Essential Daily Inspection and Maintenance Procedures for Cone Crushers

Proper maintenance of cone crushers represents a critical aspect of ensuring operational reliability, equipment longevity, and consistent product quality in material processing

operations. These complex machines require systematic attention to their mechanical, hydraulic, and electrical systems to maintain optimal performance under demanding operating

conditions. This comprehensive guide examines the structured approach to cone crusher maintenance, progressing from daily operational checks through weekly procedures to

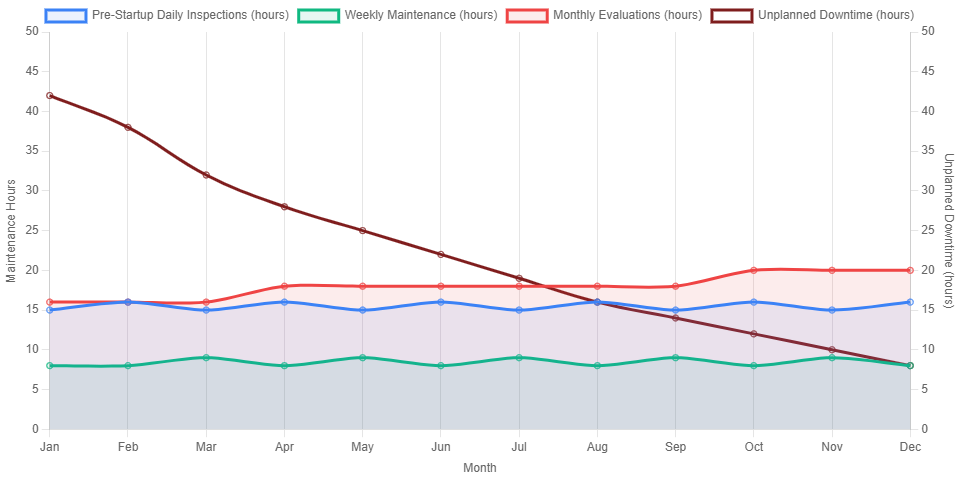

comprehensive monthly evaluations. Implementing these maintenance practices significantly reduces unexpected downtime, extends component service life, and maintains processing

efficiency throughout the equipment's operational lifespan.

Pre-Startup Daily Inspection Procedures

Daily inspection routines conducted before equipment startup form the foundation of effective cone crusher maintenance, serving to identify potential issues before they develop into significant problems. These systematic checks encompass all critical systems and components, verifying that the crusher can operate safely and efficiently throughout the upcoming production shift. Establishing consistent inspection protocols ensures that no elements are overlooked and provides baseline data for tracking equipment condition over time. Documentation of these daily inspections creates valuable historical records that support predictive maintenance strategies and help identify developing trends in equipment performance.

The inspection process should follow a logical sequence that mirrors the material flow through the crusher, beginning with feed systems and progressing through the crushing chamber to discharge arrangements. This methodological approach ensures comprehensive coverage while minimizing the possibility of missed inspection points. Operators should allocate sufficient time for these inspections, typically requiring approximately thirty minutes for a thorough evaluation, recognizing that this investment in preventive maintenance yields substantial returns through reduced unscheduled downtime and lower repair costs over the equipment's operational life.

Lubrication System Assessment Points

The lubrication system requires meticulous daily inspection as it represents the circulatory system that ensures proper functioning of all moving components within the crusher. Initial inspection should verify that oil levels fall within the operating range indicated on sight glasses or dipsticks, with particular attention to maintaining proper levels in both the main reservoir and any auxiliary systems. Operators should then examine oil condition for signs of contamination, discoloration, or moisture presence, which might indicate developing problems requiring attention before equipment operation commences.

Following level and condition checks, the lubrication system should be operated briefly without starting the main crusher drive to verify proper oil circulation and pressure development. This verification ensures that oil reaches all critical bearings and gears immediately upon startup, preventing operation without adequate lubrication. The system should maintain pressure within manufacturer-specified parameters, typically between 0.8 and 1.2 bars for most cone crusher configurations, with any deviations indicating potential issues requiring investigation before proceeding with operation.

Electrical System Safety Verification

Electrical system inspections begin with visual examination of all accessible cables, connections, and components for signs of damage, wear, or overheating that could compromise operational safety. Particular attention should focus on main power connections, control wiring, and motor termination points, ensuring all connections remain tight and free from corrosion or evidence of arcing. Infrared temperature measurements of electrical panels and components during operation provide valuable baseline data, with temperatures typically maintained below 60°C to prevent insulation degradation and ensure reliable operation.

Safety system verification forms another critical aspect of electrical inspection, ensuring that all emergency stops, guards, and protective devices function correctly before equipment operation. These verifications should include functional testing of all safety interlocks and emergency shutdown systems to confirm their proper operation. Documentation of these tests provides evidence of compliance with safety regulations while establishing performance baselines for subsequent inspections and maintenance activities.

Liner and Mantle Wear Evaluation

Wear component inspection requires careful examination of crushing chamber elements to assess remaining service life and plan for replacement before excessive wear affects product quality or equipment performance. Daily evaluation should document wear patterns on both fixed concaves and the moving mantle, noting any unusual wear patterns that might indicate improper operation or feed material characteristics. Measurements should reference established baseline dimensions, with wear typically not exceeding 70% of the original thickness before scheduling replacement to maintain crushing efficiency and product quality.

The evaluation should also include inspection of liner retention systems, ensuring that all bolts remain properly torqued and show no evidence of stretching or fatigue that could compromise component security. Proper documentation of wear rates enables predictive maintenance planning, with most manganese liners providing between 500 and 1000 operating hours of service life depending on material abrasiveness and operating conditions. This data facilitates timely ordering of replacement components and scheduling of maintenance downtime to minimize production disruptions.

Feed and Discharge Area Cleaning

Material accumulation around feed and discharge areas requires regular removal to prevent operational problems and maintain efficient material flow through the crushing circuit. Daily cleaning should remove all residual material from around the crusher feed opening, ensuring that no obstructions could interfere with proper material entry into the crushing chamber. Similarly, the discharge area must be cleared of accumulated product to prevent backup that could impede proper operation and potentially damage components through material packing.

The cleaning process should utilize appropriate tools that will not damage crusher components, typically including non-sparking implements for removing packed material and industrial vacuum systems for fine particulate removal. Particular attention should focus on areas around adjustment mechanisms and moving components where material accumulation could interfere with proper operation or conceal developing problems. Complete cleaning provides the additional benefit of allowing thorough visual inspection of components that might otherwise remain obscured by accumulated material.

Operational Monitoring Procedures

Continuous monitoring during crusher operation provides essential real-time data regarding equipment performance and condition, enabling immediate response to developing issues before they escalate into significant problems. These monitoring activities complement pre-startup inspections by capturing dynamic information that only becomes apparent during actual operation under load. Modern crushers typically incorporate sophisticated monitoring systems that track multiple parameters simultaneously, providing operators with comprehensive situational awareness regarding crusher performance and health.

Effective operational monitoring requires establishing baseline performance parameters for comparison with current operating data, enabling identification of deviations that might indicate developing issues. These baselines should encompass vibration levels, power consumption, hydraulic pressures, and product quality parameters under normal operating conditions with various material types. Documentation of operational parameters creates valuable historical data that supports trend analysis and facilitates predictive maintenance strategies based on actual operating conditions rather than fixed time intervals.

Vibration and Noise Level Monitoring

Vibration analysis during operation provides valuable insights into mechanical condition, with increased vibration levels often indicating developing problems such as component wear, imbalance, or misalignment. Baseline vibration readings should be established for new equipment or following major maintenance, with subsequent measurements compared against these references to identify changes requiring investigation. Modern monitoring systems typically incorporate accelerometers that continuously measure vibration amplitudes, with alerts generated when readings exceed predetermined thresholds indicating potential issues.

Acoustic monitoring complements vibration analysis by detecting abnormal sounds that might indicate specific problems such as component interference, lubrication issues, or material packing. Operators should become familiar with the crusher's normal operational sound signature, enabling quick recognition of unusual noises that warrant investigation. Advanced acoustic monitoring systems can automatically analyze sound patterns and identify deviations from normal operation, providing early warning of developing issues before they progress to component failure or unplanned downtime.

Crushing Force Adjustment Management

Optimal crushing force application represents a critical factor in achieving efficient size reduction while minimizing component wear and energy consumption. Modern hydraulic cone crushers provide continuous adjustment capability, allowing operators to optimize crushing force based on feed material characteristics and product requirements. Monitoring systems typically display current hydraulic pressure, which directly correlates with applied crushing force, enabling operators to maintain pressures within manufacturer-recommended ranges for specific applications.

Automatic control systems can dynamically adjust crushing force in response to changing feed conditions, maintaining optimal performance without constant manual intervention. These systems typically utilize algorithms that balance production rate, product quality, and energy consumption based on predefined operational priorities. Documentation of crushing force settings and corresponding performance metrics provides valuable data for optimizing operational parameters for specific material types and production requirements.

Product Size Quality Verification

Regular sampling and analysis of crusher product provides essential verification that the equipment continues to produce material meeting specification requirements. Sampling should follow established procedures to ensure representative samples that accurately reflect overall product quality. Frequency of sampling depends on production criticality and material consistency, with typical intervals ranging from hourly to shift-based depending on operational requirements and quality control protocols.

Particle size distribution analysis forms the core of product quality verification, typically performed using standard sieve analysis techniques or automated particle size analyzers. Results should be compared against specification limits and historical data to identify trends that might indicate wear-related performance degradation or operational issues requiring adjustment. Documentation of these quality verification activities provides essential records for product certification and supports continuous improvement initiatives aimed at optimizing crusher performance and product quality.

Hydraulic System Pressure Surveillance

Continuous monitoring of hydraulic system pressures provides crucial information regarding crusher operation and condition, with pressure readings serving as indicators of both operational parameters and potential developing issues. Main hydraulic system pressure typically operates within a range of 150 to 200 bar during normal operation, with variations indicating changes in feed material characteristics or potential problems requiring attention. Pressure transducers continuously monitor these values, with control systems automatically adjusting pump output to maintain desired operating parameters.

Accumulator pressure represents another critical monitoring point, ensuring that nitrogen precharge pressures remain within specified limits to provide proper system operation and overload protection. Regular verification of accumulator pressures, typically requiring monthly checks, ensures that the system can provide immediate fluid volume when needed for adjustment functions or overload protection. Documentation of pressure readings over time facilitates trend analysis that can reveal developing issues such as pump wear or internal leakage before they affect crusher performance.

Weekly Maintenance Emphasis Areas

Weekly maintenance procedures provide opportunities for more comprehensive evaluation and servicing of crusher components than possible during daily inspections, addressing areas requiring less frequent attention but still essential for reliable operation. These procedures typically require scheduled downtime of several hours, allowing thorough inspection, cleaning, and adjustment of critical systems. Establishing consistent weekly maintenance routines ensures that these important activities receive proper attention rather than being deferred due to production pressures.

The weekly maintenance schedule should follow a standardized checklist that encompasses all critical systems, with particular emphasis on components subject to wear or contamination that could affect reliability if not addressed regularly. Documentation of weekly maintenance activities provides valuable historical data supporting component life tracking and predictive maintenance planning. These records also facilitate identification of developing trends that might indicate the need for more frequent attention to specific systems or components based on actual operating conditions.

Lubrication System Comprehensive Cleaning

Weekly lubrication system maintenance extends beyond daily inspections to include thorough cleaning of reservoirs, filters, and cooling surfaces to maintain optimal oil condition and system performance. Reservoir cleaning involves complete oil drainage followed by removal of any sediment or contamination accumulated in the bottom of the tank. This process typically utilizes specialized vacuum extraction equipment that removes both oil and debris simultaneously, ensuring thorough cleaning without introducing additional contaminants.

Filter elements require weekly inspection and replacement when necessary, with pressure differential across filter housings serving as the primary indicator of element condition. Most systems incorporate differential pressure gauges that indicate when elements require changing, typically when pressure differential exceeds 1.5 bar across the filter. Cooling surfaces should be cleaned of any dust or debris accumulation that could impair heat transfer efficiency, maintaining oil temperatures within optimal operating ranges to preserve lubricant properties and ensure proper component protection.

Electrical Connection Security Verification

Weekly electrical maintenance focuses on verifying the security of all connections that might loosen due to vibration or thermal cycling during normal operation. This process begins with visual inspection of all accessible connections for signs of overheating, corrosion, or physical damage that could compromise electrical integrity. Thermal imaging conducted during operation provides valuable data regarding connection condition, with temperatures typically maintained within 5°C of ambient conditions for proper connections.

Torque verification of critical connections represents another essential weekly activity, ensuring that terminal connections remain properly tightened to specified values. This process should follow manufacturer recommendations for torque values and sequences, utilizing calibrated torque tools to ensure accuracy. Connection cleaning might be necessary where corrosion or contamination is evident, utilizing appropriate contact cleaners that remove oxidation without damaging components or insulating materials.

Liner Fastening Integrity Confirmation

Weekly verification of liner fastening systems ensures that crushing chamber components remain securely positioned despite the significant forces encountered during operation. This process involves torque checking of all fasteners according to manufacturer specifications, typically requiring values between 300 and 500 Newton meters for most cone crusher configurations. Fastener tension should be verified using calibrated torque wrenches, with any loose fasteners immediately tightened to specified values to prevent component movement that could cause damage or uneven wear.

The inspection should also include examination of fastener condition for signs of stretching, thread damage, or corrosion that might compromise integrity. Fasteners showing any evidence of degradation should be replaced immediately rather than simply retightened, as compromised fasteners cannot provide reliable clamping force. Documentation of fastener torque values provides historical data supporting predictive replacement before failure occurs, typically after five to seven tightening cycles depending on fastener quality and operating conditions.

Crushing Chamber Detailed Cleaning

Thorough weekly cleaning of the crushing chamber removes accumulated material that daily cleaning might not address, particularly in areas difficult to access during normal operation. This process typically requires crusher disassembly sufficient to access all chamber areas, allowing complete removal of packed material that could interfere with proper operation or conceal developing problems. The cleaning should utilize appropriate tools that will not damage chamber surfaces, typically including plastic scrapers and brushes rather than metal implements that could score or damage component surfaces.

Following material removal, all chamber surfaces should be thoroughly inspected for signs of wear, cracking, or other damage that might require attention. This inspection provides opportunity to identify developing issues before they progress to component failure, allowing planned rather than emergency maintenance. Complete cleaning also facilitates more accurate wear measurement during subsequent inspections, as reference points remain visible rather than obscured by accumulated material.

Comprehensive Monthly Evaluation Procedures

Monthly maintenance procedures provide the most comprehensive evaluation of crusher condition, encompassing detailed inspection and measurement of all major systems and components. These evaluations typically require extended downtime of several shifts, allowing thorough disassembly, measurement, and restoration of critical components to optimal condition. The comprehensive nature of monthly evaluations supports long-term reliability planning and major component life forecasting based on actual wear rates and operating conditions.

Monthly maintenance should follow detailed checklists that ensure consistent evaluation of all systems, with particular emphasis on components subject to wear that might affect safety or performance if not addressed proactively. Documentation of monthly evaluation findings provides essential data for forecasting major maintenance requirements and budgeting for component replacements based on actual wear rates rather than generalized expectations. These records also support optimization of maintenance intervals based on specific operating conditions rather than fixed time-based schedules.

Structural Integrity Comprehensive Assessment

Monthly structural evaluation examines the crusher's main frame and supporting structures for signs of fatigue, cracking, or deformation that could compromise safety or performance. This assessment typically begins with thorough cleaning of all structural surfaces to facilitate visual inspection, followed by detailed examination using appropriate lighting and magnification where necessary. Critical areas include weld joints, stress concentration points, and areas subject to high loading during operation.

Advanced non-destructive testing methods might be employed during monthly evaluations, particularly for crushers operating under demanding conditions or approaching design life expectations. These methods typically include magnetic particle inspection for surface defects or ultrasonic testing for subsurface flaws that visual inspection cannot detect. Documentation of structural condition provides baseline data for tracking potential development of issues over time, supporting decisions regarding repair, reinforcement, or replacement based on actual condition rather than age alone.

Hydraulic System Complete Evaluation

Comprehensive monthly hydraulic system evaluation extends beyond pressure monitoring to include flow measurements, fluid analysis, and component performance verification. Flow measurements establish actual pump output compared to theoretical capacity, typically showing at least 85% of rated flow for properly functioning systems. Fluid analysis provides detailed information regarding oil condition and potential contamination, with particle counting identifying developing issues before they cause component damage.

Component evaluation includes cylinder operation verification, accumulator precharge confirmation, and valve function testing to ensure all elements perform within design parameters. Hose and fitting inspection forms another critical aspect, identifying any elements showing signs of wear, abrasion, or deterioration that might lead to failure. Documentation of hydraulic system condition supports predictive replacement of components based on actual condition rather than fixed intervals, optimizing maintenance costs while ensuring reliability.

Electrical Insulation Performance Testing

Monthly electrical insulation testing provides essential verification that all systems maintain proper isolation between energized components and ground, ensuring operational safety and reliability. This testing typically utilizes megohmmeters that apply elevated voltages to measure insulation resistance, with values typically exceeding 100 megohms for properly functioning systems. Testing should encompass all major circuits including motor windings, control circuits, and power distribution components.

Insulation resistance measurements should be compared against previous readings to identify developing trends that might indicate deteriorating conditions requiring attention. Environmental factors particularly affect insulation performance, with humidity, temperature, and contamination levels all influencing measured values. Documentation of insulation resistance over time provides valuable data for predicting maintenance requirements and identifying environmental conditions that might require additional protective measures.

Lubrication Fluid Complete Replacement

Scheduled monthly oil replacement ensures that lubricating fluids maintain proper properties despite continuous operation under demanding conditions. This process begins with complete drainage of existing oil while systems remain warm to facilitate complete removal, followed by thorough cleaning of reservoirs to remove any accumulated sediment or contamination. The new oil should be filtered during introduction to the system, typically utilizing filtration units capable of removing particles larger than 10 micrometers to ensure optimal cleanliness.

Oil analysis of the drained fluid provides valuable information regarding system condition and component wear, with elemental analysis identifying specific metals that might indicate developing issues. Viscosity measurements verify that oil has maintained proper lubricating properties, while acidity testing detects oxidation products that could accelerate component deterioration. Documentation of oil analysis results supports predictive maintenance strategies and helps optimize change intervals based on actual fluid condition rather than fixed time periods.