Comprehensive Analysis of Cone Crusher Applications in the Mining Industry

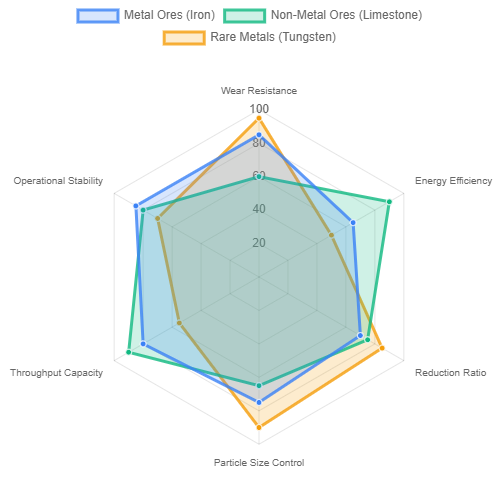

This article provides a detailed exploration of the versatile applications of cone crushers across various mining sectors. It delves into their specialized use in metal ore processing, non-metal mineral extraction, and rare metal mining, highlighting the machine's critical role in achieving efficient size reduction ratios. The discussion extends to unique operational challenges in diverse mining environments, from underground tunnels to high-altitude locations, explaining how specific engineering adaptations enable reliable performance. Furthermore, the analysis covers essential design features that contribute to energy efficiency, product quality control, and equipment longevity, offering a holistic view of this indispensable machinery in modern material processing workflows.

Cone Crusher Applications in Metal Mines

Within metal mining operations, cone crushers serve as indispensable equipment for reducing extracted ores into manageable sizes for further processing. Their robust construction and precise engineering make them particularly suitable for handling the extreme hardness and abrasive nature of metallic ores. These machines excel in maintaining consistent performance under heavy-load conditions, ensuring continuous operation throughout extended production cycles.

The efficiency of metal ore processing heavily depends on the crusher's ability to maintain specified product parameters while minimizing operational costs. Advanced models incorporate hydraulic systems that provide overload protection, preventing catastrophic failures when encountering uncrushable materials. This capability significantly reduces downtime and maintenance expenses, contributing to overall operational profitability in demanding mining environments.

High-Efficiency Performance in Iron Ore Crushing

Iron ore presents exceptional challenges due to its extreme hardness, often measuring between 7-8 on the Mohs scale. Modern cone crushers address this challenge through advanced crushing chamber designs that optimize inter-particle compression. This mechanism enables efficient size reduction while minimizing energy consumption, with some models processing up to 500 tons per hour of raw iron ore.

The exceptional wear resistance of crusher components proves crucial in iron ore applications. Manufacturers employ specially formulated manganese steel alloys for mantles and concaves that withstand continuous abrasion. These wear parts typically maintain operational effectiveness for processing approximately 50,000 tons of material before requiring replacement, ensuring sustained production efficiency.

Particle Size Control Advantages in Copper Ore Crushing

Copper ore processing demands precise particle size distribution to optimize subsequent flotation recovery rates. Cone crushers achieve this through sophisticated chamber designs and adjustable eccentric throws that influence the crushing action. The machines can produce consistent product sizes ranging from 25mm to 50mm, meeting specific metallurgical requirements for optimal mineral liberation.

Modern control systems continuously monitor and adjust the crusher's operational parameters to maintain product consistency. Through automated setting regulation, these systems compensate for wear development in the crushing chamber, ensuring stable output quality throughout the wear component lifecycle. This capability proves particularly valuable in copper processing where consistent particle size directly impacts recovery efficiency.

Wear Resistance Requirements in Gold Ore Crushing

Gold ore operations frequently encounter highly abrasive quartz matrices that accelerate equipment wear. Crusher manufacturers address this challenge through specialized alloy selections for critical components. The utilization of chromium-enhanced manganese steel in concaves and mantles provides enhanced protection against abrasive wear, extending component life by approximately 30% compared to standard materials.

Advanced lubrication systems contribute significantly to wear reduction in gold processing applications. These systems maintain optimal operating temperatures while ensuring complete contamination protection for bearings and other moving components. Proper lubrication intervals and oil filtration systems can increase bearing life by up to 40%, directly impacting overall equipment availability and maintenance costs.

Stability Assurance in Lead-Zinc Ore Crushing

Lead-zinc ore processing requires exceptional equipment stability due to the variable hardness characteristics within ore bodies. Crusher manufacturers achieve this through robust main frame designs and precision-balanced moving components. The structural integrity of these machines enables consistent performance despite fluctuating feed conditions and material properties.

Hydraulic systems provide crucial stability functions through constant pressure maintenance in the crushing chamber. These systems automatically compensate for feed variations while providing instantaneous overload protection. This capability prevents sudden shutdowns and minimizes stress concentrations on mechanical components, ensuring reliable operation throughout the equipment's service life.

Cone Crusher Applications in Non-Metal Mines

Non-metallic mining operations present distinct challenges that require specialized crusher configurations. These applications often prioritize different performance characteristics compared to metal ore processing, with emphasis on energy efficiency, specific particle shape requirements, and handling of particular material properties. Cone crushers have evolved to address these diverse needs through targeted engineering solutions.

The versatility of modern cone crushers enables effective processing of various non-metallic minerals ranging from soft gypsum to hard limestone formations. Manufacturers have developed specific chamber designs and operational parameters optimized for each material type, ensuring maximum efficiency while meeting the unique discharge size requirements of different industrial applications.

Energy-Efficient Design in Limestone Crushing

Limestone processing operations prioritize energy efficiency due to the relatively soft nature of the material and high production volumes. Modern crushers address this need through optimized mechanical designs that reduce power consumption while maintaining high throughput capacities. Advanced models can process up to 800 tons per hour while consuming less than 500 kilowatts of power, representing significant energy savings compared to traditional designs.

The hydraulic systems in these crushers contribute substantially to energy optimization through intelligent power management. These systems automatically adjust the crusher's operational parameters based on real-time feed conditions, ensuring optimal energy utilization throughout the production cycle. This dynamic adjustment capability can reduce energy consumption by up to 15% compared to fixed-setting operation.

Anti-Blocking Functionality in Gypsum Crushing

Gypsum processing presents unique challenges due to the material's tendency to compact and adhere to surfaces under pressure. Crusher manufacturers address this issue through specialized chamber designs that minimize material retention and promote continuous flow. The geometry of these chambers prevents material buildup while maintaining effective reduction ratios necessary for industrial applications.

The discharge system design plays a crucial role in preventing blockages in gypsum processing. Engineers have developed innovative feed size control mechanisms that work in conjunction with the crushing chamber to ensure smooth material flow. These systems incorporate monitoring devices that detect potential blockage conditions and automatically initiate clearing procedures, maintaining continuous operation without manual intervention.

High Reduction Ratios in Phosphate Rock Crushing

Phosphate rock processing demands exceptionally high reduction ratios to liberate the valuable mineral from the host rock. Multi-cylinder hydraulic cone crushers excel in this application through their ability to generate tremendous crushing forces while maintaining precise control over the product size distribution. These machines can achieve reduction ratios of up to 10:1 in a single crushing stage, significantly simplifying the overall processing circuit.

The crushing force adjustment capability in modern crushers allows operators to optimize performance for specific phosphate rock characteristics. Through hydraulic pressure regulation, the machines can maintain optimal crushing forces regardless of feed variations, ensuring consistent product quality throughout the production cycle. This adaptability proves particularly valuable when processing phosphate rocks with varying hardness and abrasiveness characteristics.

Environmental Considerations in Coal Gangue Crushing

Coal gangue processing requires special attention to environmental protection measures due to the dusty nature of the material. Modern crushers incorporate comprehensive dust suppression systems that capture airborne particles at their source, reducing dust emissions by up to 95% compared to unprotected equipment. These systems work in conjunction with water spray mechanisms that minimize dust generation without adversely affecting the crushing process.

Noise control represents another critical environmental consideration in coal gangue processing. Crusher manufacturers employ multiple noise reduction technologies including acoustic enclosures, vibration dampening materials, and specially designed mechanical components that operate more quietly. These measures can reduce operational noise levels by approximately 20 decibels, creating a safer and more comfortable working environment for personnel.

Cone Crusher Applications in Rare Metal Mines

Rare metal mining operations present unique challenges that demand specialized crushing solutions. These valuable minerals often occur in complex ore bodies with unusual hardness characteristics and frequently require precise particle size control for effective recovery. Cone crushers designed for these applications incorporate advanced features that address the specific requirements of rare metal processing while maintaining operational efficiency.

The economic value of rare metals justifies the use of highly specialized equipment that maximizes recovery rates through precise size control. Modern crushers achieve this through sophisticated control systems that maintain tight tolerances on product size distribution, ensuring optimal liberation of valuable minerals without excessive overgrinding. This precision directly impacts the economic viability of rare metal mining operations.

Enhanced Wear Resistance in Tungsten Ore Crushing

Tungsten ore ranks among the most challenging materials to process due to its exceptional hardness and abrasive characteristics. Crusher manufacturers address these challenges through the use of specialized alloy steels in critical wear components. These advanced materials maintain their structural integrity under extreme abrasive conditions, typically lasting 3-5 times longer than standard materials in tungsten processing applications.

Lubrication system technology plays a vital role in enhancing wear resistance in tungsten ore crushing. Advanced systems incorporate multiple filtration stages and temperature control mechanisms that ensure optimal lubrication conditions even under extreme operational stress. The main shaft assembly benefits particularly from these systems, experiencing significantly reduced wear rates and extended service intervals.

Stability and Efficiency Balance in Molybdenum Ore Crushing

Molybdenum ore processing requires careful balancing of operational stability and crushing efficiency to optimize recovery rates. Modern crushers achieve this balance through sophisticated hydraulic systems that maintain consistent operating conditions despite variations in feed material characteristics. These systems automatically adjust the crusher's operational parameters to maintain optimal performance while protecting the equipment from damage.

The rotational speed of the crusher's main shaft significantly influences both efficiency and product quality in molybdenum processing. Advanced control systems continuously optimize this parameter based on real-time performance data, ensuring maximum efficiency while maintaining the desired product specifications. This dynamic adjustment capability contributes substantially to overall operational economy in molybdenum processing plants.

Precise Particle Size Control in Rare Earth Element Crushing

Rare earth element processing demands exceptional precision in particle size control to facilitate efficient separation of these valuable minerals. Cone crushers designed for these applications incorporate advanced chamber designs that produce highly consistent product size distributions with minimal oversize or undersize material. This precision proves crucial for downstream processing stages where size consistency directly impacts separation efficiency.

The discharge opening adjustment mechanism in these specialized crushers provides precise control over product size characteristics. Automated systems continuously monitor and adjust the crusher settings to compensate for wear and feed variations, maintaining consistent product quality throughout the operational cycle. This capability ensures that rare earth element processing operations maintain optimal recovery rates despite changing feed conditions.

Energy Efficiency and High Output in Lithium Ore Crushing

Lithium ore processing operations prioritize both energy efficiency and high throughput capacity due to the relatively low grade of most lithium deposits. Modern cone crushers address these requirements through optimized mechanical designs that minimize energy consumption while maximizing processing capacity. These machines can typically process lithium ores at rates exceeding 400 tons per hour while maintaining power consumption below industry averages.

Hydraulic system innovations contribute significantly to energy management in lithium ore crushing applications. These systems recover energy during certain phases of the crushing cycle and redeploy it during power-intensive phases, reducing overall energy consumption by up to 20% compared to conventional designs. This energy recovery capability, combined with intelligent power management, makes modern crushers particularly suitable for large-scale lithium processing operations.

Specialized Cone Crusher Applications in Mining

Mining operations frequently encounter unique circumstances that demand specialized equipment configurations beyond standard crushing applications. These special conditions range from extreme environmental factors to unusual spatial constraints, all requiring customized engineering solutions. Cone crusher manufacturers have developed specific adaptations that address these challenges while maintaining the reliability and performance expected from modern crushing equipment.

The adaptability of cone crusher technology enables effective operation in virtually any mining environment through targeted modifications and specialized component selections. These adaptations ensure that operations can proceed efficiently regardless of external challenges, maintaining productivity while addressing specific operational constraints. The continuous evolution of these specialized solutions demonstrates the flexibility of cone crusher technology in meeting diverse mining requirements.

Compact Design for Underground Mining Applications

Underground mining operations impose severe spatial constraints that demand exceptionally compact equipment designs. Specialized cone crushers for these applications feature reduced overall dimensions without compromising crushing capacity or performance. These compact designs typically maintain 80-90% of the capacity of similarly rated surface crushers while occupying 40-50% less space, making them ideal for confined underground environments.

The compact design philosophy extends beyond mere size reduction to encompass comprehensive consideration of maintenance accessibility. Engineers incorporate innovative maintenance features that facilitate component replacement and servicing in tight spaces, ensuring that equipment availability remains high despite the challenging environment. These design considerations significantly impact the overall efficiency and safety of underground crushing operations.

High-Capacity Requirements in Open-Pit Mining

Open-pit mining operations demand crushing equipment with exceptionally high capacity to match the massive scale of material extraction. Large cone crushers designed for these applications feature expanded feed openings that accommodate enormous rock volumes, with some models capable of processing over 2,000 tons of material per hour. This massive throughput capacity ensures that crushing operations keep pace with extraction rates, preventing bottlenecks in the production chain.

High-power motor systems provide the necessary energy to drive these large-capacity crushers, with some units employing motors rated at over 750 kilowatts. These powerful drive systems work in conjunction with robust mechanical components designed to withstand the tremendous forces generated during high-volume crushing operations. The combination of massive capacity and extreme durability makes these crushers ideal for the demanding conditions of large-scale open-pit mining.

Altitude Adaptation for High-Altitude Mining Operations

High-altitude mining operations present unique challenges for crushing equipment due to reduced atmospheric pressure and lower oxygen levels. Crusher manufacturers address these conditions through specialized adaptations that maintain performance despite the altered environmental parameters. These adaptations typically include modified cooling systems that compensate for reduced air density and adjusted hydraulic systems that maintain proper pressure relationships.

The cooling system modifications prove particularly important for maintaining reliable operation at high altitudes. Engineers incorporate larger radiator surfaces and more powerful fans that ensure adequate heat dissipation despite the thinner air. These adaptations prevent overheating and ensure that the crusher maintains optimal operating temperatures throughout extended production cycles in high-altitude environments.

Corrosion Protection for Humid Mining Environments

Mining operations in humid or coastal environments face accelerated equipment corrosion that can significantly shorten component life. Crusher manufacturers address this challenge through comprehensive corrosion protection strategies that include specialized material selections and protective coatings. Stainless steel components appear in critical areas where corrosion resistance proves essential for maintaining structural integrity and operational reliability.

Advanced coating technologies provide additional protection against corrosive environments, with some systems offering up to 5,000 hours of salt spray resistance. These protective measures extend equipment life significantly in challenging environments, reducing maintenance requirements and downtime due to corrosion-related failures. The combination of material selection and protective coatings ensures reliable operation even in the most aggressive environmental conditions.