In-Depth Analysis of Cone Crusher Bearing Lubrication Systems: 2025 Best Practices Guide

Bearing Lubrication Fundamental Principles

The lubrication system represents the circulatory system of a cone crusher, ensuring the vital components within the crushing machinery continue to operate smoothly under extreme pressure and rotational forces. Proper lubrication reduces friction between metal surfaces, dissipates heat generated during operation, and protects against corrosion and contaminant infiltration. Understanding the fundamental principles behind this process is essential for maintaining equipment longevity and preventing catastrophic failures that can result in extensive downtime and repair costs.

In cone crushers, bearings operate under some of the most demanding conditions in industrial machinery, supporting tremendous loads while facilitating the gyratory motion of the mantle. The lubrication system must consistently deliver the right quantity and quality of oil to these critical components at the correct pressure and temperature. Failure in any aspect of this system can lead to reduced equipment life, increased energy consumption, and ultimately, bearing seizure which may cause damage to other crusher components including the main shaft and surrounding structures.

Rolling Bearing Lubrication Mechanism (Elastohydrodynamic Lubrication)

Rolling element bearings in cone crushers operate under elastohydrodynamic lubrication conditions, where the pressure between the rolling elements and races becomes extremely high, causing elastic deformation of the metal surfaces and significant changes in the lubricant's viscosity. Under these extreme pressures, which can exceed 1 GPa, the lubricant momentarily transforms into a semi-solid state, creating a protective film that separates the metal surfaces despite the tremendous loads applied during the crushing process.

Lubrication Film Thickness Calculation Formula (λ = h_min/σ)

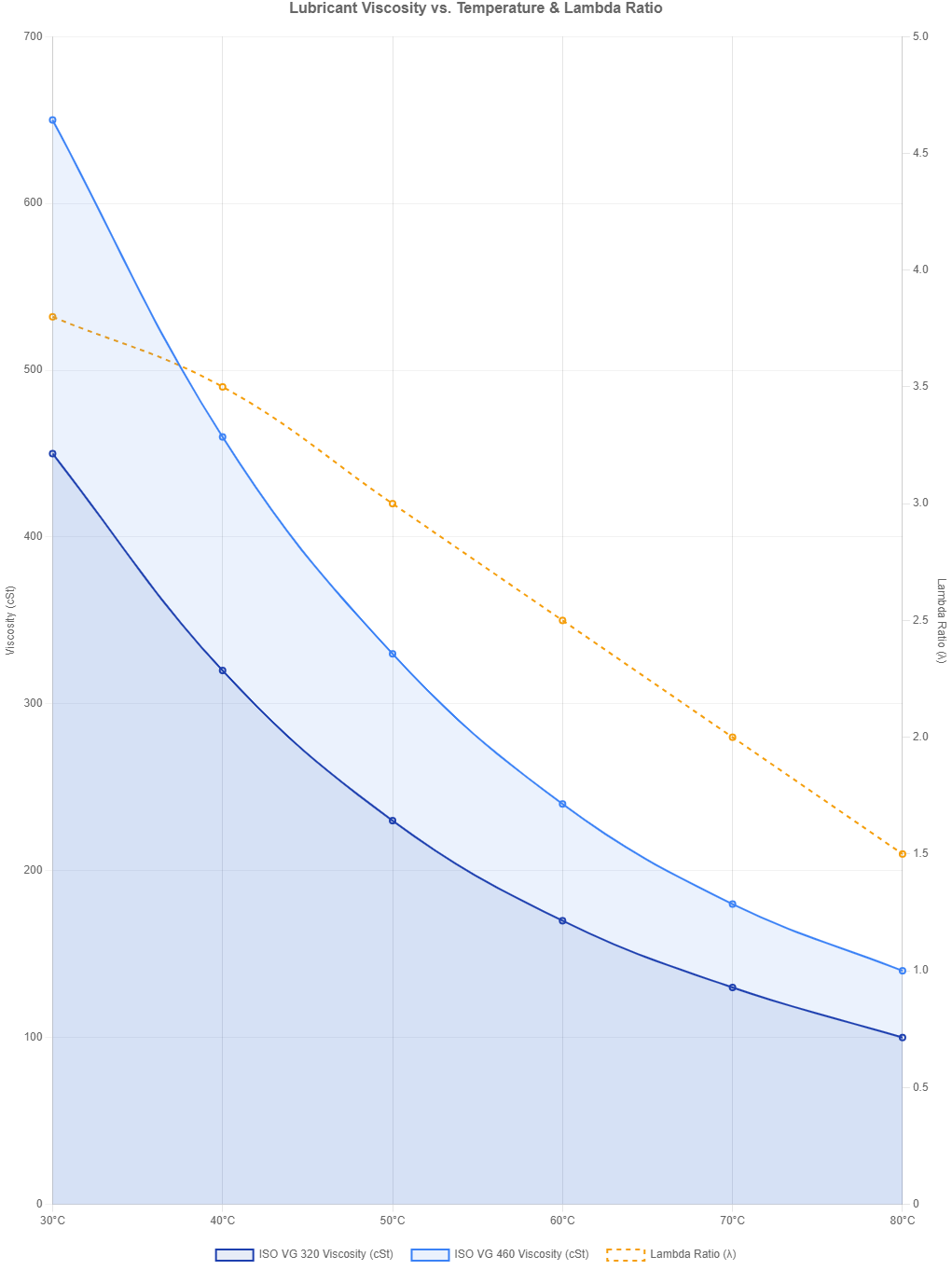

The lambda ratio (λ) is a critical parameter in bearing lubrication that represents the relationship between the lubricant film thickness (h_min) and the composite surface roughness (σ) of the bearing components. Maintaining a lambda ratio greater than 1 indicates that the lubrication film is sufficiently thick to completely separate the surfaces, while values below 1 suggest partial metal-to-metal contact. For cone crusher applications operating under severe conditions, industry standards typically recommend maintaining lambda values between 2 and 4 to ensure adequate protection against wear and surface fatigue.

Lubricant Viscosity Selection Principle (ISO VG 320-460)

Selecting the proper viscosity grade is paramount for effective bearing lubrication in cone crushers. The International Standards Organization (ISO) viscosity classification system provides guidelines for lubricant selection, with cone crushers typically requiring oils in the ISO VG 320 to 460 range. This relatively high viscosity is necessary to maintain adequate film strength under the extreme pressures and temperatures encountered during operation. The specific viscosity selection depends on factors including operating temperature, bearing size and type, rotational speed, and the crushing application's severity.

Lubrication Method Classification (Oil Circulation/Grease Lubrication)

Cone crushers employ two primary lubrication methods: oil circulation systems and grease lubrication. Oil circulation systems, which are most common in larger crushers, continuously pump filtered oil to the bearings, then collect, cool, and recirculate it. This method provides excellent cooling and contamination control. Grease lubrication, typically used in smaller crushers or auxiliary components, involves applying semi-solid lubricants at regular intervals. Each method has distinct advantages, with oil circulation generally preferred for high-load, high-speed applications where heat dissipation is critical.

Lubrication System Core Components

The lubrication system in a cone crusher consists of several integrated components that work together to ensure proper lubrication of bearings and other moving parts. Each component plays a vital role in maintaining oil quality, pressure, and temperature within specified parameters. Understanding these components and their functions is essential for effective maintenance and troubleshooting of the lubrication system.

A well-designed lubrication system not only delivers oil to the bearings but also continuously monitors and maintains its condition through filtration, cooling, and monitoring systems. The interdependence of these components means that failure in one area can quickly affect the entire system's performance. Regular inspection and maintenance of each component are necessary to prevent unexpected downtime and extend the crusher's operational life.

Oil Pump Selection Standard (Flow Rate ≥20L/min)

The heart of any forced lubrication system is the oil pump, which must be capable of delivering sufficient flow to all critical components under varying operating conditions. For medium to large cone crushers, pumps with a minimum flow capacity of 20 liters per minute are typically required to ensure adequate lubrication and cooling. Gear pumps are commonly used due to their reliability and ability to maintain relatively constant flow rates against the system's backpressure. The pump must be sized to provide sufficient flow even as internal clearances increase with wear over time.

Filter Precision Requirements (β10≥200)

Filtration is critical for maintaining oil cleanliness and protecting precision bearing components from abrasive wear. The beta ratio (β) measurement system quantifies filter efficiency, with β10≥200 indicating that for every 200 particles of a given size entering the filter, only one particle passes through. This high level of filtration is necessary to prevent contamination from causing premature bearing failure. Multi-stage filtration systems often incorporate both depth filters for removing larger contaminants and surface filters for fine particles down to 10 microns in size.

Oil Cooler Configuration (Temperature Differential<5℃)

Oil cooling is essential for maintaining proper viscosity and preventing thermal degradation of the lubricant. Heat exchangers in cone crusher lubrication systems are designed to limit the temperature differential between incoming and outgoing oil to less than 5°C. This precise temperature control ensures consistent lubricant viscosity and optimal bearing operating conditions. Plate-type heat exchangers are commonly used due to their compact size and efficient heat transfer capabilities, with water typically serving as the cooling medium.

Temperature Sensor Placement (Bushing Locations)

Strategic placement of temperature sensors is crucial for monitoring bearing health and preventing catastrophic failures. Sensors should be positioned as close as possible to the actual bearing surfaces, particularly in the eccentric bushing and bottom main frame bushing areas where temperatures are most critical. RTD (Resistance Temperature Detector) sensors are preferred for their accuracy and stability, providing reliable data for both operational monitoring and automatic shutdown systems that activate when temperatures exceed safe limits.

Lubricant Selection Guide

Selecting the appropriate lubricant for cone crusher bearings involves careful consideration of multiple factors including base oil type, additive packages, operational environment, and manufacturer specifications. The right lubricant not only reduces friction and wear but also helps dissipate heat, protect against corrosion, and extend oil change intervals. Understanding the properties and performance characteristics of different lubricants is essential for optimizing crusher performance and minimizing operating costs.

Modern lubricants for heavy industrial equipment like cone crushers have evolved significantly, with advanced formulations designed to withstand extreme pressures, temperatures, and contamination conditions. The selection process should balance performance requirements with economic considerations, as the wrong lubricant choice can lead to increased energy consumption, frequent oil changes, and premature component failure despite potentially lower initial costs.

Synthetic vs. Mineral Oil Comparison (Oxidation Stability)

The choice between synthetic and mineral-based lubricants involves trade-offs between performance, cost, and application requirements. Synthetic oils generally offer superior oxidation stability, maintaining their protective properties longer at high operating temperatures compared to mineral oils. This extended stability translates to longer oil life and reduced frequency of oil changes. However, synthetic lubricants come at a higher initial cost, which must be balanced against their potential for extended drain intervals and improved equipment protection in demanding applications.

Anti-Wear Additive Formulation (ZDDP Content)

Zinc dialkyldithiophosphate (ZDDP) is a common anti-wear additive in industrial lubricants, forming protective films on metal surfaces under boundary lubrication conditions. The concentration of ZDDP must be carefully balanced—too little provides inadequate protection, while excessive amounts can lead to deposit formation and potential corrosion issues. Modern lubricant formulations for cone crushers typically contain ZDDP concentrations between 0.7% and 1.2%, optimized to provide maximum protection without causing adverse side effects during extended service intervals.

Moisture Content Control (<0.1%)

Water contamination in lubricating oil can cause numerous problems including corrosion, hydrogen embrittlement, and accelerated additive depletion. Maintaining moisture content below 0.1% is critical for preserving bearing life and lubricant effectiveness. Various methods help control moisture, including desiccant breathers on reservoir tanks, regular oil analysis, and offline filtration systems capable of removing water through coalescence, vacuum distillation, or absorption technologies. In humid environments, additional precautions such as air dryers for reservoir venting may be necessary.

Oil Change Interval (500-1000 hours)

Determining optimal oil change intervals requires balancing lubricant condition with operational economics. Typical recommendations range from 500 to 1000 operating hours, though this varies significantly based on operating conditions, crusher age, and oil analysis results. Regular oil analysis provides the most accurate method for determining change intervals, measuring parameters including viscosity, acid number, additive depletion, and contamination levels. Extended intervals may be possible with high-quality synthetic lubricants and effective filtration systems, reducing both lubricant costs and environmental impact.

Lubrication System Maintenance Protocol

A comprehensive maintenance program is essential for ensuring the long-term reliability and performance of cone crusher lubrication systems. This program should include regular inspections, preventive maintenance tasks, and condition monitoring activities designed to identify potential issues before they lead to equipment failure. Well-documented maintenance procedures help standardize practices across shifts and ensure consistent attention to critical system components.

Maintenance activities should be scheduled according to both time-based and condition-based criteria, with more frequent attention given to components subject to the highest wear rates. Proper record-keeping of all maintenance activities facilitates trend analysis and helps optimize maintenance intervals based on actual operating conditions rather than generic recommendations. Training personnel to recognize early warning signs of lubrication system problems can prevent minor issues from developing into major failures.

Daily Inspection Items (Oil Level/Temperature/Pressure)

Daily inspections form the first line of defense against lubrication system failures. Operators should verify oil levels in the reservoir, ensuring they remain within the recommended operating range to prevent pump cavitation or overflow. Temperature readings should be recorded and compared against established baselines, with investigations initiated for any significant deviations. Pressure gauges throughout the system must be checked to confirm proper flow to all lubrication points, particularly the crusher's moveable cone bearings which experience the most severe operating conditions.

Quarterly Maintenance Tasks (Filter Element Replacement)

Quarterly maintenance typically includes replacement of filter elements, which gradually become clogged with particles despite regular cleaning of filter bowls. Even with apparently clean pressure differential readings, filter media can degrade over time, reducing their effectiveness at removing fine contaminants. During filter changes, the system should be inspected for signs of bypassing, which indicates excessive pressure differential across clogged elements. This quarterly schedule may need adjustment based on actual operating conditions and oil analysis results.

Annual Testing Content (Oil Ferrography Analysis)

Annual comprehensive oil analysis provides detailed insights into lubricant condition and equipment health. Ferrography analysis separates and examines wear particles suspended in the oil, identifying their composition, size, and concentration. This analysis can distinguish between normal wear particles and those indicating abnormal wear mechanisms such as abrasion, adhesion, or surface fatigue. The results help predict remaining component life and schedule repairs during planned shutdowns rather than experiencing unexpected failures during operation.

Winter Special Maintenance (Heater Activation Temperature)

Cold weather operation requires special maintenance considerations to ensure proper lubricant flow and crusher operation. Immersion heaters in the reservoir should be activated when oil temperatures approach the minimum recommended operating viscosity, typically around 10°C. Pipe tracing or insulation may be necessary to prevent oil congealing in external lines. During extended shutdowns in freezing conditions, operators should periodically circulate oil to maintain temperature or drain systems completely to prevent damage from frozen residual moisture.

Common Fault Diagnosis

Effective troubleshooting of lubrication system problems requires a systematic approach to identify root causes rather than simply addressing symptoms. Understanding the relationship between different system parameters helps diagnose issues accurately and implement appropriate corrective actions. Documentation of previous failures and their solutions creates a valuable knowledge base for addressing future problems more efficiently.

Many lubrication system issues manifest through changes in temperature, pressure, or unusual noises, though the actual cause may be located in a different part of the system than where the symptom appears. Cross-referencing multiple indicators provides more reliable diagnosis than relying on a single parameter. Modern control systems with data logging capabilities can significantly enhance diagnostic effectiveness by tracking parameter trends leading up to failures.

High Oil Temperature Cause Analysis (Viscosity Reduction/Overload)

Elevated oil temperatures can result from multiple causes, including reduced viscosity from contamination or degradation, excessive bearing loads from crusher overfeeding, insufficient cooling flow, or ambient heat from other sources. Diagnosis should begin with verifying proper viscosity through laboratory analysis, then checking crusher operating parameters to ensure it's not consistently operating beyond its designed capacity. Cooling system efficiency should be verified by measuring the temperature differential across the heat exchanger and checking for fouling or flow restrictions.

Abnormal Oil Pressure Treatment (Pump Wear/Pipe Blockage)

Pressure abnormalities require immediate attention as they can quickly lead to bearing damage. Low pressure may indicate pump wear, suction line leaks, clogged intake filters, or excessive bearing clearances allowing too much flow. High pressure often signals blockages in distribution lines, malfunctioning relief valves, or oil that is too viscous due to low temperature or oxidation. Systematic testing of individual circuit sections helps isolate the specific location of pressure problems for targeted repairs.

Bearing Burnout Prevention Measures (Temperature Interlock Protection)

Preventing bearing burnout requires multiple protective measures, with temperature interlock systems serving as the last line of defense. These systems should automatically reduce crusher load or initiate shutdown when bearing temperatures approach dangerous levels. Additional prevention strategies include maintaining proper alignment of the eccentric shaft, ensuring adequate lubrication flow before startup, and implementing progressive ramp-up procedures rather than immediately applying full load to cold bearings.

Lubrication System Leak Detection (Ultrasonic Testing)

Leak detection in lubrication systems has advanced significantly with ultrasonic technology, which can identify small leaks through the high-frequency sound generated by fluid passing under pressure through openings. Ultrasonic detectors can pinpoint leaks even in noisy industrial environments and behind protective covers. Regular leak surveys help identify developing problems early, preventing oil loss, environmental contamination, and potential bearing damage from insufficient lubrication. Documenting leak locations and repair histories helps identify recurring issues that may indicate design or material problems.

Innovative Technology Applications

Advancements in lubrication technology continue to improve cone crusher reliability, efficiency, and maintenance practices. These innovations range from sophisticated monitoring systems to novel lubricant formulations that enhance performance under extreme conditions. Implementing appropriate new technologies can significantly reduce operating costs while extending equipment life and reducing environmental impact.

The adoption of innovative lubrication technologies often requires balancing initial investment against potential long-term benefits, including reduced downtime, lower lubricant consumption, and decreased energy requirements. Technologies that provide better condition monitoring capabilities can be particularly valuable, enabling a shift from preventive maintenance based on time intervals to predictive maintenance based on actual equipment condition.

Online Oil Monitoring Systems (Ferromagnetic Particle Counting)

Continuous online oil monitoring systems provide real-time assessment of lubricant condition and equipment health without requiring manual sampling. These systems typically include particle counters that specifically detect ferrous wear metals through magnetic or inductive sensors, providing immediate warning of abnormal wear patterns. Additional sensors may monitor parameters including viscosity, water content, and dielectric strength, creating a comprehensive picture of oil condition that enables timely maintenance decisions before significant damage occurs.

Smart Lubrication Control Systems (PID Adjustment)

Proportional-Integral-Derivative (PID) control systems have revolutionized lubrication management by dynamically adjusting oil flow and pressure based on real-time operating conditions. These smart systems respond to changes in bearing temperature, crusher load, and operating speed, optimizing lubrication precisely when and where it's needed most. This approach reduces overall lubricant consumption while improving protection during high-demand periods, contributing to both operational efficiency and environmental sustainability through reduced resource usage.

Nano Lubricant Additive Applications (MoS2 Coating)

Nanotechnology has introduced innovative lubricant additives such as molybdenum disulfide (MoS2) nanoparticles that provide exceptional lubrication properties under extreme pressure conditions. These nanoparticles plate bearing surfaces, creating protective layers that reduce friction and wear even when oil film thickness is compromised. The extremely small particle size ensures they remain suspended in the oil rather than settling out, providing continuous protection throughout the lubrication system. Field applications have demonstrated significant reductions in wear rates and energy consumption in cone crusher operations.

Energy Recovery Devices (Waste Heat Utilization)

Advanced lubrication systems now incorporate energy recovery technologies that capture waste heat from the oil for productive use. Heat exchangers can transfer thermal energy from crusher lubrication systems to other processes requiring heat, such as facility heating or pre-warming hydraulic fluids. In larger operations, thermodynamic systems can even convert waste heat into electrical energy through organic Rankine cycle generators. These applications improve overall energy efficiency while helping to maintain optimal oil temperatures for crusher operation.