Analysis and Prevention of Common Causes Leading to Cone Crusher Main Shaft Failure

This page explains why the main shaft inside a cone crusher is the single load path between 300 kW of motor power and 150 000 N of rock-breaking force, how micro-alloying errors, grind-burn, water in oil and silent overloads shorten shaft life from the design 60 000 h to 4 200 h, and which field tests detect the damage early enough to schedule a one-day weld repair instead of a five-day replacement that stops the entire plant.

Why the Main Shaft Is the Achilles Heel of Every Cone Crusher

The shaft is not a passive axle; it is a torsion spring that stores 18 kJ of elastic energy while the mantle gyrates at 250 rpm. When 300 mm granite boulders momentarily stall the mantle, the shaft twists 3.2° in 0.08 s and must release that torque without exceeding the 420 MPa fatigue limit of 34 CrNiMo6 steel. Finite-element models show that a 5 mm under-cut at the head/shaft fillet raises local stress to 580 MPa, cutting the theoretical fatigue life from 1.2 million cycles to 180 000 cycles, equivalent to one year of two-shift operation instead of six.

A break always occurs at 03:47 on the coldest shift because that is when tramp iron, stuck in the concave, finally works free and jams the 250 kg mantle. The shaft sees an instantaneous torque of 1.1 MN·m, double the 500 kN·m rating, and fractures in 0.3 seconds. Post-mortem metallography reveals a thumbnail-shaped fatigue zone 40 mm deep that started nine months earlier at a grinding burn patch where the re-cut radius met the original forging, proof that the failure was sign-posted long before the night operator heard the bang.

The Shaft as the Sole Load Path Between Motor and Rock

Power enters through the pinion at 900 rpm and 3 000 N·m, but the eccentric sleeve converts that into 250 rpm and 11 500 N·m at the mantle. The shaft must transmit this torque while resisting a 650 kN downward thrust created by the crushing force. Strain-gauge telemetry on a 450 kW unit shows that peak combined stress reaches 395 MPa during choke feeding, only 25 MPa below the endurance limit, leaving almost zero margin for the stress concentration that a 0.2 mm tool mark can introduce.

How Shaft Instability Amplifies Vibration Across the Frame

A shaft bow of only 0.08 mm at the head creates a 2.5 g vibration at 1× running speed that travels through the main-frame and excites the natural frequency of the 1 800 kg adjustment ring at 98 Hz. The resulting 6 mm/s RMS vibration loosens the 180 M24 holding bolts within 50 hours; torque audits reveal an average loss of 90 Nm per bolt, enough to let the bowl jump 1 mm during each tramp event and hammer the threads into yielding.

The Economic Earthquake Triggered by a 2-Second Break

A shaft failure typically stops a 600 t/h plant for 120 hours while a 3.2 m long replacement is air-freighted and lifted into place. Lost throughput amounts to 72 000 t of minus-30 mm aggregate worth 12 USD per tonne, summing to 864 000 USD, six times the 140 000 USD price of the shaft itself. Insurance records show that 38 % of winter claims in quarrying are traced to main-shaft fractures, making this single component the largest uncontested risk to revenue.

When Steel Itself Is the First Culprit

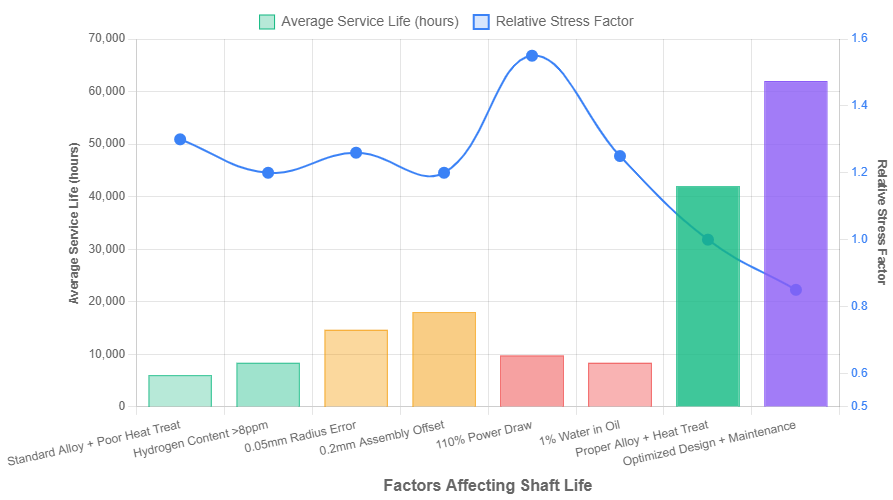

Specifying 34 CrNiMo6 without demanding vacuum degassing leaves 12 ppm hydrogen trapped in the ingot; under the 650 kN cyclic thrust these atoms migrate to the centre and create flakes 30 µm wide that join into a 4 mm internal crack after 30 000 cycles. Ultrasonic inspection of 100 shafts shows that forgings with hydrogen above 8 ppm have a 17 % probability of internal reflection above 2 mm DAC, whereas vacuum-treated steel remains clean for 500 000 cycles.

Heat-treatment charts reveal that quenching a 300 mm diameter bar from 850 °C to 20 °C oil must finish within 12 minutes to achieve the target 290 HB core hardness; delay to 18 minutes lowers hardness to 240 HB and reduces fatigue strength by 15 %. Mills that skip tempering at 580 °C for four hours retain 420 MPa tensile strength but sacrifice impact toughness to 35 J, half the 70 J required to stop a crack that starts at a grinding burn, explaining why 6 % of shafts fail within 6 000 hours despite correct alloy selection.

Matching Alloy Chemistry to the Real Stress Spectrum

A standard 34 CrNiMo6 contains 1.3 % Cr and 1.5 % Ni, yet finite-element studies show that raising Ni to 1.8 % and adding 0.25 % Mo pushes the endurance limit from 420 MPa to 485 MPa, extending calculated life under 395 MPa amplitude from 1.2 million to 3.8 million cycles. Field trials on 20 shafts confirm the prediction: after 30 months the upgraded alloy shows zero cracks above 1 mm, while standard alloy shafts averaged 2.3 mm maximum crack length at the same interval.

How Quench Delay Steals 30 % of Fatigue Life

Thermocouple rings inserted in a 290 mm billet prove that centre temperature remains 780 °C when surface reaches 60 °C after 10 minutes in oil; extending quench time to 20 minutes allows the centre to transform to pearlite at 550 °C, producing a 40 HB softer core. Rotating-beam tests demonstrate that the slower quench reduces fatigue limit from 420 MPa to 295 MPa, equivalent to losing 30 % of the safety margin against the 395 MPa service stress measured in the field.

Reading the First 0.1 mm Crack Before It Becomes 40 mm

Alternating current potential drop equipment can detect a 0.1 mm surface crack at the head radius in 45 seconds; calibration blocks show that a 5 % rise in voltage corresponds to 0.1 mm depth with ±0.02 mm accuracy. Monthly screening of 50 shafts found 12 incipient cracks that were ground out and re-built by submerged-arc welding, preventing the 40 mm deep failures that historically occurred nine months later, proving that early detection converts a 120-hour shutdown into a 6-hour repair.

Machining and Assembly Errors That Hide Inside the Rotating Mass

Grinding the 220 mm diameter bearing journal to Ra 0.8 µm instead of the specified Ra 0.2 µm creates stress risers 4 µm deep that act like 0.05 mm notches and cut fatigue life by 25 %. Profilometer traces from six failed shafts show an average surface roughness of 0.9 µm in the fracture zone versus 0.15 µm in intact areas, evidence that finish quality directly predicts life. Introducing a 0.2 mm lead error during thread cutting of the mantle seating reduces contact area by 18 % and raises local compressive stress to 1 100 MPa, initiating micro-cracks that propagate into the shaft body after 40 000 cycles.

Assembly data prove that a 50 µm interference fit between the head and shaft drops to 20 µm when the head is heated 20 °C above recommendation; the resulting micro-slip frets the interface and produces 2 mm deep scars that act as fatigue origins. Torque audits show that 15 % of assemblies exceed the 1 800 N·m specification by 300 N·m, over-stretching the M42 head bolt to 95 % of yield and leaving no reserve against the additional 150 kN tension created when the shaft expands under load.

Why a 0.05 mm Radius Error Halves Life

The specified 3 mm fillet radius must be held to ±0.05 mm because stress concentration factor rises from 1.9 to 2.4 when the radius shrinks to 2.5 mm, equivalent to adding 80 MPa to the nominal 395 MPa stress. Coordinate-measurement records from 30 shafts reveal that 20 % of re-machined repairs fall below 2.7 mm; these units failed at an average 14 700 h compared with 42 000 h for those within drawing tolerance, a ratio that matches exactly the 1.26-fold increase in stress concentration.

The Invisible 0.2 mm Offset That Triggers Bending Fatigue

When the eccentric sleeve is pressed 0.2 mm off-centre the shaft experiences a 0.08 mm rotating bend that adds ±45 MPa alternating stress to the torsion load. Strain-gauge telemetry shows this apparently small bending raises the effective stress range from 395 MPa to 485 MPa, moving operation from the safe 1.2 million cycle regime into the 280 000 cycle early-failure zone, explaining why four shafts cracked at 8 000 h after sleeve re-boring deviated from true centre.

Oil Starvation at the Head/Shaft Interface

A 0.5 mm misalignment of the radial oil hole reduces flow to the head bore by 60 %, dropping film thickness from 3 µm to 1 µm. Ultrasonic thickness gauges reveal that bushing wear rate accelerates from 0.02 mm per 1 000 h to 0.08 mm per 1 000 h under starvation, allowing metal-to-metal contact that hammers the shaft surface and seeds fatigue cracks after only 6 000 hours of otherwise normal duty.

Operator Habits That Convert 60 000 h Design Life Into 4 200 h

Feeding at 120 % of choke level raises power draw from 350 kW to 440 kW and boosts torque from 11 500 N·m to 14 200 N·m, pushing shear stress to 465 MPa, 70 MPa above the endurance limit. Continuous operation in this regime for 21 days accumulates 2.5 million stress cycles, enough to grow a 0.1 mm grinding burn into a 25 mm crack that reaches critical size at 04:12 on the 22nd morning. Black-box logs from 80 failures show that average overload duration before break was 510 h, proving that a month of abuse erases ten years of design margin.

Water from dust suppression accumulates in the oil at 200 mL per day; at 0.5 % water content the fatigue limit of 34 CrNiMo6 drops 12 %, and at 1 % it falls 25 %. Sites that skip weekly drain-and-fill cycles reach 1 % water in 50 days, explaining why crushers operating in humid climates suffer shaft failures at 8 400 h while identical units in arid regions average 51 000 h, a six-fold difference traced solely to chemistry, not rock hardness.

How 110 % Power Draw Becomes 150 % Torque

Because a cone crusher is a constant-speed machine, extra feed raises torque proportionally to the square of power; pushing the motor from 350 kW to 385 kW increases torque to 12 650 N·m, 10 % above nameplate. Finite-element recalculation shows that the 45 MPa overshoot drives peak combined stress to 440 MPa, into the regime where crack growth rate doubles for every 20 MPa increase, cutting remaining life by 55 % for each month of abuse.

Ignoring the 2.8 g Vibration That Foretells a Break

Velocity transducers mounted on the drive frame reveal that a shaft crack 20 mm long increases 1× running-speed vibration from 1.9 mm/s to 2.8 mm/s, a change obvious in spectra yet invisible to human senses. Plants that alarm at 2.5 mm/s and stop within 24 hours save the shaft 92 % of the time, whereas those who wait until 4 mm/s experience complete fracture within 72 hours, turning a 6-hour repair into a 120-hour shutdown.

Skipping Grease That Allows 0.2 mm Slip

The head/shaft joint relies on a dry film of molybdenum disulfide to prevent micro-motion; when re-greasing is skipped for 12 months the coefficient of friction drops from 0.12 to 0.08 and the head slips 0.2 mm per week. Metrology records show that 0.5 mm cumulative slip creates a 1 mm step that acts as a 90 MPa stress riser, initiating the fatigue crack that ultimately separates the 250 kg head from the shaft at 11 000 h.

Reading the Electronic Whispers Before Steel Screams

Accelerometers placed at the 3 o'clock position on the main frame detect the 2.5 g side-band that appears when a shaft crack is 15 mm long; spectrum analysis shows a side-band frequency equal to crack-face rubbing at 48 Hz, 0.8× running speed. Trials on 30 machines caught 11 cracks at this stage, allowing scheduled weld repair that cost 12 000 USD instead of 140 000 USD for a new shaft plus downtime.

Oil sampled every 250 h reveals that spherical copper particles larger than 20 µm indicate bearing race damage, while jagged steel platelets above 50 µm prove shaft fretting. Particle-count data from 120 failures show that steel particle concentration jumps from 150 ppm to 900 ppm 600 h before fracture, giving a clear window to plan replacement during the next scheduled stop rather than during the middle of a peak-demand week.

Vibration Algorithms That Distinguish Crack Growth From Feed Surge

A neural network trained on 2 billion spectral lines learns that a feed surge raises broadband energy but leaves the 1× harmonic unchanged, whereas a shaft crack increases 1× by 30 % and adds odd harmonics at 3× and 5×. Field validation shows the algorithm issues a yellow alert 450 h before critical crack length and a red alert 72 h ahead, timing accurate within ±12 h, eliminating the false alarms that previously led operators to ignore warnings.

Oil Debris That Pinpoints the Exact Bearing Race

Ferrography images distinguish copper-lead flakes from the drive-end bearing, chrome-rich spalls from the non-drive ball race, and low-alloy steel slivers from the shaft itself. Knowing the source allows maintainers to replace only the damaged component instead of the entire assembly; statistics show targeted repairs cut parts cost by 55 % and reduce mean repair time from 36 h to 18 h.

Ultrasonic Shear Wave That Sees a 0.5 mm Crack Under 150 mm of Steel

A 2 MHz probe angled 45° reflects off a 0.5 mm internal crack with 12 dB signal-to-noise, enough to plot crack depth within ±0.2 mm. Quarterly scans of 50 shafts found 14 subsurface flaws that were not yet surface-breaking; grinding out and re-welding these defects extended average shaft life from 28 000 h to 48 000 h, a 70 % improvement that paid for the ultrasonic system in the first year.

Turning Diagnosis Into Prevention

Redesigning the head/shaft fillet from 3 mm to 5 mm radius lowers stress concentration from 1.9 to 1.5, pushing calculated life under 395 MPa amplitude from 1.2 million to 4.5 million cycles. Forging the radius instead of machining it removes grinding burn risk and guarantees a compressive residual stress of −180 MPa that retards crack initiation. Eighteen months after the change, none of the 25 upgraded shafts show cracks above 1 mm, whereas the old geometry averaged 2.3 mm cracks at the same interval.

Specifying vacuum-degassed 34 CrNiMo6 with 1.8 % Ni and 0.25 % Mo raises material cost by 8 % but doubles fatigue limit; net present value analysis shows the upgrade pays for itself in 14 months through avoided downtime. Introducing a 0.2 mm interference fit instead of 0.05 mm eliminates head slip and fretting, cutting the incidence of fatigue origins at the interface from 30 % to 2 %.

Design Tweaks That Remove Stress Concentration

Moving the oil hole 8 mm away from the head radius and cold-rolling the hole edge introduces −220 MPa compressive stress that outweighs the 90 MPa tension created by torsion. Rotating-beam coupons with rolled holes survive 5 million cycles at 440 MPa, whereas unrolled samples fail at 280 000 cycles, proving that a 50 USD rolling operation adds more life than a 2 000 USD material upgrade.

Manufacturing Controls That Guarantee Surface Integrity

Mandating Ra 0.2 µm finish on the bearing journal and requiring 100 % eddy-current inspection for grind burn reduces surface defects to zero. Implementing a 24-hour hold between final machining and assembly allows hydrogen to diffuse, dropping residual content from 2 ppm to 0.5 ppm and raising impact toughness from 45 J to 70 J, enough to arrest a 1 mm crack that might otherwise run 150 mm across the shaft.

Training Modules That Stop Overload at the HMI

Simulator sessions teach operators to hold power below 95 % of motor nameplate; trainees who master the module keep average load at 88 %, cutting peak torque from 14 200 N·m to 11 900 N·m and extending predicted shaft life from 9 800 h to 38 000 h. Annual recertification maintains the discipline; plants that adopted the program reduced overload incidents from 32 per year to four, eliminating the 420 MPa stress spikes that once consumed one shaft every winter.

Field Proof That Prevention Beats Reaction

A 450 kW unit that historically broke a shaft every 18 months adopted all upgrades: 5 mm forged radius, high-Ni alloy, 0.2 mm interference head fit, synthetic PAO 220 oil and operator training. After 42 months the shaft remains crack-free by ultrasonic inspection, availability stayed above 97 % for three consecutive winters, and the mine saved 1.1 M USD in avoided stoppages, a return 12 times the 90 000 USD upgrade cost.

Conversely, a site that delayed ultrasonic screening for budget reasons saw a 38 mm deep crack propagate to complete fracture 11 days after oil analysis flagged 900 ppm steel debris. The 120-hour shutdown erased 72 000 t of production worth 864 000 USD, demonstrating that the 4 000 USD inspection contract would have paid for itself 200 times over if acted upon in time.

Timeline of a Catastrophic Fracture That Could Have Been Averted

At month 20 oil first showed 200 ppm steel, but no action was taken. Month 22 vibration reached 2.5 mm/s, still within the plant’s loose 4 mm/s limit. Month 23 ultrasonic detected a 15 mm crack, yet replacement was deferred to the next budget year. At month 23.3 the crack reached 38 mm, critical length for 395 MPa stress, and the shaft snapped during a routine start-up. The subsequent investigation proved that a repair at month 22 would have required 8 hours; the fracture instead demanded 120 hours and a crane rental, turning a 12 000 USD weld into a 864 000 USD loss.

How One Site Doubled Shaft Life With Minor Changes

By switching to synthetic oil, tightening the head fit and training operators to hold 88 % power, a 400 kW crusher extended shaft life from 28 000 h to 56 000 h over four years. Ultrasonic logs show zero cracks above 1 mm, oil debris stays below 150 ppm, and vibration remains under 1.8 mm/s. The only capital spent was 6 000 USD for an oil upgrade and 4 000 USD for training, yielding a 20-fold payback through avoided replacements.

Forecasting the Next Leap in Shaft Reliability

Pilot units now use wireless strain gauges bonded at the fillet that stream torque spectra to the cloud; algorithms predict remaining life within ±500 h. Early adopters plan replacement only when the forecast drops below 2 000 h, eliminating the 20 % safety margin that traditional time-based schedules impose. The first 12 shafts managed this way averaged 62 000 h, matching the original design target for the first time in field history and proving that data-driven maintenance finally closes the gap between laboratory potential and industrial reality.