The Application of Cone Crushers in Construction Waste Recycling

Construction Waste Characteristics Analysis

Construction and demolition waste presents unique challenges for recycling operations due to its highly variable and complex nature. Unlike natural stone quarries with consistent material, construction waste streams contain a mixture of concrete, bricks, wood, plastics, and metals, each with different crushing and separation requirements. This heterogeneity demands a flexible and robust processing approach that can handle unexpected materials without compromising equipment integrity or final product quality.

The physical properties of construction debris differ significantly from virgin aggregates. Concrete chunks often contain embedded rebar, while bricks and masonry materials have different fracture characteristics. Light materials like wood and plastics must be separated from heavy aggregates. Understanding these material characteristics is fundamental to designing an effective recycling system that can transform waste into valuable secondary raw materials, contributing to a circular economy in the construction sector.

Material Composition Complexity (Concrete/Bricks/Rebar)

The composition of construction waste is extremely complex, typically containing hardened concrete fragments, clay bricks, asphalt pieces, and significant amounts of metal reinforcement bars. This mixture requires processing equipment that can handle both the crushing of hard, brittle materials and the separation of ductile metal components. The presence of rebar embedded in concrete chunks represents a particular challenge, as it can cause serious damage to crushers if not properly addressed before the crushing stage.

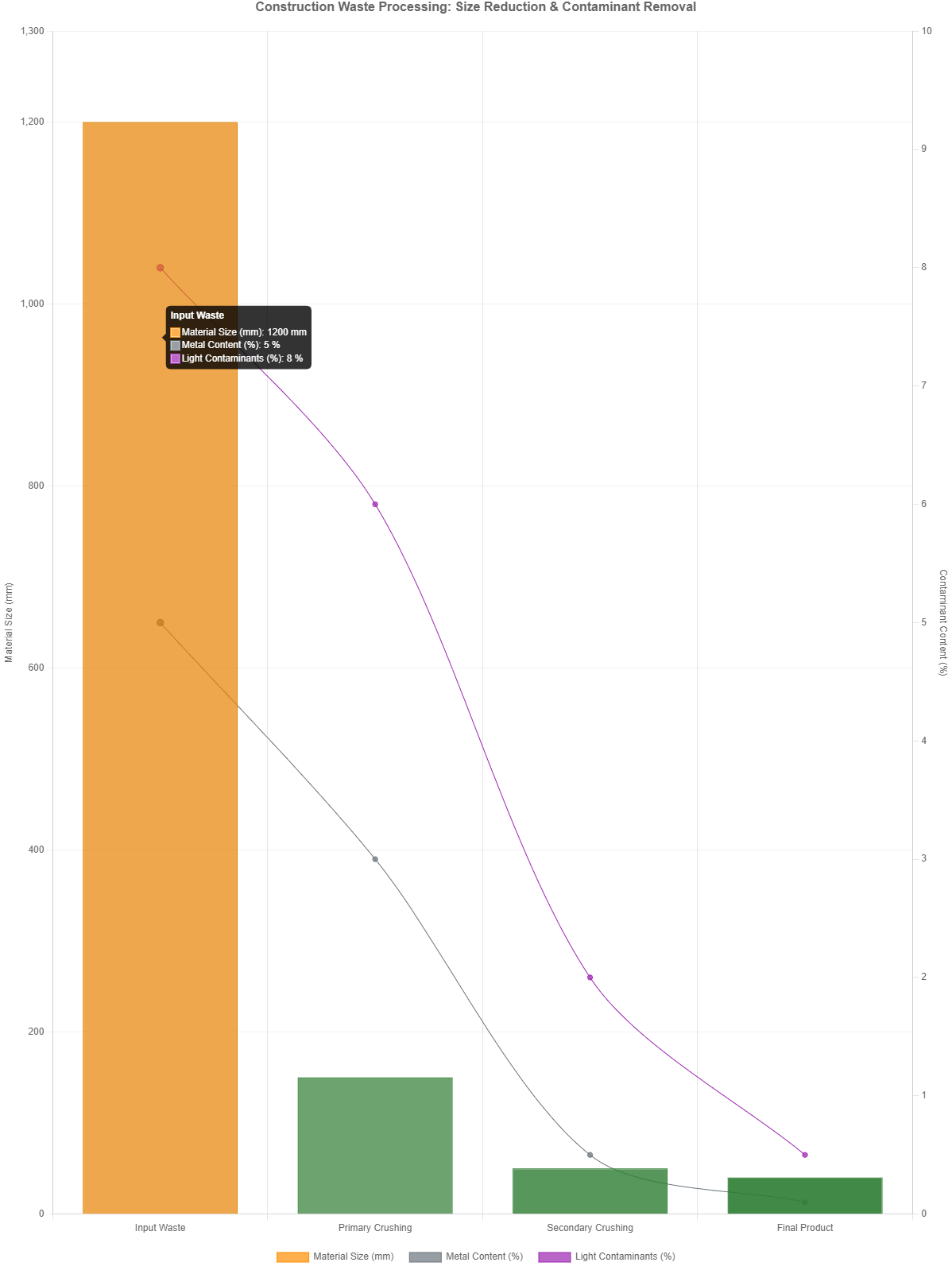

Oversized Material Handling (<1200mm)

Construction waste often includes very large elements, such as concrete slabs, foundation blocks, and structural components that can measure up to 1200mm or more in their largest dimension. Handling these oversized materials requires specialized equipment with large feed openings and robust construction. Primary crushers designed for this application must be capable of reducing these massive pieces to manageable sizes for further processing in secondary crushing stages.

Rebar Separation Requirements

The efficient separation of steel reinforcement from concrete is critical for both the quality of the final aggregate product and the economic viability of the recycling operation. Steel rebar must be removed early in the process to prevent damage to crushers and to produce a clean aggregate product. This separation typically occurs through a combination of manual pre-sorting, mechanical shearing, and powerful magnetic separation systems that extract ferrous metals after primary crushing but before fine crushing stages.

Light Material Removal

Construction waste contains various light materials such as wood, plastics, paper, and insulation that must be removed to produce high-quality aggregate. These contaminants reduce the value of the final product and can cause issues in certain applications. Effective removal systems typically employ air classification technology (wind sifters) that use controlled air flows to separate lighter materials from heavier aggregates based on their different densities and aerodynamic properties.

Equipment Adaptation Solutions

Standard crushing equipment requires specific adaptations to effectively process construction and demolition waste. These modifications focus on protecting the machinery from damaging materials, enhancing separation capabilities, and ensuring continuous operation despite the challenging feed material. Specialized crushers for recycling applications incorporate features not commonly found in quarry equipment.

The adaptation strategy involves creating a system that can handle the unpredictable nature of construction waste while maintaining high availability and productivity. This includes implementing protective measures against uncrushable elements, designing for easy maintenance and clearing of jams, and integrating separation technologies directly into the crushing process. The goal is to create a robust recycling system that maximizes material recovery and minimizes downtime.

Pre-Crushing Iron Removal System

Before construction waste enters the main crusher, it typically passes through a pre-processing stage that includes powerful electromagnetic separators. These systems remove large ferrous metals that could damage the crusher. The pre-crushing iron removal system often consists of a suspended magnetic separator that travels over the conveyor belt, extracting rebar and other steel elements before they reach the crusher's crushing chamber, significantly reducing the risk of mechanical damage and downtime.

Crushing Chamber Selection (Coarse Crushing Type)

For construction waste processing, crushers with specially designed coarse crushing chambers are preferred. These chambers feature a more open design that can accommodate large, irregularly shaped concrete pieces and provide better handling of materials with occasional metal contaminants. The geometry of these chambers promotes both impact and compression crushing, effectively breaking down reinforced concrete while allowing metallic elements to pass through without causing blockages or damage.

Hydraulic Cavity Clearing Device

Construction waste processing inevitably faces occasional blockages or bridging of materials in the crusher cavity. Hydraulic cavity clearing systems allow operators to quickly and safely clear these obstructions without entering the crusher or performing extensive disassembly. With simple push-button controls, the hydraulic system can raise and lower the main shaft, dislodging stuck materials and restoring normal operation in minutes rather than hours, significantly improving operational availability.

Automatic Reverse Discharge

Modern crushers designed for recycling applications often feature automatic reverse functionality as a protection mechanism. When the crusher experiences an overload condition or detects an uncrushable object, the system automatically reverses the crushing motion to eject the problematic material. This intelligent feature prevents damage to the crusher's internal components and eliminates the need for manual intervention, maintaining operational continuity in challenging recycling applications.

Process Flow Design

The efficient recycling of construction waste requires a carefully designed process flow that addresses material handling, size reduction, separation, and quality control. Unlike simple crushing circuits for natural stone, construction waste recycling plants must incorporate multiple stages of separation and sorting to remove contaminants and produce clean, high-value recycled aggregates.

A well-designed process flow maximizes material recovery, optimizes equipment utilization, and ensures consistent product quality. The design must be flexible enough to handle variations in feed material composition while maintaining efficient operation. The sequence of operations typically includes pre-sorting, primary crushing, metal removal, secondary crushing, and multiple stages of screening and separation to produce various aggregate fractions suitable for different applications.

Two-Stage Crushing Solution

Most construction waste recycling operations employ a two-stage crushing process to achieve the desired product size and shape. Primary crushing reduces large demolition debris to manageable sizes (typically 100-150mm), while secondary crushing further reduces the material to the final product specifications (often 0-40mm). Between these stages, efficient metal removal systems extract ferrous contaminants. This approach optimizes the crushing capacity and allows for better control over the final product's characteristics.

Air Separator Integration

Air separation technology is crucial for removing light contaminants from construction waste. After crushing, the material stream passes through an air separator or wind sifter, where controlled air currents lift and carry away light materials like wood, plastic, paper, and insulation. The heavier aggregates continue through the process unaffected. This dry separation method is highly effective and environmentally preferable to water-based washing systems, especially in regions with water scarcity or strict effluent regulations.

Magnetic Separator Configuration

Powerful magnetic separators are strategically placed at multiple points in the recycling process to remove ferrous metals. Initial magnetic separation occurs after primary crushing to extract larger metal pieces, while additional separators after secondary crushing remove smaller metallic fragments. These systems typically use permanent magnets or electromagnets suspended over conveyor belts or incorporated into drum separators, ensuring thorough metal recovery and protecting downstream equipment from damage.

Manual Sorting Platform

Despite advanced mechanical separation technologies, manual sorting remains an essential component of construction waste recycling. Sorting platforms staffed by trained personnel allow for the removal of specific contaminants that machines might miss, such as non-ferrous metals, hazardous materials, large plastic items, and other non-recyclable elements. This human intervention significantly improves the purity of the final recycled aggregates and helps ensure compliance with quality standards for construction applications.

Quality Control Standards

Producing high-quality recycled aggregates from construction waste requires strict adherence to established quality control standards. These standards ensure that the recycled materials meet technical specifications for use in new construction projects, maintaining safety and performance comparable to virgin aggregates. Quality control begins with incoming material assessment and continues through every stage of the processing operation.

Regular testing and monitoring verify that the recycled aggregates possess the necessary physical and mechanical properties for their intended applications. Key quality parameters include particle size distribution, particle shape, crushing resistance, and cleanliness. Consistent quality is essential for market acceptance and for meeting the requirements of various engineering standards that govern the use of recycled materials in construction.

Recycled Aggregate Particle Size (0-40mm)

The particle size distribution of recycled aggregates is carefully controlled to meet specific market requirements. The most common size ranges for construction applications are 0-40mm for general fill and sub-base material, with more precisely graded fractions (such as 4-8mm, 8-16mm, and 16-32mm) produced for use in concrete and asphalt production. Achieving consistent sizing requires well-maintained crushers and efficient screening systems that can separate the crushed material into the desired discharge size fractions.

Flaky and Elongated Particle Content (<15%)

The shape of aggregate particles significantly influences their performance in construction applications. Excessive flaky (flat) or elongated particles can reduce workability in concrete and compromise the stability of asphalt mixes. Quality standards typically limit the content of these irregular particles to less than 15% by weight. Cone crushers, with their inter-particle crushing action, tend to produce more cubical particles than other crusher types, making them particularly suitable for producing high-quality recycled aggregates with good particle shape.

Crushing Value Index (<30%)

The crushing value test measures the resistance of aggregates to mechanical degradation under load. A lower crushing value indicates stronger, more durable material. For recycled concrete aggregates to be suitable for structural applications, they typically need to achieve a crushing value of less than 30%. This property depends on the original concrete quality and the efficiency of the crushing process, which should minimize the creation of weak particles through over-crushing.

Clay Content Control

Excessive clay, silt, or dust coatings on aggregate particles can weaken the bond with cement in concrete applications. Quality standards limit the content of these fine materials, typically measured through washing and sedimentation tests. In recycling operations, effective dust control systems and sometimes washing equipment are employed to ensure the final product meets strict cleanliness specifications, typically requiring less than 1-2% of material finer than 75μm in concrete-grade aggregates.

Environmental Processing Requirements

Construction waste recycling operations must meet stringent environmental standards to minimize their impact on surrounding communities and ecosystems. These requirements address airborne emissions, noise pollution, water management, and waste handling. Modern recycling facilities implement comprehensive environmental protection measures that often exceed regulatory requirements, demonstrating a commitment to sustainable operations.

Environmental management in recycling plants involves implementing best available techniques for pollution control, continuous monitoring of emissions, and developing circular economy approaches to minimize waste generation. These practices not only ensure regulatory compliance but also improve community relations and create additional value from by-products that might otherwise be disposed of as waste.

Dust Control (Baghouse Filter)

Crushing operations generate significant dust emissions that must be controlled to protect worker health and minimize environmental impact. Baghouse filter systems are the most effective technology for capturing fine dust particles from construction waste processing. These systems use fabric filter bags to remove up to 99.9% of dust from exhaust air streams. The collected dust can often be reused in other applications, such as in cement production or as filler material, contributing to the overall efficiency of the recycling operation.

Noise Control (<80dB)

Crushing and screening equipment generates high noise levels that must be managed to comply with workplace safety regulations and minimize disturbance to nearby communities. Noise control measures include enclosing crushers and screens in sound-dampening cabins, installing acoustic barriers around the plant perimeter, using noise-reducing materials in equipment design, and implementing operational controls such as limiting night-time operations. Modern recycling plants aim to keep noise levels below 80dB at the property boundary.

Wastewater Circulation System

In recycling operations that include aggregate washing, a closed-loop water circulation system is essential for environmental protection and water conservation. Process water is collected, treated to remove suspended solids, and recirculated through the system. This approach minimizes freshwater consumption and eliminates the discharge of contaminated wastewater. Advanced water treatment systems using sedimentation tanks, flocculation, and filtration ensure that recirculated water meets quality standards for reuse in the process.

Solid Waste Co-Processing

Despite efficient recycling processes, some residual waste materials remain that cannot be converted into marketable products. Environmentally responsible operations identify opportunities for co-processing these materials, such as using non-recyclable fractions as alternative fuels in cement kilns or as feedstock for other industrial processes. This approach minimizes the amount of waste sent to landfill and maximizes the overall resource recovery from construction and demolition waste.

Economic Value Analysis

The economic viability of construction waste recycling depends on careful analysis of costs, revenues, and external economic factors. While recycling operations require significant investment in equipment and infrastructure, they can generate substantial economic returns through the sale of recycled materials, avoided landfill costs, and potential carbon credit revenues. A comprehensive economic analysis helps investors understand the financial prospects and payback period of recycling initiatives.

Key economic considerations include processing costs, market prices for recycled products, equipment maintenance expenses, labor costs, and regulatory compliance costs. Additionally, economic assessments should account for indirect benefits such as reduced environmental impact, conservation of natural resources, and contributions to circular economy objectives that may translate into regulatory advantages or premium market positioning.

Processing Cost ($3-8/ton)

The cost of processing construction waste into recycled aggregates typically ranges from $3 to $8 per ton, depending on the complexity of the operation, equipment efficiency, labor costs, and energy prices. This includes expenses for equipment operation and maintenance, labor, energy consumption, and management of residual wastes. Efficient operations at the lower end of this cost range typically benefit from high levels of automation, optimized process flows, and economies of scale that spread fixed costs across larger processing volumes.

Recycled Aggregate Selling Price ($15-30/ton)

High-quality recycled aggregates can command prices between $15 and $30 per ton in most markets, depending on local demand, quality specifications, and competition from natural aggregates. Premium prices are achieved for well-graded, clean aggregates that meet strict quality standards for use in concrete and asphalt production. The price differential between recycled and virgin aggregates creates the fundamental economic incentive for recycling operations, particularly in regions where natural aggregates are scarce or transportation costs are high.

Investment Payback Period (2-4 years)

Well-designed construction waste recycling facilities typically achieve investment payback within 2 to 4 years of operation. This relatively short payback period reflects the combination of revenue from material sales, avoided landfill tipping fees, and sometimes government incentives for recycling activities. The exact payback period depends on factors such as plant capacity, operational efficiency, local market conditions for recycled products, and the cost structure of competing disposal options.

Carbon Emission Reduction Benefits

Construction waste recycling provides significant carbon emission reduction benefits compared to traditional disposal methods and virgin material extraction. These benefits arise from avoided landfill methane emissions, reduced transportation needs, and the elimination of energy-intensive quarrying operations. Life cycle assessment studies indicate that using recycled concrete aggregates can reduce carbon emissions by 40-60% compared to using natural aggregates. These environmental benefits are increasingly valued in carbon-conscious markets and may translate into economic value through carbon credit mechanisms or preferential treatment in green building projects.