Fine, Medium, Coarse Crushing: How to Configure Different Cone Crusher Models for Optimal Results?

This article provides a comprehensive guide to configuring cone crushers for the specific demands of fine, medium, and coarse crushing applications. It explores the fundamental operating principles of these machines and details how different model types are engineered to excel at distinct stages within a crushing circuit. Readers will gain insights into the critical parameters that influence performance, from adjusting the closed side setting to selecting the appropriate crushing chamber design. The discussion extends to the pivotal role of modern automation and data-driven monitoring in achieving maximum efficiency, throughput, and final product quality across various industrial operations.

Overview of Cone Crusher Fundamentals and Types

Cone crushers operate on the principle of compressive crushing, where rock material is squeezed between a gyrating mantle and a stationary concave liner. This action creates high pressure that fractures the material along its natural cleavage planes. The heart of this process is an eccentric assembly that causes the mantle to gyrate, creating a progressive reduction zone from the feed opening to the discharge point. The geometry of this zone, defined by the shape of the mantle and concave, is the primary factor determining the crusher's output characteristics.

Different cone crusher models are classified based on the shape of their crushing cavity and their specific function within a processing plant. The main distinctions are found between standard, intermediate, and short-head designs. Each design is optimized for a particular range of duties, from reducing large feed material to a medium-sized product, to taking medium-sized feed and producing a finely crushed end product suitable for further processing or direct sale.

The Laminated Crushing Principle

The laminated crushing principle is central to a cone crusher's efficiency. Unlike impact crushing which relies on a single point of contact, the mantle compresses material against the concave in a continuous, multi-point action. This method applies a steady, powerful force that breaks particles against each other, resulting in a more cubicle end product and significantly reduced wear on the crusher liners compared to other crushing methods.

Differences Between Short-Head, Standard, and Intermediate Cone Crushers

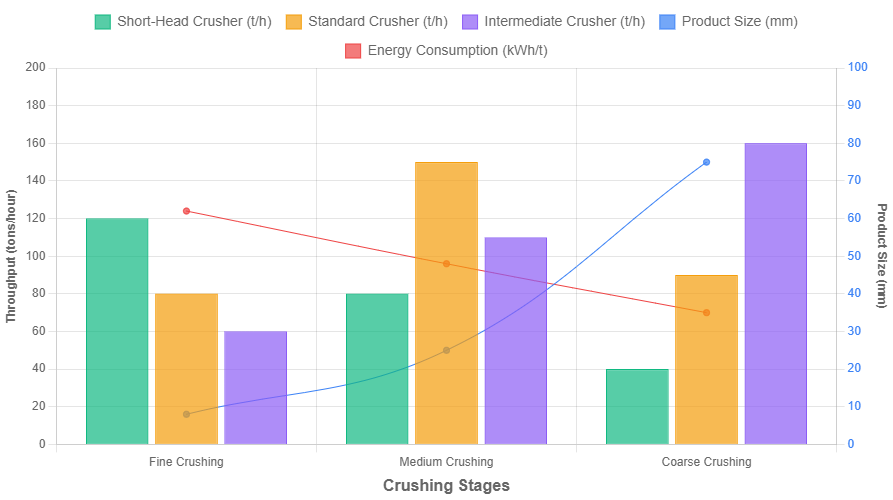

Standard cone crushers are designed for secondary crushing duties, typically producing a product ranging from 20mm to 100mm. They feature a steeper head angle and a larger crushing cavity compared to short-head models. Short-head cone crushers, with their steeper crushing chambers and finer setting capabilities, are intended for tertiary and quaternary crushing stages to generate products as fine as 5mm. Intermediate models offer a compromise, providing versatility for operations that require a wider range of product sizes from a single machine.

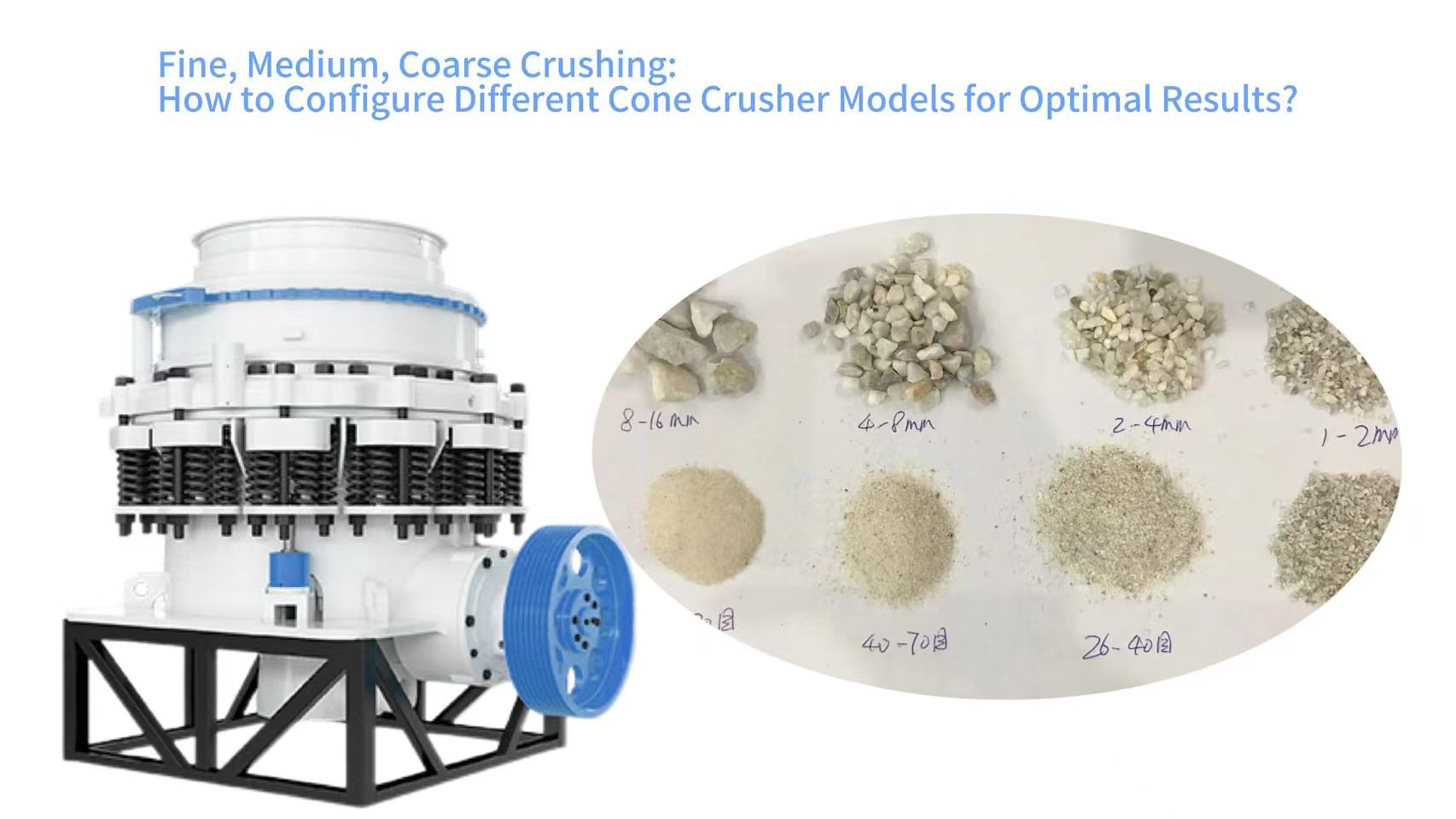

Applications of Fine, Medium, and Coarse Crushing in Mining and Construction

In mining, coarse crushing prepares run-of-mine ore for further processing, while fine crushing is often the final step before the material enters a grinding mill. The construction industry relies heavily on precisely graded aggregate. Coarse aggregates are used in concrete mixes and road base layers, medium aggregates for drainage applications, and fine aggregates for asphalt and concrete sand. Each application demands specific particle size distributions, which are achieved by configuring the correct type of crusher with the appropriate settings.

Cone Crusher Configuration for Fine Crushing Operations

Fine crushing requires a machine capable of producing a high percentage of small, well-shaped particles. This is achieved through a combination of a specific crushing chamber design, a high speed of gyration, and a narrow discharge setting. The objective is to create multiple compression events for a single particle as it travels through the crushing zone, ensuring a thorough and controlled size reduction. The feed material for this stage must already be pre-crushed to a consistent size to allow for efficient processing and to prevent chamber overload.

Operating a cone crusher in a fine crushing configuration places particular emphasis on the closed side setting (CSS). This is the smallest distance between the mantle and the concave at the bottom of the crushing chamber. A smaller CSS directly correlates with a finer output product but also reduces the volumetric capacity of the machine. Therefore, fine crushing circuits often require multiple crushers operating in parallel to achieve the desired overall plant throughput.

Advantages of Short-Head Cone Crushers in Fine Crushing

Short-head cone crushers are the preferred choice for fine crushing due to their steep crushing chamber geometry. This design allows for a much smaller discharge setting and provides a longer parallel zone between the mantle and concave. In this parallel zone, the final sizing and shaping of the particles occur, ensuring a high degree of product uniformity and a superior particle shape, which is critical for high-value applications like concrete and asphalt production.

The Impact of CSS Adjustment on Fine Product Gradation

Adjusting the Closed Side Setting is the most direct method of controlling the crusher's product size. Modern cone crushers often feature hydraulic systems that allow for CSS adjustments under load, enabling operators to react to changes in feed material or product requirements in real-time. A change of just a few millimeters in the CSS can significantly alter the entire gradation curve of the output, making precise control essential for meeting tight product specifications.

Effects of Oversized Feed Material and Solutions for Fine Crushing Efficiency

Introducing oversized material into a crusher configured for fine crushing can cause several issues, including poor productivity, accelerated wear, and potential damage to the crusher. The solution involves ensuring effective screening before the crushing stage to scalp out oversize particles. These oversize particles can be recirculated back to a previous crushing stage, typically a secondary crusher, to be reduced to a size suitable for the fine crushing circuit. This closed-loop system is vital for maintaining efficiency.

Cone Crusher Configuration for Medium Crushing Operations

Medium crushing, or secondary crushing, serves as the vital link between primary reduction and final product shaping. The goal is to achieve high throughput while producing a well-graded product that is suitable for either further reduction or direct use. Cone crushers configured for this duty must strike a balance between capacity and product size. Standard cone crushers are most commonly employed here, as their cavity design is optimized for this balance, handling a reasonably large feed size while still producing a medium-fine output.

The efficiency of a medium crushing stage is heavily influenced by the crusher's stroke and speed. A combination of a good throw and an optimal gyration speed ensures that each compression cycle processes a sufficient volume of material without choking the chamber. The focus is on achieving a high reduction ratio reliably and consistently, forming the backbone of the aggregate production process.

Application of Standard Cone Crushers in Medium Crushing

Standard cone crushers excel in medium crushing roles. Their design features a broader cavity compared to short-head models, allowing them to accept a larger feed size from the primary jaw crusher. They operate at a lower speed than fine crushers, which contributes to their ability to handle higher tonnages. Their output is typically a well-balanced mix of particle sizes that is ideal for feeding screening plants or tertiary crushers.

The Influence of Crushing Chamber Design on Product Shape in Medium Crushing

The chamber design of a standard cone crusher is engineered to promote inter-particle crushing. As material travels down through the chamber, it is compressed not only between the mantle and concave but also against other rocks. This multi-point loading breaks particles along their natural weaknesses, minimizing the creation of elongated or flaky particles and resulting in a more cubicle product. This is a key quality parameter for aggregate used in construction.

The Role of Speed Adjustment in Boosting Medium Crushing Capacity

The rotational speed of the crusher head directly affects capacity and product gradation. Increasing the speed can boost capacity for a given setting by increasing the number of compression cycles per minute. However, this must be balanced against potential increases in wear and the risk of generating more fines than desired. Modern crushers with variable frequency drives allow operators to fine-tune the head speed to find the optimal balance for the specific feed material and product goal.

Cone Crusher Configuration for Coarse Crushing Operations

Coarse crushing represents the first stage of size reduction in most mineral processing and aggregate production plants. The primary objective is to achieve a high reduction ratio, transforming large quarry-run rocks into manageable sizes for downstream secondary crushers. While jaw crushers and gyratory crushers are most common for primary crushing, large cone crushers are also capable of handling these duties, especially in operations where the abrasive nature of the rock makes other options less economical.

Cone crushers configured for coarse crushing are characterized by their robust construction, large feed opening, and ability to handle high loads. The focus is on volumetric throughput and reliability rather than precise product shaping. The crushing chambers are designed to be less steep, allowing them to accept larger rocks and provide a significant reduction in a single pass. These machines are built to withstand the tremendous forces and abrasive wear associated with breaking down primary feed.

Suitability of Intermediate Cone Crushers for Coarse Crushing

Intermediate cone crushers, sometimes referred to as fine-primary crushers, can serve as an effective primary crushing unit for medium-hard to hard rock. They offer a good compromise between the massive feed opening of a primary jaw crusher and the finer product capability of a standard cone crusher. This can simplify the crushing circuit layout by eliminating one crushing stage, which reduces capital and operational costs for certain plant configurations.

Selection and Replacement Cycle for Wear Parts in Coarse Crushing

The coarse crushing stage is the most demanding on wear parts due to the large size and often abrasive nature of the feed material. Mantles and concaves are typically made from high manganese or chrome steel to withstand impact and abrasion. The replacement cycle for these parts is a major operational consideration. Monitoring wear rates and scheduling changes based on crushed tonnage, rather than time, is a best practice to avoid unplanned downtime and catastrophic failure. Utilizing a durable concave is essential for longevity.

The Importance of Stable Feeding for Coarse Crushing Operations

Consistent and controlled feeding is paramount for coarse crushing. An uneven feed can lead to poor productivity, uneven wear on the liners, and potential damage to the crusher's eccentric assembly. A vibrating grizzly feeder is often used ahead of the crusher to ensure a steady flow of material and to scalp out the very finest particles, which can fill the crushing chamber without being effectively processed, reducing overall efficiency.

Automation and Intelligent Technology in Cone Crusher Configuration

The integration of automation has revolutionized cone crusher operation, moving it from a manual, experience-based process to a precise, data-driven function. Modern control systems constantly monitor key operational parameters such as power draw, pressure, CSS, and cavity level. This data is processed by sophisticated algorithms that automatically adjust the crusher's settings to maintain optimal performance. The goal is to run the crusher at its peak capacity without overloading it, ensuring maximum throughput while protecting the machinery from damage.

These intelligent systems facilitate a shift from reactive to predictive maintenance. Instead of waiting for a component to fail, sensors track the condition of critical parts like bearings and liners. By analyzing trends in vibration, temperature, and performance data, the system can predict when maintenance will be required. This allows for planning downtime during scheduled maintenance windows, significantly increasing overall equipment availability and reducing the cost of unscheduled stoppages.

Precise Control of CSS Adjustments by Automated Control Systems

Automated control systems provide unparalleled accuracy in maintaining the closed side setting. Hydraulic adjustment mechanisms, controlled by programmable logic controllers (PLCs), can make micro-adjustments to compensate for liner wear throughout a shift. This ensures the product size remains consistent from the first ton to the last, eliminating the gradual coarsening of output that occurs with manual operation and is crucial for meeting strict product specifications.

The Early Warning Role of Intelligent Monitoring Technology for Equipment Failure

Intelligent monitoring acts as a continuous health check for the crusher. Advanced sensors can detect subtle changes in vibration signatures or thermal patterns that indicate a developing problem, such as a failing bearing or misalignment. The system alerts operators long before the issue becomes critical, providing ample time to investigate and schedule repairs. This proactive approach is fundamental to modern main shaft and bearing life management.

Application Advantages of Remote Control in Harsh Environments

Remote monitoring and control capabilities offer significant advantages, particularly for crushers located in remote or environmentally challenging sites. Operators can monitor performance and adjust settings from a control room far from the dust, noise, and vibration of the crusher itself. This not only improves working conditions but also allows for expert oversight from centralized locations, enabling a single team to manage multiple crushing plants spread across a wide geographic area.

Practical Case Studies of Cone Crusher Configuration

Analyzing real-world applications provides invaluable insight into the successful implementation of crushing strategies. A detailed case study might examine a large granite quarry that struggled with low productivity and high wear costs in its tertiary crushing stage. By replacing an older crusher model with a modern cone crusher featuring a specialized fine-lining chamber and automating the CSS control, the operation could document a measurable increase in throughput, a improvement in product shape, and a extension of liner life. The return on investment calculation would be based on these tangible benefits.

Conversely, examining less successful configurations is equally educational. A case study might explore a situation where a crusher was incorrectly selected for a duty it was not designed for, such as using a standard head crusher for a primarily fine crushing application. The analysis would detail the consequences: lower-than-expected capacity, higher energy consumption per ton, rapid and uneven wear on crusher liners, and an inability to meet product specification. The lessons learned would focus on the importance of matching the crusher type and chamber design to the specific operational goals.

Case Study: Successful Configuration of a Cone Crusher in a Mining Fine Crushing Operation

A copper mine required a finer crush size to improve the recovery rates in its grinding circuit. The existing secondary crushers could not achieve the target product size without frequent choke-ups. The solution involved installing a tertiary stage comprising two short-head cone crushers in closed circuit with fine screens. The new setup, with its optimized crusher settings and automated control system, successfully delivered a consistent 12mm product. This resulted in a 5% increase in mineral recovery due to more efficient grinding, justifying the capital expenditure within a short period.

Case Study: Production Decline and Uneven Product Gradation Caused by Improper Configuration

An aggregate plant experiencing frequent downtime and customer complaints about inconsistent product gradation conducted an audit. It was discovered that the cone crusher's mantle and concave were from different manufacturers and did not form a perfectly matched crushing chamber. This mismatch caused uneven wear, unstable operation, and a product that failed to meet specification. Correcting this by installing a matched set of liners and implementing a strict wear parts management protocol resolved the issues, restoring production and product quality.

The Future Development Direction of Cone Crusher Configuration Towards Efficiency, Energy Savings, and Intelligence

The future of cone crusher configuration is inextricably linked to advances in digitalization and machine learning. Crushers will evolve into fully autonomous units that self-optimize based on real-time feed analysis and product demand. Energy efficiency will be a primary driver, with systems designed to minimize power consumption per ton of output. Furthermore, the integration with plant-wide optimization systems will ensure the crusher is not operating in isolation but as a harmonized component of a highly efficient processing plant, seamlessly connected to upstream and downstream mining and quarrying processes.