The Application of Cone Crushers in Copper Mining and Processing

Copper Ore Crushing Process Design

The design of a copper ore crushing circuit is a critical first step in the mineral processing chain, setting the stage for all subsequent operations. This design must efficiently reduce the size of run-of-mine ore, which can consist of large boulders, to a specific particle size that is optimal for the grinding and concentration stages. A well-designed circuit maximizes the liberation of valuable copper minerals from the waste rock while minimizing energy consumption and operational costs.

The chosen process must be robust enough to handle the variable hardness and abrasiveness of copper ore, which often contains hard, silica-rich gangue material. The design incorporates multiple stages of size reduction to achieve the target product size without overloading any single machine. The efficiency of this initial crushing stage has a direct and significant impact on the overall throughput and profitability of the entire mining operation, as it prepares the ore for efficient grinding and mineral extraction.

Three-Stage Closed-Circuit Crushing Flow

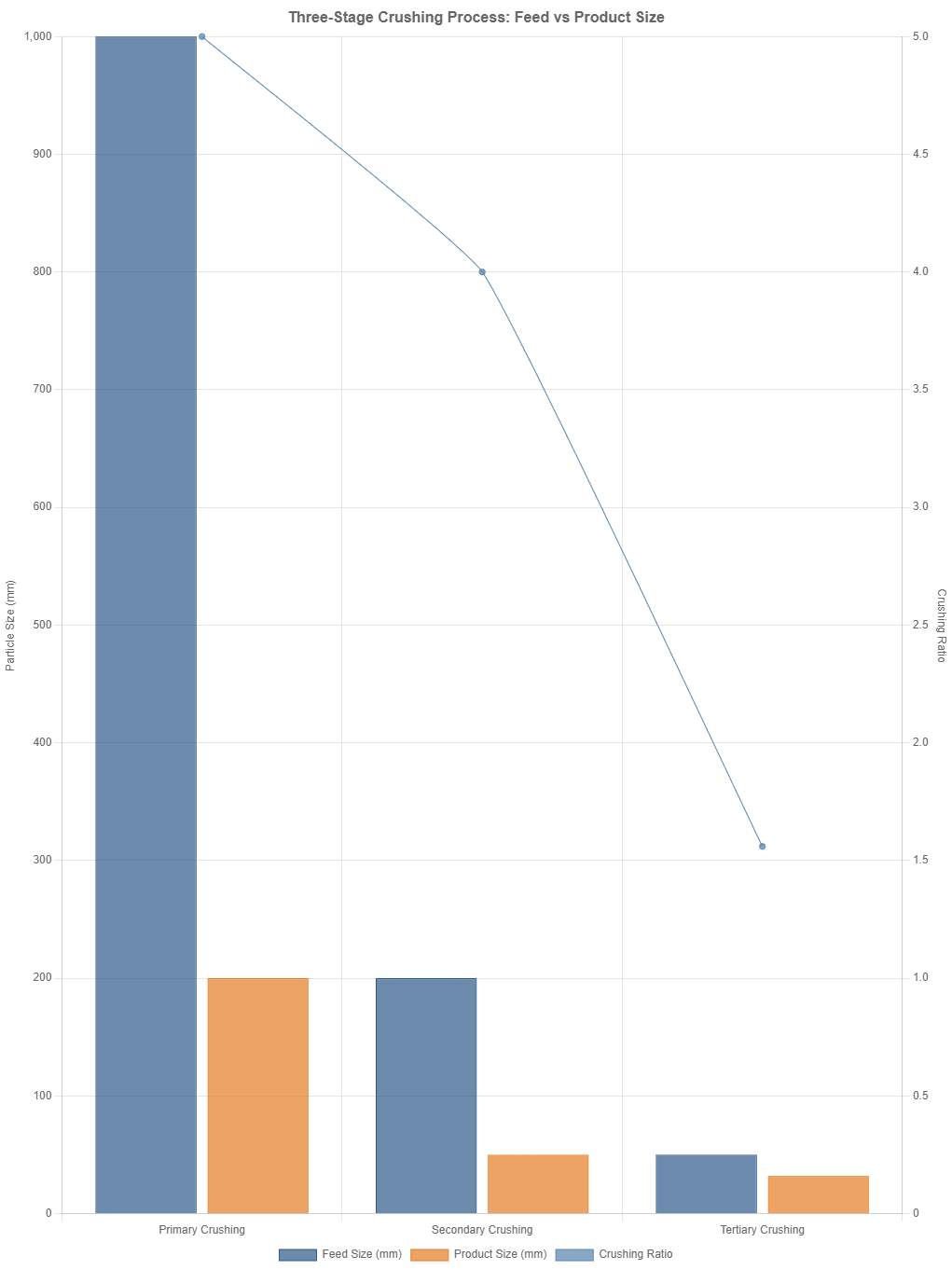

A three-stage closed-circuit crushing flow is a common and highly efficient design for hard and abrasive copper ores. This process typically involves a primary crusher, like a jaw or gyratory crusher, for initial size reduction, followed by secondary and tertiary cone crushers for further refinement. The "closed-circuit" refers to the use of screens after each crushing stage; material that is too large to pass through the screen is sent back to the crusher for further reduction. This ensures a consistently sized final product and maximizes the overall crushing capacity of the circuit.

Crushed Product Size Control (P80 <32mm)

A key objective in the crushing circuit is to achieve a specific product size, often defined as the P80. The P80 value indicates that 80% of the crushed material passes a screen with a certain aperture size. For copper ore, a common target is a P80 of less than 32 millimeters. Achieving this controlled discharge size is crucial because it directly influences the efficiency and energy requirements of the downstream ball mills. A finer crusher product allows the grinding mills to operate more efficiently, significantly reducing the total energy cost of the comminution process.

Crushing Ratio Optimization (>12:1)

The crushing ratio is the ratio of the feed size to the product size and is a measure of the size reduction achieved in a single stage. For copper processing, high reduction ratios, often greater than 12:1, are sought after in the secondary and tertiary stages to minimize the number of processing units required. Cone crushers are particularly well-suited for this task, as their design allows for a high crushing ratio while maintaining a relatively fine and consistent product size, optimizing the entire flow sheet for both capital and operating efficiency.

Capacity Matching Calculation (1000-3000 tons/hour)

Modern copper mines are large-scale operations requiring massive throughput. Crushing circuits are designed to handle between 1000 and 3000 tons of ore per hour. Accurate capacity matching calculations are essential to ensure that each crusher and screen in the circuit is correctly sized. An under-sized crusher becomes a bottleneck, limiting production, while an over-sized one represents an unnecessary capital expense and operates inefficiently at lower loads. The calculations must account for the ore's density, hardness, and feed size distribution.

Equipment Configuration Standards

Selecting and configuring the right equipment is paramount to achieving the goals set out in the process design. For copper ore, which is abrasive and often very hard, the crushers must be rugged, reliable, and equipped with features that ensure continuous operation with minimal unplanned downtime. The configuration standards focus on maximizing availability and wear life.

The components of the crusher must be selected to withstand the harsh operating conditions. This includes the choice of the crushing chamber's geometry, the type of adjustment mechanism, safety systems to protect the machine, and the materials used to combat relentless wear. A standardized approach to configuration simplifies maintenance and ensures operational consistency across the mining operation.

Crushing Chamber Selection (Extra-Coarse Type)

For the primary and sometimes secondary crushing stages, an extra-coarse crushing chamber is often selected for copper ore applications. This chamber geometry is designed to handle large feed sizes and achieve high throughput capacities. It features a steep head angle and a wide feed opening, allowing it to accept large boulders and reduce them to a manageable size for the next stage of crushing, effectively serving as the workhorse of the circuit.

Hydraulic Adjustment System

Modern cone crushers are equipped with hydraulic adjustment systems that allow operators to change the crusher's setting remotely, often under load. This enables quick and precise control over the product size. The hydraulic system also provides overload protection; if an uncrushable object enters the crushing chamber, the hydraulic cylinders can release the pressure, allowing the object to pass and preventing serious damage to the crusher's internal components.

Automatic Tramp Iron Release

Despite precautions, tramp metal such as drill bits or bucket teeth can occasionally find its way into the ore feed. An automatic tramp iron release system is a critical safety feature for the crusher. This system, often integrated with the hydraulic adjustment, detects the pressure spike caused by an uncrushable object and automatically opens the crusher's setting to discharge the tramp metal, after which it quickly returns to its original setting to resume normal operation, all without stopping the machine.

Abrasive Material Selection (High-Chromium Iron)

The wear parts of a crusher processing copper ore must be made from materials that can resist extreme abrasion. High-chromium iron alloys are a common choice for mantles and concaves. These alloys offer superior abrasion resistance compared to standard manganese steel, significantly extending the service life of these critical wear parts. This results in longer operational campaigns between shutdowns for liner changes, increasing the crusher's availability and reducing long-term operating costs.

Process Connection Optimization

A crushing circuit is more than just crushers; it is an integrated system of feeding, crushing, conveying, and screening equipment. Optimizing the connections between these units is essential for achieving a smooth, efficient, and continuous flow of material. Bottlenecks or inefficiencies in any part of this system can drastically reduce the overall performance of the entire circuit.

The goal is to create a seamless transfer of material from one stage to the next with minimal spillage, dust generation, or energy loss. This involves careful selection and sizing of auxiliary equipment to match the capacity and characteristics of the crushers. A well-optimized plant layout also considers maintenance access and operational safety.

Feed Equipment Matching (Vibrating Feeder)

A consistent and controlled feed is vital for crusher performance. Vibrating feeders are used to draw ore from a surge bin and deliver it to the crusher at a steady, regulated rate. This ensures the crusher's cavity is kept full without being overfilled, which allows it to operate at peak efficiency and prevents choking. Properly matching the feeder's capacity and stroke to the crusher's requirements is a key factor in optimizing the entire crushing process.

Conveying System Design (Belt Width/Speed)

Conveyors are the arteries of the crushing plant, moving ore between crushers and screens. Their design must be carefully calculated based on the tonnage, lump size, and incline of the transfer. The width and speed of the conveyor belt are selected to handle the peak capacity of the crusher without spillage. Robust design ensures reliable transportation of abrasive material over long distances, often from the primary crusher located in the pit to the processing plant.

Screening Equipment Configuration (Circular Vibrating Screen)

Screens are essential for classifying the crushed ore and ensuring that only correctly sized material proceeds to the next stage. Circular vibrating screens are widely used for their efficiency and reliability. They are configured with specific screen panel apertures to separate the product. Oversize material is returned to the crusher for further reduction, creating a closed circuit that tightly controls the final product size and improves the overall efficiency of the size reduction process.

Dust Collection System Integration

Crushing ore generates a significant amount of dust, which poses health risks and can damage equipment. An integrated dust collection system is therefore mandatory. This system typically consists of hoods at transfer points, ducting, and powerful fans that pull dust-laden air into fabric filter bags or other collection devices. A well-designed system can achieve collection efficiencies of over 99%, ensuring a cleaner and safer working environment and complying with stringent environmental regulations.

Quality Control Points

Maintaining strict quality control throughout the crushing process is essential for optimizing downstream recovery of copper. The physical characteristics of the crushed ore directly influence the efficiency of grinding and flotation processes. Consistent monitoring and adjustment ensure the circuit produces a product that maximizes mineral liberation while minimizing energy consumption in subsequent stages.

Quality control involves regular sampling and analysis of the ore stream at various points in the circuit. This data provides operators with the information needed to make real-time adjustments to crusher settings or feed rates, ensuring the final product consistently meets the specifications required for efficient processing.

Particle Size Distribution Testing (Sieve Analysis)

The most critical quality control measure in crushing is the particle size distribution. This is determined through regular sieve analysis, where a sample of crushed ore is passed through a series of screens with progressively smaller apertures. The weight of material retained on each screen is measured to create a size distribution curve. This data is used to verify that the P80 target is being met and to adjust crusher parameters if necessary.

Copper Mineral Liberation Analysis

Beyond just size, the degree to which copper minerals are liberated from the waste gangue is paramount. This is analyzed using specialized techniques like mineralogy scanners or microscopic analysis. The goal of crushing is to create particles where the copper minerals are fully exposed, making them easier to separate in the flotation process. The crushing circuit must be tuned to achieve sufficient liberation without over-grinding, which wastes energy and can create slimes that are difficult to process.

Moisture Content Control

The moisture content of the ore can significantly impact the efficiency of the crushing and screening processes. Very wet ore can cause clogging in crushers and blinding of screen meshes, reducing capacity and product quality. While often a function of the mine itself, processing strategies sometimes include managing moisture through storage or blending different ore types to maintain an optimal, consistent moisture level that ensures smooth material flow.

Impurity Element Removal

Early removal of impurities in the crushing circuit can improve the efficiency of downstream processes. While most chemical separation occurs later, certain physical impurities like tramp metal or wood are removed using magnets and metal detectors installed on conveyors. Preventing these materials from progressing through the circuit protects downstream equipment from damage and avoids contaminating the final concentrate.

Energy Consumption Optimization Strategies

Comminution, which includes crushing and grinding, is the most energy-intensive stage in mineral processing, accounting for a significant portion of a mine's operating costs. Therefore, implementing strategies to optimize energy consumption in the crushing circuit is a major focus for improving overall operational sustainability and profitability.

These strategies involve leveraging advanced technology and intelligent process control to ensure that every kilowatt-hour of electricity is used as efficiently as possible. The goal is to achieve the maximum amount of size reduction with the minimum input of energy, thereby lowering the cost per ton of ore processed and reducing the operation's carbon footprint.

Variable Frequency Drive Technology Application

Variable Frequency Drives (VFDs) are a powerful tool for energy optimization. Applied to crusher motors, VFDs allow the motor speed to be adjusted to match the actual load and feed conditions. This prevents the motor from running at full speed when the load is light, resulting in substantial energy savings. VFDs also provide a soft start, reducing mechanical stress on the crusher and the electrical grid during startup.

Dynamic Crushing Chamber Profile Adjustment

Some advanced cone crushers allow for dynamic adjustment of the crushing chamber profile. By changing the stroke or the speed of the mantle, operators can optimize the crusher's performance for different feed conditions or product requirements in real-time. This ensures the crusher is always operating at its most energy-efficient point, adapting to changes in ore hardness or feed size without manual intervention.

Intelligent Load Matching

Sophisticated control systems use algorithms to intelligently match the crusher's load to the available power. By monitoring power draw and other parameters, the system can automatically regulate the feed rate to keep the crusher operating at its peak efficiency—constantly full but not overloaded. This maximizes throughput for a given energy input and protects the crusher from damage caused by erratic feeding or power surges.

Waste Heat Recovery System

While more common in grinding, the concept of energy recovery is also being explored in crushing. Large crusher motors generate heat. Though challenging, systems can be designed to capture this waste heat from the crusher's lubrication system or the motor itself. This captured thermal energy could potentially be repurposed for other plant needs, such as heating buildings or process water, contributing to the overall energy efficiency of the facility.

Environmental Compliance Requirements

Operating a modern copper crushing circuit must be done in strict compliance with environmental regulations designed to protect air, water, and soil quality. These requirements are not merely legal obligations but are also critical for maintaining a social license to operate and for upholding corporate responsibility standards.

Modern mining operations implement comprehensive environmental management systems that go beyond simple compliance, aiming to minimize their ecological footprint through advanced technologies and diligent practices. This involves managing waste, controlling emissions, and continuously monitoring environmental performance.

Wastewater Circulation and Reuse

Water is a key resource in mineral processing, but its use must be managed responsibly. Modern plants aim for maximum water circulation and reuse to minimize freshwater consumption and effluent discharge. Crushing circuits often use water for dust suppression. This water, along with runoff, is collected in settlement ponds. The clarified water is then recirculated back into the process, creating a closed-loop system that drastically reduces the operation's overall water footprint.

Tailings Storage Facility Management Standards

The fine waste material from processing, known as tailings, must be stored in engineered facilities designed to the highest international standards. These Tailings Storage Facilities (TSFs) are constructed with impermeable liners, comprehensive monitoring systems for stability and seepage, and detailed water management plans. Responsible management ensures the long-term stability of these structures and prevents contamination of surrounding groundwater and ecosystems.

Dust Collection Efficiency (>99%)

As previously mentioned, controlling dust is a major environmental and health priority. Regulatory compliance often requires dust collection systems to operate at an efficiency greater than 99%. This high efficiency is typically achieved with baghouse filters, which use fabric bags to capture fine dust particles from the air stream. Continuous monitoring of emissions ensures that the system is functioning correctly and that the operation remains within permitted limits.

Noise Control Standards

Industrial noise can impact both workers and nearby communities. Crushers, screens, and conveyors are significant noise sources. Compliance with noise control standards is achieved through a combination of engineering and administrative controls. This includes installing acoustic enclosures around equipment, using sound-dampening materials on hoppers and chutes, implementing noise barriers, and scheduling particularly noisy maintenance activities for daytime hours. Regular noise monitoring at the site boundary ensures levels remain within legal limits.