate protective measures for each situation. This proactive approach to safety incident prevention represents the foundation for effective maintenance execution.

Specific safety measures for belt maintenance activities include comprehensive equipment isolation, personal protective equipment requirements, and worksite control procedures. Equipment isolation requires physical disconnection from power sources with lockout-tagout devices applied to prevent accidental re-energization. Personal protective equipment typically includes safety glasses, gloves, steel-toed footwear, and hearing protection appropriate for the specific maintenance activities. Worksite control establishes clear boundaries, communication protocols, and emergency procedures for maintenance activities involving multiple personnel or complex procedures. Additional measures for specific situations might include fall protection for elevated work areas, ventilation for confined spaces, or special tools for hazardous operations. Safety briefing before maintenance activities ensures all personnel understand specific hazards, protective measures, and emergency procedures. This comprehensive approach to safety incident prevention protects personnel while facilitating efficient maintenance execution.

Maintenance Best Practices and Preventive Strategies

Implementing comprehensive maintenance best practices maximizes belt service life while minimizing unplanned downtime and maintenance costs. Systematic approaches include regular inspection schedules, proper documentation, environmental management, and personnel training that collectively optimize belt performance. Inspection frequency should balance operational criticality, environmental conditions, and resource availability to provide adequate monitoring without excessive time commitment. Documentation practices create valuable historical data that supports maintenance decision-making and identifies trends requiring attention. Environmental management addresses external factors that accelerate belt degradation, extending service life through relatively simple measures. Personnel training ensures consistent application of maintenance procedures while developing troubleshooting skills that quickly resolve developing issues.

The economic benefits of preventive maintenance strategies significantly outweigh implementation costs through reduced downtime, extended component life, and improved operational efficiency. Studies indicate that preventive maintenance programs typically reduce belt-related downtime by 40-60% compared to reactive approaches, representing substantial production preservation. Component life extension through proper maintenance often reaches 30-50% beyond typical service life under minimal maintenance conditions, reducing replacement frequency and associated costs. Operational efficiency improvements from proper tension and alignment typically reduce energy consumption by 5-10% while maintaining production capacity. These economic benefits justify the relatively modest investment in systematic maintenance programs, particularly for critical applications where unexpected downtime creates significant production impacts. This comprehensive approach to maintenance represents the most effective strategy for optimizing belt performance and reliability.

Daily Inspection Checklist Implementation

Daily inspection checklists provide systematic monitoring of belt condition through quick visual assessment that identifies developing issues before they affect operation. Checklist items typically include visual examination for obvious damage, tension verification through simple deflection tests, and observation of operation during startup. Visual examination focuses on identifying cracks, glazing, or unusual wear patterns that might indicate developing problems. Simple tension checks using the deflection method provide early indication of tension changes requiring adjustment. Operational observation during startup identifies unusual noise, slippage, or vibration that might indicate issues requiring further investigation. This daily inspection typically requires only 5-10 minutes but provides valuable early detection of developing issues.

Effective checklist implementation requires proper design, consistent application, and appropriate response procedures for identified issues. Checklist design should focus on easily observable parameters that provide meaningful information about belt condition without requiring extensive measurement or disassembly. Consistent application ensures comparable results across different shifts and personnel, with documentation creating a historical record for trend analysis. Response procedures establish clear actions for various inspection findings, ranging from continued monitoring for minor issues to immediate shutdown for critical problems. Digital checklist implementation using mobile devices facilitates consistent application while automatically creating documentation for analysis. Training ensures personnel understand proper inspection techniques, significance of various findings, and appropriate response actions. This systematic approach to daily inspection provides cost-effective monitoring that identifies developing issues at early stages when correction is simplest and least costly.

Environmental Factor Considerations

Environmental conditions significantly influence belt performance and service life, requiring specific considerations in maintenance planning and procedure development. Temperature extremes affect belt materials differently, with high temperatures accelerating chemical aging while low temperatures reduce flexibility and increase crack susceptibility. Chemical exposure including oils, solvents, or ozone can degrade belt materials through specific mechanisms depending on the compound and belt composition. Abrasive environments containing dust, grit, or other particulates accelerate surface wear while potentially causing groove clogging that affects belt seating. Moisture exposure can affect certain belt types through dimensional changes or material degradation, particularly in combination with other environmental factors.

Addressing environmental factors involves both protective measures and maintenance adaptations that compensate for specific conditions. Protective measures might include guards, shields, or enclosures that reduce exposure to problematic environmental factors. Maintenance adaptations could include more frequent inspections, different tension settings, or alternative belt materials better suited to specific environmental challenges. Temperature considerations might require tension adjustments to account for thermal expansion or contraction between maintenance intervals. Chemical exposure might necessitate material compatibility verification or more frequent replacement intervals to prevent unexpected failures. Abrasive environments typically justify more frequent cleaning activities and inspections to detect wear before it affects performance. This proactive approach to environmental factor management extends belt service life while maintaining reliable operation under challenging conditions.

Spare Parts Management Recommendations

Effective spare parts management ensures availability of necessary components when required while minimizing inventory investment through appropriate stocking strategies. Critical spare parts including belts, fasteners, and adjustment components should be maintained in quantities sufficient to address expected needs between replenishment cycles. Stocking levels should consider lead times for procurement, criticality of the application, and historical usage patterns that indicate consumption rates. Storage conditions must protect components from environmental damage including temperature extremes, moisture, UV exposure, or chemical contamination that might compromise integrity before use. Organization systems including clear identification, proper rotation, and accessibility ensure efficient utilization when components are needed.

Spare parts selection should consider quality, compatibility, and reliability factors beyond initial cost to ensure proper performance when installed. Quality verification includes manufacturer reputation, certification compliance, and performance history that indicates reliability in similar applications. Compatibility assessment ensures components match original equipment specifications for dimensions, materials, and performance characteristics. Reliability considerations might favor established brands with proven performance over lower-cost alternatives with uncertain service life. Inventory management systems track usage patterns, identify optimal reorder points, and generate procurement requests to maintain appropriate stock levels. Criticality analysis helps prioritize inventory investment toward components with the greatest operational impact if unavailable when needed. This systematic approach to spare parts management balances availability requirements with inventory investment to support effective maintenance execution.

Training and Skill Development Programs

Comprehensive training programs ensure personnel possess the knowledge and skills required for proper belt maintenance, troubleshooting, and replacement activities. Training content should cover fundamental principles, specific procedures, safety requirements, and troubleshooting approaches relevant to belt maintenance tasks. Fundamental principles include power transmission basics, belt material characteristics, and failure mechanisms that help personnel understand the importance of proper maintenance. Specific procedures provide step-by-step guidance for inspection, adjustment, and replacement activities using the specific equipment and tools available. Safety training covers hazard identification, protective measures, and emergency procedures specific to belt maintenance activities. Troubleshooting instruction develops systematic approaches to problem identification and resolution that minimize downtime while preventing recurring issues.

Training delivery should combine theoretical instruction with practical application to develop both knowledge and skills required for effective maintenance execution. Theoretical components can utilize classroom instruction, computer-based training, or self-study materials that establish foundational understanding. Practical application should include hands-on activities using actual equipment or realistic training aids that develop proficiency in specific maintenance tasks. Certification programs provide formal recognition of achieved competency levels while establishing minimum requirements for performing specific maintenance activities. Ongoing training ensures personnel maintain skills while learning new techniques, procedures, or technologies that improve maintenance effectiveness. Documentation of training completion creates records for compliance verification and identifies needs for additional instruction. This comprehensive approach to training and skill development ensures personnel capabilities match maintenance requirements for reliable belt performance.

Economic Benefits and Long-Term Maintenance Planning

Systematic belt maintenance programs deliver significant economic benefits through reduced downtime, extended component life, and improved operational efficiency that collectively justify implementation costs. Downtime reduction represents the most substantial economic benefit, with properly maintained belts experiencing 60-70% fewer unexpected failures compared to minimally maintained systems. Component life extension through proper tension, alignment, and environmental management typically increases belt service life by 30-50%, reducing replacement frequency and associated costs. Operational efficiency improvements from proper maintenance typically reduce energy consumption by 5-15% while maintaining production capacity through optimal power transmission. These economic benefits typically yield return on investment ratios of 3:1 to 5:1 for comprehensive maintenance programs compared to reactive approaches.

Long-term maintenance planning extends these economic benefits through strategic scheduling, resource allocation, and continuous improvement that optimize maintenance effectiveness. Maintenance scheduling should coordinate belt-related activities with other maintenance requirements to minimize total downtime through combined activities. Resource allocation ensures appropriate personnel, tools, and components are available when needed to execute maintenance activities efficiently. Continuous improvement processes analyze maintenance history to identify opportunities for procedure enhancement, interval optimization, or technology implementation that further improve economic outcomes. Integration with overall operational planning ensures maintenance activities support production requirements while minimizing disruption to critical processes. This strategic approach to long-term maintenance planning maximizes economic benefits while ensuring reliable crusher operation supporting overall operational objectives.

Cost-Benefit Analysis Methodology

Comprehensive cost-benefit analysis provides quantitative justification for maintenance program investments through systematic comparison of implementation costs against expected benefits. Cost components include direct expenses for labor, materials, and tools required for maintenance activities plus indirect costs for planning, documentation, and training. Benefit quantification includes downtime reduction valued at production loss rates, component life extension valued at replacement cost avoidance, and efficiency improvements valued at energy cost reduction. Additional benefits might include quality improvements, safety incident reduction, or environmental impact mitigation that contribute value beyond direct economic measures. The analysis typically projects these costs and benefits over appropriate time horizons, often 3-5 years, to account for both short-term and long-term impacts.

Specific calculation methodologies vary based on available data and analysis objectives, but typically follow established engineering economics principles. Downtime reduction benefits calculate as production hours saved multiplied by contribution margin per production hour, representing the value of additional output enabled by reduced interruptions. Component life extension benefits compute as replacement cost avoidance through extended service life, considering both part costs and installation labor requirements. Efficiency improvements translate to energy consumption reduction multiplied by energy costs, representing ongoing operational savings. Less tangible benefits including safety, quality, and environmental impacts might be quantified through established conversion factors or described qualitatively. Sensitivity analysis examines how results change with variations in key assumptions, identifying critical factors that most significantly influence economic outcomes. This rigorous approach to cost-benefit analysis provides convincing justification for maintenance investments while identifying optimal implementation strategies.

Maintenance Schedule Development

Systematic maintenance schedule development establishes appropriate intervals for various maintenance activities based on equipment criticality, operating conditions, and resource availability. The scheduling process begins with identifying all required maintenance tasks including inspections, adjustments, cleaning, and replacements with their respective frequency requirements. Criticality assessment prioritizes tasks based on their impact on operational reliability, with higher-criticality activities typically receiving more frequent attention. Operating condition evaluation adjusts intervals based on environmental factors, load characteristics, and other variables that influence maintenance requirements. Resource availability consideration ensures schedules align with personnel, tool, and part availability to facilitate efficient execution. The resulting schedule provides a comprehensive framework for maintenance execution while allowing flexibility for adjustment based on actual operating experience.

Effective schedule implementation requires appropriate tools, communication protocols, and monitoring systems that ensure adherence while accommodating necessary adjustments. Scheduling tools range from simple calendar-based systems to sophisticated computerized maintenance management systems that track requirements and execution. Communication protocols ensure all relevant personnel understand scheduled activities, their responsibilities, and timing requirements for proper preparation. Monitoring systems track schedule adherence, identify variances, and trigger corrective actions when activities deviate from planned timing. Schedule optimization uses historical data to refine intervals based on actual component performance and failure patterns under specific operating conditions. Integration with production planning coordinates maintenance activities with operational requirements to minimize disruption while maintaining equipment reliability. This systematic approach to maintenance schedule development and implementation ensures comprehensive equipment care while optimizing resource utilization.

Maintenance Management Software Utilization

Modern maintenance management software provides powerful tools for organizing, executing, and improving maintenance activities through systematic data management and analysis. Core functionality typically includes work order management, inventory control, maintenance history tracking, and reporting capabilities that support effective maintenance execution. Work order management facilitates planning, assignment, and tracking of maintenance activities with documentation of procedures, resources, and outcomes. Inventory control maintains appropriate spare parts levels through usage tracking, reorder triggering, and stock optimization based on actual consumption patterns. Maintenance history recording creates comprehensive equipment records that support troubleshooting, life cycle analysis, and maintenance interval optimization. Reporting capabilities transform raw data into actionable information for maintenance decision-making and performance monitoring.

Advanced software implementations incorporate additional features including predictive maintenance algorithms, mobile access, and integration with other operational systems that enhance functionality. Predictive maintenance capabilities use equipment data and failure patterns to forecast maintenance needs before failures occur, optimizing intervention timing. Mobile access enables field personnel to access information, record findings, and complete documentation without returning to office locations, improving efficiency. Integration with enterprise systems including production planning, procurement, and accounting creates comprehensive operational visibility while reducing duplicate data entry. Implementation considerations include software selection matching organizational needs, data migration from existing systems, and personnel training for effective utilization. The return on investment from maintenance management software typically justifies implementation costs through improved maintenance efficiency, reduced downtime, and extended equipment life. This technological approach to maintenance management represents a significant advancement from traditional paper-based systems.

Continuous Improvement Strategy Implementation

Continuous improvement processes systematically enhance maintenance effectiveness through regular evaluation of procedures, outcomes, and opportunities for improvement. The improvement cycle typically begins with performance measurement establishing baselines for key indicators including equipment reliability, maintenance costs, and resource utilization. Analysis of measurement data identifies areas where performance falls below expectations or opportunities exist for significant improvement. Solution development generates potential approaches for addressing identified issues, ranging from procedural modifications to technology implementation or organizational changes. Implementation planning ensures proposed solutions transition effectively into practice with appropriate resources, timing, and change management considerations. Evaluation measures solution effectiveness against established baselines, confirming benefits while identifying additional improvement opportunities.

Specific improvement methodologies might include root cause analysis for recurring problems, benchmarking against industry standards, or technology assessment for potential implementation. Root cause analysis investigates underlying reasons for specific issues rather than addressing symptoms, preventing recurrence through comprehensive solutions. Benchmarking compares maintenance performance metrics against industry leaders or established standards, identifying performance gaps and improvement priorities. Technology assessment evaluates emerging tools, equipment, or systems that might enhance maintenance effectiveness through improved capabilities or efficiency. Improvement teams typically include personnel from multiple disciplines and organizational levels, bringing diverse perspectives to problem identification and solution development. Documentation of improvement activities, results, and lessons learned creates institutional knowledge that supports ongoing enhancement efforts. This systematic approach to continuous improvement ensures maintenance practices evolve to meet changing operational requirements while maximizing economic benefits.