Understanding Iron Ore Crushing: A Comprehensive Guide to Crusher Requirements and Selection

Iron Ore Crushing Requirements Analysis

Processing iron ore is a demanding task that requires robust and efficient machinery. The specific properties of the ore and the desired final product dictate the exact specifications for the crushing equipment. A thorough analysis of these requirements is the first and most critical step in selecting the right crusher, ensuring it can handle the immense stresses and continuous operation of a mining environment. This involves evaluating the raw material's physical characteristics and defining the operational goals for the entire crushing circuit.

Key parameters include the ore's hardness, the size of the raw material fed into the crusher, the expected size distribution of the output, and the required processing rate. For instance, a typical high-grade iron ore with a Mohs hardness of 8 to 10 demands a crusher with immense power and wear-resistant components. Furthermore, achieving a target where over 90% of the output is smaller than 30mm from an input of lumps up to 300mm requires precise control over the discharge size. Capacity needs, ranging from 500 to 2000 tons per hour, further narrow down the choice to heavy-duty, high-throughput machines like gyratory or large cone crushers.

Ore Hardness (Mohs Hardness 8-10)

Iron ore is an exceptionally hard material, often ranking between 8 and 10 on the Mohs scale of mineral hardness. This scale, which ranges from 1 (talc) to 10 (diamond), indicates a material's resistance to being scratched or abraded. Ore at this hardness level is highly abrasive and will cause rapid wear on components that are not designed for such conditions. This property directly influences the type of crusher selected and the materials used in its construction, necessitating the use of ultra-durable alloys for all critical wearing parts to maintain operational efficiency and reduce downtime for maintenance.

Input Feed Size Requirement (<300mm)

The initial size of the raw ore fed into the crusher is a major factor in machine selection. For primary crushing applications, the crusher must be able to accept large lumps, commonly up to 300mm in diameter. The crusher's feed opening must be adequately sized to accommodate these large rocks without causing bridging or blockage. The feed size directly impacts the crusher's capacity and the overall efficiency of the size reduction process, as consistently sized feed leads to more stable and predictable operation.

Target Particle Size Distribution (>90% <30mm)

The ultimate goal of the crushing process is to produce a specific range of particle sizes optimal for the next stage of processing, such as milling or beneficiation. A common specification is that over 90% of the crushed material must pass through a 30mm screen. Achieving this consistent product size distribution requires a crusher capable of providing a controlled and uniform reduction ratio. This often involves secondary or tertiary crushing stages with equipment that allows for precise adjustment of the output settings.

Capacity Demand (500-2000 tons/hour)

Industrial mining operations are defined by their scale, requiring machinery that can process vast quantities of material every hour. Capacity demands for iron ore crushing can range from a modest 500 tons per hour to a massive 2000 tons per hour. This crushing capacity requirement dictates the size and power of the crusher. High-capacity machines are engineered with larger crushing chambers and more powerful motors to ensure a continuous and reliable flow of processed material to downstream operations, maximizing the productivity of the entire plant.

Core Selection Parameters

Once the application requirements are clearly defined, the focus shifts to the core technical parameters of the crusher itself. These specifications determine the machine's capability to meet the production goals reliably and efficiently. Selecting the right combination of these parameters ensures that the crusher will integrate seamlessly into the production line, delivering the desired performance while managing operational costs.

The shape of the crushing chamber, the power of the drive motor, the operational speed of the moving parts, and the materials used to combat wear are all interdependent factors. A well-matched system balances these elements to optimize the crushing ratio—the ratio of the input size to the output size—while minimizing energy consumption and the cost of replacing worn components over the crusher's operational lifetime.

Crushing Chamber Type Selection (Standard/Shorthead)

The geometry of the crushing chamber is a fundamental design choice. Standard chambers are designed for secondary crushing, providing a good balance between capacity and product size. Shorthead chambers, with a steeper head angle and longer parallel zone at the bottom, are designed for tertiary crushing, producing a finer, more cubical product. The choice between a standard and a shorthead crushing chamber depends on the required product size and the specific position of the crusher within the multi-stage crushing circuit.

Motor Power Matching (300kW-750kW)

The drive motor provides the necessary energy to crush the tough iron ore. Power requirements for such demanding applications are substantial, typically ranging from 300 kilowatts to 750 kilowatts. Matching the motor's power to the crusher's duty is crucial; an underpowered motor will stall under load, while an overpowered one is inefficient. The motor must deliver consistent torque to the eccentric assembly, driving the mantle through its gyrating motion to compress and break the ore against the stationary concave liners.

Moving Cone Swing Frequency (300-500rpm)

The operational speed of the crusher, measured by the swing frequency of the moving cone, influences production capacity and product gradation. Higher speeds, typically between 300 and 500 revolutions per minute, can increase output but may also lead to increased wear and a coarser product if not carefully controlled. The optimal speed is a design feature that works in concert with the chamber profile and motor power to achieve the most efficient breakage of particles for a given application and ore type.

Abrasive Liner Material (Mn13Cr2/High-Chromium Alloy)

To withstand the extreme abrasion of iron ore, the liners inside the crushing chamber are made from special wear-resistant alloys. Two common choices are manganese steel like Mn13Cr2, which hardens under impact, and high-chromium alloys, which offer superior abrasion resistance. These concave and mantle liners are sacrificial components designed to protect the main body of the crusher. Their material composition is selected based on a trade-off between toughness, resistance to abrasion, and overall cost per ton of ore processed.

Special Configuration Requirements

Beyond the core crushing components, modern crushers are equipped with advanced systems that enhance safety, reliability, and ease of maintenance. These special configurations are essential for maintaining continuous operation in a high-volume, high-abrasion environment like an iron ore processing plant. They protect the machine from damage, reduce unplanned downtime, and automate critical maintenance functions.

Investing in these optional systems significantly improves the overall efficiency and cost-effectiveness of the crushing operation. They represent the evolution of crusher design from simple mechanical machines to sophisticated, automated process units that can be monitored and controlled remotely, ensuring optimal performance and protecting a significant capital investment.

Hydraulic Cavity Clearing System

Inevitably, crushers can become clogged due to an uneven feed or a momentary overload. A hydraulic cavity clearing system allows the operator to quickly and safely lower the main shaft and moving assembly to clear a blockage. This feature is invaluable for restoring operation rapidly without the need for lengthy and dangerous manual intervention, significantly reducing downtime and improving overall plant availability.

Tramp Iron Protection Device

Despite best efforts, uncrushable material like drill bits or bucket teeth can sometimes enter the crushing chamber. Tramp iron protection devices, often a hydraulic relief system, allow the crusher to automatically open its discharge setting to let the uncrushable object pass through, preventing catastrophic damage to the internal components. This system acts as a safety valve for the crusher, safeguarding it against events that could otherwise cause weeks of downtime and expensive repairs.

Automatic Lubrication System

Continuous and reliable lubrication is the lifeblood of any heavy-duty crusher. An automatic lubrication system ensures a precise and consistent supply of clean oil to all critical bearings and gears without operator intervention. This not only reduces maintenance labor but also provides superior protection against wear, extends component life, and can include condition monitoring to alert operators to potential issues before they lead to a failure.

Dust Seal Structure

The crushing process generates large amounts of abrasive dust, which can be highly detrimental to the crusher's bearings and other internal mechanisms. A multi-stage dust seal structure is employed to create a barrier between the crushing chamber and the lubricated interior of the crusher. These seals, often consisting of a series of rings and a positive pressure air barrier, prevent dust ingress, ensuring the longevity of the bearings and maintaining the purity of the lubricating oil.

Supplier Evaluation Dimensions

Selecting the right equipment supplier is as important as selecting the right machine. A reliable partner provides not only a quality product but also the support necessary to ensure its long-term performance. Evaluating potential suppliers across several key dimensions mitigates risk and ensures a successful long-term partnership that contributes to the profitability of the mining operation.

The evaluation should consider the proven reliability of the equipment, the supplier's ability to support the machine throughout its life cycle with parts and service, and their adherence to international quality and safety standards. A supplier's commitment to research and development is also a key indicator of their ability to provide innovative and efficient crushing solutions in the future.

Equipment Failure Rate (<2%)

A low equipment failure rate, ideally below 2%, is a strong indicator of robust engineering and quality manufacturing. This metric reflects the crusher's mechanical reliability and its ability to operate continuously under demanding conditions with minimal unplanned stops. A proven track record of high availability is crucial for meeting production targets and is often a deciding factor when comparing crushers from different manufacturers.

Spare Parts Supply Cycle (<72 hours)

When maintenance is required, the speed of spare parts delivery is critical to minimizing downtime. Leading suppliers guarantee a short spare parts supply cycle, often less than 72 hours for critical components. This requires a global logistics network and strategically located distribution centers to ensure that wear parts like blow bars or liners can be delivered to remote mining sites promptly, keeping inventory costs low and plant availability high.

Commonality of Wear Parts

Operators often benefit from crusher designs that use common or interchangeable wear parts across different models or even different stages of crushing. This commonality simplifies inventory management, reduces the number of different spare parts that need to be stocked on site, and can lead to volume purchasing discounts. It is a significant operational advantage that reduces complexity and cost over the long term.

CE/ISO Certification Credentials

International certifications such as CE (Conformité Européenne) and ISO (International Organization for Standardization) are not just badges; they are independent verifications that the equipment is designed and manufactured to high standards of safety, quality, and environmental management. These credentials provide assurance that the crusher meets stringent global requirements, facilitating its use in international projects and ensuring a baseline level of quality and safety.

Investment Return Analysis

The acquisition of a large crusher is a major capital expenditure, and its justification relies on a thorough investment return analysis. This analysis looks beyond the initial purchase price to consider the total cost of ownership, which includes energy consumption, maintenance, and the machine's overall contribution to production revenue. The goal is to select a solution that offers the best value over its entire operational life.

A comprehensive analysis compares different crusher options based on their efficiency in converting electrical energy into size reduction, the frequency and cost of replacing wear parts, and the expected lifespan of major components. The crusher with the lowest initial cost may not be the most economical choice if its operating costs are high or its reliability is poor.

Equipment Procurement Cost ($500k-$2M)

The initial procurement cost for a large-scale cone crusher capable of handling iron ore can range from $500,000 to over $2 million. This price varies significantly based on the machine's size, capacity, installed power, and the level of technology and automation included. This investment covers the engineering, manufacturing, and often the commissioning of the equipment at the customer's site.

Operational Energy Consumption (1.5-3 kWh/ton)

Energy is one of the largest ongoing operational expenses. Efficient crushers consume between 1.5 and 3.0 kilowatt-hours of electricity to process one ton of ore. This metric, known as specific energy consumption, is a key measure of efficiency. A lower value indicates a more efficient crushing process, which translates directly into lower operating costs and a reduced environmental footprint over the decades-long life of the equipment.

Maintenance Cost Proportion (Annual Maintenance Fee/Equipment Price)

A reasonable annual maintenance cost, often expressed as a percentage of the original equipment price, typically ranges from 2% to 5% for a well-maintained crusher. This cost covers routine inspections, replacement of wear parts like liners and mantles, and lubrication. Proactive maintenance is far less costly than reactive repairs following a failure, making this a critical part of the operational budget.

Investment Payback Period (3-5 years)

The payback period is the time required for the net revenue generated by the crusher (through increased production efficiency and product quality) to equal the initial capital outlay. For a well-selected crusher in an iron ore application, a payback period of 3 to 5 years is typically expected. This calculation justifies the investment by demonstrating how the crusher will contribute to the profitability of the operation within a reasonable timeframe.

Typical Application Cases

Cone crushers and other advanced crushing machines are deployed in a variety of critical roles within the mining and aggregates industries. Their ability to provide high-capacity, reliable size reduction makes them indispensable in turning raw, blasted rock into valuable, specification-grade product. Understanding these applications provides context for how these powerful machines integrate into larger material processing systems.

From the primary breaking of run-of-mine ore to the final preparation of feed for grinding mills, crushers are the workhorses of mineral processing. Their configuration and placement are carefully engineered to maximize the overall efficiency of the plant, often working in concert with screening equipment to ensure optimal performance and product quality.

Open-Pit Iron Ore Beneficiation Plant

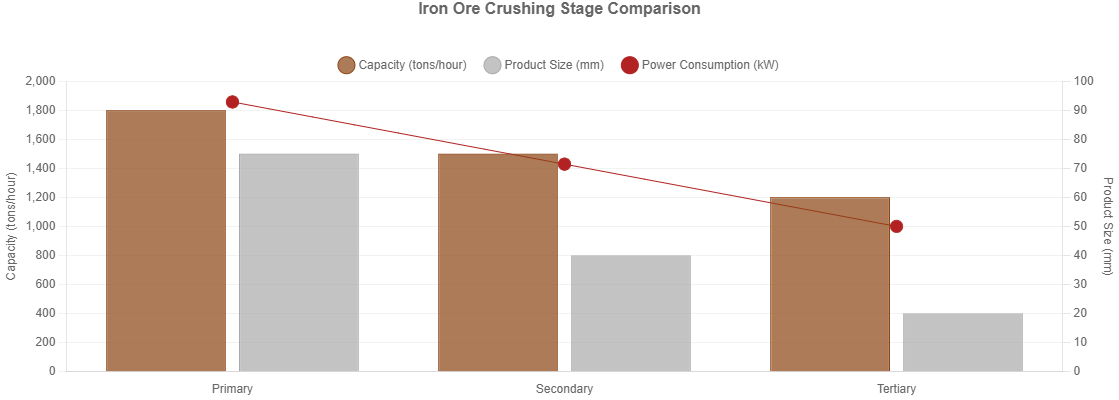

In vast open-pit mining operations, large primary gyratory crushers are often used to initially reduce the size of the ore hauled from the pit. Secondary and tertiary cone crushers then further refine the material to a size suitable for beneficiation processes like magnetic separation. This multi-stage crushing circuit is designed for maximum throughput and reliability to support the continuous operation of the mine.

Underground Mine Crushing Station

In underground mining, space is at a premium. Compact, robust crushers are installed in underground crushing stations to reduce the size of the ore before it is hoisted to the surface. This significantly reduces the energy and cost associated with transporting material vertically, as well as the size of the conveying infrastructure needed. These stations are critical for the economic viability of deep underground mines.

Pre-Treatment System for Magnetic Separation

Magnetic separation is a highly effective method for concentrating iron ore, but it requires the ore to be liberated at a specific particle size. Crushing circuits are designed to produce a finely crushed product that optimizes the recovery of iron minerals during separation. The consistent product size from a cone crusher ensures efficient operation of the downstream magnetic separators, maximizing the yield of the concentrate.

Ball Mill Feed Control

Ball mills, which grind the crushed ore into a fine powder, are highly energy-intensive. Their efficiency is greatly influenced by the size of their feed material. Crushers acting as the final stage before milling are tasked with producing a consistently fine product. This controlled feed allows the ball mills to operate at their peak grinding efficiency, reducing energy consumption per ton of final product and increasing the overall capacity of the milling circuit.