Emergency Response: Steps to Take When Your Cone Crusher Stops or Jams Suddenly

This guide provides a structured approach for operators facing the sudden stoppage or jamming of a cone crusher. It systematically covers the initial safety protocols, diagnostic procedures, and immediate corrective actions required to mitigate downtime, protect the integrity of the machine, and ensure the safety of all personnel. Understanding these steps is crucial for maintaining operational efficiency and preventing costly damage to the equipment.

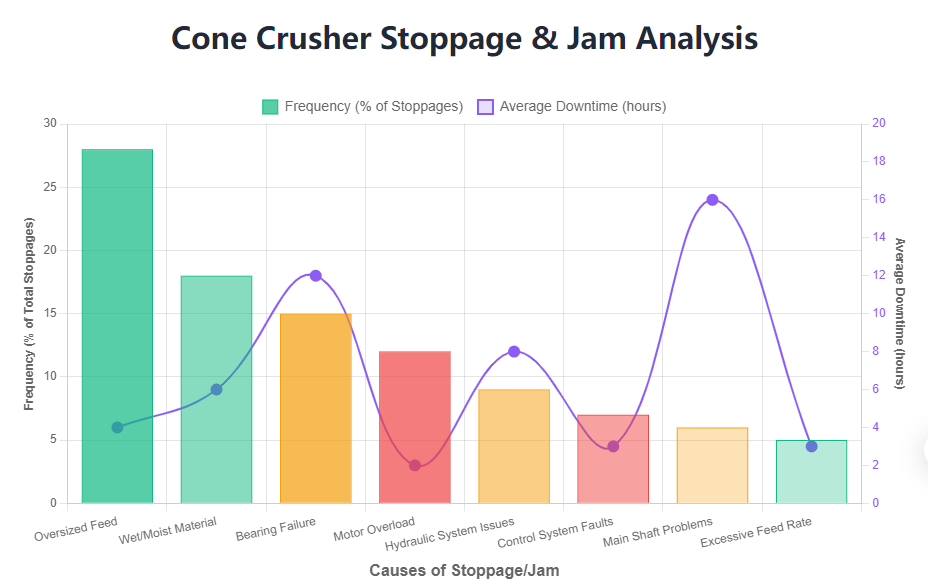

Common Causes for Sudden Stoppage or Jam

Cone crushers are robust

machines designed for continuous operation under heavy loads. However, several factors can lead to an unexpected halt. Electrical issues often stem from power surges or component

failure, causing the motor protection systems to engage and shut down the unit. Mechanical failures are typically related to the immense forces within the crushing chamber, where

components like bearings or the main shaft can succumb to fatigue or improper lubrication.

Feed-related problems are another prevalent cause. Introducing material that exceeds the crusher's designed feed size can instantly block the chamber. Similarly, feeding at a rate beyond the machine's crushing capacity overwhelms the system, while material with high moisture content can compact and adhere to the chamber walls, creating a solid mass that stops the mantle's movement.

Electrical Faults and Power Supply Issues

Electrical faults are a primary culprit for instant crusher shutdown. Motors are equipped with thermal overload protectors that trip when excessive current is detected, a condition often resulting from a jam that has already begun or a voltage irregularity from the main supply. Control system malfunctions can also occur, where a fault in the programmable logic controller or its sensors sends an erroneous stop command.

Regular inspection of electrical connections, contactors, and relay systems is a fundamental preventive measure. Ensuring stable voltage supply and calibrating motor protection settings to the specific operational load can significantly reduce the incidence of electrically induced stoppages.

Mechanical Failures and Component Damage

The mechanical heart of the cone crusher, including the main shaft and eccentric assembly, operates under extreme stress. A sudden failure of a critical component, such as a spherical bearing or a gear, will cause an immediate and catastrophic stop. This is often accompanied by loud, grinding noises and severe vibration from the crusher base.

Such failures are frequently the result of progressive wear that went undetected. Implementing a rigorous preventive maintenance schedule that includes oil analysis and vibration monitoring can provide early warnings of impending mechanical issues, allowing for intervention before a complete failure occurs.

Feed-Related Blockages from Oversized or Wet Material

Operational errors in feed management are a common and often avoidable cause of jamming. An oversight at the primary crushing stage or a malfunctioning feeder can allow a single piece of oversize rock to enter the chamber, jamming between the mantle and concave. The force required to crush such material far exceeds the crusher's design limits and the hydraulic relief system's capacity.

Furthermore, sticky, clay-rich, or overly wet material poses a significant risk. This type of feed does not flow freely through the chamber and can gradually build up, eventually seizing the mantle. Using pre-screening scalpers to remove fines and managing material moisture are key strategies to prevent these blockages.

Safety Preparations Before Emergency Response

Before any attempt to diagnose or address a crusher stoppage, a strict safety protocol must be followed. The immediate priority is to isolate the machine from all potential energy sources. This is a non-negotiable first step to prevent any accidental startup that could endanger personnel working on or near the equipment.

Concurrently, the area around the crusher must be secured and assessed. Spilled material around the base can create slip hazards, and any signs of fluid leakage indicate potential instability or other risks. Only after the environment is confirmed to be secure should the next steps be considered.

Isolating Power and Locking Out the System

Simply pressing the stop button on the control panel is insufficient. The crusher must be completely isolated from its power source at the main electrical disconnect switch. Following a lock-out-tag-out procedure is mandatory; each involved operator places their personal lock on the disconnect, ensuring that no one can inadvertently restore power while work is being done.

This process also involves verifying that all stored energy has been dissipated. For cone crushers, this means ensuring the hydraulic system pressure is bled off and that the massive flywheel and moving parts have come to a complete stop, eliminating any risk of movement from residual kinetic energy.

Utilizing Personal Protective Equipment

Approaching a malfunctioning industrial machine requires appropriate personal protective equipment. A hard hat protects against falling objects from the feed hopper, while safety glasses shield eyes from dust and loose particles. Heavy-duty gloves are necessary for handling sharp-edged metal components or rough, abrasive rock material.

Steel-toed boots and high-visibility clothing complete the essential safety attire. This equipment forms a critical barrier against the multitude of hazards present in a crushing plant environment, especially during troubleshooting and repair operations where normal safeguards might be bypassed.

Evaluating On-Site Safety Conditions

A thorough visual assessment of the immediate area is conducted before any physical inspection of the crusher begins. Operators look for obvious dangers such as material spillage creating uneven walking surfaces, hydraulic oil leaks creating slip and fire risks, or any signs of structural stress on the crusher itself.

This evaluation also includes checking for environmental factors like poor lighting or loud ambient noise that could impair communication between team members. Identifying these conditions allows for mitigating actions to be taken, such as laying down absorbent material for oils or using designated hand signals for communication.

Preliminary Inspection and Fault Diagnosis

With safety protocols firmly in place, the next phase involves a methodical inspection to identify the root cause of the stoppage. This begins with a visual external examination, looking for clear indicators of trouble such as physical damage, leaks, or the presence of unwanted material in areas it shouldn't be.

Operators then consult the crusher's control system for diagnostic information. Modern crushers are equipped with sophisticated sensors that monitor a wide array of parameters; the control panel often displays error codes or alarm messages that can pinpoint the specific system where the fault originated, dramatically narrowing down the search.

Observing Equipment Appearance and Operational Status

A careful visual walk-around can reveal many clues. Signs of fresh, bright metal around the base suggest a catastrophic internal mechanical failure where a component has fractured. Puddles of oil or grease indicate a seal failure or a cracked lubrication line, which could have led to a bearing seizure.

Inspecting the state of the feed hopper and the area around the discharge point is also telling. A pile of uncrushed material at the discharge might suggest a jam, while an empty discharge with a full hopper points towards a blockage in the chamber itself. These observations form the initial hypothesis for the problem.

Checking the Electrical System and Control Panel

The crusher's control panel is the primary source of diagnostic data. Operators review the history of alarm messages, which often log the sequence of events leading to the shutdown. An alarm for "Motor Overload" points to an electrical or mechanical jam, while a "Lube Oil Pressure Low" alarm suggests a failure in the lubrication system that may have caused a bearing to fail.

Physical checks include verifying the position of the main circuit breaker and inspecting the motor starter cabinet for any tripped breakers or blown fuses. These checks help determine if the electrical system is the cause of the problem or merely a victim of a mechanical failure elsewhere.

Listening for Abnormal Sounds and Vibrations

While the crusher is stopped, operators may attempt to identify issues through sound and feel. Using a listening device or a long screwdriver placed against bearing housings, they can listen for the tell-tale grinding or clicking sounds of damaged internal components.

Excessive vibration felt through the crusher's structure, even at rest, can indicate a misalignment or a broken part that has shifted out of balance. Although this is done cautiously, these sensory checks can provide valuable confirmation of a suspected internal mechanical failure before any dismantling begins.

Immediate Corrective Actions for Different Faults

Once a likely cause has been identified through preliminary inspection, targeted corrective actions can be initiated. The approach differs significantly depending on whether the issue is electrical, mechanical, or related to a feed blockage. The goal is to resolve the problem safely and effectively, preparing the crusher for a return to operation.

For electrical issues, the focus is on resetting protective devices and verifying circuit integrity. Mechanical interventions are more complex, often requiring tools and sometimes partial disassembly. Addressing a material jam requires a physical clearing process that must be done with care to avoid damaging the liners or other internal parts.

Addressing Electrical Faults by Inspecting Circuits and Motors

If an electrical fault is suspected, the first step after lock-out-tag-out is to inspect all visible wiring for damage, such as cuts, burns, or loose connections. The motor's windings can be tested for resistance and insulation integrity using a multimeter to check for a short circuit or a ground fault.

After identifying and rectifying any simple issues like a tripped breaker or a loose wire, the power can be cautiously restored to test the system. If the fault persists, it may indicate a deeper problem with the motor itself or the variable frequency drive, requiring specialized electrical troubleshooting.

Managing Mechanical Failures Through Manual Adjustment or Part Replacement

For suspected mechanical jams, a common first step is to carefully attempt to rotate the main shaft manually using a barring tool. If it moves freely, the issue might be minor. If it is completely locked, it confirms a serious internal jam or failure.

In cases of minor jams, engaging the crusher's built-in hydraulic clearing system can sometimes break the material free by raising and lowering the mantle. For confirmed mechanical failures, the only solution is to schedule a shutdown, dismantle the crusher, and replace the damaged components, such as bearings or the eccentric assembly.

Resolving Feed Abnormalities by Adjusting Speed and Moisture Content

Clearing a material jam begins with safely removing any rock from the feed hopper to prevent additional load. Accessing the crushing chamber through the top or side inspection hatches, operators then use specialized long tools or hydraulic rock hammers to break up and extract the compacted material.

Once cleared, the root cause of the feed problem must be addressed. This involves coordinating with the upstream loading and screening operations to ensure the feed size is controlled and that the feed rate is regulated to match the crusher's capacity, preventing a recurrence of the overload condition.

Clearing and Resetting the Equipment

After the immediate cause of the stoppage has been resolved, the process of preparing the crusher for restart begins. This involves a thorough cleaning to remove any debris from the event, a meticulous inspection of all systems, and a methodical resetting of all safety and operational controls to their standard positions.

This phase is critical to ensure that no secondary issues remain that could cause another immediate failure. It is a systematic checklist-driven process that verifies the crusher is truly ready for the stresses of operation and will not sustain further damage upon startup.

Safely Removing Jammed Material and Residual Debris

All fragmented material from the clearing process must be removed from the crusher's interior and the surrounding area. This is done using brushes, air hoses, or vacuum systems to ensure that no loose stones or metal fragments remain inside the crushing chamber or in the lubrication paths.

Special attention is paid to the discharge area to ensure it is completely clear. Any obstruction here can prevent the newly crushed material from exiting freely, leading to a rapid re-circulation and buildup that would cause another jam almost immediately after restarting.

Resetting the Equipment to Its Standard Configuration

Any systems that were activated during the emergency response must be reset. This includes resetting the hydraulic relief valves to their correct pressure settings, ensuring the adjusting ring is at the desired discharge size setting, and verifying that all safety interlocks and guards are properly secured.

The control system is also reset, which involves acknowledging and clearing all previous alarm messages from the log. This provides a clean slate for the control system to monitor the upcoming restart and ensures that old, resolved alarms do not cause confusion.

Conducting Pre-Start Checks Before Recommissioning

A final comprehensive check is performed before power is restored. This includes verifying that all tools and personnel are clear of the equipment. Critical fluid levels, such as hydraulic oil and lubricant, are checked and topped up if necessary, as leaks are a common side effect of a jam event.

All mechanical fasteners and inspection covers are checked to ensure they are tight and secure. Only after this full checklist is completed and signed off can the lock-out-tag-out devices be removed and power restored to the crusher in preparation for a controlled restart.

Post-Response Summary and Process Improvement

Every emergency event is a learning opportunity. A formal review process following a crusher stoppage is essential for continuous operational improvement. This involves meticulously documenting what happened, analyzing why it happened, and implementing changes to prevent it from happening again.

This proactive approach transforms a reactive emergency fix into a strategic investment in future reliability. It helps build a knowledge base within the team, improves maintenance schedules, and ultimately leads to higher overall equipment effectiveness and reduced operating costs.

Documenting the Incident and the Response Actions Taken

A detailed incident report is created, logging the exact time of the failure, the operating conditions at the moment of stoppage, and all observable symptoms. The report meticulously records every diagnostic step taken and every corrective action performed, including parts used and time taken for each task.

This documentation is invaluable. It provides a historical record for that specific crusher, helping to identify recurring patterns or weaknesses. It also serves as a training tool for new operators, showing real-world examples of how specific problems were resolved.

Analyzing the Root Cause and Developing Preventive Strategies

Beyond fixing the immediate problem, the team conducts a root cause analysis to understand the underlying reason for the failure. For instance, a jam caused by oversize material might reveal a faulty screen panel in the primary plant or a need for better communication between plant sections.

The outcome of this analysis is a set of actionable preventive measures. This could lead to changes in operational procedures, such as implementing more frequent checks of upstream screens, or to modifications in the preventive maintenance plan, like scheduling more frequent oil analysis to catch bearing wear earlier.

Training Operators to Enhance Future Response Capability

The lessons learned from the event are integrated into the regular training program for all crushing plant operators. Conducting simulated drills based on real past failures, like a sudden jam or motor trip, prepares the team to respond more quickly and effectively in the future.

This continuous training ensures that all personnel are not only familiar with the theoretical procedures but also confident in their practical application. A well-trained team is the most effective asset for minimizing downtime and maintaining safe and productive operations when unplanned events occur.