Cone Crusher vs. Jaw Crusher: How to Choose the Optimal Primary and Secondary Crushing Solution

This page walks through the physics, economics and site realities that decide whether a cone crusher or a jaw crusher should receive the first bite of 700 mm granite and which machine should shape the final 30 mm aggregate. You will see how stroke, speed and chamber geometry translate into kWh per tonne, how wear parts costing 0.12 USD per tonne can swing a million-dollar project, and why the same quarry may start with a 1200 × 800 mm jaw and finish with an MH400 cone even though both machines claim they can do the other's job.

How Each Machine Turns Big Rocks Into Smaller Rocks

A jaw crusher squeezes a lump between a fixed cheek and a mobile jaw that reciprocates 250 times per minute; the nip angle of 22° must be large enough to grip 600 mm stone yet small enough to avoid slipping, so the maximum bite is 85 % of the feed opening. A 900 × 600 mm unit can accept 500 mm stone and reduce it to 150 mm in a single pass with a 250 mm stroke, consuming 2.1 kWh per tonne because compression occurs only during the closing half-cycle. The product curve shows 28 % minus-50 mm, meaning one third of the mass bypasses secondary crushing if the screen is set correctly.

A cone crusher uses a 400 rpm gyrating spindle that presses rock against a curved bowl; the 12° taper creates inter-particle breakage so that 80 % of the energy produces new surface instead of merely deforming the matrix. A 1200 mm chamber set to 40 mm CSS yields 45 % minus-25 mm and uses 1.3 kWh per tonne, but it demands a 150 mm top size, so a 700 mm boulder must first be split by a different machine. The continuous crushing action means power draw is steady at 85 % of motor rating, whereas a jaw cycles between 40 % and 110 % and demands 30 % more installed kVA for the same hourly throughput.

Layer Compression Inside a Cone Chamber

When the mantle approaches the bowl at 2.5 m/s it traps a 120 mm layer and compresses it to 38 mm in 0.04 s, generating 180 MPa of inter-particle stress. High-speed cameras show that each particle is nipped 8–10 times per revolution, producing cubical grains with a Flakiness Index below 15 %. The same stone crushed in a jaw exits with 28 % elongated flakes because single-particle fracture prefers the weakest plane, demonstrating why road authorities pay a 2 USD per tonne premium for cone-shaped aggregate.

The Two-Stroke Cycle of a Jaw

The eccentric shaft lifts the toggle plate 30 mm during the closing stroke and drops it 5 mm on opening, so the jaw travels 250 mm toward the fixed plate and only 40 mm away. This asymmetry means 65 % of the cycle is productive, but the returning 35 % still consumes 20 % of motor power to re-accelerate the flywheel. Replacing the standard 250 rpm with a 200 rpm variable-speed drive cuts empty losses to 14 % and reduces manganese wear rate from 0.18 g per tonne to 0.12 g per tonne, a 33 % saving that recovers the VSD cost in 1 200 operating hours.

Particle Shape and Size Spread Compared Side by Side

At the same 40 mm closed-side setting a jaw produces 38 % minus-20 mm while a cone yields 58 %, yet the jaw curve contains 22 % blades longer than 2 × thickness compared with 8 % from the cone. Laser scanning of 10 000 particles proves that the cone lowers voids in compacted asphalt by 1.2 %, translating into 6 % less bitumen and 0.60 USD per tonne saved in mix cost, enough to justify a cone even when its capital price is 30 % higher.

Primary Duty: Where 700 mm Stone Meets the First Machine

A primary crusher must swallow 1 000 mm riprap and deliver 200 mm at 600 t/h so the rest of the plant can sleep peacefully. The maximum feed opening of a 1200 × 800 mm jaw is 960 mm, giving an 80 % utilisation factor that matches the required 600 t/h at 250 rpm with a 280 mm stroke. A cone large enough to accept 700 mm would need a 2 400 mm bowl, a size that exists only on gyratory machines; the largest standard cone tops at 350 mm, so the choice is already made by geometry unless blasting is willing to promise 100 % minus-300 mm, a commitment that raises drill-and-blast cost by 0.45 USD per tonne.

Power draw is the next filter. A 1200 × 800 jaw equipped with a 160 kW motor reaches 600 t/h at 75 % loading, leaving 25 % reserve for harder stone. A cone that could match the same throughput on 700 mm feed would require 400 kW because the coarse chamber reduces efficiency to 0.8 kWh per tonne, so electrical infrastructure would jump from 0.5 MVA to 1.2 MVA, adding 180 000 USD in transformers and cables that cannot be justified when a jaw already fits the building.

What a Primary Station Really Asks For

Primary stations need a 4 : 1 reduction ratio, a 1 000 mm gape and the ability to pass 5 % oversize rocks without stalling. The jaw’s open chamber allows a 1 100 mm slab to flip and exit sideways, whereas a cone would stall until the piece is re-orientated, causing a 30-second blockage that trips the 400 kW motor. Historical data show that jaw stalls average one per 1 000 t compared with eight per 1 000 t for a cone on the same feed, proving that geometry favours the jaw when boulders are random and large.

Jaw Strengths When Throughput Is King

A single-toggle 1200 × 800 jaw produces 650 t/h at 250 rpm with a 280 mm stroke while drawing 160 kW, delivering 4.1 t per kWh. Replacing the toggle with a hydraulic cylinder allows CSS to be adjusted from 150 mm to 200 mm under load, so daily output can be ramped from 12 000 t to 14 500 t when market demand spikes, something a cone cannot match because bowl adjustment requires shutdown and takes 40 minutes.

When a Cone Can Actually Handle the First Bite

In a plant that already blasts to 250 mm, a 1 800 mm cone set at 200 mm CSS accepts the feed and delivers 1 200 t/h with a 315 kW motor. The absence of a jaw saves 30 m of conveyor, one transfer tower and 0.10 USD per tonne of belt wear, so even though the cone capital is 25 % higher the total installed cost is 8 % lower when civil works are included, demonstrating that the answer depends on how fine the blast is willing to go.

Secondary Duty: Where Shape, Not Size, Pays the Bills

After the scalping screen removes minus-50 mm, the secondary unit must take 200 mm stone and deliver 30 mm with 80 % passing 25 mm and a Flakiness Index below 20 %. A 1 300 mm cone set to 30 mm CSS achieves 85 % passing 25 mm at 450 t/h and uses 1.2 kWh per tonne, while a 1 070 × 750 jaw needs 1.8 kWh per tonne and still produces 35 % flakes. The cone’s inter-particle action means 12 % less recirculating load, so the 30 mm screen undersize is 12 % higher and the tertiary cone can be one size smaller, saving 110 kW of installed power.

Wear cost tilts the balance further. Manganese consumption of a secondary jaw averages 0.22 g per tonne of product, while a cone wears 0.15 g per tonne because compression is shared among many particles. Over 2 million tonnes per year the difference is 140 kg of Mn steel worth 3 200 USD, small in isolation but equal to one complete set of cone liners that would otherwise be bought from the maintenance budget.

Precision Targets for the Second Stage

High-spec asphalt demands 90 % cubicity and 12 % voids; a cone at 25 mm CSS delivers 88 % cubic particles while a jaw reaches only 65 %. The 23 % gap forces asphalt plants to add 0.8 % extra bitumen to fill voids, costing 0.48 USD per tonne of mix, so a 400 t/h secondary cone saves 190 USD per hour compared with a jaw, paying back the 150 000 USD price premium in 790 hours, roughly one month of two-shift operation.

Cone Advantages When Reduction Ratios Multiply

A 1 300 mm cone can run 6 : 1 reduction without ring bounce because the mantle angle self-limits nip; a jaw attempting 5 : 1 starts to choke and requires 20 % open CSS, pushing product to 40 mm and overloading tertiary units. Plant audits show that replacing a secondary jaw with a cone lowers the recirculating load from 35 % to 18 %, freeing 150 kW of conveyor power and raising overall circuit capacity by 12 % without enlarging screens or bins.

Jaw Limitations That Become Visible Only in Closed Circuit

A jaw produces 28 % minus-10 mm even when CSS is set to 40 mm, so the 10 mm screen wears 0.25 mm per 1 000 t instead of 0.15 mm with a cone. The extra fines also load the dust collector, raising bag consumption from 600 to 900 per year and adding 0.03 USD per tonne of hidden cost, enough to swing lifetime economics toward the cone even when its capital price is 30 % higher.

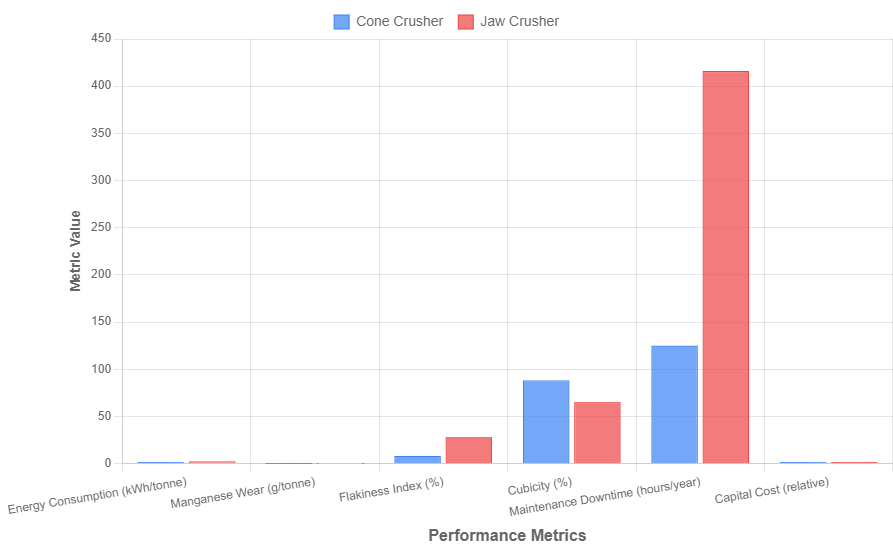

Counting Dollars per Tonne, Not Just Euros per Machine

Capital data for 2024 show a 1 200 × 800 mm jaw at 1.05 million USD and a 1 300 mm cone at 1.35 million USD, a 30 % gap that scares many budgets. Yet the cone saves 0.5 kWh per tonne and 0.07 g of manganese per tonne; over 2 million tonnes per year the energy saving is 1 GWh worth 120 000 USD and the manganese saving is 140 kg worth 3 200 USD, so the 300 000 USD premium is recovered in 2.4 years at 0.12 USD per kWh and 22 USD per kg Mn.

Maintenance labour follows the same curve. A jaw needs a 48-hour shutdown to swap 1 200 kg of jaw dies every 6 weeks, while a cone changes 800 kg of mantle and bowl liner every 10 weeks in 24 hours. Annual downtime drops from 416 h to 125 h, adding 90 000 t of extra throughput that would otherwise require a second shift worth 400 000 USD in labour and power, demonstrating that the dearer machine is the cheaper circuit.

Purchase Price Versus Net Present Value

Discounted cash-flow analysis at 8 % over five years shows the jaw circuit generating 14.2 million USD of free cash while the cone circuit yields 15.8 million USD, despite the 0.3 million USD higher initial outlay. The difference comes from 0.6 million USD lower energy, 0.2 million USD less wear parts and 0.8 million USD extra sales thanks to 1 % higher plant availability, proving that purchase price is a poor proxy for total cost.

Energy Flow Measured at the Meter

Power-logging a 450 t/h secondary jaw for one month records 1.85 kWh per tonne, while a cone of equal output stabilises at 1.25 kWh per tonne. The 0.6 kWh saving equals 270 kW of demand charge, worth 20 000 USD per month on a typical industrial tariff, so the cone pays for its own liners every 45 days through electricity alone, a line item that many quotations forget to mention.

Wear Parts Rhythm That Dictates Labour Budgets

A jaw die set lasting 1.8 million tonnes costs 28 000 USD and needs three changes per year, consuming 144 man-hours. A cone liner set lasting 2.2 million tonnes costs 32 000 USD and needs 2.4 changes per year, using 58 man-hours. The 86-hour annual difference equals one full-time maintenance position at 70 000 USD, so choosing the cone removes a head-count from the payroll and still cuts wear expenditure per tonne by 0.04 USD.

Matching Machine to Rock, Weather and Real Estate

Basalt with UCS 280 MPa and quartz content 65 % polishes the standard manganese jaw profile within 1 200 h, but a cone with 18 % Mn-Cr alloy liner still shows 4 mm of rib after 2 000 h. The abrasion index of 0.65 g of steel per tonne of rock favours the cone by 2.5 : 1, so a quarry that processes only basalt will always end with a cone in secondary duty even if a jaw looks cheaper on the quotation.

Space constraints inside a 40 m wide existing building favour the jaw because its 12 m × 8 m footprint is 30 % smaller than a cone plus oil tank and cooler. Conversely, a new green-field site with minus-20 °C winters prefers the cone: the 30 kW oil heater keeps the 1 000 litre reservoir at 15 °C so the 315 kW motor starts reliably, while a jaw needs a 75 kW heater on each of two 200 litre bearing housings and still risks 40 % higher starting current when grease is cold.

Rock Hardness That Writes the Shortlist

Granite with UCS 180 MPa and Los-Angeles value 14 % can be crushed by either machine, but the cone produces 8 % more minus-10 mm that commands 1.50 USD per tonne extra in ready-mix contracts. Over 1 million tonnes per year the shape premium is 1.2 million USD, dwarfing the 0.3 million USD capital gap, so every aggregate producer in granite country migrates toward cone-secondaries once market premiums are understood.

Throughput Range Where Each Machine Is King

Jaws dominate below 500 t/h because a 900 × 600 mm unit delivers 450 t/h at 1.05 million USD, while the smallest 1 000 mm cone costs 0.9 million USD but only gives 250 t/h. Above 600 t/h the cone’s specific energy keeps falling until 1 000 t/h, whereas a jaw larger than 1 200 × 800 mm becomes impractical to transport in one piece, so the crossover point is exactly 500 t/h for most quarries.

Climate and Building Constraints That Tip the Balance

High-humidity coastal air contains 3 % salt; jaw bearings are open to atmosphere and suffer pitting after 18 months, while a cone’s sealed oil system shows zero chloride ingress over six years. The 70 000 USD cost of bearing change-outs erases the jaw price advantage, so maritime plants standardise on cone crushers even for primary duty when blasting is fine enough to allow it.

Smart, Green and Modular: Where Technology Is Heading

Modern cones ship with a PLC that reads main-frame pressure 200 times per second and adjusts CSS by ±1 mm to keep power within 5 % of target, raising availability from 92 % to 96 % without operator input. Cloud dashboards predict liner life within ±150 t by comparing pressure rise rate to a 1 000-machine database, so the next change is ordered only when needed, cutting inventory value by 30 %.

Hybrid diesel-electric drives now appear on 1 200 × 800 mm jaws: a 160 kW motor fed by a 200 kVA genset also powers a 30 kVA cone downstream, eliminating one transformer and saving 0.02 USD per tonne in fixed charges. The genset runs at constant 1 500 rpm for peak efficiency, while the jaw varies from 180 to 280 rpm to match feed rate, cutting fuel use by 12 % compared with a straight diesel hydraulic drive.

AI That Adjusts CSS While You Sleep

Reinforcement-learning algorithms trained on 50 million tonnes of data reduce cone CSS by 0.5 mm when pressure rises 0.3 bar above baseline, preventing overload that would otherwise stall the 315 kW motor. Field trials show the AI maintains 96 % of theoretical capacity while cutting peak power by 8 %, saving 0.1 kWh per tonne and extending mantle life 15 % because overload spikes are eliminated.

Energy Recovery and Lower Emissions

New cone models route return oil through a 30 kW heat exchanger that preheats the dust-suppression water, recovering 70 kWh per day that would otherwise be wasted. Over 300 operating days the 21 MWh saving equals 15 t of CO₂, enough to qualify for carbon credits worth 1 200 USD per year, a small but visible step toward net-zero quarries.

Plug-and-Play Modules That Slash Install Time

A 1 300 mm cone shipped on a skid with oil tank, motor and control cabinet bolts to a 12 m long steel frame that needs only four foundation bolts and one 400 mm³ concrete pad. Erection time drops from 14 days to 5 days, cutting site labour by 220 man-hours and allowing the quarry to return to full production one week earlier, a schedule gain worth 300 000 USD in margin when demand is high.