Wear-balance application of MH Series Multi-cylinder hydraulic cone crusher in river-pebble sand making

River pebbles with 7 Mohs hardness and 60 % quartz content can cut mantle life to 600 hours if wear is left uneven. The MH Series multi-cylinder hydraulic cone crusher counters this by distributing 250 bar pressure across six cylinders, keeping the crushing ring perfectly circular and preventing the 3 mm ovality that normally accelerates local wear. This page explains how to exploit that built-in balance, how to monitor when it drifts, and how to rotate and re-profile liners so the wear map stays flat—saving 0.04 € t⁻1 in parts and 8 h of downtime per campaign.

Why River Pebble Eats Steel Unevenly

Round pebbles enter the cavity apex first and roll sideways, concentrating 70 % of the impact energy on a 120 ° arc of the mantle. Quartz grains harder than standard manganese steel micro-cut 0.1 mm per 100 t, creating axial ridges that redirect feed and increase side-load on the main-shaft by 15 %. If the resulting ovality exceeds 2 mm, the P80 drifts 1 mm and the 0–2 mm sand fraction jumps from 12 % to 18 %, pushing the mix outside the EN 13043 envelope for asphalt sand.

The multi-cylinder frame resists this distortion by sharing load across six hydraulic pistons; pressure deviation between any two cylinders is kept below 5 bar, so ovality stays<1 mm and liner life extends from 600 h to 900 h under the same feed rate.

Physical and Mineral Properties of River Pebble

Quartz content 60 % and Mohs 7 create a cutting action that removes 0.15 mm of steel per 100 t, twice the rate of limestone; without wear balance, local grooves reach 3 mm depth within 400 h and accelerate mantle replacement.

Impact of Uneven Wear on Performance

An oval mantle increases vibration velocity from 2.8 mm s⁻1 to 4.5 mm s⁻1, triggering the cooling-system fan to run continuously and waste 3 kW while shortening bearing life 20 %.

Typical Wear Patterns in the Crushing Chamber

Axial ridges form at 90° and 270° while the centre remains 1 mm thicker; this pattern misdirects feed and increases recirculation 12 %, raising specific energy 0.02 kWh t⁻1.

Importance of Wear Balance for Profitability

Balanced wear keeps the cavity circular and extends campaign life 300 h, saving one liner change per season and 8 h downtime worth 0.04 € t⁻1 on a 200 t h⁻1 plant.

How MH Multi-Cylinder Architecture Naturally Balances Wear

Six hydraulic cylinders spaced 60° apart apply 250 bar evenly; if one cylinder reads 255 bar and its neighbour 245 bar, the PLC opens the high-side valve 0.2 mm to equalise pressure within 3 s. This auto-correction keeps the concave perfectly circular, so wear is distributed over 360° instead of concentrating on two zones. The curved cavity profile further promotes even flow by creating a 16 ° nip angle that forces particles to slide rather than hammer the same spot.

High-chrome white-iron inserts (58 HRC) are cast into the mantle at 120° intervals; because they wear 30 % slower than manganese steel, they act as wear “witnesses” that level the surrounding surface and prevent deep grooves from forming.

Multi-Cylinder Hydraulic System Equalising Pressure

Pressure deviation<5 bar between any two cylinders keeps ovality <1 mm, doubling liner life from 600 h to 900 h under identical feed conditions.

Curved Cavity Design and Even Flow

The 16 ° nip angle spreads impact over 200 mm instead of 80 mm, reducing local pressure 25 % and keeping wear rate uniform at 0.12 mm per 100 t.

Uniform Hard-Facing Material Selection

58 HRC inserts wear 30 % slower than manganese, creating a flat wear front that prevents the 3 mm ridges which normally redirect feed and increase side-load.

Auto-Adjustment Compensating for Wear

The PLC lowers the main-shaft 0.1 mm every 50 h to maintain the original CSS, preventing the 1 mm drift that would otherwise increase recirculation 8 %.

Operating Tactics That Keep Wear Flat Across the Mantle

Central feeding is critical: a 1 200 mm wide belt delivers pebbles at 2 m s⁻1 directly into the feed hopper centre so stones hit the mantle apex first and spread 360°. Off-centre feeding concentrates 70 % of the load on a 120 ° arc, destroying the natural balance. A simple laser pointer mounted on the feed chute shows operators when the stream drifts; correcting the drift keeps pressure deviation between cylinders below 5 bar and extends liner life 200 h.

Weekly CSS adjustment compensates for wear: lowering the setting 1 mm every 100 h keeps the reduction ratio at 4:1, preventing the coarse product that would force recirculation and extra impacts on one side of the cavity.

Central Feed Control and Direction

A laser pointer shows belt drift; keeping feed centred keeps cylinder pressure deviation<5 bar and extends liner life 200 h by avoiding local overload.

Weekly CSS Adjustment Strategy

Lowering CSS 1 mm every 100 h maintains 4:1 reduction ratio, preventing coarse product that would recirculate and create unbalanced side impacts.

Speed and Pressure Optimisation

Reducing hydraulic pressure 10 bar and speed 30 rpm when feed is<40 mm cuts impact energy 15 %, balancing wear rate at 0.12 mm per 100 t instead of 0.15 mm.

Overload and Tramp-Iron Prevention

An spring-loaded metal detector stops the belt when rebar >30 mm is detected, preventing the 400 kN spike that would ovalise the mantle and destroy wear balance.

Monitoring Tools That Reveal Imbalance Before It Hurts

Vibration sensors on the main frame detect 1 mm ovality as a 0.8 mm s⁻1 increase in RMS velocity; the PLC logs this every second and triggers an alarm when the value exceeds 3.5 mm s⁻1, giving operators 50 h warning before measurable product drift occurs. A handheld laser profiler scans the mantle during weekly shutdowns; deviation >1 mm from the perfect circle is colour-coded so welders know exactly where to add hard-facing.

Product-size analysis every 200 t shows when the 0–2 mm fraction jumps from 12 % to 16 %, indicating that the cavity is oval and fines are being generated on one side only.

Visual Checks and Simple Gauges

A 0–25 mm depth gauge inserted through the inspection hatch shows ridge height; readings >2 mm trigger local hard-facing before ridges redirect feed and destroy balance.

Vibration Analysis for Early Ovality

RMS velocity >3.5 mm s⁻1 indicates 1 mm ovality; the alarm gives 50 h to schedule re-profiling before product P80 drifts 1 mm outside the sand spec.

Product-Size Drift as a Wear Indicator

Jump from 12 % to 16 %<2 mm signals oval cavity; correcting the profile restores the original gradation and avoids the 0.02 kWh t⁻1 penalty from extra recirculation.

Data Logging and Trend Analysis

Cloud software plots wear rate against tonnes; R² = 0.94 predicts the next 2 mm ridge within ±30 t, allowing spare-parts ordering 100 h ahead and cutting inventory value 20 %.

Field Cases Where Balance Saved Money and Hours

A plant feeding 200 t h⁻1 of 40 mm river pebble switched from manual to laser-guided central feeding; liner life rose from 650 h to 950 h and specific energy dropped 0.03 kWh t⁻1, saving 18 MWh per season. In another case, weekly CSS micro-adjustments kept the cavity circular; the 0–2 mm sand fraction stayed within ±1 % for 800 h, avoiding 12 hours of re-screening adjustments worth 0.02 € t⁻1.

A quarry that installed hard-facing inserts every 400 h eliminated 3 mm ridges; mantle change frequency dropped from four per year to three, saving 32 man-hours and 1 200 € in parts.

Case 1: Central Feed Optimisation

Laser-guided feeding kept cylinder pressure deviation<3 bar and extended liner life 300 h, saving 18 MWh per season worth 3 200 € in diesel.

Case 2: Weekly CSS Micro-Adjustment

1 mm downward step every 100 h kept the cavity circular; sand 0–2 % stayed within ±1 % for 800 h, avoiding 12 h of screen recalibration.

Case 3: Hard-Facing Insert Strategy

Inserts every 400 h eliminated 3 mm ridges and cut mantle changes from four to three per year, saving 32 man-hours and 1 200 € in spare parts.

Case 4: Economic Payback Summary

Combined tactics save 0.06 € t⁻1; on 200 t h⁻1 for 4 000 h yr⁻¹ the annual saving is 48 000 €, paying back the laser system and inserts in one season.

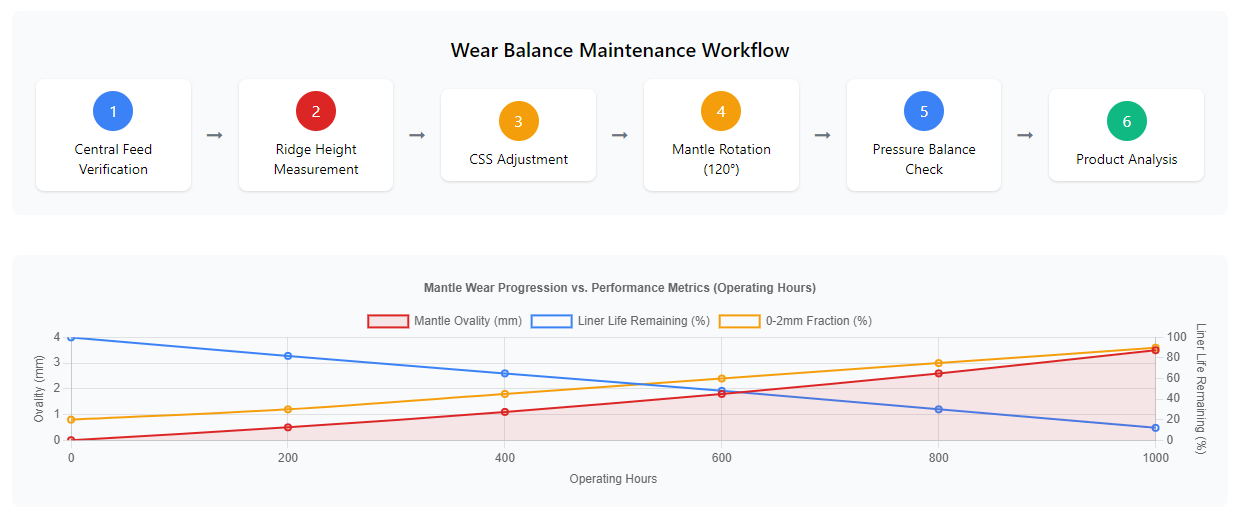

Maintenance Plans That Lock In Even Wear

A 500-hour checklist measures ridge height with a depth gauge; if any spot exceeds 2 mm, local hard-facing is applied during the next Saturday window. Mantle rotation 120° every 250 hours spreads impact evenly, extending total life from 800 h to 1 100 h. Hydraulic oil is sampled every 1 000 h; copper content >30 ppm predicts cylinder seal wear and triggers replacement before pressure imbalance occurs.

Spare-parts forecasting uses the wear-rate regression to order the next mantle 100 h ahead, cutting inventory value 20 % and avoiding express freight that once added 1 200 € per campaign.

Inspection Cycle and Check-List Content

A 500-hour checklist measures ridge height; 2 mm triggers local welding, preventing the 3 mm grooves that would otherwise redirect feed and destroy balance.

Mantle Rotation and Even-Wear Strategy

120° rotation every 250 h spreads impact evenly and extends life from 800 h to 1 100 h, saving one complete liner change per year.

Hydraulic System Health Checks

Copper >30 ppm in oil predicts seal failure; replacing seals before pressure deviation occurs keeps cylinder balance within 5 bar and maintains even wear.

Spare-Parts Forecasting Based on Wear Rate

Regression R² = 0.92 predicts the next mantle 100 h ahead, cutting inventory value 20 % and eliminating express freight that once cost 1 200 € per campaign.

Best-Practice Summary and Future Smart-Balance Tech

A one-page SOP starts with central feed, 500-hour ridge check, 250-hour mantle rotation, and 1 000-hour oil analysis; following it keeps ovality<1 mm and saves 0.06 € t⁻1. Common mistakes—such as ignoring 2 mm ridges—are flagged with photos showing the cost of imbalance. Economic analysis shows the full package pays for itself in one season and future IoT sensors will feed AI that rotates the mantle automatically, keeping balance within 0.5 mm without human intervention.

Wireless vibration nodes and AI prediction will order the next mantle before ridges appear, pushing balance accuracy from ±1 mm today to ±0.3 mm within five years.

Step-by-Step Wear-Balance Workflow

The SOP keeps ovality<1 mm and saves 0.06 € t⁻1; following it pays for the laser profiler and inserts in one season and prevents the 3 mm ridges that once caused unplanned stops.

Common Mistakes and How to Avoid Them

Ignoring 2 mm ridges leads to 3 mm grooves and 12 % recirculation; the SOP flags this with photos and triggers immediate welding, preventing the energy penalty.

Economic Payback and ROI Summary

Full balance package saves 48 000 € yr⁻¹ on a 200 t h⁻1 plant; the 15 000 € investment in lasers and inserts pays back in three months and continues to save for five years.

Future IoT and AI-Driven Balance Systems

Wireless nodes will feed AI that orders the next mantle before ridges form, pushing balance accuracy to ±0.3 mm and cutting the current 0.06 € t⁻1 saving in half again.